Abstract

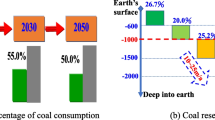

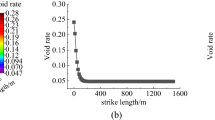

The backfilling mining method that fills gobs with coal gangue can prevent water inrush hazards, protect groundwater resources, and protect the ecological environment of the mining area. However, initial conditions including the particle size distribution of gangue and the stress environment may affect the seepage characteristics of gangue backfill and inrush prevention ability. Taking the particle size and stress as main controlling factors, the seepage tests were designed for gangue to evaluate influences of the particle size and stress on the void ratio, permeability, and non-Darcian flow factor of gangue. In the meantime, the four stages in dynamic changes of seepage channels were studied and the impervious envelope lines of gangue backfill materials were provided. The results show that the larger the particle sizes, the stronger the crushing resistance of particles; under high stress (> 6.67 MPa), seepage channels in small gangue particles (< 5 mm) change in a more complex manner, and the non-Darcian flow phenomena become more significant. The particle size and stress exert significant influences on the seepage characteristics. Therefore, when reducing water inrush hazards by gangue backfilling in gobs, the particle size distribution should be optimized by combining the stress and water pressure conditions. Seepage channels in gangue backfill materials vary with changes in the particle size and stress. Their variation can be divided into four stages: shrinkage of seepage channels, reconstruction of seepage channels, dynamic equilibrium between slight expansion and shrinkage, and persistence of the impervious effect. After the first and second stages have been fully developed, the preliminary impervious conditions are met; after full development of the fourth stage, the gangue backfill materials reach an impervious state.

Similar content being viewed by others

Data availability

The data and materials that support the findings of this study are available from the corresponding author on request.

Abbreviations

- E :

-

The elastic modulus, (GPa)

- μ :

-

The poisson’s ratio.

- σ c :

-

Uniaxial compressive strength, (MPa)

- \({G}_{P}\) :

-

The gradient of pore pressures, (Pa/m)

- \({p}_{1}\) :

-

The pore pressures at the inlet of seepage, (Pa)

- \({p}_{2}\) :

-

The pore pressures at the outlet of seepage, (Pa)

- h :

-

The instantaneous height of the specimen, (m)

- k :

-

The permeability, (m2)

- β :

-

The non-Darcian flow factor, (m−1)

- \({\mu }{\prime}\) :

-

The coefficient of viscosity, (Pa·s)

- v :

-

The seepage rate, (m/s)

- ρ :

-

The density of a penetrant, (kg/m3)

- \({\phi }_{h}\) :

-

The void ratio when the sample height is h, (%)

- \({V}_{k}\) :

-

The total void volume of the sample with the height h, (m3)

- \({V}_{h}\) :

-

The total packing volume of the sample with the height h, (m3)

- \({V}_{0}\) :

-

The volume of gangue blocks after excluding the void volume, (m3)

- \({m}_{s}\) :

-

The mass of the sample, (kg)

- \({\rho }_{s}\) :

-

The mass density of the sample, (kg/m3)

- R :

-

The radius of the permeameter, (m)

- \({h}_{0}\) :

-

The initial height of the gangue sample before compression, (m)

- ∆h :

-

The compression amount when the sample is compressed to height h, (m)

- \({h}_{c}\) :

-

The mining height, (m)

- \({H}_{z}\) :

-

The roof subsidence of gobs, (m)

- \({h}_{t}\) :

-

The roof subsidence before backfilling, (m)

- \({h}_{q}\) :

-

The gap between the backfilling body and the roof, (m)

- η :

-

The compaction rate of the backfilling body, (%)

References

Arasteh H, Saeedi G, Farsangi MAE, Esmaeili K (2020) A new model for calculation of the plastic compression index and porosity and permeability of gob materials in Longwall Mining. Geotech Geol Eng 38:6407–6420. https://doi.org/10.1007/s10706-020-01444-w

Cao Z, Du F, Xu P, Lin H, Xue Y, Zhou Y (2017) Control mechanism of surface subsidence and overburden movement in backfilling mining based on laminated plate theory. Comput Mater Continua 53:175–186. https://doi.org/10.3970/cmc.2017.053.187

Castro R, Perez A, Gomez R (2023) Evaluating wet muck risk in block caving mines: a new model. Int J Rock Mech Min Sci 170:105485. https://doi.org/10.1016/j.ijrmms.2023.105485

Chang JC, Li D, Xie TF, Shi WB, He K (2020) Deformation and failure characteristics and control technology of roadway surrounding rock in deep coal mines. Geofluids 2020:8834347. https://doi.org/10.1155/2020/8834347

Chen Y, Zhao GY, Wang SF, Wu H, Wang SW (2019) A case study on the height of a water-flow fracture zone above undersea mining: Sanshandao Gold Mine, China. Environ Earth Sci 78:122. https://doi.org/10.1007/s12665-019-8121-7

Dong S, Zheng L, Tang S, Shi P (2020) A scientometric analysis of trends in coal mine water inrush prevention and control for the period 2000–2019. Mine Water Environ 39:3–12. https://doi.org/10.1007/s10230-020-00661-2

El-Shaer YI, Aref NA, Abdel-Kader MS, El-Maddah MM, Megahed MM (2000) Experimental and analytical investigations of residual stresses induced by autofrettage. Curr Adv Mech Des Prod Vii:195–204. https://doi.org/10.1016/B978-008043711-8/50020-9

Gomez R, Loyola M, Palma S, Valdes C (2023) Experimental study of the inrush of fines events in caving mining. Int J Rock Mech Min Sci 169:105436. https://doi.org/10.1016/j.ijrmms.2023.105436

Guo S, Zhang J, Li M, Zhou N, Song W, Wang Z, Qi S (2021) A preliminary study of solid-waste coal gangue based biomineralization as eco-friendly underground backfill material: material preparation and macro-micro analyses. Sci Total Environ 770:145241. https://doi.org/10.1016/j.scitotenv.2021.145241

Guo Y, Zhang J, Li M, Timms W, Shen L, Li P (2022) Effects of loading stress and velocity on compression and particle breakage behaviour of waste rocks in backfill coal mining. Appl Sci 12:11175. https://doi.org/10.3390/app122111175

Hoffmans GJCM (2022) Influence of hydraulic flow regime on backward erosion piping. J Hydraul Res 1–8. https://doi.org/10.1080/00221686.2021.2022027

Hou JF, Guo ZP, Liu WZ, Zhang YX (2020) Mechanical properties and meso-structure response of cemented gangue-fly ash backfill with cracks under seepage- stress coupling. Constr Build Mater 250:118863. https://doi.org/10.1016/j.conbuildmat.2020.118863

Hou JF, Guo ZP, Li JB, Zhao LJ (2021) Study on triaxial creep test and theoretical model of cemented gangue-fly ash backfill under seepage-stress coupling. Constr Build Mater 273:121722. https://doi.org/10.1016/j.conbuildmat.2020.121722

Huang Y, Li J, Ma D, Gao H, Guo Y, Ouyang S (2019) Triaxial compression behaviour of gangue solid wastes under effects of particle size and confining pressure. Sci Total Environ 693:133607. https://doi.org/10.1016/j.scitotenv.2019.133607

Ju F, Zhang J, Zhang Q (2012) Vertical transportation system of solid material for backfilling coal mining technology. Int J Min Sci Technol 22:41–45. https://doi.org/10.1016/j.ijmst.2011.07.004

Li J, Wang J (2019) Comprehensive utilization and environmental risks of coal gangue: a review. J Clean Prod 239:117946. https://doi.org/10.1016/j.jclepro.2019.117946

Li S, Liu R, Zhang Q, Zhang X (2016) Protection against water or mud inrush in tunnels by grouting: a review. J Rock Mech Geotech Eng 8:753–766. https://doi.org/10.1016/j.jrmge.2016.05.002

Li M, Zhang JX, Deng XJ, Ju F, Li BY (2017) Measurement and numerical analysis of water-conducting fractured zone in solid backfill mining under an aquifer: a case study in China. Q J Eng Geol Hydroge 50:81–87. https://doi.org/10.1144/qjegh2016-018

Li B, Liang YP, Zhang L, Zou QL (2019) Experimental investigation on compaction characteristics and permeability evolution of broken coal. Int J Rock Mech Min Sci 118:63–76. https://doi.org/10.1016/j.ijrmms.2019.04.001

Li M, Li AL, Zhang JX, Huang YL, Li JM (2020) Effects of particle sizes on compressive deformation and particle breakage of gangue used for coal mine goaf backfill. Powder Technol 360:493–502. https://doi.org/10.1016/j.powtec.2019.10.075

Li JM, Huang YL, Li W, Guo YC, Ouyang SY, Cao GL (2021a) Study on dynamic adsorption characteristics of broken coal gangue to heavy metal ions under leaching condition and its cleaner mechanism to mine water. J Clean Prod 329:129756. https://doi.org/10.1016/j.jclepro.2021.129756

Li JM, Huang YL, Li W, Yu H, Ouyang SY, Guo YC, Gao HD, Shi YB, Zhu L (2021b) The 3D reconstruction of a digital model for irregular gangue blocks and its application in PFC numerical simulation. Eng Comput-Germany 38:4617–4627. https://doi.org/10.1007/s00366-021-01500-w

Li M, Zhang JX, Huang P, Sun Q, Yan H (2021c) Deformation behaviour of crushed waste rock under lateral cyclic loading. Rock Mech Rock Eng 54:6665–6672. https://doi.org/10.1007/s00603-021-02607-8

Li J, Huang Y, Ouyang S, Guo Y, Gao H, Wu L, Shi Y, Zhu L (2022) Transparent characterization and quantitative analysis of broken gangue’s 3D fabric under the bearing compression. Int J Min Sci Technol 32:335–345. https://doi.org/10.1016/j.ijmst.2021.11.013

Liang Y, Liang H, Zhu S (2016) Mercury emission from spontaneously ignited coal gangue hill in Wuda coalfield, Inner Mongolia, China. Fuel 182:525–530. https://doi.org/10.1016/j.fuel.2016.05.092

Liu Y, Li SC (2020) Permeability characteristics of granular backfill materials during creep: a case study. Energ Source Part A. https://doi.org/10.1080/15567036.2020.1841851

Liu B, Tang Z, Dong S, Wang L, Liu D (2018) Vegetation recovery and groundwater pollution control of coal gangue field in a semi-arid area for a field application. Int Biodeterior Biodegradation 128:134–140. https://doi.org/10.1016/j.ibiod.2017.01.032

Liu HF, Zhang JX, Zhou N, Guo YM, Li BY, Yan H, Deng XJ (2020) Investigation of spatial stratified heterogeneity of cemented paste backfill characteristics in construction demolition waste recycled aggregates. J Clean Prod 249:119332. https://doi.org/10.1016/j.jclepro.2019.119332

Liu HF, Zhang JX, Li BY, Zhou N, Li D, Zhang L, Xiao X (2021a) Long term leaching behavior of arsenic from cemented paste backfill made of construction and demolition waste: experimental and numerical simulation studies. J Hazard Mater 416:125813. https://doi.org/10.1016/j.jhazmat.2021.125813

Liu JW, Sui WH, Zhao QJ (2017) Environmentally sustainable mining: a case study of intermittent cut-and-fill mining under sand aquifers. Environ Earth Sci 76. https://doi.org/10.1007/s12665-017-6892-2

Liu S, Li W, Fu G, Zhang Y, Li X, Xie B, Zhang H, Zhang W (2021b) Regulatory relationship between backfill mining and environmental engineering geological patterns induced by underground coal mining. Arab J Geosci 14. https://doi.org/10.1007/s12517-021-08681-0

Ma D, Bai H, Miao X, Pu H, Jiang B, Chen Z (2015) Compaction and seepage properties of crushed limestone particle mixture: an experimental investigation for Ordovician karst collapse pillar groundwater inrush. Environ Earth Sci 75. https://doi.org/10.1007/s12665-015-4799-3

Ma D, Rezania M, Yu HS, Bai HB (2017) Variations of hydraulic properties of granular sandstones during water inrush: effect of small particle migration. Eng Geol 217:61–70. https://doi.org/10.1016/j.enggeo.2016.12.006

Ma D, Duan H, Liu J, Li X, Zhou Z (2019a) The role of gangue on the mitigation of mining-induced hazards and environmental pollution: an experimental investigation. Sci Total Environ 664:436–448. https://doi.org/10.1016/j.scitotenv.2019.02.059

Ma D, Duan HY, Li XB, Li ZH, Zhou ZL, Li TB (2019b): Effects of seepage-induced erosion on nonlinear hydraulic properties of broken red sandstones. Tunnelling and Underground Space Technology 91. https://doi.org/10.1016/j.tust.2019.102993

Ma K, Zhang Y, Ruan M, Guo J, Chai T (2019c) Land subsidence in a coal mining area reduced soil fertility and led to soil degradation in arid and semi-arid regions. Int J Environ Res Public Health 16:3929. https://doi.org/10.3390/ijerph16203929

Ma D, Zhang J, Duan H, Huang Y, Li M, Sun Q, Zhou N (2021) Reutilization of gangue wastes in underground backfilling mining: overburden aquifer protection. Chemosphere 264:128400. https://doi.org/10.1016/j.chemosphere.2020.128400

Ma D, Duan H, Zhang J (2022a) Solid grain migration on hydraulic properties of fault rocks in underground mining tunnel: radial seepage experiments and verification of permeability prediction. Tunn Undergr Space Technol 126:104525. https://doi.org/10.1016/j.tust.2022.104525

Ma D, Duan H, Zhang J, Bai H (2022b) A state-of-the-art review on rock seepage mechanism of water inrush disaster in coal mines. Int J Coal Sci Technol 9:50. https://doi.org/10.1007/s40789-022-00525-w

Ma D, Duan H, Zhang J, Liu X, Li Z (2022c) Numerical simulation of water–silt inrush hazard of fault rock: a three-phase flow model. Rock Mech Rock Eng 55:5163–5182. https://doi.org/10.1007/s00603-022-02878-9

Majkic-Dursun B, Oros I, Opartsic I, Petkovic A (2019) Assessing groundwater quality for multiuse and geochemical evolution in the South Banat Area of Serbia, Pannonian Basin. Pol J Environ Stud 28:3269–3278. https://doi.org/10.15244/pjoes/94046

Mao D, Liu Z, Wang W, Li S, Gao Y, Xu Z, Zhang C (2018) An application of hydraulic tomography to a deep coal mine: combining traditional pumping tests with water inrush incidents. J Hydrol 567:1–11. https://doi.org/10.1016/j.jhydrol.2018.09.058

Mohanty AK, Lingaswamy M, Rao VVSG, Sankaran S (2018) Impact of acid mine drainage and hydrogeochemical studies in a part of Rajrappa coal mining area of Ramgarh District, Jharkhand State of India. Groundw Sustain Dev 7:164–175. https://doi.org/10.1016/j.gsd.2018.05.005

Pang M, Zhang T, Meng Y, Ling Z (2021) Experimental study on the permeability of crushed coal medium based on the Ergun equation. Sci Rep 11:23030. https://doi.org/10.1038/s41598-021-02524-4

Shi XZ, Zhu SY, Zhang WQ (2019) Study on the mechanisms and prevention of water inrush events in a deeply buried high-pressure coal seam-a case study of the Chensilou Coal Mine in China. Arab J Geosci 12. https://doi.org/10.1007/s12517-019-4824-z

Song W, Zhang J, Li M, Yan H, Zhou N, Yao Y, Guo Y (2022) Underground disposal of coal gangue backfill in China. Appl Sci 12:12060. https://doi.org/10.3390/app122312060

Sun Q (2019) Mechanism and method of key aquiclude strata reconstruction by backfill mining technology. PhD Thesis, China University of Mining and Technology. https://doi.org/10.27623/d.cnki.gzkyu.2019.000007

Sun K, Fan L, Xia Y, Li C, Chen J, Gao S, Wu B, Peng J, Ji Y (2020a) Impact of coal mining on groundwater of Luohe Formation in Binchang mining area. Int J Coal Sci Technol 8:88–102. https://doi.org/10.1007/s40789-020-00366-5

Sun Q, Zhang JX, Li M, Zhou N (2020b) Experimental evaluation of physical, mechanical, and permeability parameters of key aquiclude strata in a typical mining area of China. J Clean Prod 267:122109. https://doi.org/10.1016/j.jclepro.2020.122109

Sun Q, Zhang JX, Zhou N, Huang YL (2021) Key aquiclude strata reconstruction and fluid-solid coupled deformation mechanism study for backfill coal mining. Mine Water Environ 40:793–802. https://doi.org/10.1007/s10230-021-00786-y

Wang MX (2017) Experimental study on the coupling mechanism of early-strength backfill and rock. Iop C Ser Earth Env 94. https://doi.org/10.1088/1755-1315/94/1/012176

Xing XF, Rao XB, Zou YQ, Li HM, Zhang LL (2021) Creep behavior of asphalt concrete core materials in embankment dams under a stepped loading path. J Mater Civil Eng 33. https://doi.org/10.1061/(Asce)Mt.1943-5533.0003841

Yang WF, Jin L, Zhang XQ (2019) Simulation test on mixed water and sand inrush disaster induced by mining under the thin bedrock. J Loss Prevent Proc 57:1–6. https://doi.org/10.1016/j.jlp.2018.11.007

Yuan R, Ma D, Zhang HW (2017) Flow Characteristics and grain size distribution of granular gangue mineral by compaction treatment. Adv Mater Sci Eng 2017. https://doi.org/10.1155/2017/2509286

Zhai M, Bai H, Wu L, Wu G, Yan X, Ma D (2022) A reinforcement method of floor grouting in high-water pressure working face of coal mines: a case study in Luxi coal mine, North China. Environ Earth Sci 81:28. https://doi.org/10.1007/s12665-021-10144-4

Zhang Q, Wang D (2021) Field study on the improvement of coal gangue filling using dynamic compaction. Plos One 16:e0250961. https://doi.org/10.1371/journal.pone.0250961

Zhang J, Yang T (2018) Study of a roof water inrush prediction model in shallow seam mining based on an analytic hierarchy process using a grey relational analysis method. Arab J Geosci 11. https://doi.org/10.1007/s12517-018-3498-2

Zhang J, Zhang Q, Sun Q, Gao R, Germain D, Abro S (2015) Surface subsidence control theory and application to backfill coal mining technology. Environ Earth Sci 74:1439–1448. https://doi.org/10.1007/s12665-015-4133-0

Zhang J, Liu Y, Zhou N, Li M (2018a) Pore pressure evolution and mass loss of broken gangue during the seepage. R Soc Open Sci 5:180307. https://doi.org/10.1098/rsos.180307

Zhang Y, Cao SG, Guo S, Wan T, Wang JJ (2018b) Mechanisms of the development of water-conducting fracture zone in overlying strata during shortwall block backfill mining: a case study in Northwestern China. Environ Earth Sci 77. https://doi.org/10.1007/s12665-018-7726-6

Zhang Y, Zhou W, Li M, Chen ZQ (2018c) Experimental study on compression deformation and permeability characteristics of grading broken gangue under stress. Processes 6. https://doi.org/10.3390/pr6120257

Zhang H, Xu G, Chen X, Wei J, Yu S, Yang T (2019) Hydrogeochemical characteristics and groundwater inrush source identification for a multi-aquifer system in a coal mine. Acta Geologica Sinica - English Edition 93:1922–1932. https://doi.org/10.1111/1755-6724.14299

Zhang K, Li H, Han J, Jiang B, Gao J (2020a) Understanding of mineral change mechanisms in coal mine groundwater reservoir and their influences on effluent water quality: a experimental study. Int J Coal Sci Technol 8:154–167. https://doi.org/10.1007/s40789-020-00368-3

Zhang Y, Cao SG, Zhang N, Zhao CZ (2020b) The application of short-wall block back fill mining to preserve surface water resources in northwest China. J Clean Prod 261. https://doi.org/10.1016/j.jclepro.2020.121232

Zhou Y, Chen Y, Zhang J, He Q (2012) Control principle and technology of final compression ratio of backfilling materials. J Min Saf Eng (In Chinese) 29:351–356. https://doi.org/kns.cnki.net.KSYL201203011.CJFQ2012

Funding

This work was supported by the National Science Fund for Distinguished Young Scholars (grant number 51725403]; the National Natural Science Foundation of China (grant number 52004271); the China Postdoctoral Science Foundation (grant number 2021M693417); the Jiangsu Postdoctoral Research Funding Program (grant number 2021K039A); the Postgraduate Research & Practice Innovation Program of Jiangsu Province (KYCX22_2611) and the Graduate Innovation Program of China University of Mining and Technology (grant number 2022WLKXJ005).

Author information

Authors and Affiliations

Contributions

All the authors contributed to the study conception and design. Yuming Guo: laboratory experiments, data curation, and writing—original draft. Jixiong Zhang: funding acquisition, methodology, supervision, and writing—review and editing. Meng Li: funding acquisition, methodology, data curation, and writing—original draft. Lihua Wang: methodology, data curation, and validation. Zejun Li: methodology, and data curation. All the authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Consent to participate

The authors agreed with being involved in the research project.

Consent for publication

The authors are willing to permit the journal to publish the article.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Shimin Liu

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Guo, Y., Zhang, J., Li, M. et al. Preventing water inrush hazards in coal mines by coal gangue backfilling in gobs: influences of the particle size and stress on seepage characteristics. Environ Sci Pollut Res 30, 104374–104387 (2023). https://doi.org/10.1007/s11356-023-29775-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-023-29775-0