Abstract

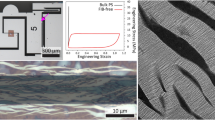

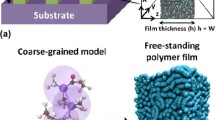

A new dynamic method based on bilayer system is proposed to characterize the residual stress formation during the crystallization of semi-crystalline polyethylene glycol 10000 (PEG10000). The resin is coated on a solid polymeric film to create a filmsubstrate compound. Its temperature field and dynamic deflection are monitored by synchronized optical and thermography cameras. The crystallization kinetics is first characterized from the former information. Then a simple dynamic model is proposed to relate the dynamic deflection with crystallization process. Residual stresses are established and in the range of 0–2.1 MPa. The generation of residual stresses is due to the edge constraints of the cantilever beam and to the increase of viscosity during solidification that allows the polymer to carry tensile loadings. The spherulite impingement is found to be important for this period from a microscopic view. Boundary condition should be well controlled to steer residual stresses. Such method is promising to measure residual stresses at the micro-scale for polymers to be spread on a flexible substrate and can mimic different mechanical situations of interest.

Similar content being viewed by others

References

Zingraff L, Michaud V, Bourban P-E, Månson J-AE (2005) Resin transfer moulding of anionically polymerised polyamide 12. Compos Part A Appl Sci Manuf 36:1675–1686. doi:10.1016/j.compositesa.2005.03.023

Luisier A, Bourban P-E, Månson J-AE (2003) Reaction injection pultrusion of PA12 composites: process and modelling. Compos Part A Appl Sci Manuf 34:583–595. doi:10.1016/S1359-835×(03)00101-5

Parton H, Verpoest I (2005) In situ polymerization of thermoplastic composites based on cyclic oligomers. Polym Compos 26:60–65. doi:10.1002/pc.20074

Parton H, Baets J, Lipnik P et al (2005) Properties of poly (butylene terephthatlate) polymerized from cyclic oligomers and its composites. Polymer (Guildf) 46:9871–9880. doi:10.1016/j.polymer.2005.07.082

Omairtin P, Mcdonnell P, Connor M et al (2001) Process investigation of a liquid PA-12/carbon fibre moulding system. Compos Part A Appl Sci Manuf 32:915–923. doi:10.1016/S1359-835×(01)00005-7

Corden TJ, Jones IA, Rudd CD et al (1999) Initial development into a novel technique for manufacturing a long fibre thermoplastic bioabsorbable composite:in-situ polymerisation of poly-e-caprolactone. Mol Cell Biol 30:737–746. doi:10.1016/S1359-835×(98)00189-4

Huskic M, Zigon M (2007) PMMA/MMT nanocomposites prepared by one-step in situ intercalative solution polymerization. Eur Polym J 43:4891–4897. doi:10.1016/j.eurpolymj.2007.09.009

Parlevliet P, Bersee H, Beukers A (2007) Residual stresses in thermoplastic composites – a study of the literature. Part III: Effects of thermal residual stresses. Compos Part A Appl Sci Manuf 38:1581–1596. doi:10.1016/j.compositesa.2006.12.005

Chiang Y-C, Rösch P, Dabanoglu A et al (2010) Polymerization composite shrinkage evaluation with 3D deformation analysis from microCT images. Dent Mater 26:223–31. doi:10.1016/j.dental.2009.09.013

Hoger A (1993) The elasticity tensors of a residually stressed material. J Elast 31:219–237. doi:10.1007/BF00044971

Eduljee RF, Gillespie JW, McCullough RL (1994) Residual stress development in neat poly (Etheretherketone). Polym Eng Sci 34:500–506. doi:10.1002/pen.760340607

Vaillancourt H KK., Wang H, Salloum G (1998) Residual stresses, shrinkage, and warpage of complex injection molded products: numerical simulation and experimental validation. 38:21–37. doi: 10.1002/pen.10162

Gilbert JL (2006) Complexity in modeling of residual stresses and strains during polymerization of bone cement : Effects of conversion, constraint, heat transfer, and viscoelastic property changes. J Biomed Mater Res. doi:10.1002/jbm.a

Gilormini P, Chevalier L, Régnier G (2010) Thermoforming of a PMMA transparency near glass transition temperature. doi: 10.1002/pen

Prime MB (2010) Plasticity effects in incremental slitting measurement of residual stresses. Eng Fract Mech 77:1552–1566. doi:10.1016/j.engfracmech.2010.04.031

Eijpe MPIM, Powell PC (1997) Residual stress evaluation in composites using a modified layer removal method. Compos Struct 37:335–342

Chang C-W, Chen PH, Lien HS (2009) Evaluation of residual stress in pre-stressed concrete material by digital image processing photoelastic coating and hole drilling method. Measurement 42:552–558. doi:10.1016/j.measurement.2008.10.004

Msallem YA (2008) Caractérisation thermique et mécanique d’un matériau composite aéronautique pendant le procédé d’élaboration : contribution à l′estimation des contraintes résiduelles. Ecole Centrale de Nantes

Khoun L, De Oliveira R, Michaud V, Hubert P (2010) Investigation of process-induced strains development by fibre Bragg grating sensors in resin transfer moulded composites. Compos Part A Appl Sci Manuf 42:274–282. doi:10.1016/j.compositesa.2010.11.013

Wróbel G (2007) Ultrasonic methods in diagnostics of polyethylene. Arch Mater Sci Eng 28:413–416

Lee Y-C, Kuo SH (2004) A new point contact surface acoustic wave transducer for measurement of acoustoelastic effect of polymethylmethacrylate. IEEE Trans Ultrason Ferroelectr Freq Control 51:114–20. doi:10.1109/TUFFC.2004.1268473

Hauk V (2000) Structural and residual stress analysis by X-ray diffraction on polymeric materials and composites. Advances 42:540–554. doi:10.1002/(SICI)1521-4052(199907)30:7<377::AID-MAWE377>3.0.CO;2-H

Coupard D, Palin-luc T, Bristiel P et al (2008) Residual stresses in surface induction hardening of steels: Comparison between experiment and simulation. Mater Sci Eng A 487:328–339. doi:10.1016/j.msea.2007.10.047

Guo Y, Liu Y, Tang JX, Valles JM (2008) Polymerization force driven buckling of microtubule bundles determines the wavelength of patterns formed in tubulin solutions. doi: 10.1103/PhysRevLett.98.198103

Vrcelj Z, Bradford MA, Uy B, Wright HD (2002) Buckling of the steel component of a composite member caused by shrinkage and creep of the concrete component. Prog Struct Eng Mater 4:186–192. doi:10.1002/pse.131

Stoney GG (1909) The Tension of Metallic Films Deposited by Electrolysis. Proc R Soc A Math Phys Eng Sci 82:172–175. doi:10.1098/rspa.1909.0021

Zhang Y (2007) Deflections and curvatures of a film – substrate structure with the presence of gradient stress in MEMS applications. 17:753–762. doi: 10.1088/0960-1317/17/4/012

Fang W, Wickert JA (1996) Determining mean and gradient residual stresses in thin films using micromachined cantilevers. 6:301–309. doi: 10.1088/0960-1317/6/3/002

Guisbiers G, Wautelet M, Buchaillot L (2009) Comparison of intrinsic residual stress models in metallic thin films. Scr Mater 60:419–422. doi:10.1016/j.scriptamat.2008.11.014

Ramani K, Zhao W (1997) The evolution of residual stresses in thermoplastic bonding to metals. Int J Adhes Adhes 17:353–357. doi:10.1016/S0143-7496(97)00030-4

Lion A, Engelhard M, Johlitz M (2012) Thermomechanical and calorimetric behaviours of supported glass-forming films: A study based on thermodynamics with internal variables. Thin Solid Films 522:441–451. doi:10.1016/j.tsf.2012.09.009

Kim KS, Hahn HT (1989) Residual stress development during processing of graphite/epoxy composites. Compos Sci Technol 36:121–132. doi:10.1016/0266-3538(89)90083-3

Li CY, Birnkrant MJ, Natarajan LV et al (2005) Polymer crystallization/melting induced thermal switching in a series of holographically patterned Bragg reflectors. Soft Matter 1:238. doi:10.1039/b506876b

Haupt P (2002) Continuum mechanics and theory of materials, 2nd edn. Springer, Berlin

Janeschitz-Kriegl H (2003) How to understand nucleation in crystallizing polymer melts under real processing conditions. Colloid Polym Sci 281:1157–1171. doi:10.1007/s00396-002-0747-3

Lion A, Yagimli B (2009) On the frequency-dependent specific heat and TMDSC: Constitutive modelling based on thermodynamics with internal state variables. Thermochim Acta 490:64–74. doi:10.1016/j.tca.2009.02.016

Strobl G (2006) Crystallization and melting of bulk polymers: New observations, conclusions and a thermodynamic scheme. Prog Polym Sci 31:398–442. doi:10.1016/j.progpolymsci.2006.01.001

Wunderlich B (1976) Macromolecular Physics: Crystal Nucleation, Growth, Annealing. Academic, New York

Velisaris CN, Seferis JC (1986) Crystallization kinetics of polyetheretherketone (PEEK) matrices. Polym Eng Sci 26:1574–1581. doi:10.1002/pen.760262208

Lehmann B (2009) Isothermal and non-isothermal crystallisation kinetics of pCBT and PBT. J Therm Anal 95:221–227. doi:10.1007/s10973-007-8939-1

Kosher E (2002) Effets du cisaillement sur la cristallisation du polypropylene: Aspects cinetiques et morphologiques. Universite Lyon I

Pielichowski K, Flejtuch K (2002) Differential scanning calorimetry studies on poly (ethylene glycol) with different molecular weights for thermal energy storage materials. Polym Adv Technol 13:690–696. doi:10.1002/pat.276

PerkinElmer (2011) Application note-Thermal analysis-Tg and Melting Point of a Series of Polyethylene Glycols Using the Material Pocket. In: PerkinElmer,Inc. Technical Libr. web. http://www.perkinelmer.com/CMSResources/Images/44-74297APP_TgandMeltofPolyethylene.pdf. Accessed 1 Jan 2011

Ding Z, Spruiell JE (1996) An experimental method for studying nonisothermal crystallization of polymers at very high cooling rates. J Polym Sci Part B Polym Phys 34:2783–2804. doi:10.1002/(SICI)1099-0488(19961130)34:16<2783::AID-POLB12>3.0.CO;2-6

Supaphol P, Spruiell JE (2002) Nonisothermal bulk crystallization of high-density polyethylene via a modified depolarized light microscopy technique: Further analysis. J Appl Polym Sci 86:1009–1022. doi:10.1002/app.11121

Nagashio K, Murata H, Kuribayashi K (2005) In situ observation of solidification behavior of Si melt dropped on Si wafer by IR thermography. J Cryst Growth 275:e1685–e1690. doi:10.1016/j.jcrysgro.2004.11.230

Solórzano E, García-Moreno F, Babcsán N, Banhart J (2009) Thermographic Monitoring of Aluminium Foaming Process. J Nondestruct Eval 28:141–148. doi:10.1007/s10921-009-0056-6

Gladky A, Ustugov V, Sorokin A (2005) Thermography study of propane oxidation to synthesis-gas over nickel. Chem Eng J 107:33–38. doi:10.1016/j.cej.2004.12.007

Incropera FP, DeWitt DP, Bergman TL, Lavine AS (2007) Fundamentals of heat and mass transfer, 6th edn. Wiley, Hoboken

Freund LB, Floro JA, Chason E (1999) Extensions of the Stoney formula for substrate curvature to configurations with thin substrates or large deformations. Appl Phys Lett 74:1987. doi:10.1063/1.123722

D. Ramos, J.Mertens MC and JT (2007) Study of the origin of bending induced by bimetallic effect on microcantilever. 7:1757–1765. doi: 10.3390/s7091757

Nairn JA, Zoller P (1985) Matrix solidification and the resulting residual thermal stresses in composites. J Mater Sci 20:355–367. doi:10.1007/BF00555929

Freund LB, Suresh S (2003) Thin film materials: stress, defect formation and surface evolution. Cambridge University Press

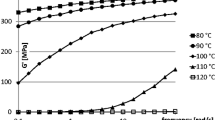

Lamberti G, Peters GWM, Titomanlio G (2007) Crystallinity and Linear Rheological Properties of Polymers. Int Polym Process 22:303–310. doi:10.3139/217.2006

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhu, Q., Binetruy, C., Burtin, C. et al. A Dynamic Method for the Residual Stress Measurement During Polymer Crystallization. Exp Mech 54, 1421–1430 (2014). https://doi.org/10.1007/s11340-014-9909-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-014-9909-8