Abstract

Background

Polymer-bonded explosives (PBX) consist of explosive crystals embedded in a polymeric binder. The properties of the crystal-binder interface of PBX strongly affect hot spot generation, which often leads to accidental detonation.

Objective

In this paper, the properties of the crystal-binder interface of polymer-bonded sugars (PBS), a known mechanical simulant of PBX, are quantified using a bilinear cohesive law.

Methods

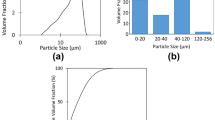

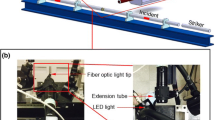

Peel tests are conducted on polydimethylsiloxane (PDMS) peel arms separating from sugar substrates. Constitutive stress-strain behavior of customized 2D columnar PBS samples was quantified with tensile testing. A semi-analytical model is developed from a composite micromechanics model modified to include properties of the interface.

Results

The analytical model is calibrated with constitutive stress-strain results to extract the bilinear cohesive law parameters. Crack propagation and strain fields around a central sugar crystal are tracked with high-magnification digital image correlation (DIC).

Conclusions

A semi-analytical approach is developed to calculate cohesive law parameters for PBS, to quantify the behavior of the crystal-binder interface.

Similar content being viewed by others

References

Bennett JG, Haberman KS, Johnson JN et al (1998) A constitutive model for the non-shock ignition and mechanical response of high explosives. JMPSo 46:2303–2322. https://doi.org/10.1016/S0022-5096(98)00011-8

Tan H, Huang Y, Liu C, Geubelle PH (2005) The Mori-Tanaka method for composite materials with nonlinear interface debonding. Int J Plast 21:1890–1918. https://doi.org/10.1016/J.IJPLAS.2004.10.001

Ravindran S, Gupta V, Tessema A, Kidane A (2019) Effect of Particle Mass Fraction on the Multiscale Dynamic Failure Behavior of Particulate Polymer Composites. Exp Mech 59:599–609. https://doi.org/10.1007/S11340-019-00493-4

Ravindran S, Kidane A (2016) Meso-scale deformation behavior of polymer bonded energetic material under quasi-static compression. Conf Proc Soc Exp Mech Ser 7:345–350. https://doi.org/10.1007/978-3-319-21762-8_40

Rae PJ, Palmer SJP, Goldrein HT et al (2002) Quasistatic studies of the deformation and failure of PBX 9501. Proc R Soc London Ser A Math Phys Eng Sci 458:2227–2242. https://doi.org/10.1098/RSPA.2002.0967

Chen P, Xie H, Huang F et al (2006) Deformation and failure of polymer bonded explosives under diametric compression test. Polym Test 25:333–341. https://doi.org/10.1016/J.POLYMERTESTING.2005.12.006

Hu Z, Luo H, Bardenhagen SG et al (2015) Internal Deformation Measurement of Polymer Bonded Sugar in Compression by Digital Volume Correlation of In-situ Tomography. Exp Mech 55:289–300. https://doi.org/10.1007/S11340-014-9856-4

Ravindran S, Tessema A, Kidane A (2016) Local Deformation and Failure Mechanisms of Polymer Bonded Energetic Materials Subjected to High Strain Rate Loading. J Dyn Behav Mater 2:146–156. https://doi.org/10.1007/S40870-016-0051-9

Gray GTI, Idar DJ, Blumenthal WR, et al (1998) High- and low-strain rate compression properties of several energetic material composites as a function of strain rate and temperature. 11 detonation symposium, Snowmass, CO (United States), 31 Aug - 4 Sep 1998

Yeager JD, Ramos KJ, Singh S et al (2013) Nanoindentation of explosive polymer composites to simulate deformation and failure. Mater Sci Technol 28:1147–1155. https://doi.org/10.1179/1743284712Y.0000000011

Chen MW, You S, Suslick KS, Dlott DD (2014) Hot spots in energetic materials generated by infrared and ultrasound, detected by thermal imaging microscopy. Rev Sci Instrum 85:023705. https://doi.org/10.1063/1.4864197

Todd SN, Caipen TL, Anderson MU, Lee BD (2012) Modeling Damage Induced Initiation of Explosives. Exp Mech 52:145–151. https://doi.org/10.1007/S11340-011-9533-9

Field JE (1992) Hot-spot ignition mechanisms for explosives and propellants. Philos Trans R Soc London Ser A Phys Eng Sci 339:269–283. https://doi.org/10.1098/rsta.1992.0034

Mares JO, Miller JK, Sharp ND et al (2013) Thermal and mechanical response of PBX 9501 under contact excitation. J Appl Phys 113:084904. https://doi.org/10.1063/1.4793495

Mares JO, Miller JK, Gunduz IE et al (2014) Heat generation in an elastic binder system with embedded discrete energetic particles due to high-frequency, periodic mechanical excitation. J Appl Phys 116:204902. https://doi.org/10.1063/1.4902848

Roberts ZA, Wickham JA, Sorensen CJ et al (2019) Mesoscale observations of the thermal decomposition of energetic composites under ultrasonic excitation. J Appl Phys 125:215114. https://doi.org/10.1063/1.5088153

Miller JK, Woods DC, Rhoads JF (2014) Thermal and mechanical response of particulate composite plates under inertial excitation. J Appl Phys 116:244904. https://doi.org/10.1063/1.4904439

Idar DJ, Lucht RA, Straight JW et al (1998) Low amplitude insult project: PBX 9501 high explosive violent reaction experiments. Los Alamos National Lab. https://doi.org/10.2172/334327

Barua A, Zhou M (2012) by Zhou A Barua CM, Zhou M (2012) Computational analysis of temperature rises in microstructures of HMX-Estane PBXs. Comput Mech 52:151–159. https://doi.org/10.1007/S00466-012-0803-X

Barua A, Zhou M (2012) Heating in microstructures of HMX/Estane PBX during dynamic deformation. AIP Conf Proc 1426:1475. https://doi.org/10.1063/1.3686561

Wu YQ, Huang FL (2010) A thermal-mechanical constitutive model for b-HMX single crystal and cohesive interface under dynamic high pressure loading. Sci China Phys Mech Astron 53:218–226. https://doi.org/10.1007/S11433-009-0264-1

Barua A, Zhou M (2011) A Lagrangian framework for analyzing microstructural level response of polymer-bonded explosives. Model Simul Mat Sci Eng 19:055001. https://doi.org/10.1088/0965-0393/19/5/055001

Barua A, Kim S, Horie Y, Zhou M (2013) Ignition criterion for heterogeneous energetic materials based on hotspot size-temperature threshold. J Appl Phys 113:064906. https://doi.org/10.1063/1.4792001

Xu XP, Needleman A (1993) Void nucleation by inclusion debonding in a crystal matrix. Model Simul Mat Sci Eng 1:111. https://doi.org/10.1088/0965-0393/1/2/001

Geubelle PH, Baylor JS (1998) Impact-induced delamination of composites: a 2D simulation. Compos B Eng 29:589–602. https://doi.org/10.1016/S1359-8368(98)00013-4

Benveniste Y (1985) The effective mechanical behaviour of composite materials with imperfect contact between the constituents. Mech Mater 4:197–208. https://doi.org/10.1016/0167-6636(85)90016-X

Tan H, Liu C, Huang Y, Geubelle P (2005) The cohesive law for the particle/matrix interfaces in high explosives. J Mech Phys Solids 53:1892–1917. https://doi.org/10.1016/j.jmps.2005.01.009

Prakash C, Olokun A, Emre Gunduz I, Tomar V (2019) Interface Mechanical Properties in Energetic Materials Using Nanoscale Impact Experiment and Nanomechanical Raman Spectroscopy. Energy, Environment, and Sustainability. Springer, Singapore, pp 275–290. https://doi.org/10.1007/978-981-13-3269-2_13

Tan H, Huang Y, Liu C (2008) The viscoelastic composite with interface debonding. Compos Sci Technol 68:3145–3149. https://doi.org/10.1016/J.COMPSCITECH.2008.07.014

Benveniste Y (1987) A new approach to the application of Mori-Tanaka’s theory in composite materials. Mech Mater 6:147–157. https://doi.org/10.1016/0167-6636(87)90005-6

Mori T, Tanaka K (1973) Average stress in matrix and average elastic energy of materials with misfitting inclusions. Acta Metall 21:571–574. https://doi.org/10.1016/0001-6160(73)90064-3

Tan H, Huang Y, Liu C et al (2007) Constitutive behaviors of composites with interface debonding: the extended Mori-Tanaka method for uniaxial tension. Int J Fract 146:139–148. https://doi.org/10.1007/S10704-007-9155-5

Timoshenko SP, Goodier JN (1970) Theory of elasticity, 3rd edn. McGraw-Hill, New York

Tsuda T, Ogasawara T, Deng F, Takeda N (2011) Direct measurements of interfacial shear strength of multi-walled carbon nanotube/PEEK composite using a nano-pullout method. Compos Sci Technol 71:1295–1300. https://doi.org/10.1016/J.COMPSCITECH.2011.04.014

Hamilton NR, Williamson DM, Lewis D et al (2017) Adhesive measurements of polymer bonded explosive constituents using the JKR experimental technique with a viscoelastic contact description. AIP Conf Proc 1793:120026. https://doi.org/10.1063/1.4971708

Yoon T, Shin WC, Kim TY et al (2012) Direct measurement of adhesion energy of monolayer graphene as-grown on copper and its application to renewable transfer process. Nano Lett 12:1448–1452. https://doi.org/10.1021/NL204123H

Liechti KM (2019) Characterizing the Interfacial Behavior of 2D Materials: a Review. Exp Mech 59:395–412. https://doi.org/10.1007/S11340-019-00475-6

Tanaka K, Stossel M, Jiang H et al (2022) Engineering the Interface: Effects of Interfacial Adhesion and Substrate Thickness on the Ductility of Polymer-supported Metal Films. Exp Mech 62:49–58. https://doi.org/10.1007/S11340-021-00759-W

Bhavanam S, Karanjgaokar N (2020) Development of miniaturized peel experiments to quantify interfacial adhesion between 2D monolayers and viscoelastic polymers. J Adhes 97:1509–1531. https://doi.org/10.1080/00218464.2020.1796654

Gohl JA, Thiele-Sardina TC, Rencheck ML et al (2021) A Modular Peel Fixture for Tape Peel Tests on Immovable Substrates. Exp Mech 61:1209–1213. https://doi.org/10.1007/S11340-021-00738-1

Huang PY, Liu C, Guo ZS, Feng JM (2021) Analytical Model and Experimental Verification of the Interfacial Peeling Strength of Electrodes. Exp Mech 61:321–330. https://doi.org/10.1007/S11340-020-00651-Z

Kendall K (1975) Thin-film peeling-the elastic term. J Phys D Appl Phys 8:1449

Kovalchick C, Xia S, Ravichandran G (2013) Cohesive zone law extraction from an experimental peel test. Conf Proc Soc Exp Mech Ser 4:237–245. https://doi.org/10.1007/978-1-4614-4226-4_28

Jonnalagadda K, Karanjgaokar N, Chasiotis I et al (2010) Strain rate sensitivity of nanocrystalline Au films at room temperature. Acta Mater 58:4674–4684. https://doi.org/10.1016/J.ACTAMAT.2010.04.048

Karanjgaokar NJ, Oh CS, Chasiotis I (2011) Microscale Experiments at Elevated Temperatures Evaluated with Digital Image Correlation. Exp Mech 51:609–618. https://doi.org/10.1007/S11340-010-9439-Y

Schreier HW, Garcia D, Sutton MA (2004) Advances in light microscope stereo vision. Exp Mech 44:278–288. https://doi.org/10.1007/BF02427894

Sutton MA, Li N, Joy DC et al (2007) Scanning electron microscopy for quantitative small and large deformation measurements Part I: SEM imaging at magnifications from 200 to 10,000. Exp Mech 47:775–787. https://doi.org/10.1007/S11340-007-9042-Z

Sutton MA, Li N, Garcia D et al (2007) Scanning electron microscopy for quantitative small and large deformation measurements Part II: Experimental validation for magnifications from 200 to 10,000. Exp Mech 47:789–804. https://doi.org/10.1007/S11340-007-9041-0

Kammers AD, Daly S (2013) Digital Image Correlation under Scanning Electron Microscopy: Methodology and Validation. Exp Mech 53:1743–1761. https://doi.org/10.1007/S11340-013-9782-X

Schreier HW, Braasch JR, Sutton MA (2000) Systematic errors in digital image correlation caused by intensity interpolation. Opt Eng 39:2915–2921. https://doi.org/10.1117/1.1314593

Mello AW, Book TA, Nicolas A et al (2017) Distortion Correction Protocol for Digital Image Correlation after Scanning Electron Microscopy: Emphasis on Long Duration and Ex-Situ Experiments. Exp Mech 57:1395–1409. https://doi.org/10.1007/S11340-017-0303-1

Acknowledgements

The financial support for this work granted by the Worcester Polytechnic Institute faculty startup fund is greatly acknowledged. The authors would like to thank Hrachya Kocharyan and the WPI machine shop for their help with specimen fabrication and data analysis.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors have no competing interests to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kodali, M., Bharadwaj, P., Bhavanam, S. et al. Semi-Analytical Approach to Determine Interfacial Adhesion in Polymer-Bonded Explosives. Exp Mech 63, 237–250 (2023). https://doi.org/10.1007/s11340-022-00913-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-022-00913-y