Abstract

Given the crucial role of the supplier selection problem (SSP) in today’s competitive business environment, the present study investigates the SSP by considering the leagile, sustainability, and Industry 4.0 (I4.0) indicators for the medical devices industry (MDI). In this regard, at the outset, the list of criteria and sub-criteria is provided based on the literature and experts’ opinions. Then, the importance of the indicators is measured utilizing the rough best–worst method (RBWM). In the next step, the potential suppliers are ranked employing the multi-attributive border approximation area comparison (IR-MABAC) method. Due to the crucial role of medical devices during the COVID-19 outbreak, the present work selects a project-based organization in this industry as a case study. The obtained results show that agility and sustainability are the most important criteria, and manufacturing flexibility, cost, reliability, smart factory, and quality are the most important sub-criteria. The main theoretical contributions of this study are considering the leagile, sustainability, and I4.0 criteria in the SSP and employing the hybrid RBWM-IR-MABAC method in this area for the first time. On the other side, The results of this research can help supply chain managers to become more familiar with the sustainability, agility, leanness, and I4.0 criteria in the business environment.

Similar content being viewed by others

Introduction

After the COVID-19 outbreak, one of the industries whose importance has been drastically highlighted is the medical device (MD) industry. During this pandemic, MDs such as ventilator, oxygen concentrators, and vaccine refrigerators played a crucial role in improving patients’ conditions (Asadi et al. 2022; Nayeri et al. 2022). Therefore, given the importance of the mentioned industry, investigating the supply chain management problem for this industry is necessary. In this regard, the supplier selection problem (SSP) is known as one of the significant branches of the SC problem (Fallahpour et al. 2018). According to the reports, around 65–75% of the capital cost is invested in purchasing raw materials, which demonstrates the crucial role of the SSP in the business environment (Li et al. 2020; Mehrbakhsh and Ghezavati 2020). Motivated by the mentioned points, the present work aims to study the SSP for the MD industry.

Nowadays, due to changing consumer attitudes, traditional approaches that only consider financial profits are no longer effective (Breque et al. 2021). In today’s modern businesses, managers should incorporate other crucial principles such as sustainability to increase customers’ satisfaction and, subsequently, the market share (Breque et al. 2021). In this regard, sustainability simultaneously considers the financial, social, and environmental dimensions (Nayeri et al. 2020; Sahebjamnia et al. 2018). In this way, sustainable SSP simultaneously incorporates the social, environmental, and financial aspects into the supplier selection process (Godil et al. 2021; Khan et al. 2021, 2019). Regarding the significance of the concept, Sazvar et al. (2021a) indicated that incorporating the sustainability pillars in the supply chain leads to providing a green and socially responsible image of the company that increases customers’ loyalty, which results in growing sales and subsequently enhancing profits. However, in today’s dynamic and uncertain marketplace, only considering the sustainability pillars may not be enough to keep a business afloat and managers must also adopt other concepts, such as leagility, to improve the efficiency of their companies.

The COVID-19 pandemic has led to dramatic fluctuations in the marketplace of many industries, especially the MD industry. In this regard, adopting strategies to cope with these fluctuations is necessary. As such, leagility is one of the relatively novel strategies that can help companies to tackle the fluctuation of the dynamic business environment and increase their market share (Galankashi and Helmi 2016; Li et al. 2020). The leagile strategy attempts to achieve competitiveness and flexibility in a cost-effective manner. One of the problems where the concept of agility can be beneficial is supplier selection. Despite the different nature of these concepts, their combination (i.e., the leagile strategy) can be successfully utilized in the supply chain field, especially in the SSP (Li et al. 2020; Mason-Jones et al. 2000). In today’s competitive market, incorporating the concept of leagility can dramatically improve the system’s performance (Alamroshan et al. 2022). Besides the merits of the mentioned concepts (i.e., sustainability and leagile), little attention has been paid to the latest technologies, which can help to gain a competitive advantage in today’s modern markets in the Industry 4.0 era. Accordingly, considering the Industry 4.0 dimensions in business activities is worthwhile.

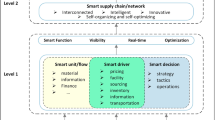

The dramatic growth of artificial intelligence and digitalization have revolutionized the business environment in the last two decades, that so-called Industry 4.0 (I4.0) (Jamwal et al. 2021). In this regard, employing new technologies, as the achievements of I4.0, has significantly affected knowledge transfer, information sharing, and communication between different facilities of the SC (Fallahpour et al. 2021b). According to Kusi-Sarpong et al. (2019), advanced technologies can lead to a drastic improvement in the performance of the SC. In general, the achievements of I4.0 can help managers to make their SCs more resilient and reduce the impact of disruptions by applying data analytics. As Lee et al. (2015) mentioned, the I4.0 has a positive impact on enhancing the service level and decreasing the inventory level, which shows the high importance of the I4.0 in modern businesses. The concept of I4.0 in the SSP problem should therefore be considered as one of the most critical components of SC management.

Many countries have suffered human and financial damages as a result of the COVID-19 pandemic over the past 2 years. One of the countries where COVID-19’s prevalence was at a high level and caused many casualties is Iran. In this regard, according to the official reports of this country, around 7.15 M people became infected with COVID-19, which resulted in 140 K deaths. The coronavirus also caused 709 deaths in this country on August 23, 2021, which was a disaster. Meanwhile, due to the COVID-19 outbreak, the consumption rate of medical devices has drastically increased in Iran. Therefore, due to the fluctuations and disruptions in the market, medical device supply chain management, including the SSP, has become a severe challenge for managers. Therefore, since medical devices are a vital tool in the process of treating patients and their use can help reduce the death rate, this work attempts to investigate the supplier selection problem for the medical devices industry in Iran.

One of the critical industries in healthcare systems is the MD industry. In this regard, during coronavirus disease, the crucial role of this industry has been highlighted more, since medical equipment has played an essential role in the treatment process of patients (WHO; Alamroshan et al. 2022). Regarding the integration of the MD industry with the introduced concepts (i.e., SSP, I4.0, leagility, and sustainability), the required explanations are provided here. The SSP is one of the critical challenges in the MD industry because selecting inappropriate suppliers may lead to several negative impacts such as higher total costs, low-quality products, and longer lead times. The mentioned points result in customer dissatisfaction and irreversible losses. Therefore, the SSP has a crucial role in the MD industry. The integration of sustainability pillars into all industries, including the MD industry, is becoming increasingly important due to growing environmental and social concerns, particularly following the COVID-19 outbreak. Furthermore, since the demand for MDs has significant fluctuation, especially during the coronavirus disease (Nayeri et al. 2022; Tavakoli et al. 2022), it may be beneficial for this industry to incorporate strategies that assist companies in coping with the fluctuation of the dynamic business environment (i.e., the leagile concept). As a result, it appears that implementing the leagile concept can significantly increase the productivity of the MD industry. Finally, since many medical devices are electrical appliances (e.g., ventilators, oxygen concentrators, vaccine refrigerators), the role of technology is dramatically highlighted in their production process, including the supplier selection process. Therefore, considering the elements of the I4.0 can lead to gaining competitive advantages and increasing market share (Javaid and Haleem 2019).

The current study aims to investigate the supplier selection problem for a medical device company by considering the leanness, agility, sustainability, and I4.0 aspects. The main motivation to select the MD industry as a case study is that its importance and application have drastically enhanced during the coronavirus outbreak. On the other side, the main motivation for considering the leanness, agility, sustainability, and I4.0 aspects is their importance in the supply chain management problem. In the literature, there are several works that studied the sustainable SSP (for example, Sen et al. (2018), Hendiani et al. (2020a, b), Beiki et al. (2021), Tong et al. (2022), Salimian et al. (2022)), the lean and agile SSP (for example, Alimardani et al. (2013), Abdollahi et al. (2015), Li et al. (2020), Foladi (2020), Alamroshan et al. (2022)), and the I4.0-based SSP (for example, Özbek and Yildiz (2020); Çalık (2021); Fallahpour et al. (2021b), Fallahpour et al. (2021c)). However, there is no research that considers all of these crucial aspects, simultaneously. In general, since the previous studies have ignored the consideration of the mentioned features, the present work attempts to cover this gap and integrate these aspects into the supplier selection problem. For this purpose, first, the potential main indicators (criteria and sub-criteria) are extracted from the literature, and then, the experts select the most related indicators for the research problem. Then, the feasible suppliers are determined. Afterwards, since investigating a problem such as the SSP needs an efficient decision-making approach, a group decision-making approach based on the rough number (RN) and rough best–worst method (RBWM) is used to compute the importance of the criteria, and multi-attributive border approximation area comparison (IR-MABAC) is utilized to rank the potential alternatives. The main reasons for employing this hybrid approach are as follows: (i) its ability to consider a large number of parameters that influence the selection of supplier performance, (ii) its ability to provide the possibility of eliminating uncertainties in a real environment by considering approximations, (iii) it is more objective about group decision-making, and (iv) it can provide a predefined, unbounded approach for dealing with uncertainty (Pamučar et al. 2018b). Despite the crucial role of the sustainability, leanness, agility, and Industry 4.0 aspects in the SSP, which have been discussed above, no study simultaneously considered these crucial aspects in the supplier selection problem. Therefore, this study attempts to investigate the leagile and sustainable SSP under I4.0 policies for the first time. Indeed, the main research gap that is fulfilled in the current work is ignoring the simultaneous consideration of the sustainability, leanness, agility, and Industry 4.0 aspects in the supplier selection problems. In this way, the main contributions of the present work are as follows:

-

(i)

The current paper is the first study in the SSP area in which leagile, sustainability, and I4.0 concepts are simultaneously considered.

-

(ii)

This is the first application of the integrated RBWM-IR-MABAC method in the sustainable and leagile SSP area.

-

(iii)

This research investigates the MD industry due to its importance during the COVID-19 outbreak.

The main questions that this research answers are as follows.

-

What are the main sub-criteria for leagile, sustainable, and I4.0-based supplier selection?

-

Which criteria are most important?

-

Which suppliers have the best performance?

The current work is organized as follows: “Literature review” section presents the literature review. The research methodology is provided in “Methodology” section. The case study and indicators are presented in “Case study” section. “Numerical results” section provides the numerical results. Finally, the conclusions are presented in “Conclusions and future suggestions” section.

Literature review

The importance of the SC management problem led to conducting several studies in this field in recent years (see Fathollahi-Fard et al. 2018; Hajiaghaei-Keshteli and Fard 2019; Jamali et al. 2021; Mamashli et al. 2021a, 2021b; Nayeri et al. 2021, 2020; Razavi et al. 2021; Samadi et al. 2018; Sazvar et al. 2021a, 2021b). In this section, we report the related literature in the three sections as follows: (i) sustainable SSP, (ii) lean and agile SSP, and (iii) SSP based on I4.0. Eventually, the research gaps and contributions are presented.

Sustainable SSP

An issue that requires organizations to focus more on supplier selection is the crucial role that suppliers play in product, service, organization, and sustainable performance selection as the primary and input factor in the supply chain (Asadabadi 2016; Rashidi et al. 2020). Also, it should be noted that one of the crucial issues in sustainable development is carbon emissions (Dogan and Inglesi-Lotz 2017; Dogan and Seker 2016; Dogan and Turkekul 2016; Hocine et al. 2020). In the sustainable selection of suppliers, more care and sensitivity should be paid because important issues such as the use of minerals, toxic substances in raw materials, and environmental pollution caused by some processes are tied to the sustainable SSP (Hofmann et al. 2018). In this way, Song et al. (2017) investigated the sustainable SSP for the solar air conditioner manufacturer. Luthra et al. (2017) proposed a model to investigate the sustainable SSP. The authors employed AHP and VIKOR approaches to measure the criteria weights and rank the suppliers. Sen et al. (2018) studied the SSP considering the sustainability aspect. They utilized the TOPSIS, MOORA, and GRA methods to investigate the research problem. To tackle the uncertainty that exists in the business environment, the authors used intuitionistic fuzzy numbers. Memari et al. (2019) developed the intuitionistic fuzzy TOPSIS to examine the sustainable SSP for a real-world case study. The achieved results showed that their approach could obtain a reliable solution for the research problem. Hendiani et al. (2020a, b) utilized a multi-stage hierarchical approach based on a new fuzzy extension for the BWM to study the sustainable SSP. Hendiani et al. (2020a) developed a new decision-making model for investigating the sustainable SSP by considering the concept of the likelihood of type 2 fuzzy. They considered the tube industry to show the efficiency of the applied method. Tavana et al. (2021) introduced the hierarchical fuzzy BWM to compute indicators’ weights in the sustainable SSP. The authors compared their method with several traditional methods to show its reliability and robustness. Fallahpour et al. (2021a) presented a hyper-hybrid model based on the decision-making methods (FDEMATEL, FBWM, and FANP) and artificial intelligence approaches (fuzzy inference system) to investigate the sustainable SSP. They implemented their model on a palm oil company. Beiki et al. (2021) proposed a new hybrid method of language entropy weight and multi-objective programming for sustainable SSP and order allocation in the automobile industry. Their model has three objectives: maximizing the procurement value and minimizing the carbon emission and total cost. Zhang et al. (2021) investigated the integration of rough DEMATEL and FVIKOR in the sustainable SSP. They have considered 15 criteria with the main aspects of sustainability. They applied the R-DEMATEL to weighted and FVIKOR for ranking suppliers. Also, there are many other sustainable supplier selection papers that interested readers can see ((Arabsheybani et al. 2018; Bai et al. 2019; Gören 2018; Tayyab and Sarkar 2021; Tirkolaee et al. 2020; Yu et al. 2019)).

SSP based on I4.0

As mentioned, in the last decade, I4.0 has influenced the industry and supply chain activities due to the growth of artificial intelligence and digitalization. Thus, considering the dimensions of I4.0 can be an important issue in the supplier selection area. In this field, Sachdeva et al. (2019) studied the SSP problem in the I4.0 era by proposing an integrated entropy-TOPSIS method. Torkayesh et al. (2020) studied the digital SSP by employing the WASPAS and BWM methods. Indeed, the authors calculated the importance of the criteria using the BWM and ranked the alternatives applying the WASPAS method. Özbek and Yildiz (2020) studied the digital SSP due to the I4.0 transformation. They identified 20 sub-criteria and three suppliers in the apparel industry in Turkey. It should be noted that the authors developed the interval type 2 fuzzy TOPSIS to rank the potential suppliers. Fallahpour et al. (2021c) proposed a hybrid approach based on fuzzy preference programming and MOORA methods to investigate the green sourcing problem considering the I4.0 dimensions. Tas and Akcan (2021) presented an integrated fuzzy-Swara-Bwm method to study agile and green SSP considering the I4.0 dimensions. The authors implemented their model on a plastic manufacturer to demonstrate the applicability and validation of their approach. Çalık (2021) developed a hybrid approach based on the Pythagorean fuzzy AHP and fuzzy TOPSIS to investigate the green SSP problem considering the I4.0 dimensions. To validate the proposed model, the authors implemented it in the agricultural tool industry case. Fallahpour et al. (2021b) presented a model for studying the relationship between Industry 4.0 criteria and the sustainable SSP. They used the FMWB and FIS approaches to measure the criteria weights and evaluate the performance of suppliers. Also, the authors selected the textile industry for implementing the developed approach to show its applicability.

Lean and agile SSP

One of the necessities that industries should focus more on is reviewing and redesigning the suppliers’ selection process so that they can withstand the pressures on themselves in this competitive market. This process in the supply chain can open new strategic doors for the industry to survive in the global competitive environment. This section discusses both lean and agile strategic perspectives on supplier selection problems. Owing to the importance of these strategies, many papers have been conducted in this area in recent years. For instance, Alimardani et al. (2013) investigated the agile SSP problem by proposing an integrated SWARA-VIKOR method for the automobile industry. Beikkhakhian et al. (2015) proposed a decision-making framework based on the TOPSIS and AHP methods to examine the agile SSP. They implemented their model in the manufacturing industry to show its efficiency. Abdollahi et al. (2015) developed a framework for selecting suppliers based on both the leagile characteristics of suppliers to make the market more competitive, and the flexibility to overcome changes in demand, suppliers, etc. Their research aims to select a suitable supplier based on the two characteristics mentioned above. To demonstrate the applicability and feasibility of the proposed model, the authors implemented their model in a real case study. El Mokadem (2017) conducted an article on how manufacturing strategies by commercial companies affect supplier selection criteria. In this study, the author used a review strategy to empirically investigate the research argument. First, factor analysis was used to confirm the underlying structure of supplier selection criteria, and then, simple regression analysis was used to test the research hypotheses. Torğul and Paksoy (2019) introduced a decision-making framework to select lean and green suppliers in a fuzzy environment. In the process of evaluating the criteria, they used the AHP method along with a linear programming model, and finally, the TOPSIS method was used to rank the alternatives. Çalık et al. (2019) proposed a multi-objective linear programming model for the SSP in the Turkish electronic board industry based on green and lean principles. They considered their problem based on the dimensions of sustainability with 12 criteria. Li et al. (2020) studied the leagile SSP for the textile industry in China. At the outset, they determined the main indicator of the research problem and then applied the DEMATEL method to measure the importance of the indicators. As a result of their study, managers were able to select their suppliers based on the introduced criteria and robust their supply chain according to global strategy. Foladi (2020) investigated the green SSP considering leagile features. The authors first identified the main indicators and then calculated their weights employing the AHP method. Finally, they used the VIKOR method to rank suppliers. Alamroshan et al. (2022) presented a fuzzy approach to studying the agile and green SSP under the fuzzy environment. In this way, they developed an integrated FDEMATEL-FBWM-FANP-FVIKOR. It should be noted that the authors implemented their model in the MD industry to demonstrate its applicability.

Research gaps and contributions

According to the literature, although many studies have been conducted in the SSP area, there are still some gaps. In this regard, there are several papers in the field of sustainable SSP, lean and agile SSP, and I4.0-based SSP. However, no research investigated all of these critical aspects, simultaneously. Additionally, in light of the recent pandemic (COVID-19), which has resulted in a drastic increase in the demand for MDs, it might be beneficial to study this vital industry. Therefore, the current work aims at employing an efficient hybrid approach, namely the integrated RBWM-IR-MABAC approach, to study the sustainable and leagile SSP in the I4.0 era. In this way, in the next step, the main criteria/sub-criteria are determined according to the literature. Then, the potential suppliers are determined based on the selected case study (the medical device). Afterwards, the RBWM is used to compute the importance of the criteria/sub-criteria, and then, the IR-MABAC is applied to rank suppliers. Overall, based on the abovementioned points, the main contributions of the current study are as follows.

-

(i)

The current work is the first study that investigates the sustainable-leagile SSP considering I4.0 dimensions.

-

(ii)

The current work considers the MD industry, as one of the crucial sectors during the coronavirus outbreak, as a case study.

-

(iii)

This is the first research that employed the integrated RBWM-IR-MABAC method in the sustainable and leagile SSP area.

Selection of the criteria

In this section, we provide the main criteria and sub-criteria of the research problem (i.e., leagile-sustainable SSP according to I4.0 dimensions). In this regard, at the outset, we searched authoritative journals for keywords “Supplier selection,” “Leagile,” “Sustainable,” “Industry 4.0,” and “Medical devices” and selected the papers from 2004 to 2022. Then, the potential indicators are extracted from the literature, and then, the most relevant of them are selected based on the experts’ opinions. In this regard, the determined indicators based on the literature and experts’ opinions are as follows. It should be noted that to select the main criteria and sub-criteria for the medical device industry, we first identified the potential sub-criteria based on the literature and then selected those more pertinent to the considered industry (medical devices). For example, wastewater is one of the potential sub-criteria for the sustainability aspect, which was considered by previous research (for example (Fallahpour et al. 2021a)) as a sub-criteria for the food industry. However, the experts in the medical device industry did not select it as one of the main sub-criteria for the research problem, and other sub-criteria that are more relevant to the mentioned industry, such as energy and resource consumption, reuse, and waste management, are selected. Indeed, we selected the most related sub-criteria based on the opinions of the medical device industry experts, which may be equally important for other similar industries (e.g., eElectrical appliances).

Leanness aspect

Table 1 shows the leanness indicators considered in the current study.

Agility aspect

Table 2 shows the agility indicators considered in this research.

Sustainability aspect

Table 3 demonstrates the sustainability indicators considered in the current work.

I4.0 aspect

Table 4 shows the indicators related to the I4.0 dimensions.

Methodology

This section is devoted to describing the utilized hybrid model for evaluating suppliers. This model can be implemented in two phases; phase one, which determines the importance of indicators using the RBWM, and phase two, ranking and evaluating alternatives (criterion) using the IR-MABAC model. The main advantages of this hybrid method are as follows: (i) it can consider a large number of parameters that influence the selection of supplier performance, (ii) it provides the possibility of eliminating uncertainties in a real environment by considering approximations, (iii) it is more objective about group decision-making, and (iv) it efficiently deals with uncertainty. A schematic of the methodology of the current work is depicted in Fig. 1. The BWM is preferred for weight extraction because it is easier than other MCDM methods such as TOPSIS, SWARA, and DEMATEL. In this method, we will need fewer pairwise comparisons, and consequently, we will achieve more consistent results. In addition, it seems unlikely that decision-makers have full knowledge of all the factors affecting supplier selection, so uncertainty should be considered in such cases. Algorithms can be used to analyze and solve the best solution to deal with the uncertainty inherent in supplier selection problems in the real world. One of these algorithms is the rough theory, which in comparison with fuzzy theory, gray theory, and other approaches is a powerful tool for dealing with uncertainty without the effect of subjectivism (Yazdani et al. 2020).

In the rough theory approach, unlike fuzzy theory, in which the degree of uncertainty is determined by assumptions, the boundaries are determined by the approximate boundary limits and the uncertainty that governs them, which is the basic concept of approximate numbers (RNs) (Song et al. 2014). As RNs are used to represent real data, only the data structure is used instead of various additional or external parameters. This will lead to the use of objective indicators in the data. This approach also creates unique interval boundaries for each expert ranking, so the deficiency eliminates the traditional fuzzy approach to interval boundaries. Another reason for choosing this hybrid method, especially IR_MABAC, compared to other methods, is that we were faced with many parameters that affected the selection of suppliers and complicated the problem. So, according to Pamučar et al. (2018a), we used this hybrid approach to employ these methods to get more objective answers to the group decision problem.

Rough best–worst method (RBWM)

RBWM is one of the relatively novel methods that has attracted the attention of researchers. Many previous papers employed this efficient method in their decision-making process (see (Chen et al. 2020; Chen and Ming, 2020; Kazemitash et al. 2021; Pamučar et al. 2018a)). The steps of RBWM will be briefly explained in this section (Kazemitash et al. 2021):

-

Step 1: A set of evaluation criteria are determined.

-

Step 2: Define the least important (W) and most effective (B) criteria.

-

Step 3: Identify the most influential priority on the set of criteria.

$${A}_{B}^{e}=\left({a}_{B1}^{e},{a}_{B2}^{e},\ldots ,{a}_{Bn}^{e}\right); 1\le e\le m$$(1)

where e represents of expert’s number.)

-

Step 4: Identify the least important priority on the set of criteria

$${A}_{W}^{e}=\left({a}_{1W}^{e},{a}_{2W}^{e},\ldots ,{a}_{nW}^{e}\right); 1\le e\le m$$(2) -

Step 5: Identify the BO matrix from the rough sequence \(RN\left({a}_{Bj}^{e}\right)\) based on the average answer of the experts’ matrix. Then calculate the average rough sequence \(RN\left({\overline{a}}_{Bj}\right)\) by Eq. 3.

$$RN\left({\overline{a}}_{Bj}\right)=RN\left({a}_{Bj}^{1},{\ldots ,a}_{Bj}^{e}\right)=\left\{\begin{array}{c}{a}_{Bj}^{-L}=\frac{1}{m}\sum\limits_{e=1}^{m}{a}_{Bj}^{eL}\\ {a}_{Bj}^{-U}=\frac{1}{m}\sum\limits_{e=1}^{m}{a}_{Bj}^{eU}\end{array}\right.$$(3) -

Step 6: Repeat step 5 for the W and calculate \(RN\left({\overline{a}}_{jw}\right)\)

$$RN\left({\overline{a}}_{jw}\right)=RN\left({a}_{jw}^{1},{a}_{jw}^{2},{\ldots ,a}_{jw}^{e}\right)=\left\{\begin{array}{c}{a}_{Bj}^{-L}=\frac{1}{m}\sum\limits_{e=1}^{m}{a}_{Bj}^{eL}\\ {a}_{Bj}^{-U}=\frac{1}{m}\sum\limits_{e=1}^{m}{a}_{Bj}^{eU}\end{array}\right.$$(4) -

Step 7: Calculate the optimal weight coefficients based on the rough numbers from the set C. This step aims to determine the optimal value for the criteria based on Eq. 5.

Now, according to the limitations that have been addressed in the previous steps, the following min–max model and its equivalent are presented in Eqs. 6 and 7.

In the above model, the values of \(N\left({W}_{j}\right)=\left[{W}_{j}^{L}, {W}_{j}^{U}\right]\), \(RN\left({W}_{B}\right)=\left[{W}_{B}^{L}, {W}_{B}^{U}\right]\), and \(RN\left({W}_{w}\right)=\left[{W}_{w}^{L}, {W}_{w}^{U}\right]\) are the optimal values of the weight of jth criteria, the best and the worst criteria. By solving the (7) model, the optimal values of the coefficients for the criteria will be obtained. In supplier selection MCDM models, decisions are often made at several levels. Therefore, in models with sub-criteria levels, all these steps should be done for each sub-level. Finally, the global weight will be achieved by multiplying the weights of the different levels together. The global weight will use in the next step to rank the alternatives (Kazemitash et al. 2021).

Interval rough multi-attributive border approximation area comparison (IR-MABAC)

This section presents the steps of the IR-MABAC method.

-

Step 1: Constructing the initial decision-making matrix (X)

where m and n referenced the alternatives criteria number, respectively.

-

Step 2: Normalizing the initial matrix (X)

$$N={\left[\begin{array}{ccc}\begin{array}{c}\begin{array}{c} \begin{array}{cc} & {C}_{1}\end{array}\\ \begin{array}{cc}{A}_{1}& IRN\left({t}_{11}\right)\end{array}\end{array}\\ \begin{array}{cc}{A}_{2}& IRN\left({t}_{21}\right)\end{array}\end{array}& \begin{array}{c}\begin{array}{c}{C}_{2}\\ IRN\left({t}_{12}\right)\end{array}\\ IRN\left({t}_{22}\right)\end{array}& \begin{array}{c}\begin{array}{cc}\begin{array}{c}\ldots \\ \cdots \end{array}& \begin{array}{c}{C}_{n}\\ IRN\left({t}_{1n}\right)\end{array}\end{array}\\ \begin{array}{cc}\cdots & IRN\left({t}_{2n}\right)\end{array}\end{array}\\ \begin{array}{cc}\vdots & \vdots \end{array}& \vdots & \begin{array}{cc}\ddots & \vdots \end{array}\\ \begin{array}{cc}{A}_{m}& IRN\left({t}_{m1}\right)\end{array}& IRN\left({t}_{m2}\right)& \begin{array}{cc}\cdots & IRN\left({t}_{mn}\right)\end{array}\end{array}\right]}_{mn}$$(9)

After normalization, matrix (X) will be converted to the \(IRN\left({t}_{ij}\right)\) matrix based on profit and cost criteria.

-

(a)

Benefit criteria

-

(b)

Cost criteria

$$IRN\left(t_{ij}\right)=\left(\left[t_{ij}^L,t_{ij}^U\right],\left[t_{ij}^{'L},t_{ij}^{'U}\right]\right)=\left(\left[\frac{x_j^{'U}-x_j^+}{x_j^--x_j^+},\frac{x_j^{'L}-x_j^+}{x_j^--x_j^+}\right],\left[\frac{x_j^U-x_j^+}{x_j^--x_j^+},\frac{x_j^L-x_j^+}{x_j^--x_j^+}\right]\right)$$(11)

\({x}_{j}^{+}\) and \({x}_{j}^{-}\) represent the minimum value of the criteria in the boundary of rough intervals.

-

Step 3: Computing the weighted matrix \(V={\left[IRN\left({x}_{ij}\right)\right]}_{m\times n}\) based on Eq. 12.

$$IRN\left({v}_{ij}\right)=IRN\left({w}_{i}\right). IRN\left({t}_{ij}\right)+IRN\left({w}_{i}\right)$$(12)where \(IRN\left({w}_{j}\right)\) represents the weight coefficient. So the weighted matrix is as follows:

$$V={\begin{bmatrix}(\left[v_{11}^L,v_{11}^U\right],\left[v_{11}^{'L},v_{11}^{'U}\right])&(\left[v_{12}^L,v_{12}^U\right],\left[v_{12}^{'L},v_{12}^{'U}\right])&\begin{array}{cc}\cdots&(\left[v_{1n}^L,v_{1n}^U\right],\left[v_{1n}^{'L},v_{1n}^{'U}\right])\end{array}\\(\left[v_{21}^L,v_{21}^U\right],\left[v_{21}^{'L},v_{21}^{'U}\right])&(\left[v_{22}^L,v_{22}^U\right],\left[v_{22}^{'L},v_{22}^{'U}\right])&\begin{array}{cc}\cdots&(\left[v_{2n}^L,v_{2n}^U\right],\left[v_{2n}^{'L},v_{2n}^{'u}\right])\end{array}\\ \begin{array}{c}\cdots\\(\left[v_{m1}^L,v_{m1}^U\right],\left[v_{m1}^{'L},v_{m1}^{'U}\right])\end{array}&\begin{array}{c}\cdots\\(\left[v_{m2}^L,v_{m2}^U\right],\left[v_{m2}^{'L},v_{m2}^{'U}\right])\end{array}&\begin{array}{cc}\begin{array}{c}\ddots\\ \cdots\end{array}&\begin{array}{c}\cdots\\(\left[v_{mn}^L,v_{mn}^U\right],\left[v_{mn}^{'L},v_{mn}^{'U}\right])\end{array}\end{array}\end{bmatrix}}_{m\times n}$$(13)

-

Step 4: In this step, calculate the matrix of border approximation area based on Eq. (14):

-

Step 5: This step seeks to calculate the distance matrix based on the boundary approximation area. This matrix is computed by the difference between V and G.

-

Step 6: In this step, the value of the criteria functions will be determined by Eq. 17 to determine the ranking of the alternatives.

Alternatives can be ranked by converting rough interval numbers to real numbers or by rough interval number rules. A complete description of this method is given in Pamučar et al. (2018b).

Case study

This section presents the case study of the current research and determines the main indicators. As World Health Organization (WHO) mentioned, MDs are among the most important and widely used products during the COVID-19 outbreak. Many medical services would not be possible without MDs. The Coronavirus outbreak demonstrated the crucial role of MDs in certifying the life quality in the world. Therefore, due to the high importance of these products, this paper investigates the MD industry to show the applicability of the research problem. In this study, a project-based organization in the MD industry in Iran is selected, and its managers and experts helped us to determine the main indicators and alternatives. The considered firm manufactures various MDs. The potential suppliers, which the company wants to assess their performances based on sustainability, leagile, and I4.0 aspects, are located in different locations in Iran (see Fig. 2).

Numerical results

Computing the criteria’s weights by RBWM

The first step in the RBWM method is to determine the worst and best criteria. Therefore, 8 experts of the company were asked to determine the worst and best criteria among the criteria. To make the pairwise comparisons, 8 experts from the case study company helped us in the data gathering process. The profiles of the experts are provided in Table 5.

In this research, there are four criteria (i.e., I4.0, agility, sustainability, and leanness) and multiple sub-criteria for each criterion. Experts chose the agility and I4.0 indicators as the best and worst criteria, respectively. Also, among the leanness sub-criteria, the best criterion is “cost” and the worst criterion is “continuous improvement.” Among the agility sub-criteria, the worst and the best criteria are “cooperation ability” and “manufacturing flexibility,” respectively. Among the sustainability sub-criteria, “pollution control” is considered as the best criterion, and “employment insurance” is determined as the worst. Finally, among the I4.0 dimensions, “smart factory” is the best criterion and “cyber security” is the worst criterion. Determining the best and worst criteria is the most important and preliminary task in computing the weight. Now it is time to take the other steps of the RBWM. After designing the questionnaire and collecting experts’ opinions, the local weight of criteria and sub-criteria is obtained using GAMS.14 software, and then. the global weight of criteria and sub-criteria is determined, the results of which can be seen in Tables 6, 7, 8 and 9. Finally, Table 10 shows the average of the sub-criteria weights (final weights). The obtained results show that the agility and sustainability indicators are the most critical aspects. On the other side, among all the sub-criteria, manufacturing flexibility, cost, reliability, smart factory, and quality are the most important indicators. As mentioned, the agility and sustainability aspects were determined as the best ones. Regarding the agility aspect, the main reason for selecting this aspect as the best one may be the COVID-19 pandemic conditions. Perhaps if the conditions of the world and the market were normal, the opinion of the experts would be such that the leanness aspect would be chosen as the best criterion, because in normal conditions, criteria such as cost and service are very important. However, since the current work was conducted during the COVID-19 outbreak in which the conditions of the market are drastically dynamic and uncertain, especially in the MD industry, agility was determined as the best aspect based on the experts’ opinion. On the other side, the main reasons for choosing sustainability as the second most important criterion are as follows: (i) Existence of numerous governmental and international regulations that require companies to consider the dimensions of sustainable development in their business has led to an increase in experts’ attention to the sustainability aspect; (ii) increasing the attention of today’s customers to the sustainability dimensions and their expectations of companies to implement the sustainable development pillars in their business. The high importance of the sustainability aspect in the supplier selection problem was also confirmed in the previous papers (for example, see Amindoust, 2018; Amindoust and Saghafinia, 2017; Fallahpour et al. 2021b). On the other hand, among the sub-criteria, manufacturing flexibility, cost, and reliability are the most important indicators. Similar to the reason mentioned for the agility aspect, these indicators were determined as the best ones due to the coronavirus disease situation, which has led to increasing uncertainty in the business environment. It should be noted that the results of Alamroshan et al. (2022), which studied the green and agile supplier selection for the medical device industry confirmed the outputs of the current research. In other words, the manufacturing flexibility, cost, and reliability criteria were also determined as the most important ones in Alamroshan et al. (2022).

Ranking the suppliers by the IR-MABAC

The second phase of the proposed hybrid method is to implement the IR-MABAC method for ranking alternatives using the weights obtained from the RBWM. After performing the relations 8–17 and normalization and crisp format, we finally reached Table 11 to evaluate and rank the alternatives. The ranking can be utilized as a policy guideline to decision makers for the implementation of leagile and sustainable suppliers in a company in the MD industry in the COVID-19 pandemic. According to Table 10, by proper planning, policymakers can adopt suitable strategies for selecting the best supplier to meet the company’s leagile and sustainability criteria. Based on the achieved results, the best suppliers are A6, A12, and A5. This means that these three suppliers have better conditions to supply the raw materials for the considered company in the MD industry based on the leagile, sustainability, and I4.0 aspects.

Validation of the applied hybrid method

To show the validation and robustness of the utilized hybrid approach, this section is presented in two parts. In the first part, we check the value of the consistency ratio (CR) obtained from the RBWM. On the other side, in the second part, we compare the results of the employed hybrid approach with the well-known traditional method (i.e., AHP and TOPSIS).

Checking CR

Based on the literature, the obtained results are more reliable when the CR is close to zero. Therefore, in this section, we present the values of the CRs obtained from the RBWM (see Table 12). As shown in this table, for the criteria, CR = 0.341. Also, for the leanness sub-criteria, CR = 0.0508. On the other side, for the agility sub-criteria, CR = 0.0472. Also, for the sustainability sub-criteria, CR = 0.0719. Eventually, for the I4.0 sub-criteria, CR = 0.0683. So, in all steps, the value of the CR is close to zero. Accordingly, the model is applicable and the global weights are reliable.

Comparing with the AHP-TOPSIS

To validate the achieved results, the outputs of the employed hybrid approach are compared with the AHP-TOPSIS method in this part. We select the AHP-TOPSIS method because these two methods are very common in the literature and most researchers are usually familiar with them. As a result, in order to obtain a better understanding of the results obtained from the proposed method, as well as to validate them, these methods were used. It is worth noting that AHP-TOPSIS is one of the methods that could be used along with other MCDM methods. Table 13 compares the final weights of the criteria obtained from the RBWM with the AHP method. As shown in Table 13, the weights obtained from both methods are close to each other, which shows the validation of the applied approach. To better understand, Fig. 3 depicts the obtained results. Also, Table 14 demonstrates the CR for the RBWM and AHP methods. According to Table 14, for all steps, the CR of RBWM is lower than the AHP method, which shows more reliability and robustness of the RBWM.

On the other hand, Table 15 makes a comparison between the results of the IR-MABAC method and the TOPSIS method. According to this table, the best suppliers are the same in both methods. This behavior shows the validation of the employed method.

Findings and discussion

In today’s modern and global business, the importance of the supplier selection problem has been highlighted more. Nowadays, evaluating the performance of potential suppliers is a very complex process, especially when collecting exact data. On the other side, after the COVID-19 outbreak, demand for MDs has drastically increased, which has dramatically highlighted the importance of this industry. In this regard, the current paper has studied the supplier selection problem considering sustainability and agility aspects in the I4.0 era for the MD industry. In this way, this research has provided a list of indicators involving four criteria (leanness, agility, sustainability, and I4.0) and 27 sub-criteria for the research problem. Also, this study has identified 15 potential suppliers as alternatives. Afterwards, a hybrid approach, named the integrated RBWM-IR-MABAC, was applied to compute the importance of the criteria and rank the alternatives. The main advantages of the employed approach are (i) it can consider a large number of parameters that influence the selection of supplier performance, (ii) it provides the possibility of eliminating uncertainties in a real environment by considering approximations, (iii) it is more objective about group decision-making, and (iv) it efficiently deals with uncertainty. The outputs showed that agility and sustainability are the most important criteria, and manufacturing flexibility, cost, reliability, smart factory, and quality are the most important sub-criteria.

Regarding the reasons for choosing the mentioned indicators as the most important ones, the following explanations can be provided. The manufacturing flexibility criterion is selected as the most important indicator because during the COVID-19 pandemic, the fluctuations and dynamics of the medical device market significantly increased and this led to many disruptions in this industry. Hence, the manufacturing flexibility in this field is known as one of the most important factors in critical conditions. Also, the second important criterion was the cost. In this regard, the purchasing cost is one of the major financial parts of each company, and it is rational that managers try to reduce it by selecting cost-efficient suppliers. In addition, reliability has been selected as the third important criterion. The main reason for the importance of this criterion is that in a critical situation such as the COVID-19 outbreak, a supplier must be capable of providing acceptable products at the required time, especially when the considered industry is medical devices that directly deal with people’s health. On the other hand, regarding the selection of the smart factory among the most important indicators, it can be said that in today’s modern and digital business and marketplace, the tendency of managers has drastically shifted toward utilizing emerging technologies. Nowadays, managers know that they need to utilize new technologies and achievements of I4.0 to achieve competitive advantages. Finally, regarding the quality criterion, the quality of the raw materials directly affects the quality of the finished product. Hence, using high-quality raw materials can enhance the quality of the finished products, which can increase customers’ satisfaction and subsequently enhance total profits in the long term. On the other hand, suppliers A6, A12, and A5 have been selected as the best suppliers. The obtained results demonstrated that the CRs achieved by the RBWM were near 0, which demonstrates the reliability and robustness of the utilized model. To validate the applied hybrid approach, the achieved results have been compared to a traditional method (AHP-TOPSIS). The comparison showed that the outputs of the employed hybrid method are very similar to the traditional AHP-TOPSIS method, which confirms the validation of the applied hybrid approach. Moreover, the results demonstrated that the value of the CR for the employed RBWM is less than the CR of the AHP method, indicating that the applied method is more reliable and robust.

The linkages of the obtained results with the extant literature

In this section, the results of the present work are compared with the results achieved in the previous related papers. The current work investigated the supplier selection problem for the medical device industry, considering the sustainability, leagility, and Industry 4.0 dimensions. The obtained results demonstrated that manufacturing flexibility, cost, reliability, smart factory, and quality are the most important indicators. In the literature, Alamroshan et al. (2022) studied the green and agile SSP for the medical device industry using a hybrid decision-making method. Based on their research outputs, manufacturing flexibility, cost, and reliability are the most important criteria for the green-agile supplier selection problem. This point confirms the results of the present work and shows the importance of the mentioned indicators. However, the main difference between the present work and Alamroshan et al. (2022) is that this paper considers the social, lean, and I4.0 dimensions that were ignored by Alamroshan et al. (2022). In this regard, in this study, some criteria, such as smart factory, are among the most important indicators, which did not exist in Alamroshan et al. (2022). Also, Fallahpour et al. (2021b) investigated the sustainable supplier selection problem based on the I4.0 policies and based on the obtained results; the price (cost), flexibility, and quality criteria were among the most important criteria. The mentioned point showed that the results of the mentioned paper are similar to the present work demonstrating the validity of this research. Nevertheless, there are some differences between this work and Fallahpour et al. (2021b). For example, the present study has considered the sub-criteria of the leagile and Industry 4.0 indicators that were ignored by Fallahpour et al. (2021b). Hence, several indicators such as reliability and smart factory did not consider in the mentioned work but have been incorporated in this research.

On the other side, the importance of the quality and cost criteria in the sustainable supplier selection for the medical device industry was demonstrated by Ghadimi and Heavey (2014), which investigated the sustainable medical device SSP problem using the FIS method. However, the mentioned work ignored some criteria such as I4.0 and leagile that have been considered in the present work. In this regard, we can see indicators like reliability and smart factory that were among the best indicators of this work but did not exist in Ghadimi and Heavey (2014). Moreover, Stević et al. (2020) developed an MCDM method to investigate the sustainable healthcare supplier selection problem in which the cost and quality criteria were the most important ones. In addition, Li et al. (2020) studied the leagile supplier selection problem. Similar to the present work’s results, the outputs of Li et al. (2020) demonstrated that quality and cost were among the most critical indicators. However, there are some differences between the present work and Li et al. (2020). In this regard, the current study has considered some important criteria, namely sustainability and I4.0 dimensions, which were ignored by Li et al. (2020). Also, Fallahpour et al. (2021a) investigated the sustainable and resilient SSP. According to the results of the mentioned paper, the cost, quality, and flexibility indicators were among the most important criteria. The mentioned point confirms the results achieved in this study. The main difference between Fallahpour et al. (2021a) and the present work is considering the Industry 4.0 dimension. In comparison with Fallahpour et al. (2021a), the current study has considered indicators such as smart factory and cyber security, as the I4.0 sub-criteria.

Mangerial implications

This research has targeted one of the most important concerns of today’s industry managers, namely the supplier selection problem. In today’s hyper-competitive and modern market, considering only the economic aspect is not acceptable. Nowadays, managers know that they need a comprehensive and appropriate plan in order to improve their productivity and increase their market share. Therefore, this work has studied the sustainable and leagile supplier selection problem considering the Industry 4.0 dimensions. The current research helps supply chain leaders to better understand how to incorporate leanness, agility, sustainability, and I4.0 dimensions into the supplier selection problem. Also, the obtained outputs can help supply chain leaders to determine the most important criteria/sub-criteria of leanness, agility, and sustainability in the I4.0-based supplier selection. Besides, an efficient hybrid model was applied to measure the indicators’ weights and to assess the suppliers’ performance. By utilizing this hybrid method, managers can select suppliers with appropriate performance in leanness, sustainability, agility, and I4.0 aspects. Moreover, a list of criteria/sub-criteria has been presented in this paper, which is very applicable and useful for managers, especially in the MDs industry. Here, based on the outputs of the current work, we provide some managerial recommendations as follows. Although at first glance, the lean aspect may appear to be the most important aspect from the managers’ point of view, the outcomes indicate that the agility and sustainability aspects are more important. Accordingly, it is recommended that managers give significant consideration to the mentioned aspects and do not ignore them. Nowadays, managers should know that considering the sustainability pillars enables them to project a green and socially responsible image of their organizations, which results in enhancing consumers’ loyalty and market share. In this regard, in addition to considering the sustainability concept in the supplier selection process, managers are advised to provide a better social and environmental image of their company to customers by doing benevolent activities and greening their production and distribution process. On the other side, about the agility concept, managers should know that although reinforcement of the dimensions such as flexibility and reliability have costs for the company, they can increase the total profits and market share in the long term by gaining competitive advantage and enhancing customers’ satisfaction. Also, establishing an efficient information sharing system to exchange required information with its suppliers for improving cooperation and flexibility is strongly recommended to managers.

Theoretical implications

This section is dedicated to presenting the theoretical implications of the current work. The main theoretical implications of this research can be described in two major parts: (i) simultaneous consideration of the leagile, sustainability, and I4.0 aspects in the SSP for the first time and (ii) employing the integrated RBWM-IR-MABAC in this area for the first time. Regarding the first part, the leagile concept is an important strategy to cope with the uncertain business environment and improve efficiency. Also, sustainable development is known as one of the major dimensions of modern businesses, and many international and governmental rules and regulations have forced companies to incorporate sustainability pillars into their activities. On the other hand, in today’s modern businesses, considering the I4.0 achievements in supply chain activities can significantly improve processes and gain a competitive advantage. In spite of the high importance of each of the above aspects, no research has been conducted that considers them simultaneously in the SSP. Therefore, the main theoretical contribution of this paper is to provide a list of indicators for the leagile-sustainable SSP under the I4.0 policies that can help future studies to expand and extend this field. Moreover, the current study applied a decision-making framework (the integrated RBWM-IR-MABAC), for the first time, which has several advantages, such as considering a large number of parameters that influence the selection of supplier performance, providing the possibility of eliminating uncertainties in a real environment by considering approximations, and tackling the uncertainty. It should be noted that the obtained results confirm the efficiency and validity of the employed method, and future researchers can employ or extend this decision-making framework for their works.

Conclusions and future suggestions

The current work investigated the sustainable and leagile SSP under policies of the I4.0. In this way, the main indicators of the research problem were identified based on the literature and then the potential alternatives were determined. In the next step, the indicators’ weights were calculated using the RBWM. Afterwards, suppliers were ranked using the IR-MABAC method. Based on the achieved results, the agility and sustainability aspects were identified as the most important criteria, and manufacturing flexibility, cost, reliability, smart factory, and quality were determined as the most important sub-criteria. Besides, suppliers A6, A12, and A5 were selected as the best suppliers based on the sustainability, leagile, and I4.0 dimensions. Moreover, the values of the achieved consistency ratios indicated the reliability and robustness of the employed hybrid approach because all CRs were close to zero. Eventually, the results of comparing the applied hybrid method with the AHP-TOPSIS method showed the efficiency and validation of the employed model.

One of the limitations of the current study is to ignore customer preferences as one of the important aspects of the market. In this way, future studies can incorporate the customer preferences in the problem using quality function deployment (QFD) and Markov transition matrix methods. To do this, at the outset, the customer preferences are identified using the QFD method, and then, their priority is calculated using the Markov transition matrix. Another limitation of the present work is to evaluate suppliers without considering the different items. In this regard, it is possible that one supplier has better performance for a specific raw material but has weak performance for another raw material. Accordingly, future works can investigate the multi-item SSP with the leagile, sustainability, and I4.0 dimensions. Also, ignoring the other crucial aspects, such as resiliency, can be considered as one of the limitations of this paper. Therefore, researchers can add the mentioned aspect to the current work.

Data availability

Not applicable.

References

Abdollahi M, Arvan M, Razmi J (2015) An integrated approach for supplier portfolio selection: lean or agile? Expert Syst. Appl 42:679–690

Alamroshan F, La’li M, Yahyaei M (2022) The green-agile supplier selection problem for the medical devices: a hybrid fuzzy decision-making approach. Environ Sci Pollut Res 29:6793–6811. https://doi.org/10.1007/s11356-021-14690-z

Alimardani M, Hashemkhani Zolfani S, Aghdaie MH, Tamošaitienė J (2013) A novel hybrid SWARA and VIKOR methodology for supplier selection in an agile environment. Technol Econ Dev Econ 19:533–548

Alimardani M, Rabbani M, Rafiei H (2014) A novel hybrid model based on DEMATEL, ANP and TOPSIS for supplier selection in agile supply chains. Int J Serv Oper Manag 18:179–211

Amindoust A (2018) A resilient-sustainable based supplier selection model using a hybrid intelligent method. Comput Ind Eng 126:122–135

Amindoust A, Ahmed S, Saghafinia A, Bahreininejad A (2012) Sustainable supplier selection: a ranking model based on fuzzy inference system. Appl Soft Comput 12:1668–1677

Amindoust A, Saghafinia A (2017) Textile supplier selection in sustainable supply chain using a modular fuzzy inference system model. J Text Inst 108:1250–1258

Arabsheybani A, Paydar MM, Safaei AS (2018) An integrated fuzzy MOORA method and FMEA technique for sustainable supplier selection considering quantity discounts and supplier’s risk. J Clean Prod 190:577–591

Asadabadi MR (2016) A Markovian-QFD approach in addressing the changing priorities of the customer needs. Int J Qual Reliab Manag (IJQRM) 33(8):1062–1075

Asadi Z, Khatir MV, Rahimi M (2022) Robust design of a green-responsive closed-loop supply chain network for the ventilator device. Environ Sci Pollut Res 29:53598–53618. https://doi.org/10.1007/s11356-022-19105-1

Bai C, Sarkis J (2010) Integrating sustainability into supplier selection with grey system and rough set methodologies. Int J Prod Econ 124:252–264

Bai C, Sarkis J, Wei X (2010) Addressing key sustainable supply chain management issues using rough set methodology. Manag Res Rev 33(12):1113–1127

Bai C, Kusi-Sarpong S, Badri Ahmadi H, Sarkis J (2019) Social sustainable supplier evaluation and selection: a group decision-support approach. Int J Prod Res 57:7046–7067

Beiki H, Seyedhosseini SM, Ponkratov VV, Olegovna Zekiy A, Ivanov SA (2021) Addressing a sustainable supplier selection and order allocation problem by an integrated approach: a case of automobile manufacturing. J Ind Prod Eng 38:239–253

Beikkhakhian Y, Javanmardi M, Karbasian M, Khayambashi B (2015) The application of ISM model in evaluating agile suppliers selection criteria and ranking suppliers using fuzzy TOPSIS-AHP methods. Expert Syst Appl 42:6224–6236

Breque M, De Nul L, Petridis A (2021) Industry 5.0: towards a sustainable, human-centric and resilient European industry. European Commission, Directorate-General for Research and Innovation, Luxembourg

Çalık A (2021) A novel Pythagorean fuzzy AHP and fuzzy TOPSIS methodology for green supplier selection in the Industry 4.0 era. Soft Comput 25:2253–2265

Çalık A, Paksoy T, Huber S (2019) Lean and green supplier selection problem: a novel multi objective linear programming model for an electronics board manufacturing company in Turkey. In: Multiple criteria decision making and aiding. Springer, Cham, pp 281–309

Chen Z, Ming X (2020) A rough–fuzzy approach integrating best–worst method and data envelopment analysis to multi-criteria selection of smart product service module. Appl Soft Comput 94:106479

Chen Z, Ming X, Zhou T, Chang Y, Sun Z (2020) A hybrid framework integrating rough-fuzzy best-worst method to identify and evaluate user activity-oriented service requirement for smart product service system. J Clean Prod 253:119954

Dogan E, Inglesi-Lotz R (2017) Analyzing the effects of real income and biomass energy consumption on carbon dioxide (CO2) emissions: empirical evidence from the panel of biomass-consuming countries. Energy 138:721–727

Dogan E, Seker F (2016) Determinants of CO2 emissions in the European Union: the role of renewable and non-renewable energy. Renew Energy 94:429–439

Dogan E, Turkekul B (2016) CO 2 emissions, real output, energy consumption, trade, urbanization and financial development: testing the EKC hypothesis for the USA. Environ Sci Pollut Res 23:1203–1213

El Mokadem M (2017) The classification of supplier selection criteria with respect to lean or agile manufacturing strategies. J Manuf Technol Manag. Chicago

Fallahpour A, Olugu EU, Musa SN, Wong KY, Noori S (2017) A decision support model for sustainable supplier selection in sustainable supply chain management. Comput Ind Eng 105:391–410

Fallahpour A, Kazemi N, Molani M, Nayyeri S, Ehsani M (2018) An intelligence-based model for supplier selection integrating data envelopment analysis and support vector machine. Iran J Manag Stud 11:209–241

Fallahpour A, Nayeri S, Sheikhalishahi M, Wong KY, Tian G, Fathollahi-Fard AM (2021a) A hyperhybrid fuzzy decision-making framework for the sustainable-resilient supplier selection problem: a case study of Malaysian palm oil industry. Environ Sci Pollut Res. https://doi.org/10.1007/s11356-021-12491-y

Fallahpour A, Wong KY, Rajoo S, Fathollahi-Fard AM., Antucheviciene J, Nayeri S (2021b) An integrated approach for a sustainable supplier selection based on industry 4.0 concept. https://doi.org/10.1007/s11356-021-17445-y

Fallahpour A, Yazdani M, Mohammed A, Wong KY (2021c) Green sourcing in the era of industry 4.0: towards green and digitalized competitive advantages. Ind Manag Data Syst

Fathollahi-Fard AM, Hajiaghaei-Keshteli M, Mirjalili S (2018) Multi-objective stochastic closed-loop supply chain network design with social considerations. Appl Soft Comput 71:505–525

Foladi F (2020) Introducing Integrated Model for Green Supplier Selection in Leagile Supply Chain. J. Oper. Res. Its Appl. (Applied Math. Azad Univ 17:81–97

Freeman J, Chen T (2015) Green supplier selection using an AHP-entropy-TOPSIS framework. Int J Supply Chain Manag

Galankashi MR, Helmi SA (2016) Assessment of hybrid lean-agile (Leagile) supply chain strategies. J Manuf Technol Manag

Galankashi MR, Hisjam M, Helmi SA (2016) Lean supplier selection: a data envelopment analysis (DEA) approach. In: Proceedings of the sixth international conference on industrial engineering and operations management (IEOM)

Ghadimi P, Heavey C (2014) Sustainable supplier selection in medical device industry: toward sustainable manufacturing. Procedia Cirp 15:165–170

Ghobakhloo M (2020) Industry 40, digitization, and opportunities for sustainability. J Clean Prod 252:119869

Godil DI, Yu Z, Sharif A, Usman R, Khan SAR (2021) Investigate the role of technology innovation and renewable energy in reducing transport sector CO2 emission in China: a path toward sustainable development. Sustain Dev 29:694–707

Gören HG (2018) A decision framework for sustainable supplier selection and order allocation with lost sales. J Clean Prod 183:1156–1169

Hajiaghaei-Keshteli M, Fard AMF (2019) Sustainable closed-loop supply chain network design with discount supposition. Neural Comput Appl 31:5343–5377

Hendiani S, Liao H, Ren R, Lev B (2020a) A likelihood-based multi-criteria sustainable supplier selection approach with complex preference information. Inf Sci 536:135–155

Hendiani S, Mahmoudi A, Liao H (2020b) A multi-stage multi-criteria hierarchical decision-making approach for sustainable supplier selection. Appl Soft Comput 94:106456

Hocine A, Guellil MS, Dogan E, Ghouali S, Kouaissah N (2020) A fuzzy goal programming with interval target model and its application to the decision problem of renewable energy planning. Environ Ecol Stat 27:527–547

Hofmann H, Schleper MC, Blome C (2018) Conflict minerals and supply chain due diligence: an exploratory study of multi-tier supply chains. J Bus Ethics 147:115–141

Jamali A, Ranjbar A, Heydari J, Nayeri S (2021) A multi-objective stochastic programming model to configure a sustainable humanitarian logistics considering deprivation cost and patient severity. Ann Oper Res 1–36

Jamwal A, Agrawal R, Sharma M, Kumar V, Kumar S (2021) Developing a sustainability framework for Industry 4.0. Procedia CIRP 98:430–435

Javaid M, Haleem A (2019) Industry 4.0 applications in medical field: a brief review. Curr Med Res Pract 9:102–109

Kazemitash N, Fazlollahtabar H, Abbaspour M (2021) Rough best-worst method for supplier selection in biofuel companies based on green Criteria. Oper Res Eng Sci Theory Appl 4:1–12. https://doi.org/10.31181/ORESTA20402001K

Khan SAR, Sharif A, Golpîra H, Kumar A (2019) A green ideology in Asian emerging economies: from environmental policy and sustainable development. Sustain Dev 27:1063–1075

Khan SAR, Yu Z, Golpira H, Sharif A, Mardani A (2021) A state-of-the-art review and meta-analysis on sustainable supply chain management: future research directions. J Clean Prod 278:123357

Kojima S, Kaplinsky R (2004) The use of a lean production index in explaining the transition to global competitiveness: the auto components sector in South Africa. Technovation 24:199–206

Kusi-Sarpong S, Gupta H, Khan SA, Chiappetta Jabbour CJ, Rehman ST, Kusi-Sarpong H (2021) Sustainable supplier selection based on industry 4.0 initiatives within the context of circular economy implementation in supply chain operations. Prod Plan Control 1–21

Lee J, Bagheri B, Kao Hung-An (2015) A Cyber-Physical Syst. Archit Ind 4:18–23

Li Y, Diabat A, Lu C-C (2020) Leagile supplier selection in Chinese textile industries: a DEMATEL approach. Ann Oper Res 287:303–322

Lichtblau K, Stich V, Bertenrath R, Blum M, Bleider M, Millack A et al (2015) Industrie 4.0 readiness. In: IMPULS-Stiftung for mechanical engineering, plant engineering, and information technology

Luthra S, Govindan K, Kannan D, Mangla SK, Garg CP (2017) An integrated framework for sustainable supplier selection and evaluation in supply chains. J Clean Prod 140:1686–1698

Mamashli Z, Bozorgi-Amiri A, Dadashpour I, Nayeri S, Heydari J (2021a) A heuristic-based multi-choice goal programming for the stochastic sustainable-resilient routing-allocation problem in relief logistics. Neural Comput Applic 33(21):14283–14309

Mamashli Z, Nayeri S, Tavakkoli-Moghaddam R, Sazvar Z, Javadian N (2021b) Designing a sustainable–resilient disaster waste management system under hybrid uncertainty: a case study. Eng Appl Artif Intell 106:104459

Mason-Jones R, Naylor B, Towill DR (2000) Engineering the leagile supply chain. Int J Agil Manag Syst 2(1):54–61. https://doi.org/10.1108/14654650010312606

Matawale CR, Datta S, Mahapatra SS (2016) Supplier selection in agile supply chain: application potential of FMLMCDM approach in comparison with fuzzy-TOPSIS and fuzzy-MOORA. Benchmarking: An International Journal 23(7):2027–2060. https://doi.org/10.1108/BIJ-07-2015-0067

Mehrbakhsh S, Ghezavati V (2020) Mathematical modeling for green supply chain considering product recovery capacity and uncertainty for demand. Environ Sci Pollut Res 27:44378–44395

Memari A, Dargi A, Jokar MRA, Ahmad R, Rahim ARA (2019) Sustainable supplier selection: a multi-criteria intuitionistic fuzzy TOPSIS method. J Manuf Syst 50:9–24

Mousakhani S, Nazari-Shirkouhi S, Bozorgi-Amiri A (2017) A novel interval type-2 fuzzy evaluation model based group decision analysis for green supplier selection problems: a case study of battery industry. J Clean Prod 168:205–218

Nayeri S, Paydar MM, Asadi-Gangraj E, Emami S (2020) Multi-objective fuzzy robust optimization approach to sustainable closed-loop supply chain network design. Comput Ind Eng 148:106716

Nayeri S, Sazvar Z, Heydari J (2022) A global-responsive supply chain considering sustainability and resiliency: application in the medical devices industry. Socio Econ Plan Sci 101303

Nayeri S, Tavakoli M, Tanhaeean M, Jolai F (2021) A robust fuzzy stochastic model for the responsive resilient inventory-location problem: comparison of metaheuristic algorithms. Ann Oper Res 315(2):1895–1935

Özbek A, Yildiz A (2020) Digital supplier selection for a garment business using interval type-2 fuzzy topsis. Text Appar 30:61–72

Pamučar D, Petrović I, Ćirović G (2018a) Modification of the best–worst and MABAC methods: a novel approach based on interval-valued fuzzy-rough numbers. Expert Syst Appl 91:89–106

Pamučar D, Stević Ž, Zavadskas EK (2018b) Integration of interval rough AHP and interval rough MABAC methods for evaluating university web pages. Appl Soft Comput 67:141–163

Rashidi K, Noorizadeh A, Kannan D, Cullinane K (2020) Applying the triple bottom line in sustainable supplier selection: a meta-review of the state-of-the-art. J Clean Prod 269:122001

Razavi N, Gholizadeh H, Nayeri S, Ashrafi TA (2021) A robust optimization model of the field hospitals in the sustainable blood supply chain in crisis logistics. J Oper Res Soc 72:2804–2828

Rezaei A, Rahiminezhad Galankashi M, Mansoorzadeh S, Mokhatab Rafiei F (2020) Supplier selection and order allocation with lean manufacturing criteria: an integrated MCDM and Bi-objective modelling approach. Eng Manag J 32:253–271

Sachdeva N, Shrivastava AK, Chauhan A (2021) Modeling supplier selection in the era of industry 4.0. Benchmarking: An International Journal 28(5):1809–1836. https://doi.org/10.1108/BIJ-12-2018-0441

Sahebjamnia N, Fathollahi-Fard AM, Hajiaghaei-Keshteli M (2018) Sustainable tire closed-loop supply chain network design: hybrid metaheuristic algorithms for large-scale networks. J Clean Prod 196:273–296

Sahu AK, Sahu AK, Sahu NK (2016) Appraisal of partner enterprises under GTFNS environment: agile supply chain. Int J Decis Support Syst Technol 8:1–19

Salimian S, Mousavi SM, Antucheviciene J (2022) An interval-valued intuitionistic fuzzy model based on extended VIKOR and MARCOS for sustainable supplier selection in organ transplantation networks for healthcare devices. Sustainability 14:3795

Samadi A, Mehranfar N, Fathollahi Fard AM, Hajiaghaei-Keshteli M (2018) Heuristic-based metaheuristics to address a sustainable supply chain network design problem. J Ind Prod Eng 35:102–117

Sarkis J, Meade LM, Presley AR (2012) Incorporating sustainability into contractor evaluation and team formation in the built environment. J Clean Prod 31:40–53

Sazvar Z, Tafakkori K, Oladzad N, Nayeri S (2021a) A capacity planning approach for sustainable-resilient supply chain network design under uncertainty: a case study of vaccine supply chain. Comput Ind Eng 159:107406

Sazvar Z, Zokaee M, Tavakkoli-Moghaddam R, Salari SAS, Nayeri S (2021b) Designing a sustainable closed-loop pharmaceutical supply chain in a competitive market considering demand uncertainty, manufacturer’s brand and waste management. Ann Oper Res 315(2):2057–2088

Schuh G, Anderl R, Gausemeier J, ten Hompel M, Wahlster W (eds) (2017) Industrie 4.0 maturity index: managing the digital transformation of companies. Herbert Utz Verlag GmbH

Schumacher A, Erol S, Sihn W (2016) A maturity model for assessing Industry 4.0 readiness and maturity of manufacturing enterprises. Procedia Cirp 52:161–166

Sen DK, Datta S, Mahapatra SS (2018) Sustainable supplier selection in intuitionistic fuzzy environment: a decision-making perspective. Benchmarking: An International Journal 25(2):545–574. https://doi.org/10.1108/BIJ-11-2016-0172

Sharma M, Joshi S (2020) Digital supplier selection reinforcing supply chain quality management systems to enhance firm’s performance. TQM J. https://doi.org/10.1108/TQM-07-2020-0160

Song W, Ming X, Wu Z, Zhu B (2014) A rough TOPSIS approach for failure mode and effects analysis in uncertain environments. Qual Reliab Eng Int 30:473–486

Song W, Xu Z, Liu H-C (2017) Developing sustainable supplier selection criteria for solar air-conditioner manufacturer: an integrated approach. Renew Sustain Energy Rev 79:1461–1471

Stević Ž, Pamučar D, Puška A, Chatterjee P (2020) Sustainable supplier selection in healthcare industries using a new MCDM method: measurement of alternatives and ranking according to compromise solution (MARCOS). Comput Ind Eng 140:106231. https://doi.org/10.1016/j.cie.2019.106231

Tas MA, Akcan S (2021) Selecting a green, agile and industry 4.0 supplier with the fuzzy-Swara-Bwm integrated method

Tavakoli M, Mesbahi R, Nayeri S, Jolai F (2022) Risk assessment of medical devices used for COVID-19 patients based on a Markovian-based weighted failure mode effects analysis (WFMEA). Sci Iran. https://doi.org/10.24200/sci.2022.57493.5266

Tavana M, Shaabani A, Santos-Arteaga FJ, Valaei N (2021) An integrated fuzzy sustainable supplier evaluation and selection framework for green supply chains in reverse logistics. Environ Sci Pollut Res 28(38):53953–53982

Tayyab M, Sarkar B (2021) An interactive fuzzy programming approach for a sustainable supplier selection under textile supply chain management. Comput Ind Eng 155:107164

Tirkolaee EB, Mardani A, Dashtian Z, Soltani M, Weber G-W (2020) A novel hybrid method using fuzzy decision making and multi-objective programming for sustainable-reliable supplier selection in two-echelon supply chain design. J Clean Prod 250:119517

Tong LZ, Wang J, Pu Z (2022) Sustainable supplier selection for SMEs based on an extended PROMETHEE II approach. J Clean Prod 330:129830

Torğul B, Paksoy T (2019) A new multi objective linear programming model for lean and green supplier selection with fuzzy TOPSIS. In: Lean and green supply chain management. Springer, Cham, pp 101–141

Torkayesh SE, Iranizad A, Torkayesh AE, Basit MN (2020) Application of BWM-WASPAS model for digital supplier selection problem: a case study in online retail shopping. J Ind Eng Decis Mak 1:12–23

Yazdani M, Tavana M, Pamučar D, Chatterjee P (2020) A rough based multi-criteria evaluation method for healthcare waste disposal location decisions. Comput Ind Eng 143:106394

Yu C, Shao Y, Wang K, Zhang L (2019) A group decision making sustainable supplier selection approach using extended TOPSIS under interval-valued Pythagorean fuzzy environment. Expert Syst Appl 121:1–17

Zhang J, Yang D, Li Q, Lev B, Ma Y (2021) Research on sustainable supplier selection based on the rough DEMATEL and FVIKOR methods. Sustainability 13:88

Author information

Authors and Affiliations

Contributions

Ali Akbar ForouzeshNejad: conceptualization, methodology, software, validation, manuscript preparation, and visualization.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflict of interest

The author declares no competing interests.

Additional information

Responsible Editor: Arshian Sharif

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

ForouzeshNejad, A.A. Leagile and sustainable supplier selection problem in the Industry 4.0 era: a case study of the medical devices using hybrid multi-criteria decision making tool. Environ Sci Pollut Res 30, 13418–13437 (2023). https://doi.org/10.1007/s11356-022-22916-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-022-22916-x