Abstract

Background

The ability to non-destructively map the residual strain field inside an engineering component is important for predicting its fatigue life or developing processing methods to prevent failure or enhance performance.

Objective

In this paper, we describe a new residual strain mapping program at the Advanced Photon Source, Argonne National Laboratory.

Methods

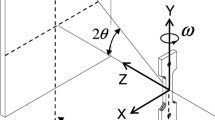

The new program is based on energy dispersive x-ray diffraction (EDXRD). It is capable of non-destructively penetrating a several-cm thick polycrystalline sample fabricated from engineering alloys using high-energy x-rays and measuring the residual strain field with mm or better spatial resolution and approximately \(\pm 1 \times 10^{-4}\) strain resolution. A multi-element detector array is employed to measure multiple strain components simultaneously. The residual strain mapping setup is augmented with a high-energy tomography capability, allowing precise alignment of the material volume of interest for residual strain mapping and providing a complementary view of the structure to understand the measured strain field.

Results

These measurement capabilities are demonstrated using several strain mapping examples ranging from polycrystalline structural alloys to biological materials. We also provide some guidance for the future users of the program for a successful residual strain mapping experiment.

Conclusions

We are expanding the capabilities of the new setup with various in situ capabilities including thermo-mechanical loading.

Similar content being viewed by others

Notes

More detailed information is available in Appendix

More detailed information is available in Appendix

For larger samples, \({X}_{L}\) and \({Z}_{L}\) translations can also be used for strain mapping.

Pseudo-strain is the deviation of plane spacing from its reference value normalized by the reference value.

This is a calibrated energy based on an absorption edge of Rhenium.

Only the radial component of strain measured in Region-I is shown for brevity. The maps for other strain components and Region-II also follow the anticipated residual strain field imparted by the sample geometry.

Matlab smoothdata with Gaussian filter was employed on the raw strain field data to reduce the noise and highlight the trends better.

Here, we only show the two detectors nominally placed orthogonal to each other for brevity.

For the experimental data presented in Fig. 15, analysis is ongoing and the full result will be presented in the near future through a separate publication.

References

Dowling NE (1999) Mechanical behavior of materials. Prentice Hall, Englewood Cliffs, N.J. https://www.pearson.com/us/higher-education/product/Dowling-Mechanical-Behavior-of-Materials-4th-Edition/9780131395060.html?tab=overview

Frost NE, Marsh KJ, Pook LP (1999) Metal fatigue. Dover, Mineola, NY

Suresh SS (2013) Fatigue of materials, vol 08. Cambridge University Press, Cambridge. pp 29–4547294547. https://doi.org/10.5860/choice.29-4547. http://ebooks.cambridge.org/ref/id/CBO9780511806575

Krupp U (2007) Fatigue crack propagation in metals and alloys. Wiley, New York, NY. https://doi.org/10.1002/9783527610686. https://onlinelibrary.wiley.com/doi/book/10.1002/9783527610686

Dölle H (2002) The influence of multiaxial stress states, stress gradients and elastic anisotropy on the evaluation of (residual) stresses by x-rays. J Appl Crystallogr 12(6):489–501. https://doi.org/10.1107/s0021889879013169

Hauk V (1997) Structural and residual stress analysis by nondestructive methods, 1st edn. Elsevier, Amsterdam, Netherlands. https://doi.org/10.1016/B978-0-444-82476-9.X5000-2. https://linkinghub.elsevier.com/retrieve/pii/B9780444824769500220. https://linkinghub.elsevier.com/retrieve/pii/B9780444824769X50002

Fitzpatrick ME, Lodini A (eds) (2003) Analysis of residual stress by diffraction using neutron and synchrotron radiation. Taylor and Francis, London, UK

Allen AJ, Hutchings MT, Windsor CG, Andreani C (1985) Neutron diffraction methods for the study of residual stress fields. Adv Phys 34(4):445–473. https://doi.org/10.1080/00018738500101791

Schajer GS (2013) Practical residual stress measurement methods. John Wiley and Sons, Ltd, New York, NY, pp 1–310. https://doi.org/10.1002/9781118402832. http://onlinelibrary.wiley.com/book/10.1002/9781118402832

Schneider LCR, Hainsworth SV, Cocks ACF, Fitzpatrick ME (2005) Neutron diffraction measurements of residual stress in a powder metallurgy component. Scripta Mater 52(9):917–921. https://doi.org/10.1016/J.SCRIPTAMAT.2004.12.030

Krawitz AD (2011) Neutron strain measurement. Mater Sci Technol 27(3):589–603. https://doi.org/10.1179/1743284710y.0000000029

Krawitz AD (2001) Introduction to diffraction in materials science and engineering. Wiley-Interscience, New York, NY, p 424

Croft M, Zakharchenko I, Zhong Z, Gurlak Y, Hastings J, Hu J, Holtz R, Dasilva M, Tsakalakos T (2002) Strain field and scattered intensity profiling with energy dispersive x-ray scattering. J Appl Phys 92(1):578–586. https://doi.org/10.1063/1.1483373

Steuwer A, Santisteban JR, Turski M, Withers PJ, Buslaps T (2004) High-resolution strain mapping in bulk samples using full-profile analysis of energy-dispersive synchrotron x-ray diffraction data. urn:issn:0021-8898 37(6):883–889. https://doi.org/10.1107/S0021889804023349

Zolotoyabko E, Pokroy B, Quintana JP (2004) Depth-resolved strain measurements in polycrystalline materials by energy-variable x-ray diffraction. J Synchrotron Radiat 11(4):309–313. https://doi.org/10.1107/S0909049504007460

Genzel C, Denks IA, Coelho R, Thomas D, Mainz R, Apel D, Klaus M (2011) Exploiting the features of energy-dispersive synchrotron diffraction for advanced residual stress and texture analysis. J Strain Anal Eng Des 46(7):615–625. https://doi.org/10.1177/0309324711403824

Chuang AC, Park J-S, Shade PA, Schwalbach EJ, Groeber MA, Musinski WD (2021) AFRL additive manufacturing modeling series: Challenge 1, characterization of residual strain distribution in additively-manufactured metal parts using energy-dispersive diffraction. Integr Mater Manuf Innov 2021:1–17. https://doi.org/10.1007/S40192-021-00233-4

Helliwell JR (1998) Synchrotron radiation facilities. Nat Struct Biol 5(8):614–617. https://doi.org/10.1038/1307

Croft M, Jisrawi N, Zhong Z, Horvath K, Holtz RL, Shepard M, Lakshmipathy M, Sadananda K, Skaritka J, Shukla V, Sadangi RK, Tsakalakos T (2008) Stress gradient induced strain localization in metals: high resolution strain cross sectioning via synchrotron X-Ray diffraction. Journal of Engineering Materials and Technology, Transactions of the ASME 130(2):0210051–02100510. https://doi.org/10.1115/1.2840962

Croft M, Shukla V, Akdogan EK, Jisrawi N, Zhong Z, Sadangi R, Ignatov A, Balarinni L, Horvath K, Tsakalakos T (2009) In situ strain profiling of elastoplastic bending in Ti-6Al-4V alloy by synchrotron energy dispersive x-ray diffraction. J Appl Phys 105(9). https://doi.org/10.1063/1.3122029

Rowles MR (2011) On the calculation of the gauge volume size for energy-dispersive X-ray diffraction. urn:issn:0909-0495 18(6):938–941. https://doi.org/10.1107/S0909049511033267

Marschilok AC, Bruck AM, Abraham A, Stackhouse CA, Takeuchi KJ, Takeuchi ES, Croft M, Gallaway JW (2020) Energy dispersive X-ray diffraction (EDXRD) for operando materials characterization within batteries. Phys Chem Chem Phys 22(37):20972–20989. https://doi.org/10.1039/D0CP00778A

Bruck AM, Li YR, Brady AB, Chuang AC, Okasinski JS, Takeuchi KJ, Takeuchi ES, Marschilok AC (2019) Tomographic 3D analysis of reduction displacement reaction with associated formation of a conductive network in high energy primary batteries. J Electrochem Soc 166(14):3210–3216. https://doi.org/10.1149/2.0411914JES/XML

Mach JC, Budrow CJ, Pagan DC, Ruff JPC, Park J-S, Okasinski J, Beaudoin AJ, Miller MP (2017) Validating a model for welding induced residual stress using high-energy x-ray diffraction. JOM 69(5):893–899. https://doi.org/10.1007/s11837-017-2298-6

Weidner DJ, Vaughan MT, Wang L, Long H, Li L, Dixon NA, Durham WB (2010) Precise stress measurements with white synchrotron x rays. Rev Sci Instrum 81(1):013903. https://doi.org/10.1063/1.3263760

Kaiser DL, Watters JRL (2007) National institute of standards & technology standard reference material674b x-ray powder diffraction intensity set for quantitative analysis by x-ray powder diffraction

Stock SR, Morse PE, Stock MK, James KC, Natanson LJ, Chen H, Shevchenko PV, Maxey ER, Antipova O, Park JS (2021) 3D tomography of shark vertebrae via energy dispersive diffraction. 11840(9):97. https://doi.org/10.1117/12.2595040

Chatterjee K, Venkataraman A, Garbaciak T, Rotella J, Sangid MD, Beaudoin AJ, Kenesei P, Park J-S, Pilchak AL (2016) Study of grain-level deformation and residual stresses in ti-7Al under combined bending and tension using high energy diffraction microscopy (HEDM). Int J Solids Struct 94–95:35–49. https://doi.org/10.1016/j.ijsolstr.2016.05.010

Turner TJ, Shade PA, Bernier JV, Li SF, Schuren JC, Kenesei P, Suter RM, Almer J (2017) Crystal plasticity model validation using combined high-energy diffraction microscopy data for a ti-7Aal specimen. Metall Mater Trans A 48(2):627–647. https://doi.org/10.1007/s11661-016-3868-x

Sangid MD, Rotella J, Naragani D, Park J-S, Kenesei P, Shade PA (2020) A complete grain-level assessment of the stress-strain evolution and associated deformation response in polycrystalline alloys. Acta Mater 201:36–54. https://doi.org/10.1016/j.actamat.2020.09.051

Webster PJ, Mills G, Wang XD, Kang WP, Holden TM (1996) Impediments to efficient through-surface strain scanning. J Neutron Res 3(4):223–240. https://doi.org/10.1080/10238169608200197

Taran YV, Balagurov AM (2012) Correction of a neutron diffraction peak shift due to a partial immersion of a gauge volume in an unstressed sample. Nucl Instrum Methods Phys Res, Sect A 679:19–24. https://doi.org/10.1016/J.NIMA.2012.03.009

Fitzpatrick ME, Fry AT, Holloway P, Khandil FA, Shackleton J, Suominen L (2005) A national measurement good practice guide, no. 52: Determination of residual stresses by x-ray diffraction. Technical report, National Physical Laboratory

Park JS, Lienert U, Dawson PR, Miller MP (2013) Quantifying three-dimensional residual stress distributions using spatially-resolved diffraction measurements and finite element based data reduction. Exp Mech 53(9):1491–1507. https://doi.org/10.1007/s11340-013-9771-0

Park JS, Ray AK, Dawson PR, Lienert U, Miller MP (2016) Determination of residual stress in a microtextured \(\alpha\) titanium component using high-energy synchrotron x-rays. J Strain Anal Eng Des 51(5):358–374. https://doi.org/10.1177/0309324716640419

Shastri SD, Fezzaa K, Mashayekhi A, Lee W-K, Fernandez PB, Lee PL (2002) Cryogenically cooled bent double-Laue monochromator for high-energy undulator x-rays (50–200 keV). J Synchrotron Radiat 9(5):317–322. https://doi.org/10.1107/S0909049502009986

Lee JH, Almer J, Ayd\(\iota\)ner C, Bernier J, Chapman K, Chupas P, Haeffner D, Kump K, Lee PL, Lienert U, Miceli A, Vera G (2007) Characterization and application of a GE amorphous silicon flat panel detector in a synchrotron light source. Nuclear Instruments and Methods in Physics Research Section A: Accelerators, Spectrometers, Detectors and Associated Equipment 582(1):182–184. https://doi.org/10.1016/j.nima.2007.08.103

Zhang X, Li M, Park J-S, Kenesei P, Almer J, Xu C, Stubbins JF (2017) In situ high-energy x-ray diffraction study of tensile deformation of neutron-irradiated polycrystalline Fe-9CR alloy. Acta Mater 126:67–76. https://doi.org/10.1016/j.actamat.2016.12.038

Stock SR, De Carlo F, Almer JD (2008) High energy x-ray scattering tomography applied to bone. J Struct Biol 161(2):144–150. https://doi.org/10.1016/j.jsb.2007.10.001

Bleuet P, Welcomme E, Dooryhée E, Susini J, Hodeau JL, Walter P (2008) Probing the structure of heterogeneous diluted materials by diffraction tomography. Nat Mater 7(6):468–72. https://doi.org/10.1038/nmat2168

Birkbak ME, Leemreize H, Frølich S, Stock SR, Birkedal H (2015) Diffraction scattering computed tomography: a window into the structures of complex nanomaterials. Nanoscale 7(44):18402–18410. https://doi.org/10.1039/C5NR04385A

Zhu Z, Katsevich A, Kapadia AJ, Greenberg JA, Pang S (2018) X-ray diffraction tomography with limited projection information. Sci Rep 2018 8:1 8(1):1–6. https://doi.org/10.1038/s41598-017-19089-w

Martins RV, Ohms C, Decroos K (2010) Full 3D spatially resolved mapping of residual strain in a 316L austenitic stainless steel weld specimen. Mater Sci Eng A 527(18–19):4779–4787. https://doi.org/10.1016/j.msea.2010.03.110

Morse PE, Stock MK, James KC, Natanson LJ, Stock SR (2022) Shark centra microanatomy and mineral density variation studied with laboratory microcomputed tomography. J Struct Biol in press

Stock SR, Morse PE, Stock MK, James KC, Natanson LJ, Chen H, Shevchenko PV, Maxey ER, Antipova O, Park J-S (2021) Microstructure and energy dispersive diffraction reconstruction of 3D patterns of crystallographic texture in shark centrum. Proceedings Volume 11840, Developments in X-Ray Tomography XIII 11840(9):104–115. https://doi.org/10.1117/12.2595040

Stock SR, Morse PE, Stock MK, James KC, Natanson LJ, Chen H, Shevchenko PD, Maxey ER, Antipova OA, Park J-S (2022) Microstructure and energy dispersive diffraction reconstruction of 3D patterns of crystallographic texture in a shark centrum. 9(3):031504. https://doi.org/10.1117/1.JMI.9.3.031504

Park J-S, Chen H, James KC, Natanson LJ, Stock SR (2022) Three-dimensional mapping of mineral in intact shark centra with energy dispersive x-ray diffraction. J Mech Behav Biol Mater. Revision under review

Yao KPC, Okasinski JS, Kalaga K, Shkrob IA, Abraham DP (2019) Quantifying lithium concentration gradients in the graphite electrode of Li-ion cells using operando energy dispersive x-ray diffraction. Energy Environ Sci 12(2):656–665. https://doi.org/10.1039/C8EE02373E

Raj A, Shkrob IA, Okasinski JS, Fonseca Rodrigues M-T, Chuang AC, Huang X, Abraham DP (2021) Spatially-resolved lithiation dynamics from operando x-ray diffraction and electrochemical modeling of lithium-ion cells. J Power Sources 484:229247. https://doi.org/10.1016/j.jpowsour.2020.229247

Hubbell JH, Seltzer SM (2004) X-Ray mass attenuation coefficients - NIST. https://doi.org/10.18434/T4D01F. https://www.nist.gov/pml/x-ray-mass-attenuation-coefficients. Accessed 2022-04-05

Bandyopadhyay R, Rotella J, Naragani D, Park J-S, Eff M, Sangid MD (2019) Residual strain analysis in linear friction welds of similar and dissimilar titanium alloys using energy dispersive x-ray diffraction. Metall Mater Trans A 50(2):704–718

Waddell M, Walker K, Bandyopadhyay R, Kapoor K, Mallory A, Xiao X, Chuang AC, Liu Q, Phan N, Sangid MD (2020) Small fatigue crack growth behavior of Ti-6Al-4V produced via selective laser melting: in situ characterization of a 3D crack tip interactions with defects. Int J Fatigue 137:105638. https://doi.org/10.1016/J.IJFATIGUE.2020.105638

Park J-S, Chen H, James KC, Natanson LJ, Stock SR Three-dimensional mapping of mineral in intact shark centra with energy dispersive xray diffraction. J Mech Behav Biomed Mater

Apel D, Klaus M, Genzel C, Balzar D (2011) Rietveld refinement of energy-dispersive synchrotron measurements. Zeitschrift fur Kristallographie 226(12):934–943. https://doi.org/10.1524/ZKRI.2011.1436/MACHINEREADABLECITATION/RIS

Apel D, Genzel M, Meixner M, Boin M, Klaus M, Genzel C (2020) Eddidat: a graphical user interface for the analysis of energy-dispersive diffraction data. urn:issn:1600-5767 53(4):1130–1137. https://doi.org/10.1107/S1600576720005506

Acknowledgements

This research used resources of the Advanced Photon Source, a U.S. Department of Energy (DOE) Office of Science User Facility at Argonne National Laboratory and is based on research supported by the U.S. DOE Office of Science-Basic Energy Sciences, under Contract No. DE-AC02-06CH11357. The authors acknowledge Ali Mashayekhi and Roger Ranay of the APS for their assistance in setting up the EDXRD program at the APS 6-BM beamline. Beamline 6BM-B, APS, is supported by COMPRES, the Consortium for Materials Properties Research in Earth Sciences under NSF Cooperative Agreement EAR-1661511. JSP acknowledges discussions with Basil Blank of PulseRay Inc., NY for the development of the interference fit sample.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of Interest

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

Supplementary Information for 6-BM-A and 6-BM-B

In Fig. 2, Slit-0 is the white beam mask. Slit-1 and Slit-2 define the incident beam size in the \({X}_{L}-{Y}_{L}\) plane. Slit-3 and Slit-4 define the vertical aperture for the detector placed in the \({Y}_{L}-{Z}_{L}\) plane (vertical detector) and collimate the diffracted beam emanating from the GV at \({O}_{L}\). Similarly, Slit-5 and Slit-6 define horizontal aperture for the detector placed in the \({X}_{L}-{Z}_{L}\) plane (horizontal detector). Table 1 summarizes the approximate distances of these setup components. Table 2 summarizes the approximate distances of the major components in the 6-BM-B hutch.

Table 3 shows the specifications of the 6-BM-A radiography system. It is an APS in-house developed detector using high-energy x-ray scintillator and a CMOS detector. The maximum beam size at 6-BM available for radiography or tomography is 4.4 mm (H) x 1.5 mm (V).

Rights and permissions

About this article

Cite this article

Park, JS., Chuang, A., Okasinski, J. et al. A New Residual Strain Mapping Program Using Energy Dispersive X-Ray Diffraction at the Advanced Photon Source. Exp Mech 62, 1363–1379 (2022). https://doi.org/10.1007/s11340-022-00859-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-022-00859-1