Abstract

Colour is typically the initial pollutant identified in wastewater. Membrane separation represents a novel approach to separation processes, with expectations of supplanting many traditional separation systems. The aim of this study is to investigate polymer inclusion membranes (PIMs) consisting of tri octyl methyl ammonium chloride as the carrier, tributylphosphate as the modifier, poly-vinyl chloride as the base polymer and 2-Nitro phenyl pentyl ether as the plasticizer for removing an acid dye (Red Erionyl A-3G) from aqueous solution. The dye adsorption on the membrane surface and its transition to the stripping phase was achieved by placing the membrane between two glass cells. Changing the stripping solution ensured both adsorption on the membrane surface and the transfer of all the dye to the stripping stage. Using a mixture of 0.8 M salicylic acid and 0.8 M NaOH, along with stirring at 1000 rpm during the stripping phase, extraction efficiency reached 98% in the feed phase and 53% in the stripping phase. When 1 M NaOH solution was employed as the stripping solution, the membrane absorbed all the dye within 10 minutes, but there was no transition to the stripping phase. The membrane has a durability of 2 days.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Water pollution has become a significant global issue with the rapid growth of industrialization. Existing surface and groundwater reserves have been susceptible to contamination by various factors, including human and animal-borne pathogens, viruses, and bacteria. Additionally, industrial activities, including releasing heavy metals, benzene, dyes, and agricultural pollutants such as herbicides and pesticides, can also impact these water resources (Eskikaya et al., 2024). Among these pollutants, synthetic dyes attract particular attention due to their chemical structure and purification needs. Synthetic dyes have distinct and stable chemical structures, classified by their chromophores. They resist degradation and removal by physical and chemical processes (Ergene et al., 2009; Robinson et al., 2001).

Wastewater containing colored dyes from various industries can contaminate surface water and groundwater, ultimately affecting drinking water. Even though the dye concentration in the water is usually very low (less than one ppm for some dyes), its intense color can harm aquatic plants and disrupt the aquatic ecosystem. Paint waste materials have high chemical oxygen demand, limited biodegradability, and a substantial salt content, posing potential environmental hazards (Islam et al., 2023; Yabalak et al., 2021).

Therefore, decreasing the concentration of dyes in wastewater is crucial before its discharge into the environment. Various methods have been created for the elimination of dyes from wastewater (Yabalak et al., 2021). Chatla et al. (2022) used Mg-Ca-Al-LDO mixed metal oxide composite as an adsorbent in the removal of Eriochrome Black T (EBT) and chromium (Cr), both of which are potential pollutants due to their toxicity and serious effects, from an aqueous solution. Liquid-liquid extraction is a common method used for dye separation experiments (Kanakasabai et al., 2023).

Membrane separation is an innovative separation method that has the potential for many applications (Gul et al., 2021; Manzak et al., 2015; Manzak et al., 2022). Liu et al. (2007) utilized anion exchange membranes as adsorbents to isolate anionic reactive dyes from water. In their investigation, Wu et al. (2008) applied a cation exchange membrane to purify water that was contaminated with a cationic dye, specifically Methyl Violet 2B. A study conducted by Khan et al. (2023) investigated the removal of anionic dye Eosin-B (EB) from wastewater at field temperature using a QPPO/PVA based anion exchange membrane (AEM) BIII. The study found that the percentage removal of EB increased from 22% to 99.56% with contact time and from 38.15% to 99.56% with increasing membrane dosage.

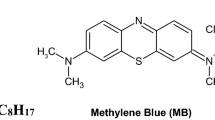

Liquid membrane techniques include emulsion liquid membrane, supported liquid membranes and polymer inclusion membranes. In 2008, Das et al. (2008). conducted experiments using two dyes, Crystal Violet (CV) and Methylene Blue (MB), in a liquid emulsion membrane. The membrane was formed using n-heptane as the membrane phase, sodium hydroxide solution as the internal phase, and dye solution as the external phase. Liquid membrane techniques have gained popularity recently for eliminating dyes from wastewater, with investigations focusing on extracting both anionic and cationic dyes from aqueous solutions (Benabela et al., 2023; Purtika & Jawa, 2022b; Raval et al., 2022).

Raval et al. (2022) were able to successfully remove Malachite Green dye (MG), which is known to be teratogenic, carcinogenic, mutagenic, and respiratory toxic, and has harmful effects on both humans and aquatic life, using the ELM method and the maximum removal efficiency of MG dye was 94.99%.

Purtika and Jawa (2022a) in their studies; they created a new, advanced and innovative green emulsion liquid membrane process (GELM) by using vegetable oils as green solvents instead of volatile organic solvents in the membrane phase and 95% success was achieved. In the work by Purtika and Jawa (2022b), Procion Blue MX-R (PB MX-R) dye, an anionic dye, was extracted from an aqueous feed solution using the green emulsion liquid membrane (GELM) technique with a recovery efficiency of 98.71%.

A supported liquid membrane is a modified form of liquid-liquid extraction that integrates a liquid membrane reinforced by a porous solid material. Ashraf et al. (2019) conducted a laboratory-scale study on the use of supported liquid membranes (SLM) for recovering and selectively removing Malachite Green dye from wastewater. Hajarabeevi et al. (2009) conducted a study on the transport of cationic dyes Methyl Violet and Rhodamine B from an aqueous synthetic dye solution using flat-type supported liquid membranes (SLM) and di(2-ethylhexyl) phosphoric acid (D2EHPA) as the carrier.

A novel liquid membrane system known as polymer PIMs has recently been developed in which a thin fixed film is created using polymer support, an organic solvent, extractant and plasticizer. PIMs offer many of the advantages of SLMs while also exhibiting excellent stability and versatility. Studies also report that PIMs are environmentally friendly and allow for the selective transport of chemical species (Manzak et al., 2017a; Manzak et al., 2017b; Mustafa et al., 2021).

A study utilized actual textile wastewater, treating it with the NF270 membrane, followed by the application of the thermally activated persulfate (TAP) oxidation method. The highest experimental values for chemical oxygen demand (COD) and color removal efficiencies reached 69% and 95%, respectively (Yabalak et al., 2021).

In 2024, Yang et al. conducted a study on modified montmorillonite. This work resulted in solvent-resistant membranes that could separate dye from salt at a high flux rate. The membranes demonstrated a significant increase in pure water flux, high dye rejection (>98.5%), low salt rejection (<10.0%), and good solvent resistance when used with six organic solvents (Yang et al., 2024).

Membrane treatment systems require membranes that possess antibacterial and anti-clogging properties. Doping nanomaterials in polymeric membranes can achieve these properties. For this purpose, in Eskikaya et al. (2024) study, black phosphorus (BP) blended with polyethersulfone (PES) to produce BP@PES membranes. During the Bovine Serum Albumin (BSA) rejection test, the bare PES membrane's removal efficiency was found to be 53.40%. In contrast, 0.5%BP@PES, 1.0%BP@PES, and 2.0%BP@PES showed removal efficiencies of 60.90%, 97.15%, and 100%, respectively.

Nawi et al., 2024, by vapor interfacial polymerization (VIP) technique, applying slow evaporation reaction, produced a finer polyamide (PA) network compared to the traditional interfacial polymerization approach and achieved significantly higher NaCl/dye selectivity than conventional ones (68.75).

Upon reviewing the recent literature on the subject, as can be seen in Table 1, it is clear that polymer inclusion membranes are not widely used for dye removal, unlike other types of membranes and extraction processes. This indicates that our research on dye removal using polymer inclusion membranes could provide a new and original approach to the field. The table presents a comparison of the applications for removing different types of dye in recent literature Table 2.

The objective of this study was to extract an acid dye from its aqueous solution using PIMs. This work has two sections. First, the dye from the aqueous solution was adsorbed on the membrane surface using PIMs and was thoroughly cleaned; on the other hand, it was transported from one phase to the other by passing through the membrane. For this purpose, a laboratory-scale mini PIM system was utilized with high precision to optimize solvent, energy, and time. The adsorption of the dye (Red Erionyl A-3G) onto the membrane and its removal by passing it through the membrane were investigated using two glass cells. The PIMs were composed of a plasticizer, 2-Nitro phenyl pentyl ether (2-NPPE), a carrier consisting of trioctylmethyl ammonium chloride (Aliquat 336) and a modifier, tributylphosphate (TBP), and a base polymer, poly-vinyl chloride (PVC). The extraction efficiency was examined across a range of experimental conditions, including initial dye concentration, mixing speed, stripping type and concentration, and membrane durability. The study resulted in a straightforward, economical, and secure option for removing dyes from aqueous solutions. The investigation yielded eliminating dyes from water-based solutions.

2 Experimental

2.1 Chemicals

The compounds employed in the investigation are all of analytical grade. The materials include PVC, 2-NPPE, TBP, and tetrahydrofuran (THF) from Riedel-de Haen, and Aliquat 336 from Cognis Corp., (Germany), NaOH (98%, pellets (anhydrous)/ ACS reagent, (97.0%, pellets), Na2CO3, HCl (36.5%), which are obtained from Merck. Erionyl Red A-3G, (Huntsman) with a molecular weight of 717.8 g/mol and a formula of C32H23N5O9S3.xNa.yK, is used in the experiments. The dye is dissolved in distilled water to prepare stock solutions, and solution concentrations are measured at the end of the process using a Shimadzu Ultraviolet brand UV-Vis spectrophotometer device at 507 nm wavelengths. In this study, 0.1 M NaOH and 0.1 M HCl solutions are employed for pH adjustment in Erionly Red A-3G solutions.

2.2 Preparation of the polymer inclusion membrane

The pouring method was used to prepare the membrane, and 480 mg of PVC was dissolved in 70 mL of THF at room temperature. Then, 0.1-0.5 mL of 2-NPPE was added to the solution. After mixing, Aliquat 336 (220 mg) and TBP (110 mg) were added, and the mixture was mechanically stirred for two hours until achieving homogeneity. The resulting mixture was poured slowly into a 24 cm x 24 cm glass container and left at room temperature overnight to allow the organic solvent to evaporate. Once the solvent had evaporated, the membrane was washed with cold distilled water and removed from its container Fig 1.

2.3 Erionyl Red A-3G Studies

The correct selection of membrane and stripping solution components can facilitate the extraction of various substances, such as dyes or organics. This article is the first study to investigate the simultaneous adsorption and transport into the stripping phase of the acid dye Erionyl Red A-3G from aqueous solutions to PIMs (Fig. 2 and Fig. 3). The study examines the effects of various parameters, including stripping phase type and concentration, mixing speed, and membrane durability on the extraction of the acid dye from dilute aqueous solutions using PIMs. The experiments were conducted twice, and the results obtained from both trials were similar.

3 Results and discussion

3.1 Effect of mixing speed

The membrane was positioned inside the test cell, and the mixing rate was adjusted from 800 to 1650 rpm. The extraction experiments used 50 ppm Erionyl Red A-3G as a feed solution and 0.01 M NaOH as the stripping solution. The time-dependent changes in extraction efficiency was shown in Fig. 4. The results showed that the highest extraction efficiency was achieved at 1000 rpm with a value of 79%. At 800 rpm, the extraction efficiency was 69%, while at 1200 rpm, it was 62%. However, the extraction efficiency significantly decreased to 28% at 1500 rpm. Finally, at 1650 rpm, the extraction efficiency was 40%.

According to Fig. 4, when mixing speeds were set at 800, 100 and 1200 rpm, the dye adsorbed on the membrane surface and did not transfer to the stripping phase. On the other hand, after 24 hours of testing, about 13% of the dye was transferred to the stripping phase at mixing speeds at 1650 rpm, as shown in Fig. 5.

As the feed mixing speed increases, the thickness of the boundary layer of the liquid phase near the feed-membrane interface decreases. As a result, the dye extraction rate increases. However, if the mixing speed continues to increase, the rate of extraction slows down and this is due to the decrease in the extraction rate as the dye-carrier complex density increases.

3.2 Effect of stripping phase type

In the PIM process, removing the extracted species from the membrane phase to the stripping phase is essential. Transport of dye from the aqueous feed phase across the membrane depends on the stripping reagent on the product side of the membrane. This means that the presence of NaOH and Na2CO3 in the stripping phase helps transport the dye by converting it to a hydrophilic moiety. Inorganic anions such as OH- and CO32- were ineffective at stripping dye at low mixing speeds, as demonstrated by stripping with 0.01 M NaOH and 0.01 M Na2CO3.

Figure 6 indicates that using 0.01 M NaOH yielded a 62% efficiency rate. In contrast, using 0.01 M Na2CO3 resulted in only 28% efficiency in the feed phase, as shown by the efficiency results.

3.2.1 Effect of NaOH concentration

The concentration of NaOH was varied 0.01 M, 0.05 M, 0,1 M, and 1 M for stripping, and the highest efficiency of 100% was achieved with 1 M NaOH solution at a mixing speed of 1500 rpm in the 10 hour in the feed phase but there was no transition to the stripping phase. However, after 24 hours with 0.1 M NaOH, 16% passed into the stripping phase. Stripping experiments for the extracted dyes were conducted at an increased rate using a NaOH solution in which water-insoluble salicylic acid was dissolved (Muthuraman & Palanivelu, 2005).

The effect of the stripping concentration in the test cell in the Erionyl Red A-3G staining solution was studied with time variations and is shown in Fig. 7.

3.2.2 Effect of salicylic acid and NaOH mixture

The stripping solution used was a combination of NaOH and salicylic acid. The concentrations of 0.1 M, 0.5 M, and 0.8 M were tested at a mixing speed of 1000 rpm. The 0.8 M salicylic acid + 0.8 M NaOH mixture achieved the most effective extraction efficiency, resulting in a 98% efficiency in the feed phase and 53% in the stripping phase, as depicted in Fig. 8.

3.3 Membrane durability

The robustness of the membrane was evaluated by performing a 2-day test in the test cell at the highest mixing speeds of 1650 rpm. 50 ppm Erionyl Red A-3G feed solution and 0.01 M NaOH stripping solution were used to test the extraction efficiency. The extraction efficiency, as shown in Fig. 9, was determined to be 53% in the feed phase and 24% in the stripping phase after 50 hours.

In Yildiz and Manzak’s (2016) study on membrane durability, the RF value was found to be 90% even though the membrane was used five times. Yıldız and Manzak (2022) study carried out with PIMs containing PVC, 2-NPPE, and Aliquat 336 carrier showed no evidence of flux decrease or substance loss in the extraction experiments for 14 days. Although the membrane composition is the same in this study, it is thought that resistance occurs on the membrane due to the density of the dye-carrier complex. This resistance limited the membrane durability to two days.

Extraction efficiency and durability are greater in newly produced membranes. Increased waiting time before experiment influence membrane of particle size and extraction efficiency (Yildiz & Manzak, 2016).

The results obtained in the study of Ozay et al. (2022) depicted that permeability, porosity, pore size, and contact angle were seriously affected by independent variables such as concentration of H2O2, treatment time, temperature. H2O2 and temperature degraded the PES polymer depending on the treatment time and caused bigger pore sizes to be obtained.

3.4 Transport mechanism

Aliquat 336 (Tricaprylmethylammonium chloride) in the membrane phase facilitates the transfer of acid dyes from the feed phase to the membrane phase. The stripping step of species extracted in the organic phase is important in the membrane process. Inorganic anions such as OH- and CO32- are ineffective in stripping dye. A stripping solution was prepared by dissolving water-insoluble salicylic acid in NaOH. The dye molecule combines with tricaprylmethylammonium chloride to produce an ion pair in a 1:1 ratio. This dye-amine complex is then transported across the membrane and reacts with the stripping solution (NaOH and salicylic acid) at the interface of the membrane stripping phase (Fig. 10). In the reaction, SA serves as the protonating agent, leading to the weakening of hydrogen bonds connected to the carrier. Hydrogen bonds are located in dye removal mechanisms in the Shah et al. (2024) study. These weakened hydrogen bonds facilitate the transport of dye ions as complexes with the carrier through the membrane phase. Subsequently, the receiving anions within the internal phase strip the dye ions from their dye-carrier complexes. The equations responsible for the extraction and stripping of the dye from the membrane are represented by equations 1, 2, and 3.

TBP acts as the modifier to improve extraction efficiency. The extraction and stripping reactions for TBP are detailed in Equations (4) and (5).

3.5 SEM and AFM Images

The Erionyl Red A-3G adsorption on PVC and the particle’s surface morphology were evaluated using the field emission scanning electron microscopes (FE-SEM) and atomic force microscope (AFM) technique. FE-SEM examination was carried out before and after dye adsorption to explore the structure and morphology of membranes and the representative images were illustrated in Fig. 11(a and b).

The cross-section and top surface morphologies of the pure and after-dye adsorption membranes were studied via FE-SEM. Membranes were cut small size and frozen in liquid nitrogen to generate a cryofracture for cross-sectional scanning. Before imaging, a conductive gold layer was deposited onto the samples. The analysis revealed that the structure and morphology of the membrane changed significantly after adsorption, indicating a notable effect on the membrane.

The AFM images depicted in Fig. 11(c) and (d) reveal that following dye adsorption, there is noticeable accumulation of dye on the membrane, leading to an increase in surface roughness. As can be seen from the cross section of (e) pure membrane and (f) FE-SEM results after the adsorption of Erionyl Red A-3G in Fig. 11, there was a thickening in the cross section after dye adsorption.

Changes in surface properties were observed after adsorption, resulting in a denser and rougher surface, as confirmed by FE-SEM and AFM images. The FE-SEM images demonstrate the membrane's uniform surfaces, which appear dense with tiny pores. Notably, the membranes exhibited regular surfaces with no substantial defects or compromise to their integrity. This indicates a homogeneous distribution of the Aliquat 336 within the PVC structure, maintaining the smooth and defect-free topography of the membranes.

Cross-sectional images of PIMs reveal that Aliquat 336 is evenly distributed within the PVC/Aliquat 336 matrix. A similar structure was also noted by Sellami et al. (2024), who used PIMs (PVC/Aliquat 336) with low filler concentration (up to 10 wt%).

The image of the membrane before adsorption displays porous tissues. The surface of the dye is attached to the porous surface. The porous surface has the surface of Erionyl Red A-3G bonded to it.

A significant change in the membrane cross-sectional structure was observed after dye adsorption. The surface pores fill and exhibit a thicker cross structure, resulting in thickening of the cross section. This indicates that dye adsorption has occurred successfully and confirms the ability of the membrane to adsorb dye without compromising its structural integrity.

The surface appearance of PVC-based PIMs is affected by the amount of carrier and/or plasticizer added. A smooth surface is obtained when the plasticizer is relatively low (i.e., <40%). However, as the content of the liquid phase increases, a rough and irregular surface forms. The surface becomes rougher when the membrane contains filler (Sellami et al., 2024).

The membrane containing the filler (Aliquat 336) becomes rougher after dye adsorption.

4 Conclusion

Through this study, a simple, cost-effective, and easy-to-implement method was found for dye removal from aqueous solutions. This is the first article to discuss both acid dye adsorption from aqueous solutions and its transport to the stripping stage through polymer inclusion membranes. The membrane contains 480 mg PVC, 0.2 mL 2-NPPE, 220 mg Aliquat 336, and 110 mg TBP. When 1 M NaOH was used as the stripping solution, 100% dye was adsorbed to the membrane, and no dye remained in the feed solution. However, dye transfer to the stripping solution did not occur. The most effective extraction efficiency was obtained with a mixture of 0.8 M salicylic acid + 0.8 M NaOH, with an efficiency of 98% in the feed phase and 53% in the stripping phase. A membrane that adsorbs the dye in the feed solution with 100% efficiency has been developed, which is vital for a successful and clean process.

Here are goals for future work:

-

Enhancing the success rate of dye recovery on the membrane during its stripping phase (currently at 53%).

-

Improving the composition of the membrane to increase its strength and durability.

-

Prioritizing the use of ecologically friendly chemicals in the membrane preparation.

Data Availability

The authors confirm the data supporting the findings are available within this article.

References

Almanassra, I. W., Jaber, L., Chatla, A., Abushawish, A., Shanableh, A., & Atieh, M. A. (2023). Unveiling the relationship between MOF porosity, particle size, and polyethersulfone membranes properties for efficient decontamination of dye and organic matter. Chemical Engineering Journal, 471, 144616. https://doi.org/10.1016/j.cej.2023.144616

Ashraf, M. W., Abulibdeh, N., & Salam, A. (2019). Selective Removal of Malachite Green Dye from Aqueous Solutions by Supported Liquid Membrane Technology. International Journal of Environmental Research and Public Health, 16(18), 3484. https://doi.org/10.3390/ijerph16183484

Ashraf, M. W., Collins, M. P., Mir, M. A., Salam, A., & Ul-Hamid, A. (2022). Separation of crystal violet dye from wastewaters by using supported liquid membrane technology. Journal of Chemistry, 2022(1), 8143981. https://doi.org/10.1155/2022/8143981

Benabela, I., Benderrag, A., Haddou, B., Canselier, J. P., & Gourdon, C. (2023). Dye removal with emulsion liquid membrane: experimental design and response surface methodology. Environmental Technology, 44(28), 4296–4312. https://doi.org/10.1080/09593330.2022.2091480

Chatla, A., Almanassra, I. A., Kochkodan, V., Laoui, T., Alawadhi, H., & Atieh, M. A. (2022). Efficient Removal of Eriochrome Black T (EBT) Dye and Chromium (Cr) by Hydrotalcite-Derived Mg-Ca-Al Mixed Metal Oxide Composite. Catalysts, 12, 1247. https://doi.org/10.3390/catal12101247

Das, C., Rungta, M., Arya, G., DasGupta, S., & De, S. (2008). Removal of dyes and their mixtures from aqueous solution using liquid emulsion membrane. Journal of Hazardous Materials, 159, 365–371. https://doi.org/10.1016/j.jhazmat.2008.02.027

Elumalai, S., Sathya, S., & Muthuraman, G. (2015). Recovery of dye from wastewater using liquid-liquid extraction and bulk liquid membrane techniques. International Journal of ChemTech Research, 7(7), 3089–3094.

Ergene, A., Ada, K., & Katırcıoğlu, H. (2009). Removal of Remazol Brilliant Blue R Dye from Aqueous Solutions by Adsorption onto Immobilized Scenedesmus quadricauda: Equilibrium and Kinetic Modeling Studies. Desalination, 249(3), 1308–1314. https://doi.org/10.1016/j.desal.2009.06.027

Eskikaya, O., Kucukosman, R., Ozdemir, S., Yalcin, M. S., Ocakoglu, K., & Dizge, N. (2024). Investigation of the treatment and antibacterial properties of pollutant-containing water using black phosphorus blended polyethersulfone membranes (BP@PES). Journal of Water Process Engineering, 57, 104581. https://doi.org/10.1016/j.jwpe.2023.104581

Fetimi, A., Dˆaas, A., Benguerba, Y., Merouani, S., Hamachi, M., Kebiche-Senhadji, O., & Hamdaoui, O. (2021). Optimization and prediction of safranin-O cationic dye removal from aqueous solution by emulsion liquid membrane (ELM) using artificial neural network-particle swarm optimization (ANN-PSO) hybrid model and response surface methodology (RSM). Journal of Environmental Chemical Engineering, 9, 105837. https://doi.org/10.1016/j.jece.2021.105837

Ghanbari, R., Kahriz, P. K., & Mahdavi, H. (2022). Metal-organic framework/H2O2- exfoliated g-C3N4/poly(vinylidene fluoride) composite nanofiltration membranes. Materials Chemistry and Physics, 292, 126751. https://doi.org/10.1016/j.matchemphys.2022.126751

Gul, S., Manzak, A., & Cetinel, G. (2021). Prediction of Succinic Acid Extraction Efficiency in the Emulsion Liquid Membrane by using Machine Learning Techniques. Journal of the Chemical Society of Pakistan (JCSP), 43(2), 104–113.

Hajarabeevi, N., Mohammed Bilal, I., Easwaramoorthy, D., & Palanivelu, K. (2009). Facilitated transport of cationic dyes through a supported liquid membrane with D2EHPA as carrier. Desalination, 245, 19–27. https://doi.org/10.1016/j.desal.2008.06.009

HajKacem, S., Galai, S., Hernández-Fernandez, F. J., et al. (2019). Bioreactor Membranes for Laccase Immobilization Optimized by Ionic Liquids and Cross-Linking Agents. Applied Biochemistry and Biotechnology, 1901(190), 1–17. https://doi.org/10.1007/S12010-019-03085-Z

Islam, T., Repon, M. R., Islam, T., Sarwar, Z., & Rahman, M. M. (2023). Impact of textile dyes on health and ecosystem: a review of structure, causes, and potential solutions. Environmental Science and Pollution Research, 30, 9207–9242. https://doi.org/10.1007/s11356-022-24398

Kaczorowska, M. A., Bozejewicz, D., & Witt, K. (2023). The Application of Polymer Inclusion Membranes for the Removal of Emerging Contaminants and Synthetic Dyes from Aqueous Solutions-A Mini Review. Membranes, 2023(13), 132. https://doi.org/10.3390/membranes13020132

Kanakasabai, P., Sivamani, S., & Thirumavalavan, K. (2023). Box–Behnkendesign and analysis for liquid–liquid extraction of methyl red dye from its aqueous solution with benzene. Chemical Papers, 77, 7225–7235. https://doi.org/10.1007/s11696-023-03013-w

Khan, M. L., Shanableh, A., Alfantazi, A. M., Lashari, M. H., Manzoor, S., Anwer, R., Farooq, N., Harraz, F. A., Alsaiari, M., Faisal, M., & M. (2023). Application of QPPO/PVA based commercial anion exchange membrane as an outstanding adsorbent for the removal of Eosin-B dye from wastewaters. Chemosphere, 321, 138006. https://doi.org/10.1016/j.chemosphere.2023.138006

Kumar, V., Karnjkar, Y., George, P., Singh, R. K., & Chowdhury, P. (2018). Effective removal of Congo red using sunflower oil/tri-n-octylamine system in a bulk liquid membrane process and studying the transport kinetics. Chemical Papers, 72(8), 2055–2069. https://doi.org/10.1007/s11696-018-0438-2

Liu, C. H., Wu, J. S., Chiu, H. C., Suen, S. Y., & Chu, K. H. (2007). Removal of anionic reactive dyes from water using anion exchange membranes as adsorbers. Journal of Water Process Engineering (JWPE), 41(7), 1491–1500. https://doi.org/10.1016/j.watres.2007.01.023

Liu, Y., Shen, L., Huang, Z., Liu, J., Xu, Y., Li, R., Zhang, M., Hong, H., & Lin, H. (2022). A novel in-situ micro-aeration functional membrane with excellent decoloration efficiency and antifouling performance. Journal of Membrane Science, 641, 119925. https://doi.org/10.1016/j.memsci.2021.119925

Mahdavi, H., & Ghanbari, R. (2022). Preparation of loose nanofiltration PVDF membrane coated with dopamine and EPPTMS layers based on mussel inspired technique and ring-opening reaction via a facile VIPS-NIGPS method for dye separation applications. Industrial & Engineering Chemistry Research, 113, 132–141. https://doi.org/10.1016/j.jiec.2022.04.029

Mahdavi, H., Zeinalipour, N., Kerachian, M. A., & Heidari, A. A. (2022). Preparation of highperformance PVDF mixed matrix membranes incorporated with PVDF-g-PMMA copolymer and GO@SiO2 nanoparticles for dye rejection applications. Journal of Water Process Engineering, 46, 102560. https://doi.org/10.1016/j.jwpe.2022.102560

Mahdavi, H. R., Arzani, M., Isanejad, M., & Mohammadi, T. (2018). Effect of hydrophobic and hydrophilic nanoparticles loaded in D2EHPA/M2EHPA - PTFE supported liquid membrane for simultaneous cationic dyes pertraction. Journal of Environmental Management, 213, 288–296. https://doi.org/10.1016/j.jenvman.2018.02.071

Manzak, A., Kurşun, C., & Yıldız, Y. (2017a). Characterization of humic acid extracted from aqueous solutions with polymer inclusion membranes. Journal of the Taiwan Institute of Chemical Engineers, 81, 14–20. https://doi.org/10.1016/j.jtice.2017.10.024

Manzak, A., Kurşun, C., & Yıldız, Y. (2017b). Extraction of humic acid from an aqueous solution with polymer inclusion membranes. Sakarya University Journal of Science, 21(6), 1160–1164. https://doi.org/10.16984/saufenbilder.295273

Manzak, A., Yıldız, Y., Sezer, M., & Demirhan, N. (2022). Extraction of metal ions using polymer inclusion membranes containing 1, 10-phenanthroline and PEG. Chemical Paper, 76(5), 2907–2915. https://doi.org/10.1007/s11696-022-02080-9

Manzak, A., Yıldız, Y., & Tutkun, O. (2015). Characterization of polymer inclusion membrane containing Aliquat 336 as a carrier. The Membrane and Water Treatment (MWT), 6(2), 95–102. https://doi.org/10.12989/mwt.2015.6.2.095

Mustafa, K., Musaddiq, S., Farrukh, S., Ahmad, S., Rasheed, H., & Fayyaz, I. (2021). 3-(Aminopropyl)triethoxysilane modified CuO nanoparticles-mediated adsorbent for removal of methylene blue through polymer inclusion membranes transport: optimization of operational variables. Desalination and Water Treatment. https://doi.org/10.5004/dwt.2021.27838

Muthuraman, G., & Palanivelu, K. (2005). Selective extraction and separation of textile anionic dyes from aqueous solution by tetrabutyl ammonium bromide. Dyes Pigments, 64(3), 251–257. https://doi.org/10.1016/j.dyepig.2004.05.014

Muthuraman, G., & Teng, T. T. (2009). Extraction and recovery of rhodamine B, methyl violet and methylene blue from industrial wastewater using D2EHPA as an extractant. Journal of Industrial and Engineering Chemistry, 15, 841–846. https://doi.org/10.1016/j.jiec.2009.09.010

Muthuraman, G., & Teng, T. T. (2010). Use of vegetable oil in supported liquid membrane for the transport of Rhodamine B. Desalination, 249(3), 1062–1066. https://doi.org/10.1016/j.desal.2009.05.017

Nawi, N. S. M., Lau, W. J., Yusof, N., Goh, P. S., Wahab, R. A., & Ismail, A. F. (2024). Solvent-free polyamide TFC membrane fabrication based on TMC vaporization for saline water recovery. Desalination, 575. https://doi.org/10.1016/j.desal.2024.117316

Ozay, Y., Yabalak, E., & Dizge, N. (2022). Effects of hydrogen peroxide, temperature and treatment time on degradation properties of polyethersulfone ultrafiltration membrane. Turkish Journal of Chemistry, 46, 206–216. https://doi.org/10.3906/kim-2109-10

Purtika, A. T., & Jawa, G. K. (2022a). Comparative study on effect of ionic liquids on static stability of green emulsion liquid membrane. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 644, 128776. https://doi.org/10.1016/j.colsurfa.2022.128776

Purtika, A. T., & Jawa, G. K. (2022b). Screening of parameters and optimization for green recovery of anionic dye by nanoparticle-ionic liquid-based green emulsion liquid membrane using response surface methodology. Chemical Engineering & Processing: Process Intensification, 181, 109156. https://doi.org/10.1016/j.cep.2022.109156

Raval, A. R., Kohli, H. P., & Mahadwad, O. K. (2022). Application of emulsion liquid membrane for removal of malachite green dye from aqueous solution: extraction and stability studies. Chemical Engineering Journal Advances, 12, 100398. https://doi.org/10.1016/j.ceja.2022.100398

Robinson, T., McMullan, G., Marchant, R., & Nigam, P. (2001). Remediation of dyes in textile effluent, a critical review on current treatment technologies with a proposed alternative. Bioresource Technology, 77, 247–255. https://doi.org/10.1016/S0960-8524(00)00080-8

Rosly, M. B., Jusoh, N., Othman, N., Rahman, H. A., Noah, N. F. M., & Sulaiman, R. N. R. (2020). Synergism of Aliquat336-D2EHPA as carrier on the selectivity of organic compound dyes extraction via emulsion liquid membrane process. Separation and Purification Technology, 239, 116527. https://doi.org/10.1016/j.seppur.2020.116527

Sellami, F., Marais, S., Kebiche-Senhadji, O., Kobzar, Y., & Fatyeyeva, K. (2024). Poly(vinyl chloride)-based advanced polymer inclusion membranes with Aliquat 336 and inorganic filler for efficient Cr(VI) removal. Chemical Engineering Journal, 493, 152056. https://doi.org/10.1016/j.cej.2024.152056

Shah, I. A., Bilal, M., Almanassra, I. A., & Ihsanullah, I. (2024). A comprehensive review of graphene oxide-based membranes for efficient dye removal from water sources. Separation and Purification Technology, 330, 125277. https://doi.org/10.1016/j.seppur.2023.125277

Shin, J. H., Yang, J. E., Park, J. E., Jeong, S. W., Choi, S. J., Choi, Y. J., & Jeon, J. (2022). Rapid and efficient removal of anionic dye in water using a chitosan-coated iron oxideimmobilized polyvinylidene fluoride membrane. ACS Omega, 7, 8759–8766. https://doi.org/10.1021/acsomega.1c06991

Suliman, S. S., Othman, N., Noah, N. F. M., & Kahar, I. N. S. (2023). Separation of phenolic compounds from fruit processing wastewater using liquid membrane technology: A short review. Biochemical Engineering Journal, 200, 109096. https://doi.org/10.1016/j.bej.2023.109096

Suresh, R., Rajendran, S., Gnanasekaran, L., Show, P. L., Wei-Hsin Chen, W. H., & Moscoso, M. S. (2023). Modified poly(vinylidene fluoride) nanomembranes for dye removal from water A review. Chemosphere, 322, 138152. https://doi.org/10.1016/j.chemosphere.2023.138152

Wu, J. S., Liu, C. H., Chu, K. H., & Suen, S. Y. (2008). Removal of Cationic Dye Methyl Violet 2B from Water by Cation Exchange Membranes. Journal of Membrane Science, 309, 239–245. https://doi.org/10.1016/j.memsci.2007.10.035

Yabalak, E., Ozay, Y., Vatanpour, V., & Dizge, N. (2021). Membrane concentrate management for textile wastewater with thermally activated persulfate oxidation method. Water and Environment Journal, 35, 1281–1292. https://doi.org/10.1111/wej.12718

Yang, X., Lin, L., Liu, Z., Yang, J., Cheng, Q., Ma, W., Xu, M., Tang, F., Wang, Q., Li, X., He, A., Wang, C., & Zhang, X. (2024). Preparation of solvent-resistant polyimide membranes for efficient separation of dyes and salts via an “internal drive” strategy. Separation and Purification Technology, 332, 125843. https://doi.org/10.1016/j.seppur.2023.125843

Yildiz, Y., & Manzak, A. (2016). Stability and durability of polyvinyl chloride membranes consisting of Aliquat 336. In 3st International Turkic World Conference on Chemical Sciences and Technologies. Macedonia.

Yıldız, Y., & Manzak, A. (2022). Polivinil Klorür İçeren Membranın Karakterizasyon ve Ekstraksiyon Veriminin Zaman İçerisinde Değişimi. Osmaniye Korkut Ata Üniversitesi Fen Bilimleri Enstitüsü Dergisi, 5(2), 897–907.

Zhang, R., Yang, Z., Hu, Z., Zhao, C., Zeng, K., Yu, J., Cai, L., Chen, Z., & Jiang, J. (2022). Modification of PVDF membranes using BiOBr precursor in-situ deposition and tannic acid self-assembly for effectively removing organic pollutants. Applied Surface Science, 599, 153888. https://doi.org/10.1016/j.apsusc.2022.153888

Funding

Open access funding provided by the Scientific and Technological Research Council of Türkiye (TÜBİTAK). The financial support of this work was provided by the scientific research commission of Sakarya University (BAPK), Project No: 2018-50-01-014 is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Manzak, A., Demirbaş, Ö., Yıldız, Y. et al. Adsorption and transport of acid dye through polymer inclusion membrane with Aliquat 336 and TBP. Water Air Soil Pollut 235, 501 (2024). https://doi.org/10.1007/s11270-024-07318-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11270-024-07318-8