Abstract

Background

Residual stress spatial mapping has been developed using various measurement methods, one such method comprising a multiplicity of one-dimensional slitting method measurements combined to form a two-dimensional (2D) map. However, an open question is how to best distribute the individual slitting measurements for 2D mapping.

Objective

This paper investigates the efficacy of different strategies for laying out the individual slitting measurements when mapping in-plane residual stress in thin stainless steel slices removed from a larger dissimilar metal weld.

Methods

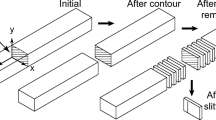

Three different measurement layouts are assessed: independent measurements on nominally identical specimens (i.e., one slitting measurement per specimen, with many specimens), repeatedly bisecting a single slice, and making nominally sequential measurements from one side of the specimen towards the other side of the specimen. Additional comparison measurements are made using neutron diffraction.

Results

The work shows little difference between the independent and bisecting slitting measurement layouts, and some differences with the sequential measurements. There is good general agreement between neutron diffraction measurement data and the data from the independent and bisecting layouts.

Conclusions

This work suggests that when using slitting to create a 2D map of in-plane residual stress, a cutting layout that repeatedly bisects the specimen works well, requires a small number of specimens, and avoids potential errors from geometric asymmetry or measurement sequence.

Similar content being viewed by others

References

Stuart DH (2010) Evaluation of linear elastic fracture mechanics predictions of one and two-dimensional fatigue crack growth at cold-expanded holes [University of California, Davis]. All Papers/S/Stuart 2010 - evaluation of linear elastic fracture mechanics predictions of one and two-dimensional fatigue crack growth at cold-expanded holes.pdf

Cuellar SD, Hill MR, DeWald AT, Rankin JE (2012) Residual stress and fatigue life in laser shock peened open hole samples. Int J Fatigue 44:8–13. https://doi.org/10.1016/j.ijfatigue.2012.06.011

Webster GA, Ezeilo AN (2001) Residual stress distributions and their influence on fatigue lifetimes. Int J Fatigue 23, Supple, 375–383. https://doi.org/10.1016/S0142-1123(01)00133-5

Yaghi A, Ayvar-Soberanis S, Moturu S, Bilkhu R, Afazov S (2019) Design against distortion for additive manufacturing. Addit Manuf 27:224–235. https://doi.org/10.1016/j.addma.2019.03.010

Li J-G, Wang S-Q (2016) Distortion caused by residual stresses in machining aeronautical aluminum alloy parts: recent advances. The International Journal of Advanced Manufacturing Technology 89:997–1012. https://doi.org/10.1007/s00170-016-9066-6

Prime MB (2013) The Contour Method. Chapter 5. In: Schajer GS (ed 1) Practical Residual Stress Measurement Methods. John Wiley & Sons, West Sussex, UK, pp 109-221. https://doi.org/10.1002/9781118402832.ch5

Pagliaro P, Prime MB, Robinson JS, Clausen B, Swenson H, Steinzig M, Zuccarello B (2011) Measuring Inaccessible Residual Stresses Using Multiple Methods and Superposition. Exp Mech 51(7):1123–1134. https://doi.org/10.1007/s11340-010-9424-5

Olson MD, Hill MR (2015) A New Mechanical Method for Biaxial Residual Stress Mapping. Exp Mech 55(6):1139–1150. https://doi.org/10.1007/s11340-015-0013-5

Olson MD, Spradlin TJ, DeWald AT, Hill MR (2018) Multi-Technique residual stress measurements to quantify stress relief of 7085-T7452 aluminum die forgings. Materials Performance and Characterization 7(4):862-885. https://doi.org/10.1520/MPC20170105

Hill MR, Olson MD, DeWald AT (2016) Biaxial Residual Stress Mapping for a Dissimilar Metal Welded Nozzle. J Pressure Vessel Technol 138(1):11404. https://doi.org/10.1115/1.4031504

Olson MD, Robinson JS, Wimpory RC, Hill MR (2016) Characteriation of residual stresses in heat treated, high strength aluminium alloy extrusions. Mater Sci Technol 32(14):1427-1438. https://doi.org/10.1080/02670836.2016.1164973

Olson MD, DeWald AT, Hill MR (2018) Assessment of Primary Slice Release Residual Stress Mapping in a Range of Specimen Types. Exp Mech. 58(9): 1371-1388. https://doi.org/10.1007/s11340-018-0420-5

Olson MD, Hill MR (2018) Two-Dimensional Mapping of In-plane Residual Stress with Slitting. Exp Mech 58(1):151–166. https://doi.org/10.1007/s11340-017-0330-y

Salehi SD, Shokrieh MM (2019) Repeated slitting safe distance in the measurement of residual stresses. Int J Mech Sci 157:599–608. https://doi.org/10.1016/j.ijmecsci.2019.05.010

Schajer GS, Prime MB (2006) Use of Inverse Solutions for Residual Stress Measurements. J Eng Mater Technol 128(3):375–382 https://doi.org/10.1115/1.2204952

Hill MR (2013) The Slitting Method. Chapter 4. In: Schajer GS (ed 1) Practical Residual Stress Measurement Methods. John Wiley & Sons, West Sussex, UK, pp 89–108. https://doi.org/10.1002/9781118402832.ch4

Prime MB (2003) Experimental procedure for crack compliance (Slitting) measurements of residual stress. Los Alamos National Laborary Report (LA-UR-03–8629). https://www.lanl.gov/residual/testing.pdf

Schajer GS, Prime MB (2006) Use of Inverse Solutions for Residual Stress Measurements. J Eng Mater Technol 128:375-382. https://doi.org/10.1115/1.2204952

Aydıner C, Prime MB (2013) Three-Dimensional Constraint Effects on the Slitting Method for Measuring Residual Stress. J Eng Mater Technol 135(3):31006. https://doi.org/10.1115/1.4023849

Olson MD, Dewald AT, Hill MR (2019) An uncertainty estimator for slitting method residual stress measurements including the influence of regularization. Exp Mech 60(1):65-79. https://doi.org/10.1007/s11340-019-00535-x

ISO (2005) Non-destructive testing - Standard test method for determining residual stresses by neutron diffraction. International Organization for Standardization, ISO/TS 21432

Olson MD, Hill MR, Clausen B, Steinzig M, Holden TM (2015) Residual Stress Measurements in Dissimilar Weld Metal. Experimental Mechanics 55(6): 1093–1103. https://doi.org/10.1007/s11340-015-0010-8

Coleman HW, Steele WG (2009) in Experimentation, Validation, and Uncertainty Analysis for Engineers, 3rd edn. John Wiley & Sons Inc, Hoboken, New Jersey. pp 61-83. https://doi.org/10.1002/9780470485682

Acknowledgements

A portion of this research was performed at ORNL’s High-Flux Isotope Reactor and sponsored by the Scientific User Facilities Division, Office of Basic Energy Sciences, US Department of Energy. The authors acknowledge the help of two Electric Power Research Institute programs in provisioning the plate used in this study, with funding from the Materials Reliability Program (Paul Crooker, Principal Technical Leader) and design and fabrication support from the Welding Research and Technology Center.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethical Statement/Conflict of Interest

The authors have no conflicts of interest to disclose and did not involve human or animal participants nor was informed consent applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Olson, M.D., DeWald, A.T. & Hill, M.R. Measurement Layout for Residual Stress Mapping Using Slitting. Exp Mech 62, 393–402 (2022). https://doi.org/10.1007/s11340-021-00791-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-021-00791-w