Abstract

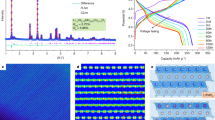

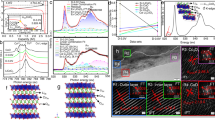

Mechanical degradation of Li-ion batteries caused by the repetitive swelling and shrinking of electrodes upon electrochemical cycles is now well recognized. Structural disintegration of the state-of-art cathode materials of a hierarchical structure is relatively less studied. We track the microstructural evolution of different marked regimes in LiNi x Mn y Co z O2 (NMC) electrodes after lithiation cycles. Decohesion of primary particles constitutes the major mechanical degradation in the NMC materials, which results in the loss of connectivity of the conductive network and impedance increase. We find that the structural disintegration is largely dependent on the charging rate – slow charging causes more damage, and is relatively insensitive to the cyclic voltage window. We use finite element modeling to study the evolution of Li concentration and stresses in a NMC secondary particle and employ the cohesive zone model to simulate the interfacial fracture between primary particles. We reveal that microcracks accumulate and propagate during the cyclic lithiation and delithiation at a slow charging rate.

Similar content being viewed by others

Reference

Whittingham MS (2008) Materials challenges facing electrical energy storage. MRS Bull 33(04):411–419

Tarascon JM, Armand M (2001) Issues and challenges facing rechargeable lithium batteries. Nature 414(6861):359–367

McDowell MT, Xia S, Zhu T (2016) The mechanics of large-volume-change transformations in high-capacity battery materials. Extreme Mech Lett 9(3):480–494

Zhao K, Cui Y (2016) Understanding the role of mechanics in energy materials: a perspective. Extreme Mech Lett 9(3):347–352

Verma P, Maire P, Novak P (2010) A review of the features and analyses of the solid electrolyte interphase in li-ion batteries. Electrochim Acta 55(22):6332–6341

Liu N, Lu Z, Zhao J, McDowell MT, Lee HW, Zhao W, Cui Y (2014) A pomegranate-inspired nanoscale design for large-volume-change lithium battery anodes. Nat Nanotechnol 9(3):187–192

Zhang S (2017) Chemomechanical modeling of lithiation-induced failure in high-volume-change electrode materials for lithium ion batteries. Nnpj Comput Mater 3:7

Woodford WH, Carter WC, Chiang YM (2012) Design criteria for electrochemical shock resistant battery electrodes. Energy Environ Sci 5(7):8014–8024

Nadimpalli SPV, Sethuraman VA, Abraham DP, Bower AF, Gudurub PR (2015) Stress evolution in lithium-ion composite electrodes during electrochemical cycling and resulting internal pressures on the cell casing. J Electrochem Soc 162(14):A2656–A2663

Sheth J, Karan NK, Abraham DP, Nguyen CC, Lucht BL, Sheldon BW, Guduru PR (2016) In situ stress evolution in Li1+ xMn2O4 thin films during electrochemical cycling in li-ion cells. J Electrochem Soc 163(13):A2524–A2530

Chung KY, Kim KB (2002) Investigation of structural fatigue in spinel electrodes using in situ laser probe beam deflection technique. J Electrochem Soc 149(1):A79–A85

Wang H, Jang YI, Huang B, Sadoway DR, Chiang YM (1999) TEM study of electrochemical cycling-induced damage and disorder in LiCoO2 cathodes for rechargeable lithium batteries. J Electrochem Soc 146(2):473–480

Hao X, Lin X, Lu W, Bartlett BM (2014) Oxygen vacancies lead to loss of domain order, particle fracture, and rapid capacity fade in lithium manganospinel (LiMn2O4) batteries. ACS Appl Mater Interfaces 6(14):10849–10857

Zhao K, Pharr M, Vlassak JJ, Suo Z (2010) Fracture of electrodes in lithium-ion batteries caused by fast charging. J Appl Phys 108(7):073517

Lee SW, Lee HW, Nix WD, Gao H, Cui Y (2015) Kinetics and fracture resistance of lithiated silicon nanostructure pairs controlled by their mechanical interaction. Nat Commun 6:7533

Liu XH, Zhong L, Huang S, Mao SX, Zhu T, Huang JY (2012) Size-dependent fracture of silicon nanoparticles during lithiation. ACS Nano 6(2):1522–1531

Liu XH, Zheng H, Zhong L, Huang S, Karki K, Zhang LQ, Liu Y, Kushima A, Liang WT, Wang JW, Cho JH, Epstein E, Dayeh SA, Picraux ST, Zhu T, Li J, Sullivan JP, Cumings J, Wang C, Mao SX, Ye ZZ, Zhang S, Huang JY (2011) Anisotropic swelling and fracture of silicon nanowires during lithiation. Nano Lett 11(8):3312–3318

Zhao K, Wang WL, Gregoire J, Pharr M, Suo Z (2011) Lithium-assisted plastic deformation of silicon electrodes in lithium-ion batteries: a first-principles theoretical study. Nano Lett 11(7):2962–2967

Zhao K, Tritsaris GA, Pharr M, Wang WL, Okeke O, Suo Z, Vlassak JJ, Kaxiras E (2012) Reactive flow in silicon electrodes assisted by the insertion of lithium. Nano Lett 12(8):4397–4403

Choi JW, McDonough J, Jeong S, Yoo JS, Chan CK, Cui Y (2010) Stepwise nanopore evolution in one-dimensional nanostructures. Nano Lett 10(4):1409–1413

Liu XH, Huang S, Picraux ST, Li J, Zhu T, Huang JY (2011) Reversible nanopore formation in Ge nanowires during lithiation–delithiation cycling: an in situ transmission electron microscopy study. Nano Lett 11(9):3991–3997

Haran B, Popov BN (2003) Capacity fade study of lithium-ion batteries cycled at high discharge rates. J Power Sources 117(1):160–169

Xu R, Zhao K (2015) Mechanical interactions regulated kinetics and morphology of composite electrodes in li-ion batteries. Extreme Mech Lett 8:13–21

Maranchi JP, Hepp AF, Evans AG, Nuhfer NT, Kumta PN (2006) Interfacial properties of the a-Si/cu: active-inactive thin-film anode system for lithium-ion batteries. J Electrochem Soc 153(6):A1246–A1253

Sun H, Xin G, Hu T, Yu M, Shao D, Sun X, Lian J (2014) High-rate lithiation-induced reactivation of mesoporous hollow spheres for long-lived lithium-ion batteries. Nat Commun 5:4526

Daniel C, Mohanty D, Li J, Wood D (2014) Cathode material review. AIP Conf Proc 1597(1):26–43

Li J, Daniel C, Wood D (2011) Materials processing for lithium-ion batteries. J Power Sources 196(5):2452–2460

Koyama Y, Tanaka I, Adachi H, Makimura Y, Ohzuku T (2003) Crystal and electronic structures of superstructural Li1− x[Co1/3Ni1/3Mn1/3]O2 (0≤ x≤ 1). J Power Sources 119:644–648

Miller DJ, Proff C, Wen JG, Abraham DP, Bareño J (2013) Observation of microstructural evolution in li battery cathode oxide particles by in situ electron microscopy. Adv Energy Mater 3(8):1098–1103

Sun G, Sui T, Song B, Zheng H, Lu L, Korsunsky AM (2016) On the fragmentation of active material secondary particles in lithium ion battery cathodes induced by charge cycling. Extreme Mech Lett 9(3):449–458

Li G, Zhang Z, Huang Z, Yang C, Zuo Z, Zhou H (2017) Understanding the accumulated cycle capacity fade caused by the secondary particle fracture of LiNi1-x-yCoxMnyO2 cathode for lithium ion batteries. J Solid State Electrochem 21(3):673–682

Li J, Daniel C, An SJ, Wood D (2015) Evaluation residual moisture in lithium-ion battery electrodes and its effect on electrode performance. MRS Adv 1(15):1029–1035

Xu R, Vasconcelos LS, Zhao K (2016) Computational analysis of chemomechanical behaviors of composite electrodes in li-ion batteries. J Mater Res 31(18):2715–2727

Reem D (2009) An algorithm for computing Voronoi diagrams of general generators in general normed spaces. ISVD 2009:144–152

COMSOL Multiphysics (2014) v5.0. COMSOL. Sweden

Abaqus (2011) v6.11. Dassault Systèmes, France

Fan XL, Xu R, Zhang WX, Wang TJ (2012) Effect of periodic surface cracks on the interfacial fracture of thermal barrier coating system. Appl Surf Sci 258(24):9816–9823

Lee BR, Noh HJ, Myung ST, Amined K, Sun YK (2011) High-voltage performance of li[Ni0. 55Co0. 15Mn0. 30]O2 positive electrode material for rechargeable li-ion batteries. J Electrochem Soc 158(2):A180–A186

Song B, Liu Z, Lai MO, Lu L (2012) Structural evolution and the capacity fade mechanism upon long-term cycling in li-rich cathode material. Phys Chem Chem Phys 14(37):12875–12883

Mohanty D, Kalnaus S, Meisner RA, Rhodesb KJ, Li J, Payzantc EA, Wood DL III, Daniel C (2013) Structural transformation of a lithium-rich Li1.2Co0.1Mn0.55Ni0.15O2 cathode during high voltage cycling resolved by in situ X-ray diffraction. J Power Sources 229:239–248

Li J, Downie LE, Ma L, Qiu W, Dahn JR (2015) Study of the failure mechanisms of LiNi0.8Mn0.1Co0.1O2 cathode material for lithium ion batteries. J Electrochem Soc 162(7):A1401–A1408

Watanabe S, Kinoshita M, Hosokawa T, Morigaki K, Nakurab K (2014) Capacity fading of LiAlyNi1−x−yCoxO2 cathode for lithium-ion batteries during accelerated calendar and cycle life tests (effect of depth of discharge in charge–discharge cycling on the suppression of the micro-crack generation of LiAlyNi1−x−yCoxO2 particle). J Power Sources 260:50–56

Zhang SS, Xu K, Jow TR (2006) EIS study on the formation of solid electrolyte interface in li-ion battery. Electrochim Acta 51(8):1636–1640

Vasconcelos LS, Xu R, Li J, Zhao K (2016) Grid indentation analysis of mechanical properties of composite electrodes in li-ion batteries. Extreme Mech Lett 9(3):495–502

Wei Y, Zheng J, Cui S, Song X, Su Y, Deng W, Wu Z, Wang X, Wang W, Rao M, Lin Y, Wang C, Amine K, Pan F (2015) Kinetics tuning of li-ion diffusion in layered li(NixMnyCoz)O2. J Am Chem Soc 137(26):8364–8367

Acknowledgements

This work is supported by the National Science Foundation through the grant CBET-1603866 and by the Office of Naval Research through the NEPTUNE program. The NMC cathodes were fabricated at the Battery Manufacturing R&D Facility (BMF) at Oak Ridge National Laboratory, managed by UT Battelle, LLC, for the U.S. Department of Energy under contract DE-AC05-00OR22725. BMF was sponsored by the Office of Energy Efficiency and Renewable Energy Vehicle Technologies Office (VTO) Applied Battery Research (ABR) subprogram (Program Managers: Peter Faguy).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

ESM 1

(PDF 10257 kb)

Rights and permissions

About this article

Cite this article

Xu, R., de Vasconcelos, L.S., Shi, J. et al. Disintegration of Meatball Electrodes for LiNi x Mn y Co z O2 Cathode Materials. Exp Mech 58, 549–559 (2018). https://doi.org/10.1007/s11340-017-0292-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-017-0292-0