Abstract

Addressing the increasing demand for green additives in drilling fluids is essential for the sustainable development of the oil and gas industry. Fluid loss into porous and permeable formations during drilling presents significant challenges. This study introduced an innovative, environmentally sustainable drilling fluid known as nano-biodegradable drilling fluid (NBDF). The NBDF formulation incorporates greenly synthesized zinc nanorods (ZNRs) and gundelia seed shell powder, with ZNRs derived from Cydonia oblonga plant extracts using an eco-friendly method. The research developed multiple drilling fluid variants for experimentation: a reference drilling fluid (BM); biodegradable drilling fluid (BDF) with particle sizes of 75, 150, 300, and 600 µm at concentrations ranging from 0.5 to 1 wt% (GSMs); a drilling nanofluid (DNF) with ZNRs at a 0.1 wt% concentration (ZNR); and NBDF combining both nano and gundelia waste (GS-ZNR). Experimental tests were conducted under various temperature and pressure conditions, including low temperature and low pressure (LTLP) and high temperature and high pressure (HTHP). Rheological and filtration measurements were performed to assess the impact of the nano-biodegradable additives on flow behavior and fluid loss. Results indicated that incorporating 1 wt% of gundelia seed shell powder with a particle size of 75 µm led to a 19.61% reduction in fluid loss compared to BM at 75 °C and 200 psi. The performance of the same GSM improved by 31% under identical conditions when 1 wt% of zinc ZNRs was added. Notably, the GS-ZNR formulation demonstrated the most effective performance in reducing fluid loss into the formation, decreasing mud cake thickness, and enhancing the flow behavior of the non-Newtonian reference drilling fluid. This study highlights the relevance of particle size in the effectiveness of biodegradable additives and underscores the potential of NBDF to address environmental concerns in the oil and gas drilling industry.

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Avoid common mistakes on your manuscript.

Introduction

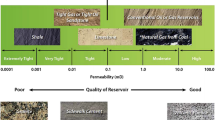

Issues within boreholes pose critical challenges in the gas and oil drilling process, with the potential loss of certain filtrates into subsurface formations during the circulation of drilling fluid within the borehole. This occurrence leads to escalated circulation rates and differential pressures between the wellbore and the fluid flow (Al-Yasir and Al-Sallami 2015; Tahr et al. 2023). Such fluid loss can cause severe complications, including pressure redistribution around the borehole, rock swelling, and alterations in rock strength (Davoodi et al. 2018; Li et al. 2023). Consequently, borehole stability is compromised, resulting in collapses, sloughing, and cavity formations (Iscan et al. 2007; Abed et al. 2022). These issues can be minimized by modifying the main properties of the drilling fluid, such as apparent viscosity, plastic viscosity, gel strength, yield point, filter cake, and fluid loss. As drilling fluid pass through the borehole and returns to the surface, it interacts with the formation rock (Ragab and Noah 2014; Al-Haj et al. 2022; Jameel and Ali 2023; Ali et al. 2024a). Biodegradable materials and nanomaterials within the fluid adhere to formation rock surfaces due to factors like electrostatic forces and Van Der Waals interactions (Ali et al. 2022a,b). Nanomaterials, outstanding to their substantial surface area and reactivity, create a stable coating on the borehole wall, enhancing its mechanical properties, reducing permeability, and mitigating wellbore instability issues (Fig. 1). Simultaneously, biodegradable compounds facilitate the breakdown of organic matter present in the drilling fluid, promoting environmentally conscious drilling practices (Shahbazi et al. 2020; Raza et al. 2023). Furthermore, the utilization of nano-biodegradable components reflects a promise to sustainable drilling methodologies and environmental preservation by leaving behind a favorable filter cake on the borehole wall which is impermeable and thin (see Fig. 1).

Biodegradable wastes and biopolymers were employed in the drilling process to improve the performance of water-based drilling fluids (WBDFs) in ecofriendly and sustainable way (Al-Hameedi et al. 2020; Sun et al. 2021; Ali et al. 2024a, b). The carboxymethyl chitosan biopolymer was added to the WBDFs, resulting in reduced yield point and filtrate volume entering the formation (Lei et al. 2020). Meanwhile, Ismail et al. (2020) employed Rhizophora Mucronata Tannin extract as a biopolymer additive, effectively diminishing gel strength and fluid loss volume to optimal levels using 8 gm of Rhizophora Mucronata Tannin extract. Al-Hameedi et al. (2019) incorporated grass powder as a biodegradable waste material to enhance drilling fluid properties. Their findings suggested a 42% reduce in fluid loss, accompanied by an improve in gel strength starting 22 to 26 Ib/100 ft2. In a separate study, Medved et al. (2022) observed significant reductions in filtration 61.54% in permeability plugging tester filtration and 42% in API filtration using an optimal concentration of 1.5 wt% mandarin peel. Recently, Awl et al. (2023) utilized the powder of broad bean peel, achieving a 35% drop in fluid loss by adding 3 wt% to the BM. Additionally, Raza et al. (2023) successfully enhanced drilling fluid rheological properties by using rice husk ash as sustainable additive. Nanotechnology has emerged as a tool to improve gas and oil drilling operations, particularly in addressing borehole issues by changing the fluid loss volume, thickness of the filter cake, plastic viscosity, yield point, and gel strength of circulating drilling mud (Vryzas et al. 2018; Ali et al. 2019; Li et al. 2019; Torres-Carrasco et al. 2019; Cheraghian 2021; Ibrahim et al. 2022; Bardhan et al. 2023a; Abdullah et al. 2024; Li et al. 2024a, b). Adding nanoparticles, typically silicon dioxide (NPs), enhances the transportation efficiency of drilling cuttings by adjusting the fluid’s rheological properties (Gbadamosi et al. 2019). Furthermore, Dejtaradon et al. (2019) highlighted significant improvements in rheological characteristics when using nano-formulated drilling fluids, with zinc nanoparticles exhibiting a more profound impact compared to copper nanoparticles. Zinc oxide (ZnO) nanostructures synthesized under microwave irradiation exhibit shapes like rods and flowers, significantly influencing the properties of WBDFs. The study found that ZnO nanoflowers enhance WBDF stability and filtration control, reducing HPHT filtrate volume by 56% and maintaining a consistent rheological profile, highlighting the impact of nanostructure morphology on drilling fluid performance (Prajapati et al. 2023). Industrially prepared silica nanoparticles coated with AEAPTS significantly enhance the rheology and filtration control of water-based drilling fluids at elevated temperatures. The addition of these coated nanoparticles reduced rheological degradation from 60 to 20% after thermal aging and improved viscosity and filtration properties, demonstrating their effectiveness as additives for high-temperature drilling applications (Bardhan et al. 2023b). Moreover, the introduction of bismuth ferrite nanoparticles increased the yield point and plastic viscosity values with the ratio of ¼ and reduced the fluid loss by 35% at ambient temperature (Perween et al. 2019).

This research aims to prepare sustainable modified drilling fluids with enhanced filtration characteristics using gundelia seed shell (GSM) and greenly synthesized zinc ZNRs. The zinc ZNRs, derived from Cydonia oblonga plant extract collected from the Kurdistan Region, were investigated for their effects on drilling fluid performance. Rheological and filtration measurements were conducted under varying pressure and temperature conditions to evaluate the impact of GSM and zinc ZNRs at different particle sizes and concentrations on drilling fluid performance.

Material and methods

Materials

Different additives were employed in this research. Bentonite with a purity 95% and a particle size between 0.8 µm and 2 µm, supplied by Carl Roth, was utilized to increase viscosity and weight. Soda ash was used to manage total hardness. A starch polymer with 95% purity (molecular weight MW of 343 g/mol), supplied by Carl Roth, was incorporated to improve filtration properties, and NaOH was introduced to raise the pH level. All these additives were sourced from Pulsar Petroleum Company. Zinc acetate, NaOH, and ethanol, each boasting a purity of 99%, were procured from Merck Company. These specific materials were integral in synthesizing zinc ZNRs, ranging in size from 1 to 100 nm. Additionally, gundelia seeds were gathered from a close field. After drying at ambient temperature, the gundelia seed shells underwent grinding into small particles using a grinder. Following this, the particles were sorted into different sizes 75, 150, 300, and 600 µm using sieves.

Green synthesis of ZNRs

The Cydonia oblonga plant leaves were cleaned using double-distilled water, dried, and cut into small pieces. Next, 10 g of the prepared leaf powder was placed into a flask with 100 mL of distilled water. Mixture was then heated for 40 min at 60 °C. Once cooling to room temperature, the extract underwent filtration using Whatman No. 1 filter paper to remove any unnecessary organic residues. Concurrently, 2 mg of zinc acetate dissolved in 50 mL of double-distilled water was stirred for 20 min at 80 °C. Then, 50 mL of the plant extract solution was gradually added to the dissolved zinc. This resulting mixture was placed on a hotplate, heated, and stirred at 70 °C for 45 min until it displayed a yellowish color, indicating the synthesis of ZNRs upon adding 50 mL of NaOH. The precipitate obtained was separated from the mixture through centrifugation at 7000 rpm for 20 min and subsequently subjected to heating at 400 °C for 2 h in an oven to eliminate impurities and organic materials surrounding the synthesized nanorods as shown in Fig. 2.

Characterization of ZNRs

The UV–Visible spectra of ZNRS were captured using a Super Aquarius Spectrophotometer-1000, covering a wavelength range of 200–700 nm with 1-nm resolution, with distilled water as the reference baseline, alongside comparative spectra for plant extract, sodium hydroxide, and zinc acetate dihydrate. Morphology analysis using an LVEM5 Benchtop Electron microscope was conducted through scanning electron microscopy (SEM), revealing essential details about the surface structures and size distributions of the ZNRS. Fourier transform infrared (FTIR) spectra obtained from a PerkinElmer Spectrum 100 FTIR, spanning 400 to 4000 cm−1 with a resolution of 1 cm−1, identified the chemical bonds and molecular structures, indicating possible organic coatings or functional groups. Dynamic light scattering (DLS) was used to analyze the particle size distribution, providing vital data on size uniformity and polydispersity, critical for various applications where consistent particle size is crucial.

Preparation of the reference drilling fluid

BM primarily comprised water as the base, along with bentonite, and additional components for instance soda ash (Na2CO3), caustic soda (NaOH), and polymer as outlined in Table 1. The drilling fluid samples were prepared in accordance with the standard American Petroleum Institute (API SPEC 13A, 1993), following the procedure described by Ali et al. (2022c).

Development of the biodegradable, nano and nano-biodegradable drilling fluids

Besides the BM, ten drilling fluid samples were prepared by incorporating various additives. These additives included ZNRs and a biodegradable powder derived from gundelia seed shells, integrated into the BM at various concentrations as specified in Table 2. Initially, the gundelia seed shell powder, functioning as the biodegradable additive, was employed to formulate biodegradable drilling fluids (BDFs) (GSMs) at concentrations of 0.05 and 0.10 wt% for four distinct particle sizes (75, 150, 300, and 600 µm). Following this, ZNR nanofluids were created by adding synthesized ZNRs at 0.1 wt% to the BM. Initially mixed with water for 2 h using an ultrasonic homogenizer, these ZNRs were later blended with bentonite and other fluid components for 1 h using a Hamilton Beach Commercial mixer. Furthermore, 0.1 wt% of zinc ZNRs were incorporated into BDFs to generate GS-ZNR NBDFs.

Drilling fluid testing

Figure 3 illustrates a flowchart depicting the experimental steps conducted in this study. The study commenced with the collection and preparation of materials and additives, encompassing conventional additives, gundelia seed shell, and ZNRs (synthesis and characterization). These materials were subsequently employed in formulating the BM, drilling nanofluid (DNF), BDF, and NBDF. Following this, drilling fluid testing, involving rheological and filtration measurements, was conducted under LTLP and HTHP conditions. The collected experimental data were analyzed using the rheological model.

Rheological properties

The apparent viscosity, yield point, plastic viscosity, and gel strength (initial at 10 s and final at 10 min) as the main effective rheological characteristics of all formulated samples were assessed utilizing the FANN 35 viscometer at 50 °C aligns with the standard temperature as per API Specification 13A (1993). Configuration of the viscometer cup was done with the BM, followed by adjusting the equipment settings accordingly. Activation of the gear switch initiated varying rotational speeds of the rotor. The maximum deflection of the dial before gel breakdown was measured at 10 s and 10 min to estimate the initial and final gel strengths of the fluids, respectively. Meanwhile, the necessary measurements of the viscometer response for the computing the viscosity and yield point were taken at different speeds of the rotation (low speed 3 and 6 RPM, moderate speed 100 and 200 RPM, and high speed 600 and 300 RPM) using Eqs. 1–3 (Madu et al. 2024).

In addition, the relationship between the shear rate and shear strain is also estimated using different rheological models such as Power law, Weibull, Herschel-Bulkley, and Vipulananda (Tahr et al. 2022a, b). In accordance with API recommendations (Bigham model), the Fann viscometer and computation of shear stress are determined by the formula (Ali et al. 2024a, b):

where ϴ is viscometer reading, K1 is torsion constant of 386 dyne-cm/degree deflection, and K2 is shear stress constant equal to 0.01323 cm−2. Then the shear rate can be calculated as follow (Ali et al. 2024a).

where N is the viscometer speed in rpm and K3 is the shear rate constant of1.7023 S−1.

Filtration properties

The filtration properties were studied for all the prepared drilling fluid samples. This investigation was conducted under two distinct conditions: LTLP at room temperature and 100 psi, and HTHP at 75 °C and 200 psi as given by API Specification 13A (1993). The assessment duration for each measurement was set at 30 min. Initiating the Series 300 LTLP filter press setup involved placing a filter paper in the cell and introducing drilling fluid. The filtrate tube was then positioned over a graduated cylinder, and the filter press was configured before commencing the testing process with the initiation of the timer. At various intervals during the 30-min timeframe, the volume of filtrate in the graduated cylinder was noted along with the thickness of the filter cake (Table 3). For testing fluid loss and mud cake formation under extreme conditions, the HTHP API filter press, modified by the OFITE Company in Houston, USA, using model 170–01-1, was utilized. This specialized equipment was designed to assess the filtering capabilities of drilling fluid samples under reservoir-like conditions of 200-psi pressure and 75 °C temperature.

Results and discussion

Characterization of the synthesized ZNRs

The eco-friendly synthesis of ZNRs led to subsequent characterization using SEM, UV–Visible spectroscopy, and DLS to ascertain their size and structure. The washed and dried nanorods were reconstituted in sterile deionized water to form a diluted suspension. UV–Visible spectra were captured using a UV–Vis double-beam spectrophotometer (Super Aquarius Spectrophotometer-1000) across the wavelength range of 200–700 nm with a 1-nm resolution. Before conducting spectral measurements, distilled water was utilized to set the reference baseline. Spectra for plant extract, sodium hydroxide, and zinc acetate dihydrate were also recorded for comparative analysis. Figure 4 displays the UV–Vis spectrum of the Cydonia Oblonga leaf extract juxtaposed with the nano-solution of the synthesized ZNRs. The peaks observed at 269.1 nm and 320.6 nm are likely associated with the phenolic components, specifically flavonoids and polyphenols, present in the Cydonia oblonga leaf extract. This extract predominantly contains flavonoids, polyphenols, and other phenolic compounds such as quercetin, kaempferol, and rutin, which are crucial in reducing zinc ions and stabilizing them at a nanoscale level. These phytochemicals wield significant influence over both the shape and size of the resulting nanorods. Additionally, the UV–Vis absorption spectrum confirms the presence of ZNRs at an ultraviolet wavelength of 341.79 nm.

SEM was employed to observe the morphologies of the yellow layer. Figure 5 displays the SEM micrograph of the synthesized zinc ZNRs at various magnifications. The nanorods’ fabrication is evident from their cylindrical and hexagonal shape, each dimension measuring less than 50 nm. Meanwhile, Fig. 6 demonstrates the application of DLS, a usually used technique for determining the hydrodynamic diameter of nanoparticles by analyzing their Brownian motion within a suspension. Discrepancies in nanoparticle size may relate to the polydispersity index (PDI), reflecting the presence of nanoparticles in aggregates or agglomerates. The synthesized ZNRs exhibit an average size of approximately 31 nm. The variation in diameter measurements obtained via DLS and SEM stems from the different processes involved in sample preparation.

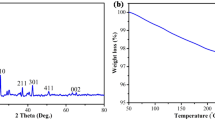

The FTIR spectrum presented in Fig. 7 displays absorption peaks spanning from around 4000 to 400 cm−1, showcasing the biosynthesized ZNRs’ characteristics. Several absorption bands are visible, notably at 1075, 1250, 1382, 1595, 2922, and 3440 cm−1. These bands signify the presence of biomolecules crucial for the stabilization, capping, and reduction of ZnO nanorods. Specifically, the bands observed at 1075 cm−1 and 1250 cm−1 characterize C–C and C–N stretching, indicating the presence of protein amines. Meanwhile, the band at 1595 cm−1 is likely connected to C–N/C–C stretching vibrations of amines or alkene, and the 1382 cm−1 band signifies the O = N symmetry stretching characteristic of nitro compounds. At 2922 cm−1, the band is associated with C–H stretching vibrations of amines. Additionally, the 3440 cm−1 band indicates O–H stretching vibrations, suggesting the presence of phenol and alcohol.

Rheological properties

Table 3 displays the findings of rheological properties for the prepared samples. In the case of the BM, the apparent and plastic viscosities measured 13 and 7 cP, respectively. The yield point was recorded at 6.5 lb/100ft2, accompanied by gel strengths of 3 lb/100ft2 at 10 s and 6 lb/100ft2 at 10 min. Overall, the behavior of the BM was adversely altered, notably influenced by the waste powder and synthesized ZNRs. The gundelia seed shell powder, particularly at a size of 600 µm, exerted the most substantial effect on the BM, while the impact of zinc ZNRs remained relatively minimal. However, the NBDF moderately influenced the rheological properties, contributing to an improvement within the desirable range.

-

Biodegradable drilling fluid

The BDF incorporates environmentally friendly waste into the BM by introducing gundelia seed shell at various particle sizes. For the BDF formulated with a 0.5 wt% concentration of gundelia seed shell powder and a particle size of 75 µm, rheological properties were measured. These properties include a plastic viscosity of 4 cP, an apparent viscosity of 7.5 cP, and a yield point of 3.5 lb/100 ft2, as shown in Fig. 8a. Furthermore, the initial and final gel strength for the same drilling fluid were observed to be 2 and 5 lb/100 ft2, respectively (Fig. 9a). The reduction in rheological properties of Gundelia seed shell samples with smaller particle size can be primarily attributed to the interaction between the seed shell particles and the base mud components (Zhong et al. 2022). The fibrous and organic nature of Gundelia seed shells can interfere with the natural gel structure of the base mud, leading to a decrease in viscosity and gel strength. These natural fibers might absorb water from the drilling fluid, causing a reduction in the fluid’s overall viscosity (Ali et al. 2022b). Another contributing factor is the particle size and distribution of the Gundelia seed shell. The gundelia seed shell powder and a particle size of 75 µm can lead to changes in the fluid’s particle size distribution, which can disrupt the mud’s rheology (Nascimento et al. 2019). This disruption can decrease the yield point and plastic viscosity of the drilling fluid, as the particles may not interact as effectively as the finer clay particles in the base mud (Ghasemi et al. 2018). However, observations indicate that as the particle size increases, the rheological properties begin to escalate, reaching their peak values at a particle size of 600 µm. At this size, the yield point, apparent viscosity, and plastic viscosity attained their highest values of 14.5 lb/100 ft2, 26.5 cP, and 12 cP, respectively.

Furthermore, for the same GSM concentration and particle size, the initial and final gel strength measures 30 and 46 lb/100 ft2, correspondingly, as illustrated in Figs. 8a and 9a. Increasing the GSM concentration to 1 wt% results in a slight increase in the rheological properties. However, there is no change in plastic viscosity compared to the BDF containing 0.5 wt% GSM concentration. When 1 wt% GSM is added to drilling fluid with larger particle sizes, all rheological properties increase, reaching their peak values at the largest particle size of 600 µm (refer to Fig. 8b). Among the prepared BDFs, the highest apparent viscosity of 28.5 cP was achieved with GSM 600 µm (1%) formulated by mixing 1 wt% of 600-µm-sized gundelia seed shell powder with the BM. The plastic viscosity of the BDFs increases by 8 cP with the increase in particle size from 75 to 600 µm at both 0.5 and 1 wt%. Figure 9 demonstrates a significant influence of the gundelia seed shell powder’s particle size on the gel strength of the BDF. In Fig. 9a, both gel strength trends are showed for the BM and BDF at 0.5 wt% and particle sizes ranging from 75 to 600 µm. Notably, the initial gel strength values are lower compared to the final gel strength across all drilling fluid samples. There is a considerable overall increase of 1000% in gel strength values, elevating from 3–4.5 to 30–45 lb/100 ft2 when 0.5 wt% of gundelia seed shell powder with a particle size of 600 µm was added to BM. Figure 9b highlights a similar trend in gel strength observed in the BDFs formulated at a concentration of 1 wt%, under the influence of particle size. The behavior of gel strength remained consistent with the increase in particle size, mirroring the observed pattern in the 0.5 wt% concentration BDFs.

-

Drilling nanofluid

A DNF was created by introducing 1 wt% of the synthesized zinc ZNRs into the BM. This addition of synthesized zinc ZNRs significantly altered the rheological properties, as illustrated in Figs. 8 and 9. Notably, the apparent viscosity and yield point of the DNF remained constant at 13 cP and 7 lb/100 ft2, respectively, competed to the BM. However, by adding 1 wt% zinc ZNRs to the BM, the plastic viscosity enhanced from 7 to 13 cP (Fig. 10). Moreover, the gel strength experienced a substantial increase with the presence of the DNF (Fig. 11). The initial gel strength rose from 3 to 13 lb/100 ft2 when the ZNRs were mixed into the BM. Furthermore, the ZNR drilling fluid exhibited a notable 65% enhancement in the final gel strength recorded.

-

Nano-biodegradable drilling fluid

Figures 10 and 11 present the rheological measurements of the NBDF (GS-ZNR). This fluid was formulated by combining the synthesized zinc ZNRs into the BDF containing GSM (75 µm and 1 wt%), comprising 1 wt% of 75 µm gundelia seed shell powder. A comparison with the BM and DNF reveals significant alterations across all determined rheological properties. The plastic viscosity of the GS-ZNR remained consistent at 7 cP in competed to the BM, but reduced by 46.15% when competed with the DNF. Conversely, the apparent viscosity slightly reduced from 13 to 11.5 cP. However, the GS-ZNR heightened the yield point from 7 to 9 lb/100 ft2, assessing both the BM and DNF (refer to Fig. 10). Furthermore, combining the optimum concentration of ZNRs with a 1 wt% concentration of GSM into the BM followed in an enhancement in both initial and final gel strengths, measuring 5.5 and 10 lb/100 ft2, respectively (Fig. 11). This raise is in comparison to the BM while showing a decrease compared to the DNF (Raza et al. 2023; Olaniyan and Sarah 2024).

Rheological modelling

Table 4 shows the values of dial readings, shear rates, shear stress, and apparent viscosity parameters dependent based on different speeds of FANN rotation. The same approach is used in plotting the rheological behavior of the shear stress versus shear rate and the viscosity versus shear rate which provides a detailed understanding of how the shear rate and shear stress are derived for evaluating the rheological properties of drilling fluids.

Figure 12 represents the relationship between shear rates and stresses across various drilling fluids, revealing different behaviors controlled by their specific compositions. Test results were compared against different rheological models such as Bingham, Power Low, Weibull, Herschel-Bulkley, and Vipulananda. Beginning with the BM, it shows that higher shear stress becomes apparent as the shear rate raises beginning 0 to 200 dynes/cm2. For drilling fluids created with different particle sizes of GSM, the smallest particle size of 75 µm displayed the lowest shear stress and shear rate correlation, dropping to 113 dynes/cm2 compared to the BM (Tahr et al. 2022a). At higher concentrations (1 wt%), there was a slight increase in shear stress. Similarly, for particle sizes of 150 µm, the shear rate and shear stress relationship remained in the range of 124 to 166 dynes/cm2. However, irregular shear stress values were noted for GSM with particle sizes of 300 and 600 µm, recording values of 234 and 404 dynes/cm2, respectively. Introducing nanorods notably increased shear stress, reaching a peak of 610 dynes/cm2. However, when combined with biodegradable materials, the shear stress decreased to 163 dynes/cm2, indicating a thinning performance of the drilling fluids. This thinning behavior is crucial for effective gel formation in stable situation and facilitates seamless flow with minimal pressure loss in cuttings transportation to surface. Remarkably, NBDFs, formed by blending GSM at 75 µm with ZNRs, exhibited exceptional thinning performance, highlighting their potential in drilling applications.

In addition, the relationship between shear rates and viscosity in various drilling fluids, each influenced by their unique compositions, is shown in Fig. 13. These behaviors were analyzed using different rheological models, including Bingham, Power Law, Weibull, Herschel-Bulkley, and Vipulananda, to highlight their differences. Shear-thinning characteristics are confirmed by the viscosity functions of shear rates, as seen in the shear stress plots. The GMS samples demonstrate a reduction in viscosity with increasing shear rates, while for BM, the viscosity remains nearly constant, indicative of its Newtonian nature. The extent of shear thinning in GMS samples varies with particle size and concentration; larger sizes and higher concentrations lead to a more noticeable drop in viscosity (Tahr et al. 2022b). At various temperatures, GMS samples exhibit higher viscosities than BM samples. This could be due to the nano-sized particles in the GMS samples, which enhance the fluid’s viscosity and stability. Additionally, the decrease in viscosity at higher shear rates is beneficial for drilling operations as it lowers pumping pressures and reduces frictional losses.

Filtration properties

The filtration characteristics of the BM modified with ZNRs and waste materials were investigated at two condition such as LTLP and HTHP as shown in Fig. 14. The filtration rate of the BM is reduced when the gundelia seed shell powder with the particle size of 75 µm was added from 14.8 to 12 cm3. Afterwards, the rate of the filtration is increased with increasing the particle size of the used waste powder. The GSM with particle size 600 µm and concentration of 0.5 wt% of the gundelia seed shell has the highest filtration rate of 20.6 cm3. In general, the BDFs, derived from gundelia seed powder with various particle sizes, demonstrated optimal performance at 75 µm by effectively reducing the filtration rate through the formation of a substantial, impermeable filter cake. Meanwhile, the filtration rate of the GSMs prepared from mixing 1 wt% of the gundelia seed shell at different particle sizes within the BM is less compared with the 0.5 wt% expect 300 µm GSM (see Fig. 14a). The measurement of the filter cake thickness under LTLP conditions served as a vital parameter for filtration assessment across varying concentrations and particle sizes of both the BM and BDFs (see Fig. 14c). As can be seen, BM without the presence of the gundelia waste provided a filter cake of 3.7 mm in thickness. The gundelia seed shell in the concentration of 0.05 wt% created thinner filter cake when mixed with the BM for all prepared particle sizes expect 300 µm compared with 1 wt%. The thickest filter cake measured when 0.5 wt% gundelia waste with the particle size of 75 µm is added into the BM, which is 1.7 mm. Alternatively, the filter cake thickness was changed to 2.8, 4.3, and 4.6 mm when 0.5 wt% of the GSM at 150, 300, and 600 µm was added into the BM. However, the values are varied when 1 wt% of the GSM at 75, 150, 300, and 600 µm was added into the BM, which are 2.5, 3.5, 3.5, and 5, respectively.

The effect of pressure and temperature on the filtration properties of the BDFs prepared from gundelia waste at different particle sizes and concentrations can be observed on Fig. 14b and d. As is obvious, when the temperature and pressure are increased to 75 °C and 200 psi, respectively, the fluid loss is increased, and thicker mud cake is generated. For instance, the filtration rate of the BM is increased from 14.8 to 27.4 cm3 and the filter cake thickness is improved from 3.7 to 6.8 mm. The mentioned values of the filtration rate obtained by BM is decreased 22.2 and 22 cm3 when the gundelia waste with the particle size of 75 µm is included at concentrations of 0.5 and 1 wt%, correspondingly. Afterwards, the rate of fluid loss is increased with increasing the particle size of the biodegradable powder to the highest value of 37.9 cm3 by 0.5 wt% of GSM 600 µm. In terms of the concentration, the effect of the 1 wt% is remained slightly higher for all the particle sizes, except 300 µm, compared with the 0.5 wt% when the temperature and pressure adjusted to 75 °C and 200 psi, respectively (see Fig. 14b). In addition, the filter cake thicknesses of the BDFs (GSMs) at HTHP are presented on Fig. 14d. The thickness value of the filter cakes is almost doubled for all cases of the drilling fluids without and with the occurrence of the gundelia waste at altered particle sizes and concentrations. The filter cake of the BM is thickened from 3.7 to 6.8 mm at HTHP condition. However, this thickness is dropped by 54.4 and 23.5% under the effect of 0.5 wt% of the gundelia waste with the particle sizes of 75 and 150 µm, respectively, and increased by 17.6 and 36.7 with the particle sizes of 300 and 600 µm. Meanwhile, when the concentration of the waste powder rose to 1 wt%, the impact of the biodegradable on the reduction of the filter cake thickness is minimized and the lowest value of 5 mm is achieved with the particle size of 75 µm. Noticeably, the particle size of 300 µm in all cases of testing exhibited strangely and is out of the recorded trends of the measurements. Hence, the particle size of 75 µm is selected as the optimal value for the preparation of the BDFs from the gundelia seed shell waste. The enhanced performance of Gundelia seed shells with 75 µm in filtration can be attributed to their unique structural and chemical properties. Gundelia seed shells contain a high concentration of fibrous materials, including cellulose, hemicellulose, and lignin. These fibrous components provide a high surface area and porosity, which enhance their ability to adsorb and retain particles, effectively reducing the permeability of the filter cake and minimizing fluid loss (Li et al. 2024a, b). The particle size of 75 µm is particularly effective for bridging the pores and microfractures within the formation. This bridging action helps to create a more compact and impermeable filter cake on the wellbore wall, which prevents further invasion of the drilling fluid into the formation (Meza et al. 2017). Additionally, the natural composition of Gundelia seed shells includes various organic compounds, such as oils and waxes, which enhance the lubricity of the drilling fluid. This increased lubricity reduces the friction between particles and facilitates the formation of a thin, uniform, and resilient filter cake. The presence of these compounds also helps in stabilizing the fluid loss control properties of the drilling fluid under different temperature and pressure conditions (Zhao et al. 2022).

Figure 15 shows the filtration properties of the drilling fluids. The filter cake thickness of the drilling fluid started to reduce by 54 and 32.4% when the recipe of the mud is changed from the bentonite water-based mud to the BDF and DNF, respectively, under the LTLP condition. Meanwhile, further reduction of additional 5.45% was noticed when the NBDF is used at the same testing condition but with mixing 1 wt. ZNRs and GSM at 75-µm particle size. The values of the mud cake thicknesses for all mentioned types of the drilling fluids are higher at HTHP condition compared with the LTLP. At the same time, the filtration rate exhibited the same behavior under the impact of temperature and pressure; when these two factors are increased, the rate of fluid loss is increased as well. As can be seen, the filtration rate is significantly reduced when the recipe of the drilling fluid is changed from the BM to GSM, ZNR, and ZNO + GSM drilling fluids (see Fig. 14). The influence of the DNF is lowest compared with the optimal biodegradable and NBDFs but it enables additional decrease of the filtration rate when mixing with the optimal biodegradable one (Oni et al. 2023; Ghazali et al. 2024). The minimum rate of the filtration is obtained by a NBDF created from combining 1 wt% zinc ZNRs and gundelia seed shell powder at 75-µm particle size within the BM at ambient testing condition, which is 2.83 cm3. However, 17.2 cm3 is the lowest filtration rate recorded under HTJP testing condition for the same drilling fluid.

The specific role of the nanorod structure of ZNRs in the filter cake buildup phenomena can be attributed to several factors related to their unique shape and properties. The high surface area to volume ratio of the nanorods allows for more effective interaction with the particles in the drilling fluid and the formation, enhancing adsorption and trapping of particles, thus contributing to a denser and more impermeable filter cake (Oseh et al. 2023). The elongated shape of ZNRs enables effective bridging across pores and fractures, blocking flow paths and forming a compact, robust filter cake that minimizes fluid loss (Vryzas and Kelessidis 2017). Additionally, the rigid structure of ZNRs provides mechanical reinforcement to the filter cake, increasing its resistance to pressure and mechanical degradation (Tang et al. 2020). The surface chemistry of ZNRs, influenced by the phytochemicals used in their synthesis, improves compatibility with drilling fluid components, leading to better dispersion and integration within the filter cake (Bardhan et al. 2024). Furthermore, the thermal stability of ZNRs, maintained by stabilizing agents from the plant extracts used in their synthesis, helps preserve the integrity of the filter cake under high-temperature conditions encountered during drilling (Ikram et al. 2021). These factors collectively contribute to the formation of a more effective and resilient filter cake, essential for minimizing fluid loss and maintaining wellbore stability.

Figure 16 demonstrates the snapshoots and micrographs of the filter cakes obtained from the filtration measurements. As is clear, a small variation in the color of the filter cakes can be noticed due to the change in the composition of the studied drilling fluids. Meanwhile, a high difference is observed between the SEM micrographs of the filter cakes. The graph shown in Fig. 14a illustrates the structure of the filter cake surface produced from the BM without the presence of the ZNRs and gundelia waste particles, while the particles of the gundelia waste are obvious of the filter cake surface created by the BDF (see Fig. 16b). In addition, the darker filter cake was produced by the DNF with the presence of the nanorods on its surface as shown in Fig. 14c. Furthermore, when both the synthesized ZNRs and the gundelia seed waste particles were mixed within the BM, their presence on the resulted filter cake is clear (see Fig. 16d). Overall, the NBDF provided the thinnest filter cake with less fluid loss.

Performance evaluation of the current work compared with the literature

A comparative evaluation of the result outcomes of this study with the recently published works related to the application of bio-based substances in improving the main properties of drilling fluid including rheology, fluid loss, and filter cake thickness is shown in Table 5. Different studies were included from various parts of the world using different materials. As can be seen, Novara et al. (2021) used two types of nanoparticles (SiO2 and Al2O3) to improve the rheology and filtration of the freshwater-based drilling fluid. Their results shown that silica was more effective in reducing the rate of fluid loss by 26.9% and thickness of the filter cake by 23.8% compared with the alumina which is left negative impact. Meanwhile, alumina provided a better performance in improving the rheological properties of the drilling fluid. In 2023, a group of researchers from Malaysia developed a bio-based graphene from the oil palm and added to the water-based drilling fluid at 1 wt% concentration (Safian et al. 2023). They conducted their experiments of filtration and rheology measurements at 120 °C and 200 psi and reported that the filtration rate reduced by 41.9% and decreased the thickness of the filter cake by 53.8% along with leaving a weak impact on the rheological behavior. In addition, eggshell (reported as eggshell nanoparticles (NPs)) as the waste substance at the ultrafine size (5 µm) was used at the concentration of 6 lb/bbl (Fadairo and Oni 2024). They reported that the eggshell NPs enabled 17% and 15.6% reduction in the filtration rate and thickness of filter cake, respectively, under 200 °C and 400 psi condition. Furthermore, the mechanism used in this study was the most effective one compared with the mentioned studies in terms of decreasing the fluid loss and the filter cake thickness by 58.38% and 55%, respectively. Although the impact of both used environmentally friendly substances were moderate on rheological properties but the main purpose was modification of the filtration properties. Overall, the idea of the development of nano-biodegradable drilling fluid from green ZNRs and gundelia waste is new and effective in terms of reducing the toxicity of the drilling mud circulation and drilling mud waste which meets current environmental standards and reduces the cost of the mud pit remediation (Martin et al. 2023; Liu et al. 2023). However, for future research, the following pathways are recommended: Conduct systematic studies to determine the optimal concentration and ensure uniform dispersion of ZNR in the drilling fluid. Investigate various surface modifications and coatings for ZNR to enhance their compatibility and interaction with the drilling fluid components. Synthesize ZNR with different sizes and aspect ratios to identify the most effective configurations for enhancing drilling fluid properties. Additionally, study the interactions between ZNR and other common drilling fluid additives to identify potential synergistic or antagonistic effects and optimal formulations.

Conclusions

The aim of this study revolves around creating a sustainable NBDF that minimizes fluid loss, produces the thinnest mud cake, and enhances rheological properties. This innovative drilling fluid is crafted using locally sourced waste from gundelia seeds and synthesized ZNRs extracted from the Cydonia oblonga plant. Evaluation was based on the performing of the BM, adhering to API-SPEC-13A-2010 standards. The study’s findings can be summarized as follows:

-

The analytical methods of Uv–Vis, SEM, DLS, and FTIR confirmed the validity of the synthesized nanorods.

-

The smaller particle size of the gundelia seed waste is more effective in enhancing the drilling fluid performance compared with the larger ones, and the particle size of 75 µm is detected as the optimal once.

-

Among both 0.5 and 1 wt% concentrations of the gundelia seeds waste, only slight change is observed in drilling fluid properties.

-

The drilling fluid properties were affected by the DNF obtained from the ZNRs, although the impact was not as noteworthy as that from the waste of gundelia seeds.

-

The developed NBDF enabled modification in the values of the plastic viscosity, apparent viscosity, gel strength, and yield point to a favorite range. Thus, better share rate and shear strain relation was achieved.

-

The created NBDF reduced the thickness of the filter cake and fluid loss volume by more than 50% competed with the BM.

-

HTHP has a direct relationship with the drilling fluid filtration properties and increased filter cake thickens and filtration rate.

Data availability

The datasets used and analyzed during the current study are available from the corresponding author on reasonable request.

References

Abdullah AD, Ali JA, Abdalqadir M (2024) Exploring the role of hydrophobic nanofluids in reducing shale swelling during drilling: a step towards eco-friendly and sustainable practices. Colloids Surf Physicochem Eng Aspects. https://doi.org/10.1016/j.colsurfa.2024.134164

Abed H, Al-Jewaree M, Adil M, Ali O (2022) An experimentally investigate the effect of physical properties on the production of lubricating materials from crude oils. Al-Kitab J Pure Scie 3(1):30–47

Al-Hameedi ATT, Alkinani HH, Dunn-Norman S, Salem E, Knick-erbocker MD, Alashwak NF, Al-Bazzaz WH (2020) Laboratory study of environmentally friendly drilling fluid additives banana peel powder for modifying the drilling fluid characteristics in water-based muds. Paper presented at the International Petroleum Technology Conference

Al-Haj A, Al-Juboury MI, Al-Hadidy AH, Hassan AK (2022) Cenomanian-early campanian carbonate reservoir rocks of Northwestern Iraq: diagenesis and porosity development. Al-Kitab J Pure Sci 2(2):1–19

Al-Hameedi ATT, Alkinani HH, Dunn-Norman S, Al-Alwani MA, Alshammari AF, Albazzaz HW, Alkhamis MM, Alashwak NF, Mutar RA (2019) Insights into the application of new eco-friendly drilling fluid additive to improve the fluid properties in water-based drilling fluid systems. J Petrol Scie Eng 183:106424

Ali JA, Kolo K, Sajadi SM, Hamad KH, Salman R, Wanli M, Hama SM (2019) Modification of rheological and filtration characteristics of water-based mud for drilling oil and gas wells using green SiO2@ZnO@Xanthan nanocomposite. IET Nanobiotechnol 13(7):748–755

Ali JA, Hamadamin AB, Ahmed SM, Mahmood BS, Sajadi SM, Manshad AK (2022a) Synergistic effect of nanoinhibitive drilling fluid on the shale swelling performance at high temperature and high pressure. Energy Fuels 36(4):1996–2006

Ali JA, Ahmed RN, Abdullah AD, Ali NH, Kalhury AM, Sabir AN, Khaksar Manshad A, Keshavarz A, Mohammadi AH (2022b) Development of a nanobiodegradable drilling fluid using Prosopis farcta plant and pomegranate peel powders with metal oxide nanoparticles. ACS Omega 7(35):31327–31337

Ali I, Ahmad M, Ganat TA-A (2022c) Experimental study on water-based mud: investigate rheological and filtration properties using cupressus cones powder. J Pet Explor Prod Technol 12(10):2699–2709

Ali I, Ahmad M, Ganat T (2022d) Biopolymeric formulations for filtrate control applications in water-based drilling muds: a review. J Petrol Scie Eng 210:110021

Ali JA, Abbas DY, Abdalqadir M, Nevecna T, Jaf PT, Abdullah AD, Rancová A (2024a) Evaluation the effect of wheat nano-biopolymers on the rheological and filtration properties of the drilling fluid: towards sustainable drilling process. Colloids Surf, A 683:133001

Ali JA, Abdalqadir M, Najat D, Hussein R, Jaf PT, Simo SM, Abdullah AD (2024b) Application of ultra-fine particles of potato as eco-friendly green additives for drilling a borehole: a filtration, rheological and morphological evaluation. Chem Eng Res Design. https://doi.org/10.1016/j.cherd.2024.04.051

Al-Yasiri MS, Al-Sallami WT (2015) How the drilling fluids can be made more efficient by using nanomaterials. Am J Nano Res Appl 3(3):41–45

Awl MJ, Mahmood BS, Mohammed PT, Hardi FM, Hamad AM, Abdulqadir AH, Abdalqadir MO (2023) Performance evaluation of the new environmentally friendly additive for enhanced fluid loss and rheological properties of drilling fluid. J Chemical Petrol Eng 57:51–61

Bardhan A, Vats S, Prajapati DK, Halari D, Sharma S, Saxena A (2023a) Utilization of mesoporous nano-silica as high-temperature water-based drilling fluids additive: Insights into the fluid loss reduction and shale stabilization potential. Geoenergy Sci Eng 232:212436

Bardhan A, Khan F, Kesarwani H, Vats S, Sharma S, Kumar S (2023b) Performance evaluation of novel silane coated nanoparticles as an additive for high-performance drilling fluid applications. https://doi.org/10.2523/IPTC-22878-MS

Bardhan A, Singh A, Nishanta H, Sharma S, Choubey AK, Kumar S (2024) Biogenic copper oxide nanoparticles for improved lubricity and filtration control in water-based drilling mud. Energy Fuels 38:8564–8578

Cheraghian G (2021) Nanoparticles in drilling fluid: a review of the state-of-the-art. J Mater Res Technol 13:737–753

Davoodi SA, Jamshidi S, Jahromi AF (2018) A novel field applicable mud formula with enhanced fluid loss properties in high pressure-high temperature well condition containing pistachio shell powder. J Petrol Scie Eng 162:378–385

Dejtaradon P, Hamidi H, Chuks MH, Wilkinson D, Rafati R (2019) Impact of ZnO and CuO nanoparticles on the rheological and filtration properties of water-based drilling fluid. Colloids and Surfaces a: Physicochemical Eng Aspects 570:354–367

Fadairo AS, Oni O (2024) The suitability of eggshell for improving the performance of water-based drilling mud in a high-temperature well. Geothermics 119:102920

Gbadamosi AO, Junin R, Abdalla Y, Agi A, Oseh JO (2019) Experimental investigation of the effects of silica nanoparticle on hole cleaning efficiency of water-based drilling mud. J Petrol Sci Eng 172:1226–1234

Ghasemi N, Mirzaee M, Aghayari R, Maddah H (2018) Investigating created properties of nanoparticles based drilling mud. Heat Mass Transf 54:1381–1393

Ghazali NA, Naganawa S, Masuda Y (2024) The effect of high-temperature environment on the rheology and filtration properties of Rhizophora spp. tannin-lignosulfonate as bio-based additive in water-based drilling fluid. J Petrol Explor Prod Technol 14(3):727–743. https://doi.org/10.1007/s13202-023-01740-0

Ibrahim MA, Jaafar MZ, Md Yusof MA, Idris AK (2022) A review on the effect of nanoparticle in drilling fluid on filtration and formation damage. J Petrol Scie Eng 217:110922

Ikram R, Mohamed Jan B, Sidek A, Kenanakis G (2021) Utilization of eco-friendly waste generated nanomaterials in water-based drilling fluids; state of the art review. Materials 14:4171

Iscan AG, Kok MV, Bagci AS (2007) Permeability reduction due to formation damage by drilling fluids. Energy Sources: Part A 29(9):851–859

Ismail AR, Mohd Norddin MNA, Latefi NAS, Oseh JO, Ismail I, Gbadamosi AO, Agi AJ (2020) Evaluation of a naturally derived tannin extracts biopolymer additive in drilling muds for high-temperature well applications. J Petrol Explor Prod Technol 10:623–639

Jameel N, Ali JA (2023) Field and experimental investigations on the effect of reservoir drill-in fluids on penetration rate and drilling cost in horizontal wells. Gels 9(7):510

Jin J, Lv K, Sun J, Zhang J, Hou Q, Guo X, Liu K (2023) Robust superhydrophobic TiO2@carbon nanotubes inhibitor with bombax structure for strengthening wellbore in water-based drilling fluid. J Molecular Liquids 370:120946

Jinhua H, Xing Z (2023) Preparation, investigation and corrosion mechanism of novel thermally stable high-density compound phosphate-based drill-in fluids for HTHP applications. J Molecular Liquids 391:123317

Lei M, Huang W, Sun J, Shao Z, Duan W, Wu T, Wang Y (2020) Synthesis, characterization, and performance of carboxymethyl chitosan with different molecular weight as additive in water-based drilling fluid. J Molecular Liquids 310:113135

Li A, Gao S, Zhang G, Zeng Y, Hu Y, Zhai R, Dong A, Zhang J (2024a) A review in polymers for fluid loss control in drilling operations. Macromol Chem Phys 225. https://doi.org/10.1002/macp.202300390

Li Q, Liu J, Wang S, Guo Y, Han X, Li Q, Cheng Y, Dong Z, Li X, Zhang X (2024b) Numerical insights into factors affecting collapse behavior of horizontal wellbore in clayey silt hydrate-bearing sediments and the accompanying control strategy. Ocean Eng. https://doi.org/10.1016/j.oceaneng.2024.117029

Li Q, Wang Y, Owusu AB (2019) A modified Ester-branched thickener for rheology and wettability during CO2 fracturing for improved fracturing property. Environmental Scie Pollution Research 26:20787–20797. https://doi.org/10.1007/s11356-019-05386-6

Li Q, Wang F, Wang Y, Zhou C, Chen J, Forson K, Miao R, Su Y, Zhang J (2023) Effect of reservoir characteristics and chemicals on filtration property of water-based drilling fluid in unconventional reservoir and mechanism disclosure. Environ Scie Pollution Research 30(19):55034–55043

Liu X, Li MC, Liao B, Liu S, Lu K, Lv K, Sun J, Liu C, Mei C, Wu Q (2023) Wood-derived lignocellulose nanomaterials as multifunctional agents in eco-friendly pickering emulsion-based drilling fluids. Chemical Eng J 475:146372

Madu C, Faraji F, Abdalqadir M, Gomari SR, Chong PL (2024) Feasibility study of biodegradable coffee ground waste and watermelon rind as water-based drilling fluid additives. J Nat Gas Sci Eng 125:205322. https://doi.org/10.1016/j.jgsce.2024.205322

Martin C, Nourian A, Babaie M, Nasr G (2023) Environmental, health and safety assessment of nanoparticle application in drilling mud – review. Geoenergy Scie Eng 226:211767

Medved I, Gaurina-Međimurec N, Novak Mavar K, Mijić P (2022) Waste mandarin peel as an eco-friendly water-based drilling fluid additive. Energies 15(7):2591

Meza OG, Yaqoob T, Bello O, Boulakhrif F, Holzmann J (2017) Combined investigation of effects of contact stresses, pore size and rotary dynamics on mud plastering in prevention of lost circulation in weak zones during casing drilling. https://doi.org/10.2118/188182-MS

Nascimento DR, Oliveira BR, Saide VGP, Magalhães SC, Scheid CM, Calçada LA (2019) Effects of particle-size distribution and solid additives in the apparent viscosity of drilling fluids. J Petrol Scie Eng 182:106275

Novara R, Rafati R, Haddad AH (2021) Rheological and filtration property evaluations of the nano-based muds for drilling applications in low temperature environments. Colloids Surf a: Physicochem Eng Aspects 622:126632

Olaniyan DD, Sarah AA (2024) The rheological and filtration properties of black seed (Nigella Sativa L.) ester as a base fluid in drilling fluid. J Eng Applied Scie 71:1

Oni O, Fadairo AS, Gosnold W, Egenhoff S, Adeyemi G, Ling K (2023) Investigating the suitability of North Dakota fly ash as fluid loss reducing additive in densified water-based drilling fluid. Powder Technol 430:118972

Oseh JO, Mohd NMNA, Gbadamosi AO, Agi A, Blkoor SO, Ismail I, Igwilo KC, Igbafe AI (2023) Polymer nanocomposites application in drilling fluids: a review. Geoenergy Sci Eng 222:211416

Perween S, Thakur NK, Beg M, Sharma S, Ranjan A (2019) Enhancing the properties of water based drilling fluid using bismuth ferrite nanoparticles. Colloids Surf, A 561:165–177

Prajapati DK, Bardhan A, Sharma S (2023) Microwave-assisted synthesis of zinc oxide nanoflowers for improving the rheological and filtration performance of high-temperature water-based drilling fluids. J Dispers Sci Technol 1–13. https://doi.org/10.1080/01932691.2023.2294303

Ragab AS, Noah A (2014) Reduction of formation damage and fluid loss using nano-sized silica drilling fluids. Petrol Technol Dev 2:75–88

Raza A, Hussain M, Raza N, Aleem W, Ahmad S, Qamar S (2023) Rice husk ash as a sustainable and economical alternative to chemical additives for enhanced rheology in drilling fluids. Environ Sci Pollut Res 30(48):105614–105626

Safian MT, Raja PB, Shen CY, Mohamad Ibrahim MN (2023) A novel preparation of bio-based graphene from oil palm biomass as a fluid loss additive in water-based drilling fluid. Geoenergy Sci Eng 231:212321

Salih AI (2022) Effect of some types of oils and Surfactant factors on the production of carotenoids from the yeast of Rhodotorula glutinis. Al-Kitab J Pure Sci 2(2):292–304

Shahbazi B, Feyzmand S, Jafari F, Ghiasvand N, Bahrami G, Fattahi A, Shokoohinia Y (2020) Antidiabetic potential of Prosopis farcta roots: in vitro pancreatic beta cell protection, enhancement of glucose consumption, and bioassay-guided fractionation. Evid Based Complement Alternat Med 2020:1–9

Sun J, Chang X, Lv K, Wang J, Zhang F, Jin J, Zhou X, Daii Z (2021) Environmentally friendly and salt-responsive polymer brush based on lignin nanoparticle as fluid-loss additive in water-based drilling fluids. Colloids Surf, A 621:126482

Tahr Z, Mohammed AS, Ali JA (2022a) Efficient models to evaluate the effect of temperature on the water loss, filter cake, and yield stress of polymerized clay bentonite using in the oil well drilling operation. Iranian J Sci Technol, Trans Civil Eng 47(2):1089–1107

Tahr Z, Mohammed A, Ali JA (2022b) Surrogate models to predict initial shear stress of clay bentonite drilling fluids incorporated with polymer under various temperature conditions. Arab J Geosci 15(17). https://doi.org/10.1007/s12517-022-10720-3

Tahr Z, Ali JA, Mohammed AS (2023) Sustainable aspects behind nano-biodegradable drilling fluids: a critical review. Geoenergy Scie Eng 222:211443

Tang X, Kang W, Zhou B, Gao Y, Cao C, Guo S, Iqbal MW, Yang H (2020) Characteristics of composite microspheres for in-depth profile control in oilfields and the effects of polymerizable silica nanoparticles. Powder Technol 359:205–215

Torres-Carrasco M, Reinosa J, de la Rubia M, Reyes E, Peralta FA, Fernández JF (2019) Critical aspects in the handling of reactive silica in cementitious materials: effectiveness of rice husk ash vs nano-silica in mortar dosage. Constr Build Mater 223:360–367

Vryzas Z, Kelessidis VC (2017) Nano-Based Drill Fluids: a Rev Energies 10:540

Vryzas Z, Zaspalis V, Nalbandian L, Terzidou A, Kelessidis VC (2018) Rheological and HP/HT fluid loss behavior of nano-based drilling fluids utilizing Fe3O4 nanoparticles. Mater Today: Proc 5:27387–27396

Wang Z, Wu Y, Luo P, Tian Y, Lin Y, Guo Q (2018) Poly (sodium P-styrene sulfonate) modified Fe3O4 nanoparticles as effective additives in water-based drilling fluids. J Petrol Scie Eng 165:786–797

Zhao X, Li D, Zhu H, Ma J, An Y (2022) Advanced developments in environmentally friendly lubricants for water-based drilling fluid: a review. RSC Adv 12:22853–22868

Zhong H, Gao X, Zhang X, Chen A, Qiu Z, Kong X, Huang W (2022) Minimizing the filtration loss of water-based drilling fluid with sustainable basil seed powder. Petroleum 8:39–52

Zhong H, Guan Y, Qiu Z, Grady BP, Su J, Huang W (2023) Application of carbon coated bentonite composite as an ultra-high temperature filtration reducer in water-based drilling fluid. J Mol Liq 375:121360

Funding

Open access publishing supported by the National Technical Library in Prague.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection, and analysis were performed by Jagar A. Ali, Rayan Gailani, Pshtiwan T. Jaf, Sherwan Mohammed Simo, Mardin Abdalqadir, and Vinos Mushir Faris. The first draft of the manuscript was written by Abdullah D. Abdullah and Jagar A. Ali and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Consent to publish

We hereby grant the full and unconditional consent for the publication of the manuscript.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Philippe Garrigues

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ali, J.A., Gailani, R., Abdullah, A.D. et al. Performance evaluation of the nano-biodegradable drilling fluid using the greenly synthesized zinc nanorods and gundelia seed waste. Environ Sci Pollut Res (2024). https://doi.org/10.1007/s11356-024-34561-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11356-024-34561-7