Abstract

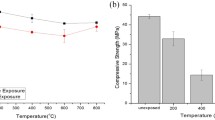

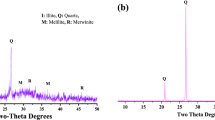

This study investigates the effect of curing temperature and foam/slag ratio on Na2SiO3- and NaOH-activated slag-based geopolymer foam composites (GFC) having thermal insulation properties. In this regard, samples used in the study were produced by adding foam at three different ratios (12.5, 15, and 17.5% by weight of slag) to the slag-based GFC having solutions with two different activator concentrations (7 M NaOH and 3 M Na2SiO3). Then, these samples were exposed to three different curing temperatures (40, 60, and 22 °C). The compressive strength, dry density, unit weight, water absorption, capillarity, apparent porosity, ultrasonic pulse velocity, and thermal conductivity tests were performed on the GFC samples for 1, 3, 7, and 28 days. Scanning electron microscopy (SEM) analyses were also conducted to characterize the pore structure and crack development of the GFCs. In addition, XRD analyses were performed on selected series to determine the formed reaction products of GFCs. As a result, it was observed that high curing temperature both improved mechanical strength and physical properties in GFC samples. The highest mechanical strength was obtained in the GFC with a 12.5% foam ratio and curing at 60 °C, while the lowest thermal conductivity coefficient was achieved in GFC with a 17.5% foam ratio and cured at 60 °C. In general, with the increase of foam ratio in slag-based GFC samples, unit weight, compressive strength, and ultrasonic pulse velocity results decreased, while capillarity, water absorption, and apparent porosity results increased. According to the results, it was seen that slag-based GFCs could be used in the construction of load-bearing and non-load-bearing walls.

Similar content being viewed by others

Data availability

Not applicable.

References

ACI 523.1R (2006) Guide for cast-in-place low-density cellular concrete. American Concrete Institute (ACI)

Alakara EH, Nacar S, Sevim O, et al (2022) Determination of compressive strength of perlite-containing slag-based geopolymers and its prediction using artificial neural network and regression-based methods. Constr Build Mater 359:129518. https://doi.org/10.1016/J.CONBUILDMAT.2022.129518

Al Bakri Abdullah MM, Hussin K, Bnhussain M, Ismail KN, Yahya Z, Razak RA (2012) Fly ash-based geopolymer lightweight concrete using foaming agent. Int J Mol Sci 13:7186–7198. https://doi.org/10.3390/ijms13067186

Alghamdi H, Neithalath N (2018) Novel synthesis of lightweight geopolymer matrices from fly ash through carbonate-based activation. Mater Today Commun 17:266–277. https://doi.org/10.1016/J.MTCOMM.2018.09.014

Alghamdi H, Dakhane A, Alum A, Abbaszadegan M, Mobasher B, Neithalath N (2018) Synthesis and characterization of economical, multi-functional porous ceramics based on abundant aluminosilicates. Mater Des 152:10–21. https://doi.org/10.1016/J.MATDES.2018.04.060

Alnahhal AM, Alengaram UJ, Ibrahim MSI, Yusoff S, Metselaar HSC, Johnson PG (2022) Synthesis of ternary binders and sand-binder ratio on the mechanical and microstructural properties of geopolymer foamed concrete. Constr Build Mater 349:128682. https://doi.org/10.1016/j.conbuildmat.2022.128682

Amran YHM, Farzadnia N, Ali AAA (2015) Properties and applications of foamed concrete; a review. Constr Build Mater 101:990–1005. https://doi.org/10.1016/j.conbuildmat.2015.10.112

Amran YHM, Alyousef R, Alabduljabbar H, El-Zeadani M (2020) Clean production and properties of geopolymer concrete; a review. J Clean Prod 251, 119679. https://doi.org/10.1016/J.JCLEPRO.2019.119679

Arellano Aguilar R, BurciagaDíaz O, Escalante García JI (2010) Lightweight concretes of activated metakaolin-fly ash binders, with blast furnace slag aggregates. Constr Build Mater 24:1166–1175. https://doi.org/10.1016/J.CONBUILDMAT.2009.12.024

ASTM C518–04 (2012) Standard test method for steady-state thermal transmission properties

ASTM C597–09 (2016) Standard test method for pulse velocity through concrete

ASTM C869/C869M-11 (2016) Standard specification for foaming agents used in making preformed foam for cellular concrete

Bai C, Colombo P (2017) High-porosity geopolymer membrane supports by peroxide route with the addition of egg white as surfactant. Ceram Int 43:2267–2273. https://doi.org/10.1016/J.CERAMINT.2016.10.205

Bai C, Franchin G, Elsayed H, Zaggia A, Conte L, Li H, Colombo P (2017) High-porosity geopolymer foams with tailored porosity for thermal insulation and wastewater treatment. J Mater Res 32:3251–3259. https://doi.org/10.1557/jmr.2017.127

Batool F, Bindiganavile V (2017) Air-void size distribution of cement based foam and its effect on thermal conductivity. Constr Build Mater 149:17–28. https://doi.org/10.1016/j.conbuildmat.2017.05.114

Cheah CB, Samsudin MH, Ramli M, Part WK, Tan LE (2017) The use of high calcium wood ash in the preparation of ground granulated blast furnace slag and pulverized fly ash geopolymers: a complete microstructural and mechanical characterization. J Clean Prod 156:114–123. https://doi.org/10.1016/J.JCLEPRO.2017.04.026

Davidovits J (1991) Geopolymers inorganic polymeric new materials. AKJ 37:1633–1656

Dhasindrakrishna K, Pasupathy K, Ramakrishnan S, Sanjayan J (2021) Progress, current thinking and challenges in geopolymer foam concrete technology. Cem Concr Compos 116:103886. https://doi.org/10.1016/j.cemconcomp.2020.103886

Duxson P, Lukey GC, van Deventer JSJ (2006) Thermal conductivity of metakaolin geopolymers used as a first approximation for determining gel ınterconnectivity. Ind Eng Chem Res 45:7781–7788

EN 12390–7:2019 (2019) Density of hardened concrete

EN 12667 (2003) Thermal performance of building materials and products - determination of thermal resistance by means of guarded hot plate and heat flow meter methods - products of high and medium thermal resistance

Gökçe HS, Hatungimana D, Ramyar K (2019) Effect of fly ash and silica fume on hardened properties of foam concrete. Constr Build Mater 194:1–11. https://doi.org/10.1016/J.CONBUILDMAT.2018.11.036

Gu G, Xu F, Huang X, Ruan S, Peng C, Lin J (2020) Foamed geopolymer: the relationship between rheological properties of geopolymer paste and pore-formation mechanism. J Clean Prod 277:123238. https://doi.org/10.1016/J.JCLEPRO.2020.123238

Huang W, Wang H (2021) Geopolymer pervious concrete modified with granulated blast furnace slag: microscale characterization and mechanical strength. J Clean Prod 328:129469. https://doi.org/10.1016/J.JCLEPRO.2021.129469

Huang T, Song D, Yin LX, Zhang SW, Liu LF, Zhou L (2020a) Microwave irradiation assisted sodium hexametaphosphate modification on the alkali-activated blast furnace slag for enhancing immobilization of strontium. Chemosphere 241:125069. https://doi.org/10.1016/J.CHEMOSPHERE.2019.125069

Huang T, Zhou L, Chen L, Liu W, Zhang S, Liu L (2020b) Mechanism exploration on the aluminum supplementation coupling the electrokinetics-activating geopolymerization that reinforces the solidification of the municipal solid waste incineration fly ashes. Waste Manag 103:361–369. https://doi.org/10.1016/j.wasman.2019.12.048

Islam A, Alengaram UJ, Jumaat MZ, Bashar II, Kabir SMA (2015) Engineering properties and carbon footprint of ground granulated blast-furnace slag-palm oil fuel ash-based structural geopolymer concrete. Constr Build Mater 101:503–521. https://doi.org/10.1016/J.CONBUILDMAT.2015.10.026

Kabir S, Al-Shayeb A, Khan IM (2016) Recycled construction debris as concrete aggregate for sustainable construction materials. Procedia Eng 145:1518–1525. https://doi.org/10.1016/J.PROENG.2016.04.191

Kearsley EP, Wainwright PJ (2001a) The effect of high fly ash content on the compressive strength of foamed concrete. Cem Concr Res 31:105–112. https://doi.org/10.1016/S0008-8846(00)00430-0

Kearsley EP, Wainwright PJ (2001b) Porosity and permeability of foamed concrete. Cem Concr Res 31:805–812. https://doi.org/10.1016/S0008-8846(01)00490-2

Kearsley EP, Wainwright PJ (2002a) The effect of porosity on the strength of foamed concrete. Cem Concr Res 32:233–239. https://doi.org/10.1016/S0008-8846(01)00665-2

Kearsley EP, Wainwright PJ (2002b) Ash content for optimum strength of foamed concrete. Cem Concr Res 32:241–246. https://doi.org/10.1016/S0008-8846(01)00666-4

Liew YM, Heah CY, Mohd Mustafa AB, Kamarudin H (2016) Structure and properties of clay-based geopolymer cements: a review. Prog Mater Sci 83:595–629. https://doi.org/10.1016/J.PMATSCI.2016.08.002

Liew KM, Sojobi AO, Zhang LW (2017) Green concrete: prospects and challenges. Constr Build Mater 156:1063–1095. https://doi.org/10.1016/J.CONBUILDMAT.2017.09.008

Liu MYJ, Alengaram UJ, Jumaat MZ, Mo KH (2014) Evaluation of thermal conductivity, mechanical and transport properties of lightweight aggregate foamed geopolymer concrete. Energy Build 72:238–245. https://doi.org/10.1016/J.ENBUILD.2013.12.029

Luukkonen T, Sarkkinen M, Kemppainen K, Rämö J, Lassi U (2016) Metakaolin geopolymer characterization and application for ammonium removal from model solutions and landfill leachate. Appl Clay Sci 119:266–276. https://doi.org/10.1016/J.CLAY.2015.10.027

Mehta A, Siddique R (2018) Sustainable geopolymer concrete using ground granulated blast furnace slag and rice husk ash: strength and permeability properties. J Clean Prod 205:49–57. https://doi.org/10.1016/J.JCLEPRO.2018.08.313

Meyer C (2009) The greening of the concrete industry. Cem Concr Compos 31:601–605. https://doi.org/10.1016/J.CEMCONCOMP.2008.12.010

Mustafa M, Abdullah AB, Hussin K, Bnhussain M, Ismail KN, Yahya Z, Razak RA, My RAR (2012) Fly ash-based geopolymer lightweight concrete using foaming agent. Int J Mol Sci 13:7186–7198. https://doi.org/10.3390/ijms13067186

Nambiar EKK, Ramamurthy K (2007) Air-void characterisation of foam concrete. Cem Concr Res 37:221–230. https://doi.org/10.1016/J.CEMCONRES.2006.10.009

Nath P, Sarker PK (2014) Effect of GGBFS on setting, workability and early strength properties of fly ash geopolymer concrete cured in ambient condition. Constr Build Mater 66:163–171. https://doi.org/10.1016/J.CONBUILDMAT.2014.05.080

Neville AM (1997) Properties of concrete, 4th edn. Pearson Education Limited, Harlow, United Kingdom

Oren OH, Gholampour A, Gencel O, Ozbakkaloglu T (2020) Physical and mechanical properties of foam concretes containing granulated blast furnace slag as fine aggregate. Constr Build Mater 238:117774. https://doi.org/10.1016/J.CONBUILDMAT.2019.117774

Papa E, Medri V, Kpogbemabou D, Morinière V, Laumonier J, Vaccari A, Rossignol S (2016) Porosity and insulating properties of silica-fume based foams. Energy Build 131:223–232. https://doi.org/10.1016/j.enbuild.2016.09.031

Pilehvar S, Cao VD, Szczotok AM, Carmona M, Valentini L, Lanzón M, Pamies R, Kjøniksen AL (2018) Physical and mechanical properties of fly ash and slag geopolymer concrete containing different types of micro-encapsulated phase change materials. Constr Build Mater 173:28–39. https://doi.org/10.1016/J.CONBUILDMAT.2018.04.016

Polat R, Demirboǧa R, Karakoç MB, Türkmen I (2010) The influence of lightweight aggregate on the physico-mechanical properties of concrete exposed to freeze-thaw cycles. Cold Reg Sci Technol 60:51–56. https://doi.org/10.1016/j.coldregions.2009.08.010

Posi P, Lertnimoolchai S, Sata V, Chindaprasirt P (2013) Pressed lightweight concrete containing calcined diatomite aggregate. Constr Build Mater 47:896–901. https://doi.org/10.1016/j.conbuildmat.2013.05.094

Posi P, Ridtirud C, Ekvong C, Chammanee D, Janthowong K, Chindaprasirt P (2015) Properties of lightweight high calcium fly ash geopolymer concretes containing recycled packaging foam. Constr Build Mater 94:408–413. https://doi.org/10.1016/J.CONBUILDMAT.2015.07.080

Posi P, Thongjapo P, Thamultree N, Boontee P, Kasemsiri P, Chindaprasirt P (2016) Pressed lightweight fly ash-OPC geopolymer concrete containing recycled lightweight concrete aggregate. Constr Build Mater 127:450–456. https://doi.org/10.1016/J.CONBUILDMAT.2016.09.105

Ramamurthy K, KunhanandanNambiar EK, Ranjani GIS (2009) A classification of studies on properties of foam concrete. Cem Concr Compos 31:388–396. https://doi.org/10.1016/J.CEMCONCOMP.2009.04.006

Sanjayan JG, Nazari A, Chen L, Nguyen GH (2015) Physical and mechanical properties of lightweight aerated geopolymer. Constr Build Mater 79:236–244. https://doi.org/10.1016/J.CONBUILDMAT.2015.01.043

Singh NB (2018) Foamed geopolymer concrete. Mater Today Proc 5:15243–15252. https://doi.org/10.1016/J.MATPR.2018.05.002

Sukmak P, Horpibulsuk S, Shen SL (2013) Strength development in clay–fly ash geopolymer. Constr Build Mater 40:566–574. https://doi.org/10.1016/J.CONBUILDMAT.2012.11.015

Tasdemir C (2003) Combined effects of mineral admixtures and curing conditions on the sorptivity coefficient of concrete. Cem Concr Res 33:1637–1642. https://doi.org/10.1016/S0008-8846(03)00112-1

Tikalsky PJ, Pospisil J, MacDonald W (2004) A method for assessment of the freeze-thaw resistance of preformed foam cellular concrete. Cem Concr Res 34:889–893. https://doi.org/10.1016/j.cemconres.2003.11.005

TS EN 1015–11 (2020) Methods of test for mortar for masonry - Part 11: determination of flexural and compressive strength of hardened mortar. Turkish Stand Inst

TS EN 772–11:2012 (2012) Determination of water absorption of aggregate concrete, autoclaved aerated concrete, manufactured stone and natural stone masonry units due to capillary action and the initial rate of water absorption of clay masonry units. Turkish Stand Inst

TS EN 772–4 (2000) Determination of real and bulk density and of total and open porosity for natural stone masonry units. Turkish Stand Inst

Wongkeo W, Seekaew S, Kaewrahan O (2019) Properties of high calcium fly ash geopolymer lightweight concrete. Mater Today Proc 17:1423–1430. https://doi.org/10.1016/J.MATPR.2019.06.163

Wongsa A, Sata V, Nuaklong P, Chindaprasirt P (2018) Use of crushed clay brick and pumice aggregates in lightweight geopolymer concrete. Constr Build Mater 188:1025–1034. https://doi.org/10.1016/J.CONBUILDMAT.2018.08.176

Zakka WP, Abdul Shukor Lim NH, Chau Khun M (2021) A scientometric review of geopolymer concrete. J Clean Prod 280:124353. https://doi.org/10.1016/J.JCLEPRO.2020.124353

Zhang Z, Provis JL, Reid A, Wang H (2014) Geopolymer foam concrete: an emerging material for sustainable construction. Constr Build Mater 56:113–127. https://doi.org/10.1016/J.CONBUILDMAT.2014.01.081

Zhang Z, Provis JL, Reid A, Wang H (2015) Mechanical, thermal insulation, thermal resistance and acoustic absorption properties of geopolymer foam concrete. Cem Concr Compos 62:97–105. https://doi.org/10.1016/J.CEMCONCOMP.2015.03.013

Zhang S, Keulen A, Arbi K, Ye G, (2017) Waste glass as partial mineral precursor in alkali-activated slag/fly ash system. Cem Concr Res 102:29–40. https://doi.org/10.1016/j.cemconres.2017.08.012

Zhang P, Wang K, Li Q, Wang J, Ling Y (2020) Fabrication and engineering properties of concretes based on geopolymers/alkali-activated binders - a review. J Clean Prod 258:120896. https://doi.org/10.1016/J.JCLEPRO.2020.120896

Zhao X, Lim S-K, Tan C-S, Li B, Ling T-C, Huang R, Wang Q (2015) Properties of foamed mortar prepared with granulated blast-furnace slag. Materials (Basel). 8:462–473. https://doi.org/10.3390/ma8020462

Zhao J, Tong L, Li B, Chen T, Wang C, Yang G, Zheng Y (2021) Eco-friendly geopolymer materials: a review of performance improvement, potential application and sustainability assessment. J Clean Prod 307:127085. https://doi.org/10.1016/J.JCLEPRO.2021.127085

Author information

Authors and Affiliations

Contributions

Hüseyin Ersoy: conceptualization, data collection and analysis, writing—original draft. Murat Çavuş: data collection, methodology, writing—review and editing, supervision.

Corresponding author

Ethics declarations

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: George Z. Kyzas

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ersoy, H., Çavuş, M. Thermomechanical properties of environmentally friendly slag-based geopolymer foam composites in different curing conditions. Environ Sci Pollut Res 30, 58813–58826 (2023). https://doi.org/10.1007/s11356-023-26663-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-023-26663-5