Abstract

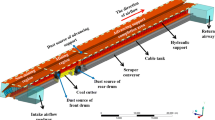

In order to investigate the diffuse pollution mechanisms of high-concentration dusts in the blasting driving face, the airflow-dust coupled model was constructed based on CFD-DEM coupled model; the diffusion rules of the dusts with different diameters at microscopic scale were analyzed in combination with the field measured results. The simulation results demonstrate that single-exhaust ventilation exhibited more favorable dust suppression performance than single-forced ventilation. Under single-exhaust ventilation condition, the motion trajectories of the dusts with the diameter smaller than 20 μm were close to the airflow streamline and these dusts were mainly distributed near the footway walls; by contrast, under single-forced ventilation condition, the motion trajectories of the dust particles with a diameter range of 20~40 μm were close to the airflow streamlines, and a large number of dusts with the diameter smaller than 20 μm accumulated in the regions 5 m and 17~25 m away from the head-on section. Moreover, under the single-exhaust ventilation, the relationship between dust diameter D and negative-pressured-induced dust emission ratio P can be expressed as P = − 25.03ln(D) + 110.39, and the dust emission ratio was up to 74.36% for 7-μm dusts, and the path-dependent settling behaviors of the dusts mainly occurred around the head-on section; under single-forced ventilation condition, the z value of the dusts with the diameter over 20 μm decreased and the dusts with a diameter smaller than 7 μm are particularly harmful to human health, but their settling ratios were below 22.36%.

The airflow-dust CFD-DEM coupling model was established. The numerical simulation results were verified. The migration laws of airflow field were obtained in a blasting driving face. The diffusion laws of dusts were obtained after blasting.

Similar content being viewed by others

References

Akbarzadeh V, Hrymak AN (2016) Coupled CFD-DEM of particle-laden flows in a turning flow with a moving wall. Comput Chem Eng 86:184–191

Akhshik S, Behzad M, Rajabi M (2015) CFD–DEM approach to investigate the effect of drill pipe rotation on cuttings transport behavior. J Pet Sci Eng 127:229–244

Amritkar A, Deb S, Tafti D (2014) Efficient parallel CFD-DEM simulations using OpenMP. Academic Press Professional, Inc, Cambridge

Chen M, Hu Y, Lu W et al (2011) Numerical simulation of blasting excavation induced damage to deep tunnel. Rock Soil Mech 32:1531–1537

Chen J, Wang Y, Jiang Z (2013) Numerical simulation of blasting dust concentration distribution and diffusion regularities in stope. J China Coal Soc 38:147–152(6)

Chen J, Wang Y, Li X et al (2015) Erosion prediction of liquid-particle two-phase flow in pipeline elbows via CFD–DEM coupling method. Powder Technol 275:182–187

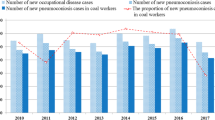

Erol I, Aydin H, Didari V, Ural S (2013) Pneumoconiosis and quartz content of respirable dusts in the coal mines in Zonguldak, Turkey. Int J Coal Geol 116–117:26–35

Fan T, Zhou G, Wang J (2018) Preparation and characterization of a wetting-agglomeration-based hybrid coal dust suppressant. Process Saf Environ Prot 113:282–291

Feng Y, Owen D (2014) Discrete element modelling of large scale particle systems—I: exact scaling laws. Comput Part Mech 1:159–168

Goldasteh I, Ahmadi G, Ferro AR (2013) Monte Carlo simulation of micron size spherical particle removal and resuspension from substrate under fluid flows. J Aerosol Sci 66:62–71

Habeeb L (2013) ANSYS 13.0 help, FLUENT theory guide

Han Q, Yang N, Zhu J, Liu M (2015) Onset velocity of circulating fluidization and particle residence time distribution: a CFD-DEM study. Particuology 21:187–195

Hertz H (1880) On the contact of elastic solids 92:

Hu S, Wang Z, Feng G (2015) Temporal and spatial distribution of respirable dust after blasting of coal roadway driving faces: a case study. Fortschr Mineral 5:679–692

Hu S, Feng G, Ren X et al (2016) Numerical study of gas–solid two-phase flow in a coal roadway after blasting. Adv Powder Technol 27:1607–1617

Ji Y, Ren T, Peter W et al (2016) A comparative study of dust control practices in Chinese and Australian longwall coal mines. Int J Min Sci Technol 26:199–208

Jiang Z, Chen M, Chen J (2013) Numerical simulation of dust concentration distribution and changing regularities in roadway stope blasting. J Cent South Univ 44:1190–1196

Kim S, Jeong W, Jeong D, Seok J (2006) Numerical simulation of blasting at tunnel contour hole in jointe rock mass. Tunn Undergr Space Technol Inc Trenchless Technol Res 21:306–307

Korevaar MW, Padding JT, Van Der Hoef MA, Kuipers JAM (2014) Integrated DEM–CFD modeling of the contact charging of pneumatically conveyed powders. Powder Technol 258:144–156

Kurnia JC et al (2014) Dust dispersion and management in underground mining faces. Int J Min Sci Technol 24:39–44

Nakayama S, Uchino K, Inoue M (1996) 3 dimensional flow measurement at heading face and application of CFD. Shigen-to-Sozai 112:638–644

Nie W, Cheng WM, Bin YY et al (2012) The research and application on whole-rock mechanized excavation face of pressure ventilation air curtain closed dust removal system. J China Coal Soc 37:1165–1170(6)

Nie W, Liu Y, Wei X, Hu X et al (2016a) Effect of suppressing dust by multi-direction whirling air curtain on fully mechanized mining face. Int J Min Sci Technol 26:629–635

Nie W, Ma X, Cheng W et al (2016b) A novel spraying/negative-pressure secondary dust suppression device used in fully mechanized mining face: a case study. Process Saf Environ Prot 103:126–135

Pandey SK, Tripathi BD, Mishra VK (2008) Dust deposition in a sub-tropical opencast coalmine area, India. J Environ Manag 86:132–138

Petrov T, Wala AM, Huang G (2014) Parametric study of airflow separation phenomenon at face area during deep cut continuous mining. Min Technol 122:208–214

Qin YP, Zhang MM, Cui LJ, Liu JY (2011) Numerical simulation of dust migration and study on dust removal modes with the forced ventilation shunt in a fully mechanized workface. J Univ Sci Technol Beijing 33:790–794

Ren YH, Qin YP (2013) Study on contraction of dust control system in continuous coal mining. Adv Mater Res 734-737:824–827

Ren T, Wang Z, Cooper G (2014) CFD modelling of ventilation and dust flow behaviour above an underground bin and the design of an innovative dust mitigation system. Tunn Undergr Space Technol 41:241–254

Sa Z, Li F, Qin B, Pan X (2012) Numerical simulation study of dust concentration distribution regularity in cavern stope. Saf Sci 50:857–860

Shao T, Yinyu HU, Wang W et al (2013) Simulation of solid suspension in a stirred tank using CFD-DEM coupled approach. Chin J Chem Eng 21:1069–1081

Toraño J, Torno S, Menéndez M, Gent M (2011) Auxiliary ventilation in mining roadways driven with roadheaders: validated CFD modelling of dust behaviour. Tunn Undergr Space Technol Inc Trenchless Technol Res 26:201–210

Tsuji Y, Tanaka T, Ishida T (1992) Lagrangian numerical simulation of plug flow of cohesionless particles in a horizontal pipe. Powder Technol 71:239–250

Wang (2011) Numerical simulation of dust distribution at a fully mechanized face under the isolation effect of an air curtain. Int J Min Sci Technol 21:65–69

Wang Z, Ren T (2013) Investigation of airflow and respirable dust flow behaviour above an underground bin. Powder Technol 250:103–114

Wang H, Wang D, Tang Y, Wang Q (2015a) Foaming agent self-suction properties of a jet-type foam preparation device used in mine dust suppression. Process Saf Environ Prot 98:231–238

Wang Y, Luo G, Geng F et al (2015b) Numerical study on dust movement and dust distribution for hybrid ventilation system in a laneway of coal mine. J Loss Prev Process Ind 36:146–157

Xie Y, Fan G, Dai J et al (2007) New respirable dust suppression systems for coal mines. Int J Min Sci Technol 17:321–325

Zheng Y, Feng C, Jing G et al (2009) A statistical analysis of coal mine accidents caused by coal dust explosions in China. J Loss Prev Process Ind 22:528–532

Zhou G, Qiu H, Zhang Q et al (2016a) Experimental investigation of coal dust wettability based on surface contact angle. J Chem 2016:1–8

Zhou G, Zhang Q, Bai R, Ni G (2016b) Characterization of coal micro-pore structure and simulation on the seepage rules of low-pressure water based on CT scanning data. Fortschr Mineral 6:78

Zhou G, Zhang Q, Bai R et al (2017) The diffusion behavior law of respirable dust at fully mechanized caving face in coal mine: CFD numerical simulation and engineering application[J]. Process Saf Environ Prot 106:117–128

Acknowledgements

This work was financially supported by State Key Program of National Natural Science of China (Grant No. U1261205), the Outstanding Youth Fund Project of Provincial Universities in Shandong Province (Grant No. ZR2017JL026), the Key Research and Development Program of Shandong Province (Grant No. 2016GSF120002), the Qingdao City Science and Technology Project (Grant No. 16-6-2-52-nsh), and Sub Project of National Key Research and Development Program (Grant No. 2017YFC0805202).

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Marcus Schulz

Rights and permissions

About this article

Cite this article

Yu, H., Cheng, W., Xie, Y. et al. Micro-scale pollution mechanism of dust diffusion in a blasting driving face based on CFD-DEM coupled model. Environ Sci Pollut Res 25, 21768–21788 (2018). https://doi.org/10.1007/s11356-018-1992-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-018-1992-4