Abstract

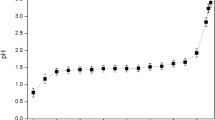

Mining waste that is rich in iron-, calcium- and magnesium-bearing minerals can be a potential feedstock for sequestering CO2 by mineral carbonation. This study highlights the utilization of iron ore mining waste in sequestering CO2 under low-reaction condition of a mineral carbonation process. Alkaline iron mining waste was used as feedstock for aqueous mineral carbonation and was subjected to mineralogical, chemical, and thermal analyses. A carbonation experiment was performed at ambient CO2 pressure, temperature of 80 °C at 1-h exposure time under the influence of pH (8–12) and particle size (< 38–75 µm). The mine waste contains Fe-oxides of magnetite and hematite, Ca-silicates of anorthite and wollastonite and Ca-Mg-silicates of diopside, which corresponds to 72.62% (Fe2O3), 5.82% (CaO), and 2.74% (MgO). Fe and Ca carbonation efficiencies were increased when particle size was reduced to < 38 µm and pH increased to 12. Multi-stage mineral transformation was observed from thermogravimetric analysis between temperature of 30 and 1000 °C. Derivative mass losses of carbonated products were assigned to four stages between 30–150 °C (dehydration), 150–350 °C (iron dehydroxylation), 350–700 °C (Fe carbonate decomposition), and 700–1000 °C (Ca carbonate decomposition). Peaks of mass losses were attributed to ferric iron reduction to magnetite between 662 and 670 °C, siderite decarbonization between 485 and 513 °C, aragonite decarbonization between 753 and 767 °C, and calcite decarbonization between 798 and 943 °C. A 48% higher carbonation rate was observed in carbonated products compared to raw sample. Production of carbonates was evidenced from XRD analysis showing the presence of siderite, aragonite, calcite, and traces of Fe carbonates, and about 33.13–49.81 g CO2/kg of waste has been sequestered from the process. Therefore, it has been shown that iron mining waste can be a feasible feedstock for mineral carbonation in view of waste restoration and CO2 emission reduction.

Similar content being viewed by others

Data availability

The datasets used in the current study are available from the corresponding author on reasonable request.

References

Ah-Hyung AP, Liang-Shih F (2004) CO2 mineral sequestration: physically activated dissolution of serpentine and pH swing process. Chem Eng Sci 59:5241–5247

Alkac D, Atalay U (2008) Kinetics of thermal decomposition of Hekimhan-Deveci siderite ore samples. Int J Miner Process 87:120–128

Arce GLAF, Neto TGS, Ávila I, Luna CMR, dos Santos JC, Carvalho JA (2017) Influence of physicochemical properties of Brazilian serpentinites on the leaching process for indirect CO2 mineral carbonation. Hydrometallurgy 169:142–151

Ashraf W (2016) Carbonation of cement-based materials: challenges and opportunities. Constr Build Mater 120:558–570

Assima GP, Larachi F, Beaudoin G, Molson J (2013) Dynamics of carbon dioxide uptake in chrysotile mining residues - Effect of mineralogy and liquid saturation. Int J Greenh Gas Control 12:124–135

Azdarpour A, Asadullah M, Junin R, Manan M, Hamidi H, Mohammadian E (2014) Direct carbonation of red gypsum to produce solid carbonates. Fuel Process Technol 126:429–434

Azdarpour A, Asadullah M, Mohammadian E, Junin R, Hamidi H, Manan M, Mohamad-Daud AR (2015) Mineral carbonation of red gypsum via pH-swing process: effect of CO2 pressure on the efficiency and products characteristics. Chem Eng J 264:425–436

Azdarpour A, Karaei AK, Hamidi H, Mohammadian E, Honarvar B (2018) CO2 sequestration through direct aqueous mineral carbonation of red gypsum. Petroleum 4:398–407

Bobicki ER, Liu Q, Xu Z, Zeng H (2012) Carbon capture and storage using alkaline industrial wastes. Prog Energ Combust 38:302–320

Bodénan F, Bourgeois F, Petiot C, Augé T, Bonfils B, Julcour-Lebigue C, Guyot F, Boukary A, Tremosa J, Lassin A et al (2014) Ex situ mineral carbonation for CO2 mitigation: evaluation of mining waste resources, aqueous carbonation processability and life cycle assessment (Carmex project). Miner Eng 59:52–63

Bonfils B, Julcour-Lebigue C, Guyot F, Bodénan F, Chiquet P, Bourgeois F (2012) Comprehensive analysis of direct aqueous mineral carbonation using dissolution enhancing organic additives. Int J Greenhouse Gas Control 9:334–346

Chang EE, Shu-Yuan P, Yi-Hung C, Chung-Sung T, Pen-Chi C (2012) Accelerated carbonation of steelmaking slags in a high-gravity rotating packed bed. J Hazard Mater 227–228:97–106

Childs CW (1992) Ferrihydrite: a review of structure, properties and occurrence in relation to soils. J Pant Nutr Soil Sci 155:441–448

Córdoba P, Cherqaoui L, Garcia S, Maroto-Valer MM (2017) Effect of limestone and buffer solution in the aqueous speciation and pH of brines for CO2 sequestration. Energy Procedia 114:4865–4871

Das S, Hendry MJ, Essilfie-Dughan J (2011) Transformation of two-line ferrihydrite to goethite and hematite as a function of pH and temperature. Environ Sci Technol 45(1):268–275

Ding W, Chen Q, Sun H, Peng T (2019) Modified mineral carbonation of phosphogypsum for CO2 sequestration. J of CO2 Utilization. 34:507–515

Eikeland E, Blichfeld AB, Tyrsted C, Jensen A, Iversen BB (2015) Optimized Carbonation of Magnesium Silicate Mineral for CO2 Storage. ACS Appl Mater Interfaces 7(9):5258–5264

El-Bellihi AA (2010) Kinetics of thermal decomposition of iron carbonate. Egypt J Chem 53(6):871–884

El-Hassan H, Shao Y (2015) Carbon Storage through Concrete Block Carbonation Curing. J Clean Energy Technol 2(3):287–291

Gabrielli P, Gazzani M, Mazzotti M (2020) The role of carbon capture and utilization, carbon capture and storage, and biomass to enable a net-zero-co2 emissions chemical industry. Ind Eng Chem Res 59:7033–7045

Gerdemann SJ, O’Connor WK, Dahlin DC, Penner LR, Rush H (2007) Ex situ aqueous mineral carbonation. Environ Sci Technol 41:2587–2593

Gras A, Beaudoin G, Molson J, Plante B, Bussière B, Lemieux JM, Dupont PP (2017) Isotopic evidence of passive mineral carbonation in mine wastes from the Dumont Nickel Project (Abitibi, Quebec). Int J Greenh Gas Con 60:10–23

Guillot LM, Lloret PA, Velasco A, Martinez AF, Agudo ER, Navarro CR (2020) CO2 sequestration and simultaneous zeolite production by carbonation of coal fly ash: impact on the trapping of toxic elements. J of CO2 Utilization. 40:101263

Haddaway NR, Cooke SJ, Lesser P, Macura B, Nilsson AE, Taylor JJ, Raito K (2019) Evidence of the impacts of metal mining and the effectiveness of mining mitigation measures on social–ecological systems in Arctic and boreal regions: a systematic map protocol. Environ Evid 8:9

Harrison AL, Power IM, Dipple GM (2013) Accelerated carbonation of brucite in mine tailings for carbon sequestration. Environ Sci Technol 47:126–134

He Z, Jia Y, Wang S, Mahoutian M, Shao Y (2019) Maximizing CO2 sequestration in cement-bonded fiberboards through carbonation curing. Constr Build Mater 213:51–60

Hills CD, Tripathi N, Carey PJ (2020) Mineralization technology for carbon capture, utilization, and storage. Frontiers in Energy Research 8:142

Hitch M, Ballantyne SM, Hindle SR (2010) Revaluing mine waste rock for carbon capture and storage. Int J Min Reclam Environ 24(1):64–79

Huijgen WJJ, Witkamp GJ, Comans RNJ (2005) Mineral CO2 sequestration by steel slag carbonation. Environ Sci Technol 39:9676–9682

Ibrahim MH, El-Naas MH, Benamor A, Al-Sobhi SS, Zhang Z (2019) Carbon mineralization by reaction with steel-making waste: a review. Process 7:115

Jorat ME, Aziz M, Marto A, Zaini N, Jusoh SN, Manning DAC (2018) Sequestering atmospheric CO2 inorganically: a solution for Malaysia’s CO2 emission. Geosci 8(483):1–14

Jorat ME, Goddard MA, Manning P, Lau HK, Ngeow S, Sohi SP, Manning DAC (2020) Passive CO2 removal in urban soils: evidence from brownfield sites. Sci Total Environ 703:135573

Kawigraha A, Soedarsono JW, HarjantoPramusanto S (2013) Thermogravimetric analysis of the reduction of iron ore with hydroxyl content. Adv Mater Res 774–776:682–686

Kiptarus JJ, Muumbo AM, Makokha AB, Kimutai SK (2015) Characterization of selected mineral ores in the eastern zone of Kenya: case study of Mwingi North Constituency in Kitui County. Int J Min Eng Miner Process 4(1):8–17

Kivinen S (2017) Sustainable post-mining land use: are closed metal mines abandoned or re-used space? Sustain 9:1705

Kusin FM, Che-Awang NH, Syed-Hasan SNM, Abdul-Rahim HA, Azmin N, Jusop S, Kyoung-Woong K (2019) Geo-ecological evaluation of mineral, major and trace elemental composition in waste rocks, soils and sediments of a gold mining area and potential associated risks. CATENA 183:104229

Kusin FM, Syed-Hasan SNM, Hassim MA, Molahid VLM (2020) Mineral carbonation of sedimentary mine waste for carbon sequestration and potential reutilization as cementitious material. Environ Sci Pollut Res 27(11):12767–12780

Lackner KS, Wendt CH, Butt DP, Joyce EL, Sharps DH (1995) Carbon dioxide disposal in carbonate minerals. Energy 20:1153–1170

Lavikko S (2017) Geological and mineralogical aspects on mineral carbonation. Ph.D Thesis, Åbo Akademi University.

Lechat K, Jean-Michel L, Molson J, Beaudoin G, Hébert R (2016) Field evidence of CO2 sequestration by mineral carbonation in ultramafic milling wastes, Thetford Mines. Canada Int J Greenh Gas Con 47:110–121

Lee CY, Abdoul-Fatah IH (2002) Prospecting for iron ore in the Bedong area, Kedah using geophysical techniques. Geological Society of Malaysia Annual Geological Conference.

Liu W, Teng L, Rohani S, Qin Z, Zhao B, Xu CC, Ren S, Liu Q, Liang B (2021) CO2 mineral carbonation using industrial solid wastes: a review of recent developments. Chem Eng J 416:129093

Luo Y, Zhu D, Pan J, Zhou X (2016) Thermal decomposition behaviour and kinetics of Xinjiang siderite ore. Miner Process Extract Metall 125:17–25

Manning DAC, Renforth P (2013) Passive sequestration of atmospheric CO2 through coupled plant-mineral reactions in urban soils. Environ Sci Technol 47:135–141

Manning DAC, Renforth P, Lopez-Capel E, Robertson S, Ghazireh N (2013) Carbonate precipitation in artificial soils produced from basaltic quarry fines and composts: an opportunity for passive carbon sequestration. Int J Greenh Gas Con 17:309–317

Mendoza EYM, Santos AS, López EV, Drozd V, Durygin A, Chen J, Saxena SK (2019) Iron oxides as efficient sorbents for CO2 capture. J Matter Res Technol 8(3):2944–2956

Mo L, Zhang F, Deng M, Jin F, Al-Tabbaa A, Wang A (2017) Accelerated carbonation and performance of concrete made with steel slag as binding materials and aggregates. Cem Concr Compos 83:138e145

Mohd-Isha NS, Kusin FM, Kamal NMA, Hasan SNMS, Molahid VLM (2021) Geochemical and mineralogical assessment of sedimentary limestone mine waste and potential for mineral carbonation. Environ Geochem & Health 43(5):2065–2080

Molahid VLM, Kusin FM, Hasan SNM, Ramli NAA, Abdullah AM (2021) CO2 sequestration through mineral carbonation: effect of different parameters on carbonation of Fe-rich mine waste materials. Processes 10(2):432

Muhd-Nor NH, Selamat SN, Rashid MHA, Ahmad MF, Jamian S, Kiong SC, Hassan MF, Mohamad F, Yokoyama S (2016) Carbon sequestration and carbon capture and storage (CCS) in Southeast Asia. J Phys Conf Ser 725:012010

Muwanguzi AJB, Karasev AV, Byaruhanga JK, Jonsson PG (2012) Characterization of chemical composition and microstructure of natural iron ore from Muko deposits. Int Sch Res Net ISRN Mater Sci. 1–9

Ohenoja K, Rissanen J, Kinnunen P, Illikainen M (2020) Direct carbonation of peat-wood fly ash for carbon capture and utilization in construction application. J of CO2 Utilization. 40:101203

Oelkers EH, Gislason SR, Matter J (2008) Mineral carbonation of CO2. Elements 4:333–337

Olajire AA (2013) Review of mineral carbonation technology in sequestration of CO2. J Petrol Sci Eng 109:364–392

Omale SO, Choong TSY, Abdullah LC, Siajam SI, Yip MW (2019) Utilization of Malaysia EAF slags for effective application in direct aqueous sequestration of carbon dioxide under ambient temperature. Heliyon 5:e02602

Pan S-Y, Chang EE, Chiang P-C (2012) CO2 capture by accelerated carbonation of alkaline wastes: a review on its principles and applications. Aerosol Air Qual Res 12:770–791

Pan S, Chen Y, Fan L (2020) CO2 mineralization and utilization by alkaline solid wastes for potential carbon reduction. Nat Sustain 3:399–405

Park AHA, Fan LS (2004) CO2 mineral sequestration: physically activated dissolution of serpentine and pH swing process. Chem Eng Sci 59(22–23):5241–5247

Qin L, Gao X, Chen T (2019) Influence of mineral admixtures on carbonation curing of cement paste. Constr Build Mater 212:653–662

Rahmani O (2020) An experimental study of accelerated mineral carbonation of industrial waste red gypsum for CO2 sequestration. J of CO2 Utilization. 35:265–271

Rahmani OJ, Highfield R, Junin M, Tyrer A, Pour B (2016) Experimental investigation and simplistic geochemical modeling of CO2 mineral carbonation using the Mount Tawai Peridotite. Molecules 21:353

Ramli NAA, Kusin FM, Molahid VLM (2021) Influencing factors of the mineral carbonation process of the iron ore mining waste in sequestering atmospheric carbon dioxide. Sustain 13(4):1866

Renforth P, Washbourne CL, Taylder J, Manning DAC (2011) Silicate production and availability for mineral carbonation. Environ Sci Technol 45:2035–2041

Revathy TDR, Palanivelu K, Ramachandran A (2016) Direct mineral carbonation of steelmaking slag for CO2 sequestration at room temperature. Environ Sci Pollut Res 23(8):7349–7359

Reynes JF, Mercier G, Blais JF, Pasquier LC (2021) Feasibility of a mineral carbonation technique using ironsilicate mining waste by direct flue gas CO2 capture and cation complexation using 2,20-bipyridine. Minerals 11:343

Ristic M, Krehula S, Reissner M, Music S (2017) Fe Mössbauer, XRD, FT-IR, FE SEM Analyses of Natural Goethite. Hematite and Siderite Croat Chem Acta 90(3):499–507

Ritchie H, Roser M (2020) Emissions Sector, https://ourworldindata.org/emissions-by-sector. Accessed 10 Sept 2022

Roy R (2020) Bacteria-based self-healing mortar with bio- plastic healing agents: comparative analysis on quantification and characterization of self-healing by various experimental techniques. Master thesis. KTH Royal Institute of Technology, School of Architectural and the Built Environment, Delft University fo Technology, Stockholm Sweden, p 179

Ruhaimi AH, Aziz MAA, Jalil AA (2021) Magnesium oxide-based adsorbents for carbon dioxide capture: current progress and future opportunities. J of CO Utilization. 43:101357

Sanna A, Uibu M, Caramanna G, Kuusik R, Maroto-Valer MM (2014) A review of mineral carbonation technologies to sequester CO2. Chem Soc Rev 43:8049

Sara K, Javad G, Alireza Y, Hosein M (2010) Reserve estimation of the high phosphorous stockpile at the Choghart iron mine of Iran using geostatistical modeling. Min Sci Technol 20:0855–0860

Sarvaramini A, Assima GP, Beaudoin G, Larachi F (2014) Biomass torrefaction and CO2 capture using mining wastes - A new approach for reducing greenhouse gas emissions of co-firing plants. Fuel 115:749–757

Shi Z (2016) Durability of Portland cement – calcined clay – limestone blends. PhD thesis. Interdisciplinary Nanoscience Centre (iNANO), Aarhus University, Denmark

Sipilä J, Teir S, Zevenhoven R (2008) Carbon dioxide sequestration by mineral carbonation. Åbo Akademi University, Faculty of Technol Heat Eng Labo, Report 2008–1:59

Smith KS, Hageman PL, Ramsey CA, Wildeman TR, Ranville JF (2006) Reconnaissance sampling and characterization of mine-waste material. In Proceedings of the US Environmental Protection Agency Hard Rock Mining 2006 Conference, Tucson, Arizona, USA, November 14–16, 2006

Stopic S, Dertmann C, Modolo G, Kegler P, Neumeier S, Kremer D, Wotruba H, Etzold S, Telle R, Rosani D, Knops P, Friedrich B (2018) Synthesis of magnesium carbonate via carbonation under high pressure in an autoclave. Metals 8:993

Syed-Hasan SNM, Kusin FM, Jusop S, Yusuff FM (2019) The mineralogy and chemical properties of sedimentary waste rocks with carbon sequestration potential at the Selinsing gold mine. Pahang Pertanika J Sci Technol 27(2):1005–1012

Syed-Hasan SNM, Kusin FM, Hassim MA, Molahid VLM (2020) Incorporation of gold and limestone mining waste materials for carbon capture and storage in bricks. IOP Conf Ser Mater Sci Eng 736:022046

Syed-Hasan SNM, Kusin FM, Daud NNN, Saadon MA, Yusuf FM, Ashaari ZH (2021) Characterization of gold mining waste for carbon sequestration and utilization as supplementary cementitious material. Process 9(8):1384

Teir S, Eloneva S, Fogelholm CJ, Zevenhoven R (2007) Dissolution of steelmaking slags in acetic acid for precipitated calcium carbonate production. Energy 32(4):528–539

Thiery M, Villain G, Dangla P, Platret G (2007) Investigation of the carbonation front shape on cementitious materials: effects of the chemical kinetics. Cem Concr Res 37:1047–1058

UNDP (2016) Mapping mining to the sustainable development goals: an atlas. White Paper, World Economic Forum, United Nations Development Programme, Geneva, Switzerland, p 10

USEPA U.S. Environmental Protection Agency. EPA and hardrock mining: a source book for industry in the Northwest and Alaska, Appendix C: Characterization of Ore, Waste Rock, and Tailings; Office of Solid Waste: Washington, D.C., 2003.

Vodyanitskii YN, Shoba SA (2016) Ferrihydrite in Soils. Eurasian Soil Sc 49:796–806

Wang D, Chang J, Ansari WS (2019) The effects of carbonation and hydration on the mineralogy and microstructure of basic oxygen furnace slag products. J of CO Utilization. 34:87–98

Washbourne CL, Lopez-Capel E, Renforth P, Ascough PL, Manning DAC (2015) Rapid removal of atmospheric CO2 by urban soils. Environ Sci Technol 49:5434–5440

Wei S, Cui H, Jiang Z, Liu H, He H, Fang N (2015) Biomineralization processes of calcite induced by bacteria isolated from marine sediments. Braz J Microbiol 46(2):455–464

Wilson SA, Dipple GM, Power IM, Thom JM, Anderson RG, Raudsepp M, Gabite JE, Southam G (2009) Carbon dioxide fixation within mine wastes of ultramafic-hosted ore deposits: examples from the Clinton Creek and Cassiar chrysotile deposits. Canada Econ Geol 104:95–112

Yan H, Zhang J, Zhao Y, Liu R, Zheng C (2015) CO2 sequestration by direct aqueous mineral carbonation under low-medium pressure conditions. J Chem Eng Jpn 48:937–946

Zarandi AE, Larachi F, Beaudoin G, Plante B, Sciortino M (2017) Ambient mineral carbonation of different lithologies of mafic to ultramafic mining wastes/tailings - A comparative study. Int J Greenh Gas Con 63:392–400

Zulkarnia A, Rochmadi R, Cahyono RB, Hidayat M (2021) Investigation into biomass tar-based carbon deposits as reduction agents on iron ore using the tar impregnation method. Metals 11:1623

Acknowledgements

The authors would like to acknowledge the manager of the iron mine in Jerantut, Pahang, Malaysia, for his kind permission to perform the sampling. The authors also wish to thank the laboratory staffs of the Centre for Research and Instrumentation (CRIM), Universiti Kebangsaan Malaysia, Bangi, Malaysia, and Department of Chemical and Environmental Engineering, Faculty of Engineering, Universiti Putra Malaysia, for providing technical assistance during laboratory analysis.

Funding

Funding for this research was provided by the Ministry of Higher Education Malaysia, grant number FRGS/1/2018/TK10/UPM/02/7 (FRGS 5540081), and Universiti Putra Malaysia, grant number IPS 9709500.

Author information

Authors and Affiliations

Contributions

Faradiella Mohd Kusin: Conceptualization, methodology, funding acquisition, resources, supervision, validation, writing—original draft and editing. Sharifah Nur Munirah Syed Hasan: Conceptualization, methodology, formal analysis, writing—original draft. Verma Loretta M. Molahid: Methodology, formal analysis. Ferdaus Mohamat Yusuff: Conceptualization, supervision. Shamsuddin Jusop: Conceptualization, supervision, methodology, validation.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Guilherme L. Dotto

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kusin, F.M., Hasan, S.N.M.S., Molahid, V.L.M. et al. Carbon dioxide sequestration of iron ore mining waste under low-reaction condition of a direct mineral carbonation process. Environ Sci Pollut Res 30, 22188–22210 (2023). https://doi.org/10.1007/s11356-022-23677-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-022-23677-3