Abstract

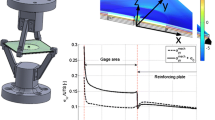

We propose a novel experimental method, based on a fiber Bragg grating (FBG) sensor, to measure the elastic properties of epoxy molding compound (EMC) from a single specimen configuration. The FBG sensor is embedded in the center of a cylindrical EMC specimen, and deforms together with the EMC. The Bragg wavelength (BW) shifts are documented during compressive and hydrostatic loadings. Young’s modulus and bulk modulus are determined from the BW shifts using the relationships between the elastic constants and the BW shift. Two major developments to accommodate the unique requirements of EMC testing include: (1) a large mechanical pressure to be applied during curing; and (2) a very high gas pressure required for hydrostatic testing. The shear modulus and Poisson’s ratio are calculated from the two measured constants to provide a complete set of elastic properties of EMC.

Similar content being viewed by others

Reference

Kelly G, Lyden C, Lawton W, Barrett J, Saboui A, Pape H, Peters HJ (1996) Importance of molding compound chemical shrinkage in the stress and warpage analysis of PQFPs. Components Packag Manuf Technol B IEEE Trans Adv Packag 19:296–300

Kong JW, Kim J-K, Yuen MM (2003) Warpage in plastic packages: effects of process conditions, geometry and materials. IEEE Trans Electron Packag Manuf 26:245–252

Ernst L, Zhang G, Jansen K, Bressers H (2003) Time-and temperature-dependent thermo-mechanical modeling of a packaging molding compound and its effect on packaging process stresses. J Electron Packag 125:539–548

O’Brien DJ, Sottos N, White SR (2007) Cure-dependent viscoelastic Poisson’s ratio of epoxy. Exp Mech 47:237–249

Van Driel W, Janssen J, Zhang G, Yang D, Ernst L (2003) Packaging induced die stresses—effect of chip anisotropy and time-dependent behavior of a molding compound. J Electron Packag 125:520–526

Tschoegl NW, Knauss WG, Emri I (2002) Poisson’s ratio in linear viscoelasticity–a critical review. Mech Time-Dependent Mater 6:3–51

Sadeghinia M, Jansen K, Ernst L (2012) Characterization and modeling the thermo-mechanical cure-dependent properties of epoxy molding compound. Int J Adhes Adhes 32:82–88

Emri I, Prodan T (2006) A measuring system for bulk and shear characterization of polymers. Exp Mech 46:429–439

Wang Y, Woodworth L, Han B (2011) Simultaneous measurement of effective chemical shrinkage and modulus evolutions during polymerization. Exp Mech 51:1155–1169

Sun Y, Wang Y, Jang C, Han B, Choi K (2013) Generalized hybrid modeling to determine chemical shrinkage and modulus evolutions at arbitrary temperatures. Exp Mech 53:1783–1790

Sun Y, Wang Y, Kim Y, Han B (2014) Dual-configuration fiber Bragg grating sensor technique to measure coefficients of thermal expansion and hygroscopic swelling. Exp Mech 54:593–603

Sun Y, Han B, Parsa E, Dasgupta A (2014) Measurement of effective chemical shrinkage and equilibrium modulus of silicone elastomer used in potted electronic system. J Mater Sci 49:8301–8310

Karalekas D, Cugnoni J, Botsis J (2008) Monitoring of process induced strains in a single fibre composite using FBG sensor: a methodological study. Compos A: Appl Sci Manuf 39:1118–1127

Tanaka N, Okabe Y, Takeda N (2003) Temperature-compensated strain measurement using fiber Bragg grating sensors embedded in composite laminates. Smart Mater Struct 12:940

Tao X, Tang L, Du W-c, Choy C-l (2000) Internal strain measurement by fiber Bragg grating sensors in textile composites. Compos Sci Technol 60:657–669

Prigogine I (1967) Introduction to thermodynamics of irreversible processes. New York: Interscience, 3rd ed., vol. 1, 1967

Procter P and Solc J (1991) Improved thermal conductivity in microelectronic encapsulants. In: Electronic Components and Technology Conference, Proceedings., 41st, pp. 835–842

Brinson HF and Brinson LC (2008) Polymer engineering science and viscoelasticity: Springer

Blankleider B, Woloshyn R (1984) Quasi-elastic scattering of polarized electrons on polarized He 3. Phys Rev C 29:538

Brenner R, Masson R, Castelnau O, Zaoui A (2002) A “quasi-elastic” affine formulation for the homogenised behaviour of nonlinear viscoelastic polycrystals and composites. Eur J Mech-A/Solids 21:943–960

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

Substituting Eq. (2) into Eq. (6) yields:

Next, substituting Eq. (4) into Eq. (A.1) yields:

Finally, the governing equation can be obtained by substituting Eq. (5) into Eq. (A.2).

Rights and permissions

About this article

Cite this article

Sun, Y., Lee, HS. & Han, B. Measurement of Elastic Properties of Epoxy Molding Compound by Single Cylindrical Configuration with Embedded Fiber Bragg Grating Sensor. Exp Mech 57, 313–324 (2017). https://doi.org/10.1007/s11340-016-0215-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-016-0215-5