Abstract

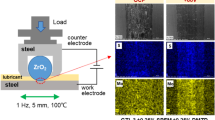

Nickel acetyl acetonate (Ni(acac)2), a metal-organic compound, was directly dispersed in base oils alkylated naphthalene (AN-5), diisooctyl sebacate (DIOS), poly-α-olefin (PAO6), and mineral oil (liquid hydrocarbon mixtures:150 N) in the presence of commercial dispersant RF1151 (monoallyl poly(isobutylene succinimide). The tribological properties of the lubricants were tested with a four-ball friction and wear tester. The friction-induced in-situ formation of carbon films on rubbed steel surfaces under the catalysis of Ni(acac)2 was investigated, and the as-formed carbon films were characterized by scanning electron microscopy, Raman spectroscopy, and X-ray photoelectron spectroscopy. The results show that Ni(acac)2 added in the base oils can decompose to form metallic nickel to form nickel layer on the rubbed metal sub-surfaces and catalyze the degradation of the base oil molecules adsorbed to form carbon-based tribofilms. The carbon film formed from AN-5 with aromatic ring structure has a high degree of graphitization and the best friction-reducing and antiwear abilities, and those formed from PAO6 and 150 N with linear structure have a low degree of graphitization as well as good tribological properties. Under the lubrication of DIOS with Ni(acac)2, however, there is no carbon film formation while the tribological properties of the lubricant are relatively poor, due to the absence of the catalytic metallic nickel and nickel oxide layer on the rubbed metal sub-surface. Thanks to the catalytic effect of metallic nickel released from Ni(acac)2 for the degradation of various base oils with different molecular structure, the present approach could provide a rational pathway to tune the in-situ formation of carbon-based tribofilm on rubbed steel surfaces so as to effectively reduce the friction and wear of steel-steel sliding pair.

Similar content being viewed by others

Data Availability

The data that support the findings of this study are available from the corresponding author (S.Z.) upon reasonable request.

References

He, D.Q., He, C., Li, W.S., Shang, L.L., Wang, L.P., Zhang, G.G.: Tribological behaviors of in-situ textured DLC films under dry and lubricated conditions. Appl. Surf. Sci. 525, 164581 (2020). https://doi.org/10.1016/j.apsusc.2020.146581

Cyriac, F., Yi, T.X., Poornachary, S.K., Chow, P.S.: Behavior and interaction of boundary lubricating additives on steel and DLC-coated steel surfaces. Tribol Int. 164, 107199 (2021). https://doi.org/10.1016/j.triboint.2021.107199

Liu, Y., Zhang, H.: Roles of transfer layer and surface adhesion on superlubricity behaviors of diamond-like carbon film depending on rotating and reciprocating motion. Appl. Surf. Sci. 604, 154538 (2022). https://doi.org/10.1016/j.apsusc.2022.154538

Chen, S., Song, N., Zhang, S., Zhang, Y., Yu, L., Zhang, P.: Synergistic tribological effect between polyisobutylene succinimide-modified molybdenum oxide nanoparticle and zinc dialkyldithiophosphate for reducing friction and wear of diamond-like carbon coating under boundary lubrication. Friction. 11, 2021–2035 (2023). https://doi.org/10.1007/s40544-022-0708-4

Rajak, D.K., Kumar, A., Behera, A., Menezes, P.L.: Diamond-Like Carbon (DLC) Coatings: Classification, Properties, and applications. Appl. Sci. 11(10), 4445 (2021). https://doi.org/10.3390/app11104445

Aisenberg, S., Chabot, R.: Ion-Beam Deposition of Thin films of Diamondlike Carbon. J. Appl. Phys. 42, 2953–2958 (1971). https://doi.org/10.1063/1.1660654

Bendavid, A., Martin, P.J., Comte, C., Preston, E.W., Haq, A.J., Magdon Ismail, F.S., et al.: The mechanical and biocompatibility properties of DLC-Si films prepared by pulsed DC plasma activated chemical vapor deposition. Diam. Relat. Mater. 16, 1616–1622 (2007). https://doi.org/10.1016/j.diamond.2007.02.006

Yılmaz Ozmen, A.T., Touru Sumiya: The effect of humidity on the tribological behavior of diamond-like carbon (DLC) film coated on WC-Co by physical vapor deposition method. Surf. Coat. Technol. 133–134, 455–459 (2000). https://doi.org/10.1016/S0257-8972(00)00929-4

Fein, R.S., Kreuz, K.L.: Chemistry of Boundary Lubrication of Steel by hydrocarbons. A S. L E Trans. 8, 29–38 (1965). https://doi.org/10.1080/05698196508972076

Erdemir, A., Ramirez, G., Eryilmaz, O.L., Narayanan, B., Liao, Y., Kamath, G., et al.: Carbon-based tribofilms from lubricating oils. Nature. 536(7614), 67–71 (2016). https://doi.org/10.1038/nature18948

Xu, X., Xu, Z., Sun, J., Tang, G., Su, F.: In situ synthesizing Carbon-based Film by Tribo-Induced Catalytic degradation of poly-alpha-olefin oil for reducing friction and wear. Langmuir. 36(35), 10555–10564 (2020). https://doi.org/10.1021/acs.langmuir.0c01896

Hu, J., Zhang, Y., Yang, G., Gao, C., Song, N., Zhang, S., et al.: In-situ formed carbon based composite tribo-film with ultra-high load bearing capacity. Tribol Int. 152, 106577 (2020). https://doi.org/10.1016/j.triboint.2020.106577

Hu, J., Wang, C., Zhang, P., Zhang, S., Zhang, Y.: Diisooctyl Sebacate-Containing Nickel Nanoparticles for Lubrication of Steel Sliding Parts under magnetic fields. ACS Appl. Nano Mater. 4(7), 7007–7016 (2021). https://doi.org/10.1021/acsanm.1c01053

Chang, Q., Rudenko, P., Miller, D.J., Wen, J., Berman, D., Zhang, Y., et al.: Operando formation of an ultra-low friction boundary film from synthetic magnesium silicon hydroxide additive. Tribol Int. 110, 35–40 (2017). https://doi.org/10.1016/j.triboint.2017.02.003

Johnson, B., Wu, H., Desanker, M., Pickens, D., Chung, Y.-W., Wang, J.: Direct formation of lubricious and wear-Protective Carbon films from Phosphorus- and sulfur-free oil-soluble additives. Tribol Int. 66(1) (2017). https://doi.org/10.1007/s11249-017-0945-2

Fu, X., Cao, L., Wan, Y., Li, R.: Superlubricity achieved with TiN coatings via the in situ formation of a carbon-based film at the sliding interfaces. Ceram. Int. 47(23), 33917–33921 (2021). https://doi.org/10.1016/j.ceramint.2021.08.229

Corsini, C., Peeters, S., Righi, M.C.: Adsorption and Dissociation of Ni(acac)2 on Iron by ab Initio calculations. J. Phys. Chem. A. 124, 8005–8010 (2020). https://doi.org/10.1021/acs.jpca.0c05040

Yu, H., Liu, X., Zheng, Z., Qiao, D., Feng, D., Gong, Z., et al.: In situ graphene formation Induced by Tribochemical reaction for sustainable lubrication. ACS Sustainable Chem. Eng. 11(6), 2238–2248 (2023). https://doi.org/10.1021/acssuschemeng.2c05639

El Mendili, Y., Bardeau, J.F., Randrianantoandro, N., Greneche, J.M., Grasset, F.: Structural behavior of laser-irradiated gamma-Fe2O3 nanocrystals dispersed in porous silica matrix: gamma- Fe2O3 to alpha- Fe2O3 phase transition and formation of epsilon- Fe2O3. Sci. Technol. Adv. Mater. 17(1), 597–609 (2016). https://doi.org/10.1080/14686996.2016.1222494

Bushiri, M.J., Gopi, D.N., Monteseguro, V., Sans, J.A.: High-pressure Raman investigation of high index facets bounded alpha- Fe2O3 pseudocubic crystals. J. Phys. Condens. Matter. 33(8), 085701 (2020). https://doi.org/10.1088/1361-648X/abcb11

Erdemir, A., Eryilmaz, O.L., Kim, S.H.: Effect of tribochemistry on lubricity of DLC films in hydrogen. Surf. Coat. Technol. 257, 241–246 (2014). https://doi.org/10.1016/j.surfcoat.2014.08.002

Vautard, F., Ozcan, S., Paulauskas, F., Spruiell, J.E., Meyer, H., Lance, M.J.: Influence of the carbon fiber surface microstructure on the surface chemistry generated by a thermo-chemical surface treatment. Appl. Surf. Sci. 261, 473–480 (2012). https://doi.org/10.1016/j.apsusc.2012.08.038

Couzi, M., Bruneel, J.-L., Talaga, D., Bokobza, L.: A multi wavelength Raman scattering study of defective graphitic carbon materials: The first order Raman Spectra revisited. Carbon. 107, 388–394 (2016). https://doi.org/10.1016/j.carbon.2016.06.017

Moseenkov, S.I., Kuznetsov, V.L., Zolotarev, N.A., Kolesov, B.A., Prosvirin, I.P., Ishchenko, A.V., et al.: Investigation of Amorphous Carbon in Nanostructured Carbon materials (a comparative study by TEM, XPS, Raman Spectroscopy and XRD). Mater. (Basel). 16(3), 1112 (2023). https://doi.org/10.3390/ma16031112

Fan, X.Q., Wang, L.P.: High-performance lubricant additives based on modified graphene oxide by ionic liquids. J. Colloid Interf Sci. 452, 98–108 (2015). https://doi.org/10.1016/j.jcis.2015.04.025

Zhang, R., Qiao, D., Liu, X., Guo, Z., Cai, M., Shi, L.: A facile and effective method to improve the dispersibility of WS2 nanosheets in PAO8 for the tribological performances. Tribol Int. 118, 60–70 (2018). https://doi.org/10.1016/j.triboint.2017.09.012

Rajendhran, N., Palanisamy, S., Periyasamy, P., Venkatachalam, R.: Enhancing of the tribological characteristics of the lubricant oils using Ni-promoted MoS2 nanosheets as nano-additives. Tribol Int. 118, 314–328 (2018). https://doi.org/10.1016/j.triboint.2017.10.001

Meng, Y., Su, F., Chen, Y.: Nickel/Multi-walled Carbon Nanotube Nanocomposite synthesized in supercritical fluid as efficient lubricant additive for Mineral Oil. Tribol Int. 66(4), 134 (2018). https://doi.org/10.1007/s11249-018-1088-9

Wang, L., Huang, Y., Li, C., Chen, J., Sun, X.: Hierarchical composites of polyaniline nanorod arrays covalently-grafted on the surfaces of graphene@Fe3O4@C with high microwave absorption performance. Compos. Sci. Technol. 108, 1–8 (2015). https://doi.org/10.1016/j.compscitech.2014.12.011

Huang, J., Li, Y., Jia, X., Song, H.: Preparation and tribological properties of core-shell Fe3O4@C microspheres. Tribol Int. 129, 427–435 (2019). https://doi.org/10.1016/j.triboint.2018.08.036

Yu, H., Chen, H., Zheng, Z., Ba, Z., Qiao, D., Feng, D., et al.: Transformation mechanism between the frictional interface under dioctyl sebacate lubrication. Tribol Int. 155, 106745 (2021). https://doi.org/10.1016/j.triboint.2020.106745

Wu, Q., Wen, M., Yan, W., Wu, Q., Wang, H., Fu, Y.: Carbon nanotubes Coated with NiOOH-Ni converted from Ni(HCO3)2-Ni nanoflakes for Electrochemical Energy Storage. ACS Appl. Nano Mater. 3(2), 1713–1721 (2020). https://doi.org/10.1021/acsanm.9b02417

Wang, Y., Duan, F.: Tribochemistry of 1-Octene on three transition metal surfaces: Fe(100), pt(111) and ni(111). Tribol Int. 71(2), 37 (2023). https://doi.org/10.1007/s11249-023-01709-4

Ghadami Yazdi, M., Moud, P.H., Marks, K., Piskorz, W., Öström, H., Hansson, T., et al.: Naphthalene on Ni(111): Experimental and theoretical insights into Adsorption, Dehydrogenation, and Carbon Passivation. J. Phys. Chem. C. 121(40), 22199–22207 (2017). https://doi.org/10.1021/acs.jpcc.7b07757

Marks, K., Yazdi, M.G., Piskorz, W., Simonov, K., Stefanuik, R., Sostina, D., et al.: Investigation of the surface species during temperature dependent dehydrogenation of naphthalene on Ni(111). J. Chem. Phys. 150(24), 244704 (2019). https://doi.org/10.1063/1.5098533

Price, R.J., Ladislaus, P.I., Smith, G.C., Davies, T.J.: A novel ‘bottom-up’ synthesis of few- and multi-layer graphene platelets with partial oxidation via cavitation. Ultrason. Sonochem. 56, 466–473 (2019). https://doi.org/10.1016/j.ultsonch.2019.03.020

Kolesnikova, A.S., Safonov, R.A., Shinkarenko, O.A., Chumakov, A.S., Soldatenko, E.M., Glukhovskoy, E.G.: Synthesis of graphene from naphthalene molecules on the surface of a Langmuir monolayer. J. Surf. Invest. 11(3), 510–516 (2017). https://doi.org/10.1134/s1027451017030089

Wang, C.-G., Shao, X.-H., Xue, R.-S.: The formation of Carbon Nanostructures via Catalytic Pyrolysis of Naphthalene under its autogenic pressure. J. Nanomater. 752647 (2015). https://doi.org/10.1155/2015/752647

Acknowledgements

We acknowledge the financial support provided by National key research development plan, grant number 2023YFB3812104, National Natural Science Foundation of China, grant numbers, 52305189 and 52105180, Henan Province key research and development project, grant number 231111230600, Henan Province science and technology research and development joint project, grant number 235101610007, and Program of National & Local United Engineering Laboratory for Advanced Bearing Tribology, Grant No. 202305.

Author information

Authors and Affiliations

Contributions

Writing—Original draft: F.P.; Data curation: F.P., S.F., N.S., C.G., Y.Z.; Writing—Review & editing: S.Z. All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic Supplementary Material

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Peng, F., Fan, S., Song, N. et al. Effect of Nickel Acetyl Acetonate as Lubricant Additive in Base Oils with Different Molecular Structure on In-Situ Formation and Tribomechanism of Carbon-Based Tribofilms of Steel-Steel Sliding Pair. Tribol Lett 72, 56 (2024). https://doi.org/10.1007/s11249-024-01859-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-024-01859-z