Abstract

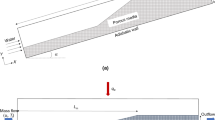

A numerical assessment of the heat transfer efficacy of a solar air heater (SAH) was carried out. The SAH is supplied with a porous metal foam layer to improve thermal mixing. Both the local thermal non-equilibrium (LTNE) and Darcy-extended Forchheimer (DEF) models were employed to forecast fluid and thermal transport within the partly filled SAH channel. The analysis was performed for various values of dimensionless foam layer lengths (\(S=0-1\)), pore densities (\(\omega =10-40 {\text{PPI}}\)), and Reynolds numbers (\(Re = 4000-1\mathrm{6,000}\)) at a fixed value of layer thickness (\({H}_{f} =0.6\)). Based on the position of the porous layer, three distinct arrangements, marked as Case 1, Case 2, and Case 3, were explored. Regarding the parameters examined, the findings indicate a definite improvement in the average Nusselt number (\(Nu\)), but unfortunately, the friction factor also increases unfavorably. By reducing the length of the porous layer, a reasonable reduction in heat transfer rate and a significant decrease in pressure drop were noticed. The results showed about 26.64%, 48.73%, and 70.74% reductions in pressure drop by reducing the dimensionless foam length from 1 to 0.25, 0.5, and 0.75 respectively for \(\omega =10\) at \(Re = \mathrm{16,000}\). On the other side, there are only about 11.05%, 23.11%, and 40.78% reductions in \(Nu\). The exhaustive analysis of the thermal performance of SAH was conducted using the thermal performance factor (TPF), which considers the trade-off between the SAH channel’s potential for improved heat transmission and its cost for pressure loss. The TPF may reach a maximum of 2.82 compared to the empty channel when the metal foam layer is inserted with \(S=1\), for \(\omega =10\), and \(Re = \mathrm{16,000}\).

Similar content being viewed by others

Data availability

The data supporting the conclusions of this study are available within the work itself.

Abbreviations

- \({a}_{sf}\) :

-

specific surface area, M−1

- C :

-

Forchheimer coefficient

- \({C}_{\upepsilon 1}, {C}_{\upepsilon 2}, {C}_{\mu }, {\sigma }_{k}, {\sigma }_{\epsilon }\) :

-

Constants in the \(k \_\varepsilon\) turbulent model

- \({D}_{h}\) :

-

Hydraulic diameter, m

- \({d}_{p}\) :

-

Pore diameter (m)

- \({d}_{f}\) :

-

Fiber diameter (m)

- f :

-

Friction factor

- \(h\) :

-

heat transfer coefficient, Wm−2 K−1

- H:

-

Duct height (m)

- \({\text{t}}\) :

-

Metal foam layer thickness (m)

- \({H}_{f}={\text{t}}/H\) :

-

Dimensionless metal foam height

- \(K\) :

-

permeability (m2)

- \(k\) :

-

Turbulent kinetic energy (m2/s2)

- L 1 :

-

Inlet section length (m)

- L 2 :

-

Absorber plate length (m)

- L 3 :

-

Outlet section length (m)

- \(l\) :

-

Metal foam layer length (m)

- \(Nu=\frac{\overline{h} {D }_{h}}{{\lambda }_{f}}\) :

-

Nusselt number

- P:

-

pressure (Pa)

- \(Re=\frac{\rho {u}_{av}{D}_{h}}{{\mu }_{f}}\) :

-

Reynolds number

- \(S=\frac{l}{{L}_{1}}\) :

-

Dimensionless metal foam length

- T:

-

temperature (K)

- \(u,v\) :

-

Velocity component, m s−1

- \(x, y\) :

-

Cartesian coordinates (m)

- \(X, Y\) :

-

Non-dimensional Cartesian coordinates, \(X=x/{L}_{2}\), \(Y=y/H\)

- \(\overset{{^\prime}^\prime}q\) :

-

Heat flux (W m−2)

- \(\rho\) :

-

density, kg/m3

- µ:

-

dynamic viscosity, kg. m−1.s−1

- \(\varnothing\) :

-

porosity

- \(\omega\) :

-

pore density, PPI

- λ:

-

thermal conductivity, Wm−1 K.−1

- \(\varepsilon\) :

-

dissipation rate of k, (m2s−3)

- av :

-

average

- s :

-

smooth duct, solid

- f :

-

fluid

- e :

-

effictive

- i :

-

inlet

- o :

-

Outlet

- DEF :

-

Darcy-extended Forchheimer model

- FPSC :

-

flat-plate solar collector

- LTE :

-

local thermal equilibrium

- LTNE :

-

local thermal non-equilibrium

- PEC :

-

performance evaluation criteria

- PPI :

-

pore per inch

- SAH :

-

solar air heater

- TPF :

-

thermal performance factor

References

Alazmi B, Vafai K (2002) Constant wall heat flux boundary conditions in porous media under local thermal non-equilibrium conditions. Int J Heat Mass Transf 45(15):3071–3087

Albojamal A, Haghighi A, Hamzah H (2017) Analysis of thermal transport through a flat-plate solar collector integrated with metal-foam blocks. Int J Energy Eng Sci 2(2):55–68

Al-Chlaihawi KKI, Hasan MR, Ekaid AL (2024a) Compound passive heat transfer augmentation techniques: a comprehensive review. Heat Transfer 53(2):363–421

Al-Chlaihawi KKI, Hasan MR, Ekaid AL (2024b) Thermohydraulic performance assessment of a solar air heater with equilateral-triangular, trapezoidal, and square sectional ribs on the absorber plate: a comparative study. Heat Transfer 53(2):441–471

Al-Chlaihawi KKI, Alyas BH, Badr AA (2023) CFD Based numerical performance assessment of a solar air heater duct roughened by transverse-trapezoidal sectioned ribs. Int J Heat Technol 41:5

Ali RMK, Ghashim SL (2023) Numerical analysis of the heat transfer enhancement by using metal foam. Case Stud Therm Eng 49:103336

Anirudh K, Dhinakaran S (2020a) Numerical study on performance improvement of a flat-plate solar collector filled with porous foam. Renew Energy 147:1704–1717

Anirudh K, Dhinakaran S (2020b) Performance improvement of a flat-plate solar collector by inserting intermittent porous blocks. Renew Energy 145:428–441. https://doi.org/10.1016/j.renene.2019.06.015

Anirudh K, Dhinakaran S (2021) Numerical analysis of the performance improvement of a flat-plate solar collector using conjugated porous blocks. Renew Energy 172:382–391. https://doi.org/10.1016/j.renene.2021.02.145

Balakrishnan P, Vengadesan E, Bhowal B, Senthil R (2023) Energy and enviro-economic analysis of a solar air heater with wedge turbulators. Environ Sci Pollut Res 30(57):120844–120862. https://doi.org/10.1007/s11356-023-30792-2

Bashria A, Adam NM (2008) Performance analysis of single and double passes flat plate collector with and without porous media. J Mech Eng 58(5–6):275–290

Bayrak F, Oztop HF (2015) Experimental analysis of thermal performance of solar air collectors with aluminum foam obstacles. J Therm Sci Technol 35(1):11–20

Boomsma K, Poulikakos D (2001) On the effective thermal conductivity of a three-dimensionally structured fluid-saturated metal foam. Int J Heat Mass Transf 44(4):827–836

Bovand M, Rashidi S, Esfahani JA (2016) Heat transfer enhancement and pressure drop penalty in porous solar heaters: numerical simulations. Sol Energy 123:145–159. https://doi.org/10.1016/j.solener.2015.10.054

Calmidi VV, Mahajan RL (2000) Forced convection in high porosity metal foams. J Heat Transfer 122(3):557–565

Calmidi VV (1998) Transport phenomena in high porosity fibrous metal foams. University of Colorado at Boulder. Ph.D. thesis

Chen C-C, Huang P-C (2012) Numerical study of heat transfer enhancement for a novel flat-plate solar water collector using metal-foam blocks. Int J Heat Mass Transf 55(23):6734–6756. https://doi.org/10.1016/j.ijheatmasstransfer.2012.06.082

Chen Z, Gu M, Peng D (2010) Heat transfer performance analysis of a solar flat-plate collector with an integrated metal foam porous structure filled with paraffin. Appl Therm Eng 30(14–15):1967–1973

Diganjit R, Gnanasekaran N, Mobedi M (2022) Numerical study for enhancement of heat transfer using discrete metal foam with varying thickness and porosity in solar air heater by LTNE method. Energies 15(23):8952

Dukhan N, Al-Rammahi MA, Suleiman AS (2013) Fluid temperature measurements inside metal foam and comparison to Brinkman-Darcy flow convection analysis. Int J Heat Mass Transf 67:877–884

Dukhan N, Bağcı Ö, Özdemir M (2015) Thermal development in open-cell metal foam: an experiment with constant wall heat flux. Int J Heat Mass Transf 85:852–859

Fu Y, Xia Y, Lin X, Cheng Z, Zhang Z, Feng J, Wang H (2023) A novel structure design and numerical analysis of porous media-assisted enhanced thermal performance of flat-plate solar collector. Therm Sci Eng Prog 40:101777. https://doi.org/10.1016/j.tsep.2023.101777

Garrity PT, Klausner JF, Mei R (2010) Performance of aluminum and carbon foams for air side heat transfer augmentation. J Heat Transfer 132(12):121901

Granqvist CG (2007) Transparent conductors as solar energy materials: a panoramic review. Sol Energy Mater Sol Cells 91(17):1529–1598

Handbook AA, Atlanta G (2003) UAS: American Society of Heating. Refrigerating and Air Conditioning Engineers

Jadhav PH, Gnanasekaran N (2021) Optimum design of heat exchanging device for efficient heat absorption using high porosity metal foams. Int Commun Heat Mass Transfer 126:105475

Jasim NM, Fayyadh EM, Razoki Hasan M (2023) Numerical analysis to study the effect of foam thickness on the thermal-hydraulic performance of the metal foam heat exchanger. ICPER 2020, Singapore

Jouybari HJ, Saedodin S, Zamzamian A, Nimvari ME (2017) Experimental investigation of thermal performance and entropy generation of a flat-plate solar collector filled with porous media. Appl Therm Eng 127:1506–1517

Kotresha B, Gnanasekaran N (2020) Numerical simulations of fluid flow and heat transfer through aluminum and copper metal foam heat exchanger – a comparative study. Heat Transfer Eng 41(6–7):637–649. https://doi.org/10.1080/01457632.2018.1546969

Kurtbas I, Celik N (2009) Experimental investigation of forced and mixed convection heat transfer in a foam-filled horizontal rectangular channel. Int J Heat Mass Transf 52(5–6):1313–1325

Lin W, Xie G, Yuan J, Sundén B (2016) Comparison and analysis of heat transfer in aluminum foam using local thermal equilibrium or nonequilibrium model. Heat Transfer Eng 37(3–4):314–322

Lu W, Zhao C, Tassou S (2006) Thermal analysis on metal-foam filled heat exchangers. Part I: Metal-foam filled pipes. Int J Heat Mass Tran 49(15–16):2751–2761

Nimvari ME, Maerefat M, El-Hossaini M (2012) Numerical simulation of turbulent flow and heat transfer in a channel partially filled with a porous media. Int J Therm Sci 60:131–141

Nimvari ME, Jouybari NF, Esmaili Q (2018) A new approach to mitigate intense temperature gradients in ceramic foam solar receivers. Renew Energy 122:206–215

Patel SS, Lanjewar A (2022) A critical review on different roughness geometries and their effect on heat transfer and friction factor. Environ Sci Pollut Res 29(11):15391–15431. https://doi.org/10.1007/s11356-021-16298-9

Patel YM, Jain SV, Lakhera VJ (2020) Thermo-hydraulic performance analysis of a solar air heater roughened with reverse NACA profile ribs. Appl Therm Eng 170:114940

Prakash C, Saini RP (2019) Use of artificial roughness for performance enhancement of solar air heaters—a review. Int J Green Energy 16(7):551–572. https://doi.org/10.1080/15435075.2019.1598418

Rajendran V, Singaraj K, Rajarathinam J (2023) Environmental, economic, and performance assessment of solar air heater with inclined and winglet baffle. Environ Sci Pollut Res 30(6):14337–14352. https://doi.org/10.1007/s11356-022-23213-3

Rashidi S, Bovand M, Esfahani JA (2015) Heat transfer enhancement and pressure drop penalty in porous solar heat exchangers: a sensitivity analysis. Energy Convers Manage 103:726–738. https://doi.org/10.1016/j.enconman.2015.07.019

Saedodin S, Zamzamian S, Nimvari ME, Wongwises S, Jouybari HJ (2017) Performance evaluation of a flat-plate solar collector filled with porous metal foam: experimental and numerical analysis. Energy Convers Manage 153:278–287

Sahu MK, Gorai VK, Saha BC (2023) Applications of extended surfaces for improvement in the performance of solar air heaters—a detailed systematic review. Environ Sci Pollut Res 30(19):54429–54447. https://doi.org/10.1007/s11356-023-26360-3

Singh AK, Saxena A, Agarwal N (2023) Performance analysis of a serrated absorber plate solar air heater with paraffin wax storage. Environ Sci Pollut Res. https://doi.org/10.1007/s11356-023-27961-8

Webb R, Eckert E (1972) Application of rough surfaces to heat exchanger design. Int J Heat Mass Transf 15(9):1647–1658

Xia Y, Lin X, Cheng Z, Xie F, Huang J (2023a) Numerical study on the enhanced thermal performance of the porous media-assisted flat-plate solar collector. Int J Energy Res 2023:2244771. https://doi.org/10.1155/2023/2244771

Xia Y, Lin X, Shu Y, Cheng Z (2023b) Enhanced thermal performance of a flat-plate solar collector inserted with porous media: a numerical simulation study. Therm Sci Eng Prog 44:102063. https://doi.org/10.1016/j.tsep.2023.102063

Zhao C (2012) Review on thermal transport in high porosity cellular metal foams with open cells. Int J Heat Mass Transf 55(13–14):3618–3632

Zhu Q, Xuan Y (2017) Pore scale numerical simulation of heat transfer and flow in porous volumetric solar receivers. Appl Therm Eng 120:150–159

Acknowledgements

The authors acknowledge the University of Technology, Iraq for providing some data included in this work.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Mathematical modeling, numerical simulations, and analysis were performed by Kadhim Al-Chlaihawi, Moayed Hasan, and Ali Ekaid. The first draft of the manuscript was written by Kadhim Al-Chlaihawi and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethical approval

This article does not require ethical approval.

Consent to participate

Authors consent to participate.

Consent for publication

Authors consent to publish.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Philippe Garrigues

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Al-Chlaihawi, K., Hasan, M. & Ekaid, A. Optimizing of a metal foam-assisted solar air heater performance: a thermo-hydraulic analysis of porous insert placement. Environ Sci Pollut Res 31, 34995–35017 (2024). https://doi.org/10.1007/s11356-024-33593-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-024-33593-3