Abstract

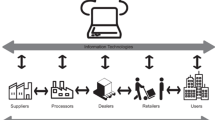

Industrial and technological growth, sponsored by the new organizational systems generated by the fourth industrial revolution, require adapt new business management ways in the companies. Within the organizational and business area we can conceive all activities as an operations set that are linked to computer systems and information management in the network, achieving more efficiency in the flow, in addition, this new industry perception and businesses includes different analytical tools which are useful to support the customer service efficiency improvement. The research objective is to propose and validate a methodological tool, for evaluating the technological and operational criteria within companies and place them in the right level for a transfer to the new industrial revolution, considering as well the vertical and horizontal systems in Industry 4.0.

Similar content being viewed by others

References

Schlechtendahl, J., Keinert, M., Kretschmer, F., Lechler, A., & Verl, A. (2014). Making existing production systems Industry 4.0-ready: Holistic approach to the integration of existing production systems in Industry 4.0 environments. Production Engineering, 91(1), 143. https://doi.org/10.1007/s11740-014-0586-3.

Dombrowski, U., & Wagner, T. (2014). Mental strain as field of action in the 4th industrial revolution. Procedia CIRP, 17, 100. https://doi.org/10.1016/j.procir.2014.01.077.

Fielt, E. (2013). Conceptualising business models: Definitions, frameworks and classifications. Journal of Business Models, 1(1), 85. https://doi.org/10.1177/0149206311406265.

Lee, J., Kao, H. A., & Yang, S. (2014). Service innovation and smart analytics for Industry 4. 0 and big data environment. Procedia CIRP, 16, 3. https://doi.org/10.1016/j.procir.2014.02.001.

Schuh, G., Potente, T., Wesch-potente, C., Weber, A. R., & Prote, Jp. (2014). Collaboration mechanisms to increase productivity in the context of Industrie 4.0. Procedia CIRP, 19(RoMaC), 51. https://doi.org/10.1016/j.procir.2014.05.016.

Vyas, D., & Nijholt, A. (2016). From Mundane to smart: Exploring interactions with ‘smart’ design objects. International Journal of Mobile Human Computer Interaction, 8(1), 59. https://doi.org/10.4018/IJMHCI.2016010103.

Schumacher, A., Erol, S., & Sihn, W. (2016). A maturity model for assessing Industry 4.0 readiness and maturity of manufacturing enterprises. Procedia CIRP, 52, 161. https://doi.org/10.1016/j.procir.2016.07.040.

Saucedo-Martínez, J. A., Pérez-Lara, M., Marmolejo-Saucedo, J. A., Salais-Fierro, T. E., & Vasant, P. (2017). Industry 4.0 framework for management and operations: A review. Journal of Ambient Intelligence and Humanized Computing. https://doi.org/10.1007/s12652-017-0533-1.

Gilchrist, A. (2016). Industry 4.0: The industrial internet of things. Bangken, Nonthaburi, Thailand: Apress.

Toro, C., Barandiaran, I., & Posada, J. (2015). A perspective on knowledge based and intelligent systems implementation in Industrie 4. 0. Procedia—Procedia Computer Science, 60, 362. https://doi.org/10.1016/j.procs.2015.08.143.

Joyce, A., & Paquin, R. L. (2016). The triple layered business model canvas: A tool to design more sustainable business models. Journal of Cleaner Production, 135, 1474. https://doi.org/10.1016/j.jclepro.2016.06.067.

Stock, T., & Seliger, G. (2016). Opportunities of sustainable manufacturing in Industry 4. 0. Procedia CIRP, 40(Icc), 536. https://doi.org/10.1016/j.procir.2016.01.129.

Wainstein, M. E., & Bumpus, A. G. (2015). Business models as drivers of the low carbon power system transition: A multi-level perspective. Journal of Cleaner Production, 126, 572. https://doi.org/10.1016/j.jclepro.2016.02.095.

Bauer, W., Hämmerle, M., Schlund, S., & Vocke, C. (2015). Transforming to a hyper-connected society and economy—Towards an “Industry 4. 0”. Procedia Manufacturing, 3(Ahfe), 417. https://doi.org/10.1016/j.promfg.2015.07.200.

Felicio, J. A., Couto, E., & Caiado, J. (2014). Human capital, social capital and organizational performance. Management Decision, 52(2), 350. https://doi.org/10.1108/MD-04-2013-0260.

Hashemy, S. H., Yousefi, M., Soodi, S., & Omidi, B. (2016). Explaining human resource empowerment pattern and organizational excellence among employees of emergency of Guilan’s University Hospitals. Procedia—Social and Behavioral Sciences, 230, 6. https://doi.org/10.1016/j.sbspro.2016.09.002.

Longo, F., Nicoletti, E., & Padovano, A. (2017). Smart operators in industry 4.0: A human-centered approach to enhance operators ’ capabilities and competencies within. Computers and Industrial Engineering. https://doi.org/10.1016/j.cie.2017.09.016.

Pelinescu, E. (2015). The impact of human capital on economic growth. Procedia Economics and Finance, 22, 184. https://doi.org/10.1016/S2212-5671(15)00258-0.

Smits, C. C. A., Justinussen, J. C. S., & Bertelsen, R. G. (2016). Human capital development and a Social License to Operate: Examples from Arctic energy development in the Faroe Islands, Iceland and Greenland. Energy Research and Social Science, 16, 122. https://doi.org/10.1016/j.erss.2016.03.016.

Hecklau, F., Galeitzke, M., Flachs, S., & Kohl, H. (2016). Holistic approach for human resource management in Industry 4.0. Procedia CIRP, 54, 1. https://doi.org/10.1016/j.procir.2016.05.102.

Estrin, S., Mickiewicz, T., & Stephan, U. (2016). Human capital in social and commercial entrepreneurship. Journal of Business Venturing, 31(4), 449. https://doi.org/10.1016/j.jbusvent.2016.05.003.

Vidotto, J. D. F., Ferenhof, H. A., Selig, P. M., & Bastos, R. C. (2017). A human capital measurement scale. Journal of Intellectual Capital, 18(2), 316. https://doi.org/10.1108/MRR-09-2015-0216.

Bücker, I., Hermann, M., Pentek, T., & Otto, B. (2016). Towards a methodology for Industrie 4 . 0 Transformation. Springer International Publishing Switzerland 1, 209. https://doi.org/10.1007/978-3-319-39426-8.

Ferriols, F. J., Mula, J., & Díaz-Madroñero, M. (2013). Supply chain management as the company engine in automotive manufacturing, vol. 46. IFAC. https://doi.org/10.3182/20130619-3-RU-3018.00614.

Syntetos, A. A., Babai, Z., Boylan, J. E., Kolassa, S., & Nikolopoulos, K. (2016). Supply chain forecasting: Theory, practice, their gap and the future. European Journal of Operational Research, 252(1), 1. https://doi.org/10.1016/j.ejor.2015.11.010.

Brandenburg, M. (2016). Supply chain efficiency, value creation and the economic crisis—An empirical assessment of the European automotive industry 2002–2010. International Journal of Production Economics, 171, 321. https://doi.org/10.1016/j.ijpe.2015.07.039.

Ojha, D., Shockley, J., & Acharya, C. (2016). Supply chain organizational infrastructure for promoting entrepreneurial emphasis and innovativeness: The role of trust and learning. International Journal of Production Economics, 179, 212. https://doi.org/10.1016/j.ijpe.2016.06.011.

Golmoradi, R., & Sattari Ardabili, F. (2016). The effects of social capital and leadership styles on organizational learning. Procedia-Social and Behavioral Sciences, 230, 372. https://doi.org/10.1016/j.sbspro.2016.09.047.

Ahuett-Garza, H., & Kurfess, T. (2018). A brief discussion on the trends of habilitating technologies for Industry 4.0 and smart manufacturing. Manufacturing Letters. https://doi.org/10.1016/j.mfglet.2018.02.011.

Davies, R., Coole, T., & Smith, A. (2017). Review of socio-technical considerations to ensure successful implementation of Industry 4.0. Procedia Manufacturing, 11, 1288. https://doi.org/10.1016/j.promfg.2017.07.256.

Lee, K. S., & Chen, W. (2017). A long shadow: Cultural capital, techno-capital and networking skills of college students. Computers in Human Behavior, 70, 67. https://doi.org/10.1016/j.chb.2016.12.030.

Kolberg, D., & Zühlke, D. (2015). Lean automation enabled by Industry 4.0 technologies. IFAC-PapersOnLine, 28(3), 1870. https://doi.org/10.1016/j.ifacol.2015.06.359.

Zhao, S., Technology, S., Cheng, B., Technology, S., Yu, L., Corporation, C., et al. (2016). Internet of things service provisioning platform for cross-application cooperation. International Journal of Web Services Research, 13(1), 1. https://doi.org/10.4018/IJWSR.2016010101.

Müller, J. M., Buliga, O., & Voigt, K. I. (2018). Fortune favors the prepared: How SMEs approach business model innovations in Industry 4.0, Technological Forecasting and Social Change (December 2017), 0. https://doi.org/10.1016/j.techfore.2017.12.019.

Barreto, L., Amaral, A., & Pereira, T. (2017). Industry 4.0 implications in logistics: An overview. Procedia Manufacturing, 13, 1245. https://doi.org/10.1016/j.promfg.2017.09.045.

Santos, K., Loures, E., Piechnicki, F., & Canciglieri, O. (2017). Opportunities assessment of product development process in Industry 4.0. Procedia Manufacturing, 11, 1358. https://doi.org/10.1016/j.promfg.2017.07.265.

Schöggl, J. P., Baumgartner, R. J., & Hofer, D. (2017). Improving sustainability performance in early phases of product design: A checklist for sustainable product development tested in the automotive industry. Journal of Cleaner Production, 140, 1602. https://doi.org/10.1016/j.jclepro.2016.09.195.

Anderl, R. (2014). Advanced engineering of smart products and smart production, technological innovations in the produuct develoment. In 19 th International Seminar on High Tecnology, 1.

Thoben, Kd, Busse, M., Denkena, B., & Gausemeier, J. (2014). Editorial: System-integrated Intelligence—New challenges for product and production engineering in the context of Industry 4. 0. Procedia Technology, 15, 1. https://doi.org/10.1016/j.protcy.2014.09.028.

Nunes, M. L., Pereira, A. C., & Alves, A. C. (2017). Smart products development approaches for Industry 4.0. Procedia Manufacturing, 13, 1215. https://doi.org/10.1016/j.promfg.2017.09.035.

Xing, K., & Ness, D. (2016). Transition to product-service systems: Principles and business model. Procedia CIRP, 47, 525. https://doi.org/10.1016/j.procir.2016.03.236.

Sousa-Zomer, T. T., & Cauchick Miguel, P. A. (2015). Sustainable business models as an innovation strategy in the water sector: An empirical investigation of a sustainable product-service system. Journal of Cleaner Production. https://doi.org/10.1016/j.jclepro.2016.07.063.

Toro-Jarrín, M. A., Ponce-Jaramillo, I. E., & Güemes-Castorena, D. (2016). Methodology for the of building process integration of business model canvas and technological roadmap. Technological Forecasting and Social Change, 110, 213. https://doi.org/10.1016/j.techfore.2016.01.009.

Imran, S., Sanin, C., Szczerbicki, E., & Toro, C. (2015). Virtual engineering object/virtual engineering process: A specialized form of cyber physical system for Industrie 4. 0. Procedia—Procedia Computer Science, 60, 1146. https://doi.org/10.1016/j.procs.2015.08.166.

Geissdoerfer, M., Bocken, N. M. P., & Hultink, E. J. (2016). Desing thinking to enhace the sustainable business modelling process—A workshop based on a value mapping process. Journal of Cleaner Production, 135, 1218.

Tarhan, A., Turetken, O., & Reijers, H. A. (2016). Business process maturity models: A systematic literature review. Information and Software Tecnology: Elsevier, 75, 122.

Küber, C., Westkämper, E., Keller, B., & Jacobi, H. F. (2016). Planning method for the design of flexible as well as economic assembly and logistics processes in the automotive Industry. Procedia CIRP, 41, 556. https://doi.org/10.1016/j.procir.2015.12.038.

Liep, Ž., & Sakalas, A. (2014). Evaluation of human capital role in the value creation process. Procedia—Social and Behavioral Sciences, 156(April), 78. https://doi.org/10.1016/j.sbspro.2014.11.123.

Aledo Ruíz, M. D., Gutiérrez, J. O., Martínez-Caro, E., & Cegarra-Navarro, J. G. (2016). Linking an unlearning context with firm performance through human capital. European Research on Management and Business Economics, 23(1), 1. https://doi.org/10.1016/j.iedeen.2016.07.001.

Metallo, C., Agrifoglio, R., Schiavone, F., & Mueller, J. (2018). Understanding business model in the Internet of Things industry, Technological Forecasting and Social Change (2017). https://doi.org/10.1016/j.techfore.2018.01.020.

Zhong, R. Y., Newman, S. T., Huang, G. Q., & Lan, S. (2016). Big Data for supply chain management in the service and manufacturing sectors: Challenges, opportunities, and future perspectives. Computers and Industrial Engineering, 101, 572. https://doi.org/10.1016/j.cie.2016.07.013.

Volker, S., & Prostean, G. (2016). Research of automotive change management and combined risk-management models. Procedia—Social and Behavioral Sciences, 221, 395. https://doi.org/10.1016/j.sbspro.2016.05.129.

Liukkonen, M., & Tsai, T. N. (2016). Toward decentralized intelligence in manufacturing: Recent trends in automatic identification of things. International Journal of Advanced Manufacturing Technology, 87(9–12), 2509. https://doi.org/10.1007/s00170-016-8628-y.

Tantik, E., & Anderl, R. (2017). Potentials of the asset administration shell of Industrie 4.0 for service-oriented business models. Procedia CIRP, 64, 363. https://doi.org/10.1016/j.procir.2017.03.009.

Möller, D. P. (2016). Guide to computing fundamentals in cyber-physical systems. https://doi.org/10.1007/978-3-319-25178-3.

Prause, M., & Weigand, J. (2016). Industry 4. 0 and object-oriented development: Incremental and architectural change. Journal of Technology Management and Innovation, 11(2), 104.

Tjahjono, B., Esplugues, C., Ares, E., & Pelaez, G. (2017). What does Industry 4.0 mean to supply chain? Procedia Manufacturing, 13, 1175. https://doi.org/10.1016/j.promfg.2017.09.191.

Li, D. (2016). Perspective for smart factory in petrochemical industry. Computers and Chemical Engineering, 91, 136. https://doi.org/10.1016/j.compchemeng.2016.03.006.

Tupa, J., Simota, J., & Steiner, F. (2017). Aspects of risk management implementation for Industry 4.0. Procedia Manufacturing, 11, 1223. https://doi.org/10.1016/j.promfg.2017.07.248.

Benešová, A., & Tupa, J. (2017). Requirements for education and qualification of people in Industry 4.0. Procedia Manufacturing, 11, 2195. https://doi.org/10.1016/j.promfg.2017.07.366.

Miškuf, M., & Iveta, Z. (2016). Comparison between multi-class classifiers and deep learning with focus on Industry 4.0. In Proceedings of 28th international conference cybernetics & informatics (K&I), pp. 1–5.

Lom, M., Priibyl, O., & Svitek, M. (2016). Industry 4.0 as a Part of Smart Cities (pp. 2–7). Prague: Smart Cities Symposium.

Mosterman, P. J., & Zander, J. (2015). Industry 4.0 as a cyber-physical system study. Software and Systems Modeling. https://doi.org/10.1007/s10270-015-0493-x.

Arnold, C., Kiel, D., & Voigt, K. I. (2017). Innovative business models for the industrial internet of things, (pp. 1–12 ). Springer, Originalarbeit. https://doi.org/10.1007/s00501-017-0667-7.

Reinheimer, S. (2015). Rezension Industrie 4.0 in Produktion, Automatisierung und Logistik (pp. 802–806). Springer IFachmedien: Wiesbad.

Stevens, G. C. (2005). Integrating the supply chain.

Hernández Sampieri, R., Fernández Collado, C., & Baptista Lucio, M. D. P. (2014). Metodología de la investigación (6th ed.). México: McGraw-Hill.

Rockwell-Automation, The Connected Enterprise Maturity Model, Rockwell Automation. (2014). http://literature.rockwellautomation.com. Accessed 24 May 2017.

FH-Obersterreich, Fitness-Check für industrie 4.0 Entwickelt, FH-Obersterreich. (2015). https://www.fh-ooe.at/facebook/fitness-check-fuer-industrie-40-entwickelt/. Accessed 24 May 2017.

Consult, Industry 4.0 Readiness Online Self-Check for Businesses, IMPULS Foundation of the German Engineering Federation (VDMA). (2015). https://www.industrie40-readiness.de/?lang=en. Accessed 10 June 2017.

competitividad, HADA - Herramienta de Autodiagnóstico Digital Avanzada, Gobierno de Espaa. (2016). https://hada.industriaconectada40.gob.es. Accessed 12 June 2017.

Lanza, G., Nyhuis, P., Ansari, S.M., Kuprat, T., & Liebrecht, C. (2016). Empowered and implementation strategy for Industry 4.0, Befhigungs-und Einfhrungsstrategien fr Industrie 4.0.

PWC, The Industry 4.0/Digital Operations Self Assessment, PricewaterhouseCoopers. (2016). https://i40-self-assessment.pwc.de/i40/landing/. Accessed 23 June 2017.

Acknowledgements

The authors thank the Consejo Nacional de Ciencia y Tecnología (CONACYT) for the support provided to the development of this research, as well as the Universidad Autónoma de Nuevo Len for being the study house to knowledge generation and the Facultad de Ingeniería Mecánica y Eléctrica (FIME) by the support granted.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pérez-Lara, M., Saucedo-Martínez, J.A., Marmolejo-Saucedo, J.A. et al. Vertical and horizontal integration systems in Industry 4.0. Wireless Netw 26, 4767–4775 (2020). https://doi.org/10.1007/s11276-018-1873-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11276-018-1873-2