Abstract

Spent cathode carbon (SCC) is a hazardous waste containing fluorides and cyanides from aluminum electrolysis. Many literatures have focused on SCC leaching; however, SCC hazard-free treatment remains understudied. This article used 10.0 g raw SCC sample to explore the vitric/kaolin solidification and calcium stabilization of SCC, and analyze their hazard-free mechanisms by the methods of XRD and SEM. The leached fluorides were all below the Chinese identification standard for hazardous wastes (GB5085.3-2007), whether at 750/950 °C for 60 min above 8.0 g vitric, or at 1200 °C for 120 min with above 8.0 g kaolin, or above 700 °C for more than 30 min with above 0.5 g CaCO3. Kaolin/vitric solidification relied on the massive addition of vitric and kaolin to produce glassy or glass-like material (K2O·Al2O3·6SiO2) which may retain fluoride. Calcium stabilization converted soluble fluoride NaF in raw SCC sample into insoluble CaF2. Heating 60 min at 500–1200 °C at oxygen atmosphere decomposed almost of cyanides, with leached cyanides meeting Chinese standard GB5085.3-2007. Mass-loss rates of kaolin addition came from a large amount of adsorbed water and structural water in kaolinite and illite wai lost, and that of CaCO3/CaSO4 addition was attributed to their decomposition into volatile CO2/SO2, while that of CaO was a little negative due to its absorption of water vapor and CO2. In brief, as the effective hazard-free manner of SCC, both kaolin/vitric solidification and calcium stabilization successfully have achieved fluoride immobilization and cyanide decomposition.

Similar content being viewed by others

Data availability

Not applicable

References

Andrade-Vieira LF, Trento MVC, César PHS, Marcussi S (2019) Spent pot liner from aluminum industry: genotoxic and mutagenic action on human leukocytes. Environ Sci Pollut Res 26(27):27640–27646. https://doi.org/10.1007/s11356-019-04782-2

Barth E, Percin P, Arozarena M, Zieleinswski J, Dosani M, Maxey H, Hokanson S, Pryately C, Whipple T, Whipple R, Kravitz M, Cullinane L, Jones P (1989) Malone. In: Stabilization and solidification of hazardous wastes. Noyes Data Corporation, New Jersey

Batchelor B (2006) Overview of waste stabilization with cement. Waste Manag 26:689–698. https://doi.org/10.1016/j.wasman.2006.01.020

Chanania F, Eby E (2000) Best demonstrated available technology (BDAT) background document for spent aluminum potliners—K088. US Environmental Protection Agency, Office of Solid Waste, Washington, pp 2.1–2.16

Chandra S, Chauhan LKS, Murthy RC, Saxena PN, Pande PN, Gupta SK (2005) Comparative biomonitoring of leachates from hazardous solid waste of two industries using Allium test. Sci Total Environ 347(1):46–52. https://doi.org/10.1016/j.scitotenv.2005.01.002

Chandrasekhar S, Ramaswamy S (2002) Influence of mineral impurities on the properties of kaolin and its thermally treated products. Appl Clay Sci 21:133–142. https://doi.org/10.1016/S0169-1317(01)00083-7

Chen X (2009) Studying on pyro-process for spent potlining and its heat transfer analyzing. Central South University, PhD dissertation, Changsha

Conner JR (1990) Chemical fixation and solidification of hazardous waste. Van Nostrand Reinhold, New York, pp 1–682

Contessi S, Calgaro L, Dalconi MC, Bonetto A, Bellotto MP, Ferrari G, Marcomini A, Artioli G (2020) Stabilization of lead contaminated soil with traditional and alternative binders. J Hazard Mater 382:120990. https://doi.org/10.1016/j.jhazmat.2019.120990

Courbariaux Y, Chaouki J, Guy C (2004) Update on spent potliners treatments: kinetics of cyanides destruction at high temperature. Ind Eng Chem Res 43:5828–5837. https://doi.org/10.1021/ie049775x

Feng Z (2019) Study on preparation and chemical stability of pyrochlore-based borosilicate glass-ceramic waste forms. Southwest University of Science and Technology, Mianyang, pp 20–23

Freitas AS, Fontes IM, Cunha LF, Andrade-Vieira VHT (2016) Effect of SPL (spent pot liner) and its main components on root growth, mitotic activity and phosphorylation of Histone H3 in Lactuca sativa L. Ecotoxicol Environ Saf 124:426–434. https://doi.org/10.1016/j.ecoenv.2015.11.017

Gao L, Mostaghel S, Ray S, Chattopadyay K (2016) Using SPL (spent pot-lining) as an alternative fuel in metallurgical furnaces. Metall Mater Trans E 3:179–188. https://doi.org/10.1007/s40553-016-0099-4

Glasser FP (1993) Chemistry of cement solidified waste forms. In: Spencer RD (ed) Chemistry and microstructure of solidified waste form, 1st edn. Lewis publishers, New York

Holywell G, Breault R (2013) An overview of useful methods to treat, recover, or recycle spent potlining. JOM 65(11):1441–1451. https://doi.org/10.1007/s11837-013-0769-y

International Aluminum Institute, (2010-2022) International aluminum institute statistics [WWW Document]. Retrieved from. http://www.worldaluminium.org/statistics/#data. Accessed 20 June 2021

Kang JM, Murnandari A, Youn MH, Lee W, Park KT, Kim YE, Kim HJ, Kang S-P, Lee J-H, Jeong SK (2018) Energy-efficient chemical regeneration of AMP using calcium hydroxide for operating carbon dioxide capture process. Chem Eng J 335:338–344. https://doi.org/10.1016/j.cej.2017.10.136

Karunadasa KSP, Manoratne CH, Pitawala HMTGA, Rajapakse RMG (2019) Thermal decomposition of calcium carbonate (calcite polymorph) as examined by in-situ high-temperature X-ray powder diffraction. J Phys Chem Solids 134:21–28. https://doi.org/10.1016/j.jpcs.2019.05.023

Kati T, Cristian S, Jorn R, Tor G (2012) Chemical degradation of cathode linings in hall-héroult cells—an autopsy study of three spent pot linings. Metall Mater Trans B 43(2):290–301. https://doi.org/10.1007/s11663-011-9604-4

Kavouras P, Kaimakamis G, Ioannidis TA, Kehagias T, Komninou P, Kokkou S, Pavlidou E, Antonopoulos I, Sofoniou M, Zouboulis A, Hadjiantoniou CP, Nouet G, Prakouras A, Karakostas T (2003) Vitrification of lead-rich solid ashes from incineration of hazardous industrial wastes. Waste Manag 23:361–371. https://doi.org/10.1016/S0956-053X(02)00153-8

Li WX, Chen XP (2008) Chemical stability of fluorides related to spent potlining. Light metals-warrendale-proceedings-TMS (The Minerals, Metals & Materials Society) Annual Meeting & Exhibition, New Orlean, pp 855–858

Li N, Xie G, Wang ZX, Hou YQ, Li RX (2014) Recycle of spent potlining with low carbon grade by floatation. Adv Mater Res 881:1660–1664. https://doi.org/10.4028/www.scientific.net/AMR.881-883.1660

Li RB, Lu TT, Xie MZ, Liu FQ (2020) Analysis on thermal behavior of fluorides and cyanides for heat-treating spent cathode carbon blocks from aluminum smelters by TG/DSC-MS & ECSA®. Ecotoxicol Environ Saf 189:110015. https://doi.org/10.1016/j.ecoenv.2019.110015

Lisbona DF, Steel KM (2008) Recovery of fluoride values from spent pot-lining: precipitation of an aluminium hydroxy fluoride hydrate product. Sep Purif Technol 61(2):182–192. https://doi.org/10.1016/j.seppur.2007.10.012

Lisbona DF, Somerfield C, Steel KM (2012) Leaching of spent pot-lining with aluminum anodizing wastewaters: fluoride extraction and thermodynamic modeling of aqueous speciation. Ind Eng Chem Res 51(25):8366–8377. https://doi.org/10.1021/ie3006353

Malviya R, Chaudhary R (2006) Factors affecting hazardous waste solidification/stabilization: a review. J Hazard Mater B137:267–276. https://doi.org/10.1016/j.jhazmat.2006.01.065

Miksa D, Homsak M, Samec N (2003) Spent potlining utilisation possibilities. Waste Manag Res 21(5):467. https://doi.org/10.1177/0734242X0302100509

Scarinci G, Brusatin G, Barbieri L, Corradi A, Lancellotti I, Colombo P, Hreglich S, Dall’Igna R (2000) Vitrification of industrial and natural wastes with production of glass fibres. J Eur Ceram Soc 20:2485–2490. https://doi.org/10.1016/S0955-2219(00)00146-1

Silveira BI, Dantas AE, Blasquez JE, Santos RKP (2002) Characterization of inorganic fraction of spent potliners evaluation of the cyanides and fluorides content. J Hazard Mater 89(2-3):177–183. https://doi.org/10.1016/S0304-3894(01)00303-X

Skalny J, Daugherty KE (1972) Everything you always wanted to know about Portland cement. Chemtech 2(1):38

Sleap SB, Turner BD, Sloan SW (2015) Kinetics of fluoride removal from spent pot liner leachate (SPLL) contaminated groundwater. J Environ Chem Eng 3(4):2580–2587. https://doi.org/10.1016/j.jece.2015.09.004

Song Y, Peng J, Di Y, Wang Y, Li B, Feng N (2016) The impact of cathode material and shape on current density in an aluminum electrolysis cell. JOM 68:593–599. https://doi.org/10.1007/s11837-015-1719-7

Sun G, Zhang G, Liu JY, Xie WM, Evrendilek F, Buyukada M (2019) (Co-) combustion behaviors and products of spent potlining and textile dyeing sludge. J Clean Prod 224:384–395. https://doi.org/10.1016/j.jclepro.2019.03.208

Tabery RS, Dangtran K (1990) Fluidized bed combustion of aluminum smelting waste. Environ Prog Sustain Energy 9(1):61–68. https://doi.org/10.1016/S1369-703X(01)00117-6

Tropenauer B, Klinar D, Klinar D, Samec N, Golob J, Kortnik J (2019) Sustainable waste-treatment procedure for the spent potlining (SPL) from aluminium production. Mater Tehnol 53(2):277–284. https://doi.org/10.17222/mit.2018.147

Vizcayno C, de Gutiérrez RM, Castello R, Rodriguez E, Guerrero CE (2010) Pozzolan obtained by mechanochemical and thermal treatments of kaolin. Appl Clay Sci 49:405–413. https://doi.org/10.1016/j.clay.2009.09.008

Wang YW, Peng JP, Di YZ (2018) Separation and recycling of spent carbon cathode blocks in the aluminum industry by the vacuum distillation process. JOM 70(9):1877–1882. https://doi.org/10.1007/s11837-018-2858-4

Wang DY, Wang HB, Chunlei L, Yongrong Q, Liting F, Li P (2021) Process for stabilizing fluorine in electrolytic aluminum spent pot lining by roasting method. In IOP Conf Series: Earth Environ Sci 621(1):012036. https://doi.org/10.1088/1755-1315/621/1/012036

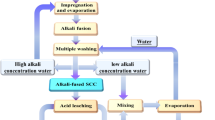

Xiao J, Yuan J, Tian ZL, Yang K, Yao Z, Yu BL, Zhang LY (2018) Comparison of ultrasound-assisted and traditional caustic leaching of spent cathode carbon (SCC) from aluminum electrolysis. Ultrason Sonochem 40:21–29. https://doi.org/10.1016/j.ultsonch.2017.06.024

Xie MZ, Li RB, Zhao HL, Liu W, Lu TT, Liu FQ (2020) Detoxification of spent cathode carbon blocks from aluminum smelters by joint controlling temperature-vacuum process. J Clean Prod 249:119370. https://doi.org/10.1016/j.jclepro.2019.119370

Yang K, Zhao Z, Xin X, Tian Z, Peng K, Lai Y (2019) Graphitic carbon materials extracted from spent carbon cathode of aluminium reduction cell as anodes for lithium ion batteries: Converting the hazardous wastes into value-added materials. J Taiwan Inst Chem Eng 104:201–209. https://doi.org/10.1016/j.jtice.2019.09.012

Yang K, Gong P, Tian Z, Lai Y, Li J (2020) Recycling spent carbon cathode by a roasting method and its application in Li-ion batteries anodes. J Clean Prod 261:121090. https://doi.org/10.1016/j.jclepro.2020.121090

Yuan J, Xiao J, Li FC, Wang BJ, Yao Z, Yu BL, Zhang LY (2018) Cotreatment of spent cathode carbon in caustic and acid leaching process under ultrasonic assisted for preparation of SiC. Ultrason Sonochem 41:608–618. https://doi.org/10.1016/j.ultsonch.2017.10.027

Zhang G, Sun G, Liu JY, Evrendilek F, Buyukada M, Xie WM (2020) Thermal behaviors of fluorine during (co-) incinerations of spent potlining and red mud: transformation, retention, leaching and thermodynamic modeling analyses. Chemosphere 249:126204. https://doi.org/10.1016/j.chemosphere.2020.126204

Zhao HL, Liu FQ, Xie MZ, Liu W, Yong H, Sohn. (2021) Recycling and utilization of spent potlining by different high temperature treatments. J Clean Prod 289:125704. https://doi.org/10.1016/j.jclepro.2020.125704

Zhu Z, Lei X, Han Z, Liu J, Zhang L, Yang C, Zhangbiao X, Liu P (2022) Defluorination study of spent carbon cathode by microwave high-temperature roasting. J Environ Manag 302:114028. https://doi.org/10.1016/j.jenvman.2021.114028

Funding

This research was supported by the R&D Project on Hazard-Free Treatment and Recycling of Hazardous Waste from Aluminum Electrolysis (H15-075).

Author information

Authors and Affiliations

Contributions

YS: resources, methodology, original draft writing, writing—review and editing, funding acquisition, project administration, supervision. ZL: experiment, original draft writing. CL, TL: experiment. LZ, YS: writing—review and editing. QG: methodology, writing—review and editing.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable

Consent for publication

Not applicable

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Ioannis A. Katsoyiannis

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sang, Y., Liang, Z., Li, C. et al. Solidification/stabilization of spent cathode carbon from aluminum electrolysis by vitric, kaolin and calcification agent: fluorides immobilization and cyanides decomposition. Environ Sci Pollut Res 29, 85537–85546 (2022). https://doi.org/10.1007/s11356-022-21803-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-022-21803-9