Abstract

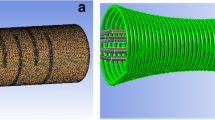

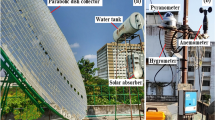

This work focuses on meeting the growing demand in solar energy conversion for small-scale applications. In this regard, experimental and CFD research has been done to examine the thermal performance (energy and exergy efficiencies) of a dish collector (reflector and receiver) system with different receiver models. In this work, receivers with uniform absorber cavity areas having cylindrical and hemispherical shapes were modeled for length-to-diameter ratios (L/D) of 1.5, 1, and 0.75. The modeled receivers having coil tube configurations concerning the geometrical shape of the models were tested with two different materials of aluminum and copper. The performance of the receiver models was compared by experimental and CFD methods for the average solar direct normal irradiations of 860 W/m2 by the dish reflector area of almost 12 m2. The supplied average heat flux by the dish reflector was 7 kW/m2 at the absorbing area of the cavity receivers. The energy and exergy efficiencies from the experimental and CFD analyses on the models were determined based on the cavity surface temperature distribution of receiver walls, and heat gain for different mass flow rates by the heat transfer fluid water. The receiver with copper material and L/D ratio of 0.75 has been found as the optimized one among all other models with the maximum obtained energy and exergy efficiencies of 73.64 and 7.31% when water is used as the heat transfer fluid. The performance of the optimized receiver model was also validated with a few other heat transfer fluids such as SiC + water nanofluid and therminol VP1.

Similar content being viewed by others

Data availability

All data are given in the manuscript.

Abbreviations

- A R :

-

Area of the receiver (m2)

- A ref :

-

Area of the reflector (m2)

- T atm :

-

Atmospheric temperature (°C)

- c av :

-

Average specific heat capacity (J/kg K)

- T avg :

-

Average wall temperature (°C)

- DNI:

-

Direct normal irradiation (Wh/m2)

- E a :

-

Energy focused on the receiver (kWh)

- E R :

-

Energy gained by the receiver (kWh)

- T in :

-

Fluid inlet temperature (°C)

- ṁ :

-

Mass flow rate of heat transfer fluid (kg/s)

- η EnR :

-

Receiver energy efficiency

- η ExR :

-

Receiver exergy efficiency

References

Arjun Singh K, Natarajan SK (2021) Thermal analysis of modified conical cavity receiver for a paraboloidal dish collector system. Energy Sources, Part A: Recov Util Environ Effects. https://doi.org/10.1080/15567036.2021.2017516

Bhutta MMA, Hayat N, Bashir MH, Khan AR, Ahmad KN, Khan S (2012) CFD applications in various heat exchangers design: a review. Appl Therm Eng 32:1–12

Daabo AM, Mahmoud S, Al-Dadah RK (2016) The effect of receiver geometry on the optical performance of a small-scale solar cavity receiver for parabolic dish applications. Energy 114:513–525

Kanatani K, Yamamoto T, Tamaura Y, Kikura H (2017) A model of a solar cavity receiver with coiled tubes. Sol Energy 153:249–261

Kumar NS, Reddy KS (2008) Comparison of receivers for solar dish collector system. Energy Convers Manage 49(4):812–819

Li S, Xu G, Luo X, Quan Y, Ge Y (2016) Optical performance of a solar dish concentrator/receiver system: influence of geometrical and surface properties of cavity receiver. Energy 113:95–107

Loni R, Kasaeian AB, Asli-Ardeh EA, Ghobadian B, Le Roux WG (2016) Performance study of a solar-assisted organic Rankine cycle using a dish-mounted rectangular-cavity tubular solar receiver. Appl Therm Eng 108:1298–1309

Loni R, Asli-Ardeh EA, Ghobadian B, Bellos E, Le Roux WG (2018) Numerical comparison of a solar dish concentrator with different cavity receivers and working fluids. J Clean Prod 198:1013–1030

Mahian O, Kianifar A, Kalogirou SA, Pop I, Wongwises S (2013) A review of the applications of nanofluids in solar energy. Int J Heat Mass Transf 57(2):582–594

Mahian O, Kolsi L, Amani M, Estellé P, Ahmadi G, Kleinstreuer C, … & Pop I (2019a) Recent advances in modeling and simulation of nanofluid flows-part I: fundamentals and theory. Phys Rep 790:1–48

Mahian O, Kolsi L, Amani M, Estellé P, Ahmadi G, Kleinstreuer C, … & Pop I (2019b) Recent advances in modeling and simulation of nanofluid flows-part II: applications. Phys Rep 791:1–59

Naphon P (2011) Study on the heat transfer and flow characteristics in a spiral-coil tube. Int Commun Heat Mass Transfer 38(1):69–74

Naphon P, Wongwises S (2005) A study of the heat transfer characteristics of a compact spiral coil heat exchanger under wet-surface conditions. Exp Therm Fluid Sci 29:511–521. https://doi.org/10.1016/j.expthermflusci.2004.07.002

Pavlović SR, Bellos EA, Stefanović VP, Tzivanidis C, Stamenković ZM (2016) Design, simulation and optimization of a solar dish collector with spiral-coil thermal absorber. Therm Sci 20(4):1387–1397

Pavlovic S, Daabo AM, Bellos E, Stefanovic V, Mahmoud S, Al-Dadah RK (2017) Experimental and numerical investigation on the optical and thermal performance of solar parabolic dish and corrugated spiral cavity receiver. J Clean Prod 150:75–92

Prakash M, Kedare SB, Nayak JK (2009) Investigations on heat losses from a solar cavity receiver. Sol Energy 83(2):157–170

Prakash M, Kedare SB, Nayak JK (2012) Numerical study of natural convection loss from open cavities. Int J Therm Sci 51:23–30

Rashidi S, Eskandarian M, Mahian O, Poncet S (2019a) Combination of nanofluid and inserts for heat transfer enhancement. J Therm Anal Calorim 135(1):437–460

Rashidi S, Hormozi F, Sundén B, Mahian O (2019b) Energy saving in thermal energy systems using dimpled surface technology–a review on mechanisms and applications. Appl Energy 250:1491–1547

Rashidi S, Javadi P, Esfahani JA (2019c) Second law of thermodynamics analysis for nanofluid turbulent flow inside a solar heater with the ribbed absorber plate. J Therm Anal Calorim 135(1):551–563

Reddy KS, Kumar NS (2008) Combined laminar natural convection and surface radiation heat transfer in a modified cavity receiver of solar parabolic dish. Int J Therm Sci 47(12):1647–1657

Roldán MI, Canadas I, Casas JL, Zarza E (2013) Thermal analysis and design of a solar prototype for high-temperature processes. Int J Heat Mass Transf 56(1–2):309–318

Shuai Y, Xia XL, Tan HP (2008) Radiation performance of dish solar concentrator/cavity receiver systems. Sol Energy 82(1):13–21

Stainfeld A, Schubnell M (1993) Optimum aperture size and operating temperature of a solar cavity receiver. Sol Energy 50:19–25

Steinfeld A, Schubnell M (1993) Optimum aperture size and operating temperature of a solar cavity-receiver. Sol Energy 50(1):19–25

Wang M, Siddiqui K (2010) The impact of geometrical parameters on the thermal performance of a solar receiver of dish-type concentrated solar energy system. Renewable Energy 35(11):2501–2513

Yu W, France DM, Smith DS, Singh D, Timofeeva EV, Routbort JL (2009) Heat transfer to a silicon carbide/water nanofluid. Int J Heat Mass Transf 52(15–16):3606–3612

Zhu ZY (2016) CFD simulation in helical coiled tubing. J Appl Sci Eng 19(3):267–272

Zhu J, Wang K, Wu H, Wang D, Du J, Olabi AG (2015) Experimental investigation on the energy and exergy performance of a coiled tube solar receiver. Appl Energy 156:519–527

Funding

There is no funding received for the research work carried out.

Author information

Authors and Affiliations

Contributions

RDR—writing original manuscript, review and editing. GSE—project administration, formal analysis, review and editing. SKN—software, review and editing. MMA—review and editing.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Philippe Garrigues

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ramalingam, R.D., Esakkimuthu, G.S., Natarajan, S.K. et al. Energy and exergy studies on the receiver models with materials and heat transfer fluids. Environ Sci Pollut Res 31, 4764–4778 (2024). https://doi.org/10.1007/s11356-023-31428-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-023-31428-1