Abstract

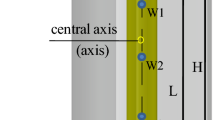

A special conical diffuser was presented and fixed on the top of the filter cartridge to improve the flow field. The existence of the diffuser can disperse the jet flow from the nozzle, and the high-speed airflow can act on more areas of the filter cartridge, including the top area of the filter cartridge. To improve the cleaning efficiency, the present study is aimed at optimizing the structure of the filter cartridge. The DPM model was used to simulate the dust dispersion process and the falling dust sedimentation from the filter under the action of the pulsed airflow. To validate the established model, the pressure values at the monitoring points were analyzed and compared with the related experimental results. It is found that the pressure values are consistent with the experimental results. Moreover, the installation distance and the size of the diffuser were studied and their influence on the dust distribution on the surface of the filter cartridge. It is found that the dust removal effect is relatively better when the installation distance is 90 mm and the size radius is 25 mm. The maximum dust concentration can be reduced by 15 mg/m3. The present research results can provide theoretical guidance for the cleaning process of the filter cartridge and finally improve the dust-removal efficiency of the dust collector.

Graphical abstract

Similar content being viewed by others

Data availability

The datasets used and/or analyzed during the current study are available from the corresponding author on reasonable request.

Abbreviations

- \({C}_{D}\) :

-

Drag coefficient

- \({\text{C}}_{1}\) :

-

Constant

- \({\text{C}}_{2}\) :

-

Constant

- \({\text{C}}_{{1}\varepsilon }\) :

-

Constant

- \({\text{C}}_{{3}\varepsilon }\) :

-

Constant

- \({d}_{p}\) :

-

Particle diameter (m)

- \({\text{G}}_{\text{k}}\) :

-

The generation of turbulence kinetic energy due to mean velocity gradients

- \({\text{G}}_{\text{b}}\) :

-

The generation of turbulence kinetic energy due to buoyancy

- \({\text{k}}\) :

-

Turbulence kinetic energy (J/kg)

- \({m}_{p}\) :

-

Mass of particles (kg)

- \({\text{S}}_{k}\) :

-

User-defined source term

- \({\text{S}}_{\varepsilon }\) :

-

User-defined source term

- \({\text{S}}\) :

-

The modulus of the mean rate-of-strain tensor

- \(\overline{u }\) :

-

Average air velocity (m/s)

- \({u}^{^{\prime}}\) :

-

Random fluctuation velocity (m/s)

- \(u\) :

-

Air velocity (m/s)

- \({u}_{p}\) :

-

Particle velocity (m/s)

- \({u}_{i}\) :

-

Velocity of the surrounding fluid (m/s)

- \(\rho\) :

-

Air density (kg/m3)

- \({\rho }_{p}\) :

-

Particle density (kg/m3)

- \({\Gamma }_{k}\) :

-

The effective diffusivity of k

- \({\Gamma }_{\varepsilon }\) :

-

The effective diffusivity of \(\varepsilon\)

- \(\varepsilon\) :

-

The specific dissipation rate

- \({\sigma }_{k}\) :

-

The turbulent Prandtl numbers for k

- \({\sigma }_{\varepsilon }\) :

-

The turbulent Prandtl numbers for \(\varepsilon\)

- \({\mu }_{t}\) :

-

The turbulent viscosity

- \(\mu\) :

-

Air viscosity

- \(\varsigma\) :

-

Normally distributed random number

- \({\overline{\Omega } }_{ij}\) :

-

The mean rate-of-rotation tensor viewed in a rotating reference frame

- \({\omega }_{k}\) :

-

The angular velocity

References

ANSYS (2010) Fluent theory guide. ANSYS Inc, Release, p13

Aroussi A, Simmons K, Pickering SJ (2001) Particulate deposition on candle filters. Fuel 80:335–343

Bao Q, Nie W, Liu CQ, Liu YH (2018) Preparation and characterization of a binary-graft-based, water-absorbing dust suppressant for coal transportation. J Appl Polym Sci 136:47065

Cai P, Nie W, Chen DW, Yang SB, Liu ZQ (2019) Effect of air flowrate on pollutant dispersion pattern of coal dust particles at fully mechanized mining face based on numerical simulation. Fuel 239:623–635

Fan L, Liu SM (2021) Respirable nano-particulate generations and their pathogenesis in mining workplaces: a review. Int J Coal Sci Technol 8(2):179–198

Fan F, Zhang S, Peng Z, Chen J, Su M, Moghtaderi B, Doroodchi E (2019) Numerical investigation of heterogeneous nucleation of water vapour on PM10 for particulate abatement. Can J Chem Eng 97:930–939

Gao DH, Zhou G, Liu RL, Li SL, Kong Y, Wang YM (2021a) CFD investigation on gas-solid two-phase flow of dust removal characteristics for cartridge filter: a case study. Environ Sci Pollut Res 28:13243–13263

Gao DH, Zhou G, Yang Y, Duan JJ, Kong Y, Meng QZ (2021b) Design of pulse cleaning device for single-filter cartridge dust collector by multi-factor orthogonal method based numerical simulation. Powder Technol 391:494–509

Geng F, Luo G, Zhou FB, Zhao PT, Ma L, Chai HL, Zhang TT (2017) Numerical investigation of dust dispersion in a coal roadway with hybrid ventilation system. Powder Technol 313:260–271

Geng F, Luo G, Wang YC, Peng ZB, Hu SY, Zhang TT, Chai HL (2018) Dust dispersion in a coal roadway driven by a hybrid ventilation system: a numerical study. Process Saf Environ Prot 113:388–400

Geng F, Gui CG, Wang YC, Zhou FB, Hu SY, Luo G (2019) Dust distribution and control in a coal roadway driven by an air curtain system: a numerical study. Process Saf Environ Prot 121:32–42

Geng F, Gui CG, Teng HX, Tang JH, Niu HW, Zhou FB, Liu C, Hu SD, Li SH (2020a) Dispersion characteristics of dust pollutant in a typical coal roadway under an auxiliary ventilation system. J Clean Prod 275:122889

Geng F, Teng HX, Gui CG, Wang YC, Yuan LJ, Yang YY, Xu DY (2020b) Investigation on distribution characteristics of flexible biomass particles in a fluidized bed riser-ScienceDirect. Fuel 271:117528

Gui CG, Geng F, Tang JH, Niu HW, Zhou FB, Liu C, Hu SD, Teng HX (2021) Gas-solid two-phase flow in an underground mine with an optimized air-curtain system: a numerical study. Process Saf Environ Prot 140:137–150

Han H, Wang PF, Liu RH, Tian C (2020) Experimental study on atomization characteristics and dust-reduction performance of four common types of pressure nozzles in underground coal mines. Int J Coal Sci Technol 7(3):581–596

He CH, Yan CP, Tang CY, Huang M, Ren L, Zhang MX (2021) Nitrogen pulse jet cleaning of the pleated filter cartridge clogged with adhesive hygroscopic dusts. Process Saf Environ Prot 147:430–438

Hu SY, Feng GR, Ren XY, Xu G, Chang P, Wang Z, Zhang YT, Li Z, Gao Q (2016) Numerical study of gas-solid two-phase flow in a coal roadway after blasting. Adv Powder Technol 27:1607–1617

Hu SY, Gao Y, Feng GR, Huang YS, Shao H, Liao Q, Hu F (2021) Characteristics of dust distributions and dust control measures around road-header drivers in mining excavation roadways. Particuology 58:268–275

Jin M, Guo X, Wang XW, Yang D, Shen ZQ, Qiu ZG, Chen ZL, Li JW (2014) Development of a novel filter cartridge system with electropositive granule media to concentrate viruses from large volumes of natural surface water. Environ Sci Technol 48:6947

Jin H, Nie W, Zhang HH, Liu YH, Bao Q, Wang HK, Huang DM (2019) Preparation and characterization of a novel environmentally friendly coal dust suppressant. J Appl Polym Sci 136:47354

Li JL, Li SH, Zhou FB (2016) Effect of moisture content in coal dust on filtration and cleaning performance of filters. Physicochem Probl Mineral Pro 52:365–379

Li SH, Song SL, Wang F, Jin H, Zhou SM, Xie B, Hu SD, Zhou FB, Liu C (2019) Effects of cleaning mode on the performances of pulse-jet cartridge filter under varying particle sizes. Adv Powder Technol 30:1835–1841

Li SH, Jin H, Hu SD, Júnior JFM, Xie B, Liu H, Tan XY, Zhou FB (2020) Experimental investigation and field application of pulse-jet cartridge filter in TBM tunneling construction of Qingdao Metro Line 8 subsea tunnel. Tunn Undergr Space Technol 108:103690

Lin LJ, Chen HY, Zhou X (2009) Experiment of dust-cleaning performances of pulse-jet cartridge filters. Heating Ventilating Air Conditioning 39:148–151

Liu Q, Nie W, Hua Y, Peng HT, Liu CQ, Wei CH (2019) Research on tunnel ventilation systems: dust diffusion and pollution behavior by air curtains based on CFD technology and field measurement. Build Environ 147:444–460

Liu Q, Nie W, Hua Y, Yin S, Guo LD, Peng HT, Ma H, Zhou WJ (2020) Investigation of efficient dust control strategy for construction tunnels: ventilation system’s implications for cleaner production. Build Environ 180:107032

Lo LM, Chen DR, Pui DYH (2010) Experimental study of pleated fabric cartridges in a pulse-jet cleaned dust collector. Powder Technol 197:141–149

Nie W, Ma X, Cheng WM, Liu YH, Xin L, Peng HT, Wei WL (2016) A novel spraying/negative-pressure secondary dust suppression device used in fully mechanized mining face: a case study. Process Saf Environ Prot 103:126–135

Nie W, Liu YH, Wang H, Wei WL, Peng HT, Cai P, Hua Y, Jin H (2017) The development and testing of a novel external-spraying injection dedusting device for the heading machine in a fully-mechanized excavation face. Process Saf Environ Prot 109:716–731

Niu W, Nie W, Yuan M, Bao Q, Xue Q (2021) Study of the microscopic mechanism of lauryl glucoside wetting coal dust: environmental pollution prevention and control. J Hazard Mater 412:125223

Qiu J, Wu DS, Chen DR, Li JL (2021) Reverse pulsed-flow cleaning of pleated filter cartridges having an inner pleated filter cone. Process Saf Environ Prot 146:481–489

Ren T, Wang ZW, Zhang J (2018) Improved dust management at a longwall top coal caving (LTCC) face-A CFD modelling approach. Adv Powder Technol 29:2368–2379

Toraño J, Torno S, Menéndez M, Gent M (2011) Auxiliary ventilation in mining roadways driven with roadheaders: validated CFD modelling of dust behaviour. Tunn Undergr Space Technol 26:201–210

Wang YC, Luo G, Geng F, Li YB, Li YL (2015) Numerical study on dust movement and dust distribution for hybrid ventilation system in a laneway of coal mine. J Loss Prevent Proc Ind 36:146–157

Wang ZW, Li SG, Ren T, Wu JM, Lin HF, Shuang HQ (2019) Respirable dust pollution characteristics within an underground heading face driven with continuous miner-A CFD modelling approach. J Clean Prod 217:267–283

Xie B, Li SH, Jin H, Hu SD, Wang F, Zhou FB (2018) Analysis of the performance of a novel dust collector combining cyclone separator and cartridge filter. Powder Technol 339:695–701

Yan C, Liu G, Chen H (2013) Effect of induced airflow on the surface static pressure of pleated fabric filter cartridges during pulse jet cleaning. Powder Technol 249:424–430

Yao HF, Wang HY, Li YC, Jin L (2020) Three-dimensional spatial and temporal distributions of dust in roadway tunneling. Int J Coal Sci Technol 7(1):88–96

Yin S, Nie W, Liu Q, Hua Y (2019) Transient CFD modelling of space-time evolution of dust pollutants and air-curtain generator position during tunneling. J Clean Prod 239:117924

Yuan N, Ren L, Wang BZ, Teng DL, Lin P, Xu ZY, Li YJ, Chen HY, Lin LY (2020) Experimental study on the effects of diversion device on pulse-jet cleaning of horizontal filter cartridge. Process Saf Environ Prot 145:247–254

Zhang Q, Qian YL, Bi YX, Chen JD (2014) Numerical simulation of induction nozzle improving dust-cleaning efficiency of filters. Chin J Environ Eng 8:2975–2979 (In China)

Zhang T, Jing DJ, Ge SC, Wang JR, Meng XX, Ren SS (2020) Numerical simulation of the dimensional transformation of atomization in a supersonic aerodynamic atomization dust-removing nozzle based on transonic speed compressible flow. Int J Coal Sci Technol 7(3):597–610

Funding

Financial support from the Fundamental Research Funds for the Project of National Natural Science Foundation of China (52174215) and Natural Science Foundation of Jiangsu Province (BK20200642) are sincerely acknowledged. This research was funded by the Graduate Innovation Program of China University of Mining and Technology (grant no. 2022WLJCRCZL202) and the Postgraduate Research & Practice Innovation Program of Jiangsu Province (grant no. SJCX22_1164). Financial support from the Fundamental Research Funds for the Central Universities (no. 2019XKQYMS56) is sincerely acknowledged.

Author information

Authors and Affiliations

Contributions

Fan Geng and Shihang Li: conceptualization and methodology. Fan Geng and Xinyue Feng: software, formal analysis and visualization, and writing—review and editing. Haixu Teng, Xinyue Feng, and Changgeng Gui: investigation, validation, data curation, and writing—original draft. Jiajun An: resources and writing—review and editing.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Shimin Liu

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

(1) Coupling of the different-sized dust and the hybrid airflow was conducted.

(2) Using porous media model and CFD-DPM method.

(3) The installation distance and size of the diffuser are optimized to get the optimal value.

(4) The results obtained provide a reference for the optimization of dust collectors.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Feng, X., Geng, F., Teng, H. et al. Dust dispersion during the pulse-jet cleaning process with the diffuser effect of the cartridge filter. Environ Sci Pollut Res 30, 41486–41504 (2023). https://doi.org/10.1007/s11356-022-24865-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-022-24865-x