Abstract

Purpose

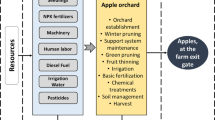

The aim of this work is to analyse and minimise, using a life cycle approach, the environmental performances of apple powders’ production. Fruit powders, with respect to fresh fruits’ juices, are easier to handle and used as an ingredient for the production of baby foods, snacks, and other items. A detailed life cycle assessment (LCA) analysis was made to compare and optimise the two production processes, based on two drying techniques (drum or multistage drying), made by an Italian firm.

Methods

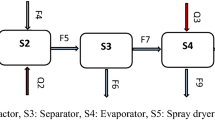

All the quantities related to materials, energy consumption and emissions to air, soil and water were reported to the chosen functional unit (one apple powders’ package). Data were analysed using SimaPro 8.0.4 software, whereas the Ecoinvent 3.1 database was used for the life cycle inventory, according to the reference standard for LCA (i.e. ISO 14040–14044). The system boundaries were set from apples’ transportation to the company up to apple powders’ distribution; in this way, a “from gate to gate” approach was followed. The IMPACT 2002+ method was used to select the impact categories. The ones that are mainly influenced by the industrial stages of apple powders’ production are carcinogens, non-carcinogens, respiratory inorganics, aquatic acidification, global warming potential and mineral extraction.

Results and discussion

Among the two processes under study (a drum drying-based process and a multistage drying one), the first one (that is also the simpler and cheaper one) generated the higher emissions on all the impact categories. An in-depth analysis regarding all the industrial stages was made, in order to select the industrial steps whose impacts have to be minimised. For the process based on drum drying, the midpoint considered categories are mainly affected by the drying operation, whereas for the multistage drying-based process, some categories are mainly affected by drying, some others by storage. Different improvement scenarios were proposed to minimise the emissions related to both the apple powders’ productions.

Conclusions

Global emissions related to the apple powders’ production were lowered using improved industrial scenarios. In order just to compare different scenarios characterised by not summable parameters, a global index (calculated as the sum of normalised values) was used. For the drum drying-based process, the global saving was equal to 31 %, whereas for the multistage drying-based process, it is equal to 27 %. Also in the case of improved scenarios, the drum drying-based process generated higher emissions on all the impact categories with respect to the multistage drying-based process.

Similar content being viewed by others

Abbreviations

- AA:

-

Aquatic acidification

- AE:

-

Aquatic eutrophication

- AET:

-

Aquatic ecotoxicity

- C:

-

Carcinogens

- DD:

-

Drum drying-based technique

- FU:

-

Functional unit

- GWP:

-

Global warming potential

- ICAM:

-

Integrated computer-aided manufacturing

- IDEF:

-

Icam def for function modelling

- IR:

-

Ionising radiations

- LCA:

-

Life cycle assessment

- LCI:

-

Life cycle inventory

- LO:

-

Land occupation

- MD:

-

Multistage drying-based technique

- ME:

-

Mineral extraction

- NC:

-

Non-carcinogens

- NRE:

-

Non-renewable energy consumption

- OLD:

-

Ozone layer depletion

- RI:

-

Respiratory inorganics

- RO:

-

Respiratory organics

- TAN:

-

Terrestrial acidification/nitrification

- TET:

-

Terrestrial ecotoxicity

References

Aprea C, Maiorino A (2011) An experimental investigation of the global environmental impact of the R22 retrofit with R422D. Energy 36:1161–1170

Beccali M, Cellura M, Iudicello M, Mistretta M (2009) Resource consumption and environmental impacts of the agrofood sector: life cycle assessment of Italian citrus-based products. Environ Manag 43:707–724

Beccali M, Cellura M, Iudicello M, Mistretta M (2010) Life cycle assessment of Italian citrus-based products. Sensitivity analysis and improvement scenarios. J Environ Manag 91:1415–1428

Cerutti AK, Bruun S, Donno D, Beccaro GL, Bounous G (2013) Environmental sustainability of traditional foods: the case of ancient apple cultivars in Northern Italy assessed by multifunctional LCA. J Clean Prod 52:245–252

Cerutti AK, Beccaro GL, Bruun S, Bosco S, Donno D, Notarnicola B, Bounous G (2014) Life cycle assessment application in the fruit sector: state of the art and recommendations for environmental declarations of fruit products. J Clean Prod 73:125–135

Coltro L, Mourad AL, Kletecke RM, Mendonça TA, Germer SPM (2009) Assessing the environmental profile of orange production in Brazil. Int J Life Cycle Assess 14:656–664

De Marco I, Iannone R, Miranda S, Riemma S (2015) Life cycle assessment of apple powders produced by a drum drying process. Chem Eng Trans 43:193–198

Desobry SA, Netto FM, Labuza TP (1997) Comparison of spray-drying, drum-drying and freeze-drying for β-carotene encapsulation and preservation. J Food Sci 62(6):1158–1162

Finnveden G, Hauschild MZ, Ekvall T, Guinée J, Heijungs R, Hellweg S, Koehler A, Pennington D, Suh S (2009) Recent developments in life cycle assessment. J Environ Manag 91:1–21

Gustavsson J, Cederberg C, Sonesson U (2011) Global food losses and food waste. Food and agricultural organization of the United Nations

Henriquez M, Almonacid S, Lutz M, Simpson R, Valdenegro M (2013) Comparison of three drying processes to obtain an apple peel food ingredient. J Food 11(2):127–135

Henriquez C, Cordova A, Almonacid S, Saavedra J (2014) Kinetic modeling of phenolic compound degradation during drum-drying of apple peel by-products. J Food Eng 143:146–153

Humbert S, De Schryver AM, Margni M, Jolliet O (2012) IMPACT 2002+: user guide. Draft for version Q2.2 (version adapted by Quantis). Quantis, Lausanne, Switzerland

Iannone R, Miranda S, Riemma S, De Marco I (2014) Life cycle assessment of red and white wines production in southern Italy. Chem Eng Trans 39:595–600

Iannone R, Miranda S, Riemma S, De Marco I (2015) Improving environmental performances in wine production by a life cycle assessment analysis. J Clean Prod. doi:10.1016/j.jclepro.2015.04.006

Jakubczyk E, Ostrowska-Ligeza E, Gondek E (2010) Moisture sorption characteristics and glass transition temperature of apple puree powder. Int J Food Sci Technol 45:2515–2523

Karakaya A, Özilgen M (2011) Energy utilization and carbon dioxide emission in the fresh, paste, whole-peeled, diced, and juiced tomato production processes. Energy 36:5101–5110

Kudra T (2004) Energy aspects in drying. Dry Technol 22(5):917–932

Kumar C, Karim MA, Joardder MUH (2014) Intermittent drying of food products: a critical review. J Food Eng 121:48–57

Manfredi M, Vignali G (2014) Life cycle assessment of a packaged tomato puree: a comparison of environmental impacts produced by different life cycle phases. J Clean Prod 73:275–284

Milà i Canals L, Burnip GM, Cowell SJ (2006) Evaluation of the environmental impacts of apple production using life cycle assessment (LCA): case study in New Zealand. Agric Ecosyst Environ 114:226–238

Neto B, Dias AC, Marina Machado M (2013) Life cycle assessment of the supply chain of a Portuguese wine: from viticulture to distribution. Int J Life Cycle Assess 18:590–602

Phisut N (2012) Spray drying technique of fruit juice powder: some factors influencing the properties of product. Int Food Res J 19(4):1297–1306

Pszczola DE (2003) Delivery systems help send the right message. Food Technol 57:68–85

Roy P, Nei D, Orikasa T, Xu Q, Okadame H, Nakamura N, Shiina T (2009) A review of life cycle assessment (LCA) on some food products. J Food Eng 90:1–10

Villanueva-Rey P, Vázquez-Rowe I, Moreira MT, Feijoo G (2014) Comparative life cycle assessment in the wine sector: biodynamic vs. Conventional viticulture activities in NW Spain. J Clean Prod 65:330–341

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Niels Jungbluth

Rights and permissions

About this article

Cite this article

De Marco, I., Miranda, S., Riemma, S. et al. Environmental assessment of drying methods for the production of apple powders. Int J Life Cycle Assess 20, 1659–1672 (2015). https://doi.org/10.1007/s11367-015-0971-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-015-0971-y