Abstract

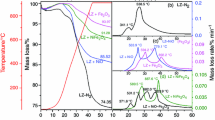

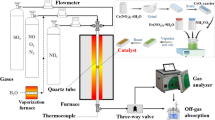

Siderite is a naturally occurring mineral that can be found extensively in coal. The structural evolution of siderite in the process of coaling and its performance in the transformation of NO in the presence of NH3 were investigated in this work. In addition, the effects of the coexisting component, including vapor, SO2, and the alkali metal K, were also discussed. Heat treatment was performed at 450, 500, 550, 600, and 700 °C to obtain siderite-derived α-Fe2O3, which was then evaluated in de-NOx via the selective catalytic reduction (SCR) of NO with NH3 in a fixed bed. The X-ray diffraction (XRD), the X-ray fluorescence spectrometer (XRF), N2 adsorption-desorption (BET), the X-ray photoelectron spectrometer (XPS), the scanning electron microscope (SEM), and the transmission electron microscope (TEM) were used to investigate the variations in the morphology and structure of the thermally treated siderite. The results showed that siderite was gradually oxidized and decomposed into α-Fe2O3 with a nanoporous structure and large surface area of 27.27 m2 g−1 after calcination under an air atmosphere. The α-Fe2O3 derived from siderite at 500 °C (H500) exhibited an excellent SCR performance, where the NO conversion rate was great than 90% between 250 and 300 °C due to the pore structure and high specific surface area, additional adsorbed oxygen states, abundant oligomeric Fe oxide clusters, and large amount of acid sites. Regardless of the vapor content, SO2 concentration, and reaction temperature, the α-Fe2O3 derived from siderite at 500 °C (H500) still favored the conversion of NO. When the reaction temperature was lower than 350 °C, H500 favored the conversion of NO even in the presence of an alkali metal (K). The experimental data demonstrated the positive effect of siderite-derived α-Fe2O3 in SCR technology and provided insight into NO behavior in coaling flue gas after NH3 injection.

Similar content being viewed by others

References

Apostolescu N, Geiger B, Hizbullah K, Jan MT, Kureti S, Reichert D, Schott F, Weisweiler W (2006) Selective catalytic reduction of nitrogen oxides by ammonia on iron oxide catalysts. Appl Catal B Environ 62:104–114

Balle P, Geiger B, Kureti S (2009) Selective catalytic reduction of NOx by NH3 on Fe/HBEA zeolite catalysts in oxygen-rich exhaust. Appl Catal B Environ 85:109–119

Brandenberger S, Kröcher O, Tissler A, Althoff R (2010) Estimation of the fractions of different nuclear iron species in uniformly metal-exchanged Fe-ZSM-5 samples based on a Poisson distribution. Appl Catal A Gen 373:168–175

Chen L, Weng D, Si Z, Wu X (2012) Synergistic effect between ceria and tungsten oxide on WO3-CeO2-TiO2 catalysts for NH3-SCR reaction. Progr Nat Sci: Mater Int 22:265–272

Dahlin S, Nilsson M, Bäckström D, Bergman SL, Bengtsson E, Bernasek SL, Pettersson LJ (2016) Multivariate analysis of the effect of biodiesel-derived contaminants on V2O5-WO3/TiO2 SCR catalysts. Appl Catal B Environ 183:377–385

Fisher QJ, Raiswell R, Marshall JD (1998) Siderite concretions from nonmarine shales (Westphalian A) of the Pennines, England: controls on their growth and composition. J Sediment Res 68:1034–1045

Forzatti P, Nova I, Tronconi E (2009) Enhanced NH3 selective catalytic reduction for NOx abatement. Angew Chem Int Ed 121:8366–8368

France LJ, Yang Q, Li W, Chen Z, Guang J, Guo D, Wang L, Li X (2017) Ceria modified FeMnOx-enhanced performance and sulphur resistance for low-temperature SCR of NOx. Appl Catal B Environ 206:203–215

Grosvenor AP, Kobe BA, Biesinger MC, Mcintyre NS (2004) Investigation of multiplet splitting of Fe 2p XPS spectra and bonding in iron compounds. Surf Interface Anal 36:1564–1574

Guo RT, Wang QS, Pan WG, Zhen WL, Chen QL, Ding HL, Yang NZ, Lu CZ (2014) The poisoning effect of Na and K on Mn/TiO2 catalyst for selective catalytic reduction of NO with NH3: a comparative study. Appl Surf Sci 317:111–116

Hu H, Zha K, Li H, Shi L, Zhang D (2016) In situ DRIFTs investigation of the reaction mechanism over MnOx-MOy/Ce0.75Zr0.25O2 (M = Fe, Co, Ni, Cu) for the selective catalytic reduction of NOx with NH3. Appl Surf Sci 387:921–928

Iwasaki M, Yamazaki K, Banno K, Shinjoh H (2008) Characterization of Fe/ZSM-5 DeNOx catalysts prepared by different methods: relationships between active Fe sites and NH3-SCR performance. J Catal 260:205–216

Jiang BQ, Wu ZB, Liu Y, Lee SC, Ho WK (2010) DRIFT study of the SO2 effect on low-temperature SCR reaction over Fe-Mn/TiO2. J Phys Chem C 114:4961–4965

Jiang B, Deng B, Zhang Z, Wu Z, Tang X, Yao S, Hao L (2012) Effect of Zr addition on the low-temperature SCR activity and SO2 tolerance of Fe-Mn/Ti catalysts. J Phys Chem C 118:14866–14875

Jing L, Zhiquan T, Yan H, Bin X, He L (2010) Effects of H2O and SO2 on a Cr-Ce/TiO2 catalyst for NO catalytic oxidation. Acta Sci Circumst 30:1023–1029

Kumar MS, Schwidder M, Grünert W, Brückner A (2004) On the nature of different iron sites and their catalytic role in Fe-ZSM-5 DeNOx catalysts: new insights by a combined EPR and UV/VIS spectroscopic approach. J Catal 227:384–397

Li J, Xiong D (2009) Tribological behavior of graphite-containing nickel-based composite as function of temperature, load and counterface. Wear 266:360–367

Li Q, Liu H, Chen T, Chen D, Zhang C, Xu B, Zhu C, Jiang Y (2017) Characterization and SCR performance of nano-structured iron-manganese oxides: effect of annealing temperature. Aerosol & Air Quality Research 17:2328–2337

Liang Y, Huang Y, Zhang H, Lan L, Zhao M, Gong M, Chen Y, Wang J (2017) Interactional effect of cerium and manganese on NO catalytic oxidation. Environ Sci Pollut Res Int 24:9314–9324

Liu F, He H, Zhang C, Feng Z, Zheng L, Xie Y, Hu T (2010) Selective catalytic reduction of NO with NH3 over iron titanate catalyst: catalytic performance and characterization. Appl Catal B Environ 96:408–420

Liu F, He H, Zhang C, Shan W, Shi X (2011) Mechanism of the selective catalytic reduction of NOx with NH3 over environmental-friendly iron titanate catalyst. Catal Today 175:18–25

Liu Z, Li J, Woo SI (2012) Recent advances in the selective catalytic reduction of NOx by hydrogen in the presence of oxygen. Energy Environ Sci 5:8799–8814

Liu C, Yang S, Ma L, Peng Y, Hamidreza A, Chang H, Li J (2013) Comparison on the performance of α-Fe2O3 and γ-Fe2O3 for selective catalytic reduction of nitrogen oxides with ammonia. Catal Lett 143:697–704

Liu Z, Zhang S, Li J, Zhu J, Ma L (2014) Novel V2O5-CeO2/TiO2 catalyst with low vanadium loading for the selective catalytic reduction of NOx by NH3. Appl Catal B Environ 158–159:11–19

Liu H, Zhang L, Li Q, Zhu H, Deng L, Liu Y, Che D (2019) Effect of FGR position on the characteristics of combustion, emission and flue gas temperature deviation in a 1000 MW tower-type double-reheat boiler with deep-air-staging. Fuel 246:285–294

Maes II, Gryglewicz G, Yperman J, Franco DV, D'Haes J, D'Olieslaeger M, Poucke LCV (2000) Effect of siderite in coal on reductive pyrolytic analyses. Fuel 79:1873–1881

Metkar PS, Harold MP, Balakotaiah V (2012) Selective catalytic reduction of NOx on combined Fe- and Cu-zeolite monolithic catalysts: sequential and dual layer configurations. Appl Catal B Environ 111–112:67–80

Odenbrand CUI, Gabrielsson PLT, Brandin JGM, Andersson LAH (1991) Effect of water vapor on the selectivity in the reduction of nitric oxide with ammonia over vanadia supported on silica-titania. Appl Catal 78:109–122

Ren Z, Hao F, Rui W (2017) A novel ring-like Fe2O3-based catalyst: tungstophosphoric acid modification, NH3-SCR activity and tolerance to H2O and SO2. Catal Commun 100:71–75

Shen B, Yao Y, Hongqing MA, Liu T (2011) Ceria modified MnOx/TiO2-pillared clays catalysts for the selective catalytic reduction of NO with NH3 at low temperature. Chin J Catal 32:1803–1811

Tao Z, Qu R, Su W, Li J (2015) A novel Ce-Ta mixed oxide catalyst for the selective catalytic reduction of NOx with NH3. Appl Catal B Environ 176-177:338–346

Wang ZM, Yamaguchi M, Goto I, Kumagai M (2000) Characterization of Ag/Al2O3 de-NOx catalysts by probing surface acidity and basicity of the supporting substrate. Phys Chem Chem Phys 2:3007–3015

Wang XT, Hu HP, Zhang XY, Su XX, Yang XD (2019) Effect of iron loading on the performance and structure of Fe/ZSM-5 catalyst for the selective catalytic reduction of NO with NH3. Environ Sci Pollut Res Int 26:1706–1715

Xie B, Luo H, Tang Q, Du J, Liu Z, Tao C (2017) The black rock series supported SCR catalyst for NOx removal. Environ Sci Pollut Res Int 24:21761–21769

Xiong Z, Lu C, Guo D, Zhang X, Han K (2013) Selective catalytic reduction of NOx with NH3 over iron-cerium mixed oxide catalyst: catalytic performance and characterization. J Chem Technol Biotechnol 88:1258–1265

Yang S, Wang C, Li J, Yan N, Ma L, Chang H (2011) Low temperature selective catalytic reduction of NO with NH3 over Mn-Fe spinel: performance, mechanism and kinetic study. Appl Catal B Environ 110:71–80

Yang S, Wang C, Chen J, Peng Y, Ma L, Chang H, Chen L, Liu C, Xu J, Li J, Yan N (2012) A novel magnetic Fe-Ti-V spinel catalyst for the selective catalytic reduction of NO with NH3 in a broad temperature range. Catalysis Science & Technology 2:915

Yang S, Liu C, Chang H, Ma L, Qu Z, Yan N, Wang C, Li J (2013) Improvement of the activity of γ-Fe2O3 for the selective catalytic reduction of NO with NH3 at high temperatures: NO reduction versus NH3 oxidization. Ind Eng Chem Res 52:5601–5610

Ye J, Xiang G, Weihong WU (2013) Effects of H2O and SO2 on the performance of V2O5/TiO2 catalysts for selective catalytic reduction of NO in flue gas. Proc CSEE 33:28–33

Zhang L, Zhang D, Zhang J, Cai S, Fang C, Huang L, Li H, Gao R, Shi L (2013) Design of meso-TiO2@MnO(x)-CeO(x)/CNTs with a core-shell structure as DeNO(x) catalysts: promotion of activity, stability and SO2-tolerance. Nanoscale 5:9821–9829

Zhang W, Shi Y, Li C, Zhao Q, Li X (2016) Synthesis of bimetallic MOFs MIL-100 (Fe-Mn) as an efficient catalyst for selective catalytic reduction of NOx with NH3. Catal Lett 146:1956–1964

Zhang C, Chen T, Liu H, Chen D, Xu B, Qing C (2018) Low temperature SCR reaction over nano-structured Fe-Mn oxides: characterization, performance, and kinetic study. Appl Surf Sci 457:1116–1125

Zhou H, Su Y, Liao W, Deng W, Zhong F (2016) NO reduction by propane over monolithic cordierite-based Fe/Al2O3 catalyst: reaction mechanism and effect of H2O/SO2. Fuel 182:352–360

Zhou X, Huang X, Xie A, Luo S, Yao C, Li X, Zuo S (2017) V2O5-decorated Mn-Fe/attapulgite catalyst with high SO2 tolerance for SCR of NOx with NH3 at low temperature. Chem Eng J

Zhu ZP, Liu ZY, Liu SJ, Niu HX, Hu TD, Liu T, Xian YN (2000) Flue gas NOx removal by SCR with NH3 on CuO/AC at low temperatures. Stud Surf Sci Catal 130:1385–1390

Zhu Z, Liu Z, Niu H, Liu S, Hu T, Liu T, Institute of Coal Chemistry, Chinese Academy of Sciences, Taihuan (2001) Mechanism of SO2 promotion for NO reduction with NH3 over activated carbon-supported vanadium oxide catalyst. J Catal 197:6–16

Zhu L, Zhong Z, Yang H, Wang C (2016) NH3-SCR performance of Mn-Fe/TiO2 catalysts at low temperature in the absence and presence of water vapor. Water Air Soil Pollut 227:476

Zi Z, Zhu B, Sun Y, Fang Q, Ge T (2019) Promotional effect of Mn modification on DeNOx performance of Fe/nickel foam catalyst at low temperature. Environ Sci Pollut Res Int 26:10117–10126

Funding

This study was financially supported by the National Natural Science Foundation of China (Nos. 41772038, 41672040, 41572029) and Anhui Provincial Natural Science Foundation (1708085MD87).

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Philippe Garrigues

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(DOC 19 kb)

Rights and permissions

About this article

Cite this article

Shu, D., Liu, H., Chen, T. et al. The positive effect of siderite-derived α-Fe2O3 during coaling on the NO behavior in the presence of NH3. Environ Sci Pollut Res 27, 12376–12385 (2020). https://doi.org/10.1007/s11356-020-07829-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-020-07829-x