Abstract

Polyacrylamide hydrogels are widely used in biomedical applications due to their tunable mechanical properties and charge neutrality. Our recent tribological investigations of polyacrylamide gels have revealed tunable and pH-dependent friction behavior. To determine the origins of this pH-responsiveness, we prepared polyacrylamide hydrogels with two different initiating chemistries: a reduction–oxidation (redox)-initiated system using ammonium persulfate (APS) and N,N,N′N′-tetramethylethylenediamine (TEMED) and a UV-initiated system with 2-hydroxy-4′-(2-hydroxyethoxy)-2-methylpropiophenone (Irgacure 2959). Hydrogel swelling, mechanical properties, and tribological behavior were investigated in response to solution pH (ranging from ≈ 0.34 to 13.5). For polyacrylamide hydrogels in sliding contact with glass hemispherical probes, friction coefficients decreased from µ = 0.07 ± 0.02 to µ = 0.002 ± 0.002 (redox-initiated) and from µ = 0.05 ± 0.03 to µ = 0.003 ± 0.003 (UV-initiated) with increasing solution pH. With hemispherical polytetrafluoroethylene (PTFE) probes, friction coefficients of redox-initiated hydrogels similarly decreased from µ = 0.06 ± 0.01 to µ = 0.002 ± 0.001 with increasing pH. Raman spectroscopy measurements demonstrated hydrolysis and the conversion of amide groups to carboxylic acid in basic conditions. We therefore propose that the mechanism for pH-responsive friction in polyacrylamide hydrogels may be credited to hydrolysis-driven swelling through the conversion of side chain amide groups into carboxylic groups and/or crosslinker degradation. Our results could assist in the rational design of hydrogel-based tribological pairs for biomedical applications from acidic to alkaline conditions.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

For the past half century, polyacrylamide hydrogels have been widely used in biomedical applications (e.g., drug delivery [1], cell scaffolds [2, 3], gel electrophoresis [4, 5]) due to their ease of fabrication, tunable mechanical and transport properties, and charge neutrality. These hydrogels are three-dimensional crosslinked networks of hydrophilic polymer chains swollen with water (typically 30 to 99%) and may be polymerized in many forms, from monoliths to microspheres [6, 7]. The elastic modulus, permeability, and tribological behavior of polyacrylamide hydrogels can be tuned by controlling the monomer and crosslinker concentrations [3, 8, 9]. The polymerization conditions and kinetics (e.g., surface energy of molding material, environmental oxygen) can also control network structure and composition near the surface [10,11,12,13,14], and thus the tribological performance [15, 16].

The consensus in literature is that polyacrylamide is nonionic, and its swelling properties are pH-independent due to the lack of ionizable functional groups [17,18,19]. To create pH-responsive hydrogels, acrylamide is often copolymerized with monomers containing ionizable groups, such as gelatin [17] or acrylic acid [20,21,22,23,24]. These ionizable groups deprotonate when solution pH exceeds the pKa of the hydrogel, increasing negative charge within the network [25]. Our recent investigations of the tribological behavior of polyacrylamide gels copolymerized with acrylic acid have revealed pH-responsiveness; friction coefficients of the copolymerized gels decreased with increasing pH [26]. This pH-dependent friction behavior was attributed to the protonation state of the acrylic acid and electrostatic interactions between the hydrogel and glass probe. Surprisingly, the friction coefficient of charge neutral polyacrylamide hydrogels—without any acrylic acid—also decreased with increasing pH [26]. While the existence of local charges along polyacrylamide chains has been proposed to account for adhesion to colloidal probes during nanoindentation [27], systematic studies have not yet been conducted to investigate the effects of pH on the mechanical or tribological properties of polyacrylamide hydrogels. In this study, 33 wt% polyacrylamide hydrogels were synthesized via free radical polymerization at room temperature with two different initiating chemistries. Reduction–oxidation (redox)-initiated hydrogels using ammonium persulfate (APS) and N,N,N′N′-tetramethylethylenediamine (TEMED) as the initiator and catalyst respectively were compared to UV-initiated hydrogels with 2-hydroxy-4′-(2-hydroxyethoxy)-2-methylpropiophenone (Irgacure 2959) as the photoinitiator. Hydrogels were swollen in solutions with varying pH, and their swelling behavior and elastic modulus were compared. Their tribological behavior was investigated using glass and polytetrafluorethylene (PTFE) countersurfaces, and the mechanism behind this pH-responsive behavior was explored with Raman spectroscopy.

2 Materials and Methods

2.1 Hydrogel Synthesis

Polyacrylamide disks (pre-swollen dimensions: 4 mm thickness, 26 mm diameter) were prepared with two different initiating systems. The first set of gels were prepared with a reduction–oxidation (redox)-initiating system using ammonium persulfate (APS, Sigma-Aldrich, Product #A3678) as the initiator and N,N,N′,N′-tetramethylethylenediamine (TEMED, Sigma-Aldrich Product #T9281) as the catalyst, as shown in Fig. 1a. The second set of gels were prepared using 2-hydroxy-4′-(2-hydroxyethoxy)-2-methylpropiophenone (Irgacure 2959, Sigma-Aldrich, Product #410,896) as the photoinitiator (Fig. 1b). The mechanism of free radical generation for these initiating systems is detailed in Wilems et al. [28]. Stock solutions of acrylamide (AAm, Sigma-Aldrich Product #A9099) (1 g/mL), N,N′-methylenebisacrylamide (MBAm, Sigma-Aldrich Product #M7279) (25 mg/mL), APS (50 mg/mL), and TEMED (50 mg/mL) were prepared in ultrapure water. The final AAm concentration in both the redox- and UV-initiated gels was 0.5 g/mL (≈ 33 wt%) and molar ratio of monomer:crosslinker was 200:1 (≈ 0.4 wt%). Gels were cast between two flat and smooth polystyrene sheets (average surface roughness, Ra < 20 nm), and reactions were conducted in ambient conditions (20 °C). A thermocouple (Fluke 51 II Thermometer Type-K) was used to monitor the temperature of the solution during polymerization. For the redox-initiated hydrogels, the molar ratios of monomer:catalyst and monomer:initiator were 200:1 and 400:1 (both ≈ 0.3 wt%), respectively. For the UV-initiated hydrogels, a molar ratio of 3200:1 (≈ 0.03 wt%) monomer:photoinitiator was used. Redox-initiated gels polymerized within 5 min, whereas UV-initiated gels polymerized under UV light for 22 min.

Chemical structures of the acrylamide monomer and N,N′-methylenebisacrylamide crosslinker. For all polyacrylamide hydrogels, the final monomer concentration was ≈ 33 wt% and molar ratio of monomer:crosslinker was 200:1 (≈ 0.4 wt%). The chemical components of the (a) redox-initiated and (b) UV-initiated systems. Blue circles highlight negative charge

A 26 mm diameter circular punch was used to section the gels, which were swollen in solutions of varying pH (see Table 1). With the exception of DI water, solution pH was determined using a Mettler Toledo FiveEasy pH meter. For DI water, which has exceptionally low ion content, the pH was measured with litmus paper (Whatman pH indicator papers, CF strips, pH range = 0–14, Cat. No. 2613-991), which indicated that fresh unbuffered MilliQ water had a pH ≈ 6–7, consistent with the measured resistivity of 18.2 MΩ cm. The pH is reported as an approximate ≈ 7 in this case.

2.2 Swelling Behavior

Hydrogel water content was calculated following the methods described in Chau et al. [26]. Briefly, hydrogels were equilibrated in solutions ranging from pH = 0.34 to pH = 13.5 (Table 1) for at least 1 week before their swollen mass (ms) was measured with a Mettler Toledo XPR105DR analytical balance. The dried mass (md) was obtained after drying the samples in an oven for 10 days at 60 °C, and the water content (%) was calculated using Eq. 1:

The volume change (%) was also calculated using Eq. 2 following the methods described in McGhee et al. [29]:

where Vs is the volume of the equilibrated swollen gel and Vi is the initial volume after polymerization. The reported water content and volume change values herein are the averages and standard deviations from three independent hydrogel samples (n = 3).

2.3 Micromechanical Analysis

The reduced elastic modulus, E*, of the hydrogels was determined through microindentation measurements using a custom-built linear reciprocating tribometer following the methods described in Chau et al. [26]. A hemispherical borosilicate glass probe (Type 1 Class A; radius of curvature, R = 2.6 mm) attached to a titanium double-leaf cantilever with normal and tangential spring constants of 220 µN/µm and 100 µN/µm, respectively, was used to investigate the mechanics over three different locations for each hydrogel sample. Indentations were conducted while the hydrogel and probe were completely submerged in solutions of varying pH (Table 1) using a constant indentation velocity of vind = 10 µm/s and maximum applied normal force of Fn = 1.5 mN (contact pressure, P ≈ 10 kPa). E* was determined by using the Hertzian contact mechanics theory (Eq. 3) to fit the approach curves up to Fn = 1 mN.

In Eq. 3, Fn is the applied normal force, R is the probe radius of curvature, d is the indentation depth, and E* = E/(1 − \(\nu\)2), where E is the compressive elastic modulus and \(\nu\) is the Poisson’s ratio of the hydrogel. The reported reduced elastic modulus, E*, is the average and standard deviation across three separate hydrogels (n = 3).

2.4 Friction Measurements

Tribological experiments were performed with a linear reciprocating tribometer. Hydrogels were secured in a custom polyetheretherketone (PEEK) dish and submerged in solutions of varying pH (Table 1) for the entire experiment. Hemispherical borosilicate glass probes (radius of curvature, R = 2.6 mm) and polytetrafluoroethylene (PTFE) probes (radius of curvature, R = 3.2 mm) were used as sliding countersurfaces. Probe surface roughness analyses are included in SI Section S1. Samples were mounted to a motorized stage (Physik Instrumente, L-509.20DG10, 52 mm travel range), which traveled at a sliding velocity of v = 100 µm/s across a sliding path of 4 mm (1/2) cycle. An applied normal load of Fn = 4 mN was maintained for at least 30 cycles. The applied contact pressures were well below the osmotic pressures of the gels, ranging between P = 15 ± 1 kPa and P = 13 ± 1 kPa for the glass and PTFE probes, respectively. Equation 4 was used to calculate the friction coefficient for each individual cycle, µcycle.

The friction forces in the forward (Ff,forward) and the reverse (Ff,reverse) directions were averaged across the middle 25% of the sliding path along with the normal force (Fn). The average friction coefficient for the hydrogel sample, µsample, was determined by averaging µcycle over the last 25 cycles in the steady state friction regime. The reported friction coefficients are the averages and standard deviations of µsample from three separate hydrogels.

2.5 Raman Spectroscopy

Polyacrylamide and poly(acrylamide-co-acrylic acid) [P(AAm-co-AA)] hydrogels were prepared for Raman spectroscopy to determine changes in functional groups over different pH environments. Redox-initiated hydrogels were swollen in pH = 0.34, pH ≈ 7, or pH = 13.5 for 10 days and then equilibrated in DI water for 2 weeks. The P(AAm-co-AA) hydrogels were synthesized following the protocol in Chau et al. [26] and swollen in DI water for 2 weeks. For all samples, the solution was exchanged daily to ensure that no unreacted monomer or excess NaOH or HCl would interfere with the measurements. Laser Raman spectroscopy was then conducted at room temperature on swollen polyacrylamide and P(AAm-co-AA) hydrogels using a confocal Raman microscope (Horiba Jobin Yvon T64000) with an excitation wavelength of 488 nm and laser power of 400 mW. Samples were gently dried with lens paper to remove excess liquid and then placed on a fused quartz microscope slide before measurements. During spectra acquisition, the laser light was focused with a 50 × objective lens 10 µm below the sample surface, and spectra data was obtained with a resolution of 0.66 cm−1. Three spectra were obtained at separate locations per sample, and each spectrum was the average of 25 eight-second measurements at the same location. Using the Spectragryph software, spectra data were smoothed using a 3rd-order Savitsky-Golay filter with an interval of 30, and spectra baselines were removed using the adaptive baseline subtraction tool with a coarseness of 15. For quantitative analyses, the deconvolution of peaks was carried out in Origin with details described in SI Sect. 4.

3 Results and Discussion

3.1 Observations of pH-Responsive Behavior

The mechanical and tribological properties of redox-initiated polyacrylamide hydrogels were compared to UV-initiated hydrogels to determine the source of their pH-responsiveness. As shown in Fig. 2a, the friction coefficient decreased with increasing pH for both the redox-initiated and UV-initiated polyacrylamide hydrogels. This trend held for both sliding configurations: glass-on-gel and PTFE-on-gel.

The tribological and mechanical properties of redox-initiated (black circle) and UV-initiated (red squares) hydrogels. a Friction coefficient, µ (semi-log plot) and b reduced elastic modulus, E*, of polyacrylamide hydrogels (≈ 33 wt% polymer) as a function of solution pH. The friction coefficients obtained with the PTFE-on-gel sliding configuration (open blue circles) for the redox-initiated hydrogels follow the same trend as the glass-on-gel sliding configuration (filled black circles), where µ decreases with increasing pH. Each data point is an average of three independent samples (n = 3) with error bars as the standard deviation, except for the UV-initiated gels at pH = 13.5, where n = 2. The experimental noise floor for the tribometer is µ = 0.0002, calculated following the methods in Chau et al. [26] (Color figure online)

The friction coefficient was sensitive to initiator selection; redox-initiated polyacrylamide hydrogels exhibited higher friction coefficients than photoinitiated samples with identical polymer composition. The friction coefficient of redox-initiated hydrogels against a glass countersurface drastically decreased from µ = 0.07 ± 0.02 (pH = 0.34) to µ = 0.002 ± 0.002 (pH = 13.5). For UV-initiated hydrogels, the friction coefficient decreased from µ = 0.05 ± 0.03 (pH = 0.34) to µ = 0.003 ± 0.003 (pH = 13.5). In both cases, the decrease in friction coefficient surpassed superlubricity (µ \(\le\) 0.005). Even with a PTFE countersurface, friction coefficients for the redox-initiated hydrogels decreased with increasing pH, from µ = 0.06 ± 0.01 in acid to µ = 0.002 ± 0.001 in base. The reduced elastic modulus followed a similar trend to the tribological behavior, with redox-initiated gels maintaining relatively consistent E* (186 ± 11 kPa) until pH = 13.5 when it decreased to E* = 146 ± 16 kPa. For UV-initiated gels, reduced elastic modulus slightly decreased from E* = 192 ± 15 kPa to E* = 165 ± 13 kPa with increasing pH (Fig. 2b).

Surprisingly, water content (%) was virtually pH-independent, with redox- and UV-initiated hydrogels maintaining 85 ± 3% water across all pH conditions (Fig. 3a). Previous swelling studies comparing completely dried and swollen hydrogels also reported pH-independent swelling behavior [17, 19, 22, 23]. However, hydrogels in alkaline conditions were noticeably larger than those swollen in acidic and neutral solutions. Moreover, elastic modulus typically scales with swelling [30,31,32], with lower elastic moduli corresponding to greater swelling [17, 30]. Therefore, as a comparison to water content, which is one of the many approaches that involves hydrogel desiccation (Table S1), we evaluated volume change, which allowed the hydrogels to remain hydrated. Here, the volumes of the redox-initiated hydrogels immediately after polymerization were compared to their fully swollen volumes (Eq. 2). When calculating volume change rather than water content, the gels exhibited pH-dependent swelling and significantly increased in volume (457 ± 32%) at pH = 13.5 (Fig. 3b), in agreement with the reduced elastic moduli trends (Fig. 2b).

a Hydrogel water content (%) and b volume change (%) as a function of solution pH for redox-initiated (black circles) and UV-initiated (red squares) polyacrylamide hydrogels. Water content did not fully capture the swelling difference between the gels in acidic, neutral, and basic solutions, so volume change was used to represent the size change observed for the redox-initiated gels when swollen in basic solution. The dashed line is a guideline and not meant to indicate a fit. Each data point is an average of three samples (n = 3) with error bars as the standard deviation (Color figure online)

3.2 Effects of Free Radical Initiator on Mechanical Properties

Redox- and UV-initiated polyacrylamide hydrogels slid against glass probes exhibit different friction coefficients and reduced elastic moduli despite having the same acrylamide concentration (≈ 33 wt% before swelling) and molar ratio of monomer to crosslinker (200:1, corresponding to ≈ 0.4 wt% before swelling). We observe somewhat lower elastic moduli for UV-initiated gels compared to redox-initiated gels across all pH solutions (Fig. 2b) and significant reduction in friction coefficient with the glass countersurface, especially at pH > 0.34 (Fig. 2a). One explanation for the differences in mechanical and tribological properties is the initiator selection. In previous studies of poly(ethylene glycol) (PEG) hydrogels, initiator selection impacted the mechanical properties due to variations in gelation kinetics, which led to structural differences [28]; the redox-initiated PEG hydrogels had higher elastic moduli than the UV-initiated PEG hydrogels due to smaller mesh sizes. N-alkyl acrylamide/acrylic acid copolymer nanoparticles have also been reported to have differences in network structure due to the initiating chemistry [33]. Another possibility is initiator concentration, which has been shown to influence the swelling ratio, with increasing concentration leading to greater swelling [34]. Here, the redox-initiated hydrogels had a monomer:initiator molar ratio of 400:1 (≈ 0.3 wt%), while the UV-initiated hydrogels had a molar ratio of 3200:1 monomer:photoinitiator (≈ 0.03 wt%). It is possible that the network structure was different since the UV-initiated hydrogels had a lower initiator concentration due to the low solubility limit of Irgacure 2959 in water (< 2%) [35]. In both cases, the gels were cast against polystyrene sheets while exposed to atmospheric oxygen, which has been postulated to create a loosely crosslinked surface layer [15, 36, 37]. With a lower concentration of photoinitiator, UV-initiated gels took longer to polymerize than redox-initiated gels, exposing them to oxygen longer, which could have led to a more open network at the surface. While this difference in network structure may be indicated by the friction coefficient decrease, it is not reflected in the elastic modulus or water content, indicating that these structural differences may be confined to the surface.

For redox-initiated polyacrylamide hydrogels in self-mated tribological contact, Urueña et al. demonstrated that friction coefficients decreased with increasing mesh size [9]. The difference in friction behavior between redox-initiated and UV-initiated gels against glass countersurfaces may suggest differences in mesh size since the same probe material was used. It is possible that our UV-initiated hydrogels have a larger surface mesh size than the redox-initiated hydrogels but similar bulk properties due to a combination of gelation kinetic differences and initiator concentration, although further experimentation is needed.

3.3 Potential Contributions of Probe-Mediated Electrostatics to Hydrogel Friction

The mechanism of hydrogel lubricity for polyelectrolyte hydrogels with charged sliding countersurfaces is often attributed to hydration lubrication [38,39,40,41,42] or electrostatic interactions [43,44,45]. By introducing charge to the hydrogel network via hydrolysis, electrostatic interactions between polyacrylamide hydrogels and smooth (Sa < 100 nm) glass probes may explain the decrease in friction coefficient with increasing pH. Redox-initiated polyacrylamide hydrogels exhibited similar trends in tribological behavior when slid against rough (Sa ≈ 1 µm) PTFE probes (Figs. 2a, S1). Although PTFE is a well-known hydrophobic and inert material, its surface properties depend on solution pH and ionic strength due to an interfacial water layer that accumulates OH− ions at pH > 4 and H3O+ ions at lower pH values [46]. Since glass and PTFE are both pH-responsive, electrostatics may impact the resulting friction coefficients in both cases. Figure 4 illustrates our predicted friction coefficient trend for polyacrylamide hydrogels with increasing pH if electrostatics was the main contributor.

Predicted friction coefficient trend for polyacrylamide hydrogels with varying pH if electrostatic interactions were the driving force behind the pH-dependent tribological behavior. Due to electrostatic repulsion between the probe and hydrogel surface in acidic and basic solutions, the friction coefficient would decrease, leading to a parabolic-like friction behavior, with the highest friction exhibited in neutral pH

In acidic conditions, both glass and PTFE can be positively charged; conversely, in basic conditions they can be negatively charged [46, 47]. For polyacrylamide hydrogels, the carbonyl oxygen, which has a pKa ≈ 0 [48], could become protonated in extremely acidic conditions, creating a positive charge. In extremely basic conditions, the amide group, with a pKa ≈ 16 [48], could potentially deprotonate, although this is unlikely. Therefore, in acidic and basic conditions, electrostatic repulsion between the probe and hydrogel surface could lead to lower friction coefficients whereas in the neutral solution, only the probe would be negatively charged. However, our friction coefficients do not follow this predicted trend (Fig. 2a) and decrease with increasing pH.

One limitation to our study is the lack of systematic control of the ionic strengths of our solutions, which ranged between 0 (pH ≈ 7), 0.001 M (pH = 2 and 10), and 0.5 M (pH = 0.34 and 13.5). Since ionic strength was not kept constant across pH solutions, it is difficult to draw definitive conclusions about the effects of electrostatics on the tribological behavior of our hydrogels. Despite the lack of control of ionic strength, friction coefficients were still the lowest at pH = 13.5, where ionic strength is the highest. Therefore, electrostatics may not be the sole mechanism driving the pH-responsive behavior of the polyacrylamide hydrogels. We propose that the dominant mechanism of friction reduction at high pH is hydrolysis-induced swelling resulting from deprotonated carboxylic acid pendant groups and/or crosslinker degradation, which is discussed further in Sects. 3.4 and 3.5.

3.4 Base-Induced Amide Hydrolysis

We initially hypothesized that the pH-sensitivity of redox-initiated polyacrylamide hydrogels may be due to the incorporation of negatively-charged sulfate groups at the chain ends of the network structure. These negatively-charged functionalities may lead to lower friction coefficients at high pH due to electrostatic repulsion between the glass probe and hydrogel and higher friction coefficients at low pH due to the protonation of the sulfate groups. While x-ray photoelectron spectroscopy (XPS) confirmed the presence of sulfate groups incorporated into the network (SI Sect. 3), it does not explain the pH-dependent friction behavior of the UV-initiated hydrogels, which use a charge-neutral photoinitiator (Fig. 1). If the pH-dependence was solely due to negative charges from sulfate groups, the friction coefficient should stay constant across all pH solutions for the UV-initiated hydrogels, which was not observed (Fig. 2a). Therefore, another mechanism is likely responsible for the pH-dependent friction behavior of polyacrylamide hydrogels.

The pH-sensitivity of polyacrylamide may be due to side chain and crosslinker hydrolysis through the conversion of the amide groups into ionizable carboxyl groups, as shown in the following reaction scheme for basic conditions.

Typically, hydrolysis is intentionally performed on polyacrylamide at elevated temperatures (> 40 °C) in acidic [18, 49, 50] or basic environments [49,50,51,52] to form copolymerized poly(acrylamide-co-acrylic acid). In acidic conditions, complete conversion from polyacrylamide to poly(acrylic acid) can be achieved [49] while conversion is limited to 67% in basic conditions due to the increase of negative charge built up along the backbone [49, 51]. Hydrolysis can even occur at neutral pH under elevated temperatures (75–150 °C) [53, 54]. However, Tanaka et al. demonstrated that polyacrylamide hydrolysis was also possible in alkaline conditions at room temperature, and even used TEMED (pH = 12) to partially hydrolyze polyacrylamide hydrogels [52, 55]. Other studies have similarly shown that using TEMED as the catalyst in the polymerization reaction was enough to trigger hydrolysis due to its high pH [6, 56, 57]. Similarly, Ilavský et al. demonstrated that almost 6 mol% of amide groups converted to carboxyl groups in polyacrylamide hydrogels swollen in a basic solution (pH ≈ 8–9) at room temperature over the course of 103 days. For the redox- and UV-initiated hydrogels in this study, the aging time ranged between 10–70 days and 7–15 days, respectively. Within this timeframe, Ilavský et al. observed 1–4 mol% conversion [58]. Therefore, it is possible for hydrolysis to have occurred in our polyacrylamide hydrogels while they equilibrated over 7–70 days in acidic and basic solutions at room temperature. Our hydrolysis hypothesis is supported by the volume change of the redox-initiated hydrogels, which swelled dramatically at pH = 13.5 (Fig. 3b). Others have noted increased swelling in hydrolyzed polyacrylamide hydrogels due to increased polymer chain repulsion caused by the conversion of amide groups (–NH2) into deprotonated carboxylic acid groups (–COO−) at high pH [6, 25, 56,57,58,59,60,61,62,63].

To confirm the possibility of hydrolysis, Raman spectroscopy (Figs. 5 and S3–S6) was conducted on redox-initiated hydrogels swollen at pH = 0.34 (0.5 M HCl), pH ≈ 7 (unbuffered DI water), and pH = 13.5 (0.5 M NaOH) for 10 days. These spectra were compared to the measured spectra of poly(acrylamide-co-acrylic acid) [P(AAm-co-AA)] hydrogels with varying amounts of acrylic acid (1, 5, 6, 9, and 12 wt%) swollen in water. Raman peak assignments can be found in Fig. S4. The polyacrylamide gels herein at neutral pH had peaks that corresponded to polyacrylamide spectra in literature [64, 65], including peaks at 1428 cm−1 (C–N stretching, or Amide III), 1617 cm−1 (–NH2 bending, or Amide II), and 1670 cm−1 (C–O stretching, or Amide I) (Fig. 5a). For the P(AAm-co-AA) gels, the peaks associated with the carboxyl group near 1555 cm−1 and 1716 cm−1 increased in intensity and merged with the two amide peaks near 1617 cm−1 and 1670 cm−1 with increasing acrylic acid concentration. Correspondingly, the normalized amide peak near 1428 cm−1 reduced in intensity, in agreement with the reduced portion of amide groups (Fig. 5b). Remarkably, the spectra of the polyacrylamide gels swollen in NaOH are very similar to the spectra of P(AAm-co-AA) gels with high AA concentrations, with carboxyl peaks appearing as well as the emergence of a new peak near 1412 cm−1 which corresponded to sodium carboxylate [66]. These spectroscopic results suggest the formation of carboxyl groups in polyacrylamide gels swollen in NaOH due to hydrolysis at room temperature. In comparison, the spectra of polyacrylamide gels swollen in HCl have almost identical spectra to the gels swollen in water but with a very small carboxyl peak near 1716 cm−1, suggesting minimal hydrolysis occurred at low pH (Fig. 5a).

Averaged Raman spectra of redox-initiated a polyacrylamide and b P(AAm-co-AA) hydrogels, with intensity normalized to the peak near 1617 cm−1. At pH = 0.34 (light pink) and pH ≈ 7 (pink), the spectra of the polyacrylamide gels almost overlap. At pH = 13.5 (dark pink), the amide peaks of polyacrylamide gels near 1428 cm−1 decreased in intensity and the carboxyl peaks near 1555 and 1716 cm−1 increased. In comparison, for P(AAm-co-AA) hydrogels swollen in water, the amide peaks near 1428 cm−1 decreased in intensity while the carboxyl peaks increased with increasing acrylic acid concentration (from 1 to 12 wt%, light to dark blue, respectively) (Color figure online)

To estimate the percentage of amide groups hydrolyzed for redox-initiated polyacrylamide hydrogels, the Raman spectra were deconvoluted into individual bands (Fig. S5), and linear calibration curves were established from the P(AAm-co-AA) gels based on the normalized peak areas and AA concentrations (Fig. S6). From this analysis, about 12.7 mol% and 0.3 mol% of the amide groups were hydrolyzed after 10 days for the redox-initiated polyacrylamide hydrogels swollen at pH = 13.5 and pH = 0.34, respectively. Although it should be noted that the accuracy of these values may be subject to potential uncertainties during baseline removal, Raman band deconvolution, curve fitting processes, and peak area normalization processes, the results indicate that a significant degree of hydrolysis occurred for the redox-initiated polyacrylamide hydrogels swollen at pH = 13.5. These values are slightly higher than those found by Ilavský et al. [58], but during polymerization of the redox- and UV-initiated polyacrylamide hydrogels, temperatures reached a maximum of 88 °C and 48 °C, respectively. While longer reaction times and higher polymerization temperatures typically increase amide to carboxylic acid conversion [57], it is unlikely that this transient temperature rise during polymerization led to greater hydrolysis since the redox-initiated gels polymerized within 5 min. Rather our gels may have exhibited greater hydrolysis due to the high pH of our solution (pH = 13.5 as opposed to pH ≈ 8–9).

Since N,N′-methylenebisacrylamide (MBAm) is used as the crosslinker, amide hydrolysis of the crosslinker may have occurred in addition to side chain hydrolysis. One indication of possible crosslinker degradation is that gels initially swollen in base and transferred to acid decreased in elastic modulus (Fig. S7). However, it is difficult to distinguish from the Raman spectra whether the side chain primary amides were more susceptible to attack than the crosslinker secondary amides. Nevertheless, these results suggest that significant polyacrylamide hydrolysis can occur at room temperature over the course of days when gels are swollen in extremely basic solutions.

3.5 Impact of Hydrolysis on Hydrogel Friction

Raman spectroscopy confirmed hydrolysis of polyacrylamide hydrogels in both acidic and basic environments over the course of 10 days at room temperature (Fig. 5a), while swelling measurements indicated a volume increase with increasing pH (Fig. 3b). This swelling increase could be due to the deprotonation of the carboxylic acid pendant group and/or the breakage of crosslinks, both of which would influence the friction coefficient. Figure 6 illustrates our predicted trend of friction behavior for polyacrylamide hydrogels with increasing pH if hydrolysis was the driving mechanism.

Predicted trend for polyacrylamide hydrogels if hydrolysis was the driving mechanism behind the pH-dependent friction. At low pH, hydrolysis of the pendant amide groups would not greatly impact swelling due to the protonation of the carboxylic acid, leading to charge neutrality. At high pH, hydrolysis of the pendant and crosslinker amide groups would lead to increased swelling and decreased friction coefficient

At low pH, acid hydrolysis of the pendant amide groups is possible but the conversion is low. In contrast, conversion of the pendant and crosslinker amide groups to carboxylic acid is greater at high pH. Additionally, the carboxylic acid groups will deprotonate as long as the pH > pKa, creating negative charges along the polymer chains, leading to increased electrostatic repulsion between chains and greater swelling. This increase in swelling could lead to a decrease in friction coefficient. While our tribological measurements do not completely follow this trend (Fig. 2a), we still see a general decrease in friction coefficient with increasing pH, rather than the parabolic-like trends that would be expected if electrostatic repulsion between the probe and hydrogel were the predominant mechanism. Therefore, it is likely that the mechanism behind the pH-dependent behavior of the polyacrylamide hydrogels is driven by hydrolysis. Studies investigating the kinetics of hydrolysis at room temperature and its effects on the tribological properties of polyacrylamide hydrogels are outside the scope of this paper but would greatly benefit the tribological community.

4 Conclusion

For tribological investigations of hydrogel lubricity in biological environments or biomedical applications where pH must be well-controlled, it is important to consider the possibility of pH-dependent friction behavior of polyacrylamide networks. In this work, the friction coefficients of both redox- and UV-initiated polyacrylamide hydrogels decreased with increasing pH against glass and PTFE countersurfaces, with redox-initiated gels achieving superlubricity at pH = 13.5 (µ = 0.002 ± 0.002). This pH dependence may be due to hydrolysis within 10 days of swelling, which was confirmed by Raman spectroscopy for redox-initiated polyacrylamide hydrogels. Our measurements indicated a high degree (approximately 12.7 mol%) of amide to carboxylic acid conversion at pH = 13.5 and a minimal degree (about 0.3 mol%) of conversion at pH = 0.34. Additional evidence of hydrolysis was given by increased swelling (volume change = 457 ± 32%) and decreased modulus (E* = 146 ± 86 kPa) at pH = 13.5 for redox-initiated hydrogels. Our results suggest that polyacrylamide hydrogels equilibrated in highly basic conditions, even at mild temperatures, are subject to hydrolysis, which can reduce friction coefficient and elastic modulus.

Data Availability

The original data for all the figures in the main text and Supplementary Information are available in the Dryad Data Repository (https://doi.org/10.25349/D9261M) and are available upon publication of this work.

References

Hoffman, A.S.: Hydrogels for biomedical applications. Adv. Drug Deliv. Rev. 64, 18–23 (2012). https://doi.org/10.1016/j.addr.2012.09.010

Buxboim, A., Rajagopal, K., Brown, A.E.X., Discher, D.E.: How deeply cells feel: methods for thin gels. J. Phys. Condens. Matter. 22, 194116 (2010). https://doi.org/10.1088/0953-8984/22/19/194116

Denisin, A.K., Pruitt, B.L.: Tuning the range of polyacrylamide gel stiffness for mechanobiology applications. ACS Appl. Mater. Interfaces 8, 21893–21902 (2016). https://doi.org/10.1021/acsami.5b09344

Ornstein, L.: Disc electrophoresis-i background and theory. Ann. N. Y. Acad. Sci. 121, 321–349 (1964). https://doi.org/10.1111/j.1749-6632.1964.tb14207.x

Raymond, S., Weintraub, L.: Acrylamide gel as a supporting medium for zone electrophoresis. Science 1979(130), 711–711 (1959). https://doi.org/10.1126/science.130.3377.711

Patel, S.K., Rodriguez, F., Cohen, C.: Mechanical and swelling properties of polyacrylamide gel spheres. Polymer 30, 2198–2203 (1989). https://doi.org/10.1016/0032-3861(89)90249-8

Shepherd, R.F., Conrad, J.C., Rhodes, S.K., Link, D.R., Marquez, M., Weitz, D.A., Lewis, J.A.: Microfluidic assembly of homogeneous and janus colloid-filled hydrogel granules. Langmuir 22, 8618–8622 (2006). https://doi.org/10.1021/la060759+

Li, H., Choi, Y.S., Rutland, M.W., Atkin, R.: Nanotribology of hydrogels with similar stiffness but different polymer and crosslinker concentrations. J. Colloid Interface Sci. 563, 347–353 (2020). https://doi.org/10.1016/j.jcis.2019.12.045

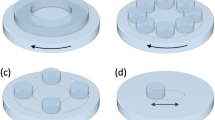

Urueña, J.M., Pitenis, A.A., Nixon, R.M., Schulze, K.D., Angelini, T.E., Sawyer, W.G.: Mesh size control of polymer fluctuation lubrication in gemini hydrogels. Biotribology 1–2, 24–29 (2015). https://doi.org/10.1016/j.biotri.2015.03.001

Baselga, J., Llorente, M.A., Hernández-Fuentes, I., Piérola, I.F.: Network defects in polyacrylamide gels. Eur. Polym. J. 25, 471–475 (1989). https://doi.org/10.1016/0014-3057(89)90188-2

Ikeda-Fukazawa, T., Ikeda, N., Tabata, M., Hattori, M., Aizawa, M., Yunoki, S., Sekine, Y.: Effects of crosslinker density on the polymer network structure in poly-N, N-dimethylacrylamide hydrogels. J. Polym. Sci. B 51, 1017–1027 (2013). https://doi.org/10.1002/polb.23305

Cohen, Y., Ramon, O., Kopelman, I.J., Mizrahi, S.: Characterization of inhomogeneous polyacrylamide hydrogels. J. Polym. Sci. B 30, 1055–1067 (1992). https://doi.org/10.1002/polb.1992.090300913

Gombert, Y., Roncoroni, F., Sánchez-Ferrer, A., Spencer, N.D.: The hierarchical bulk molecular structure of poly(acrylamide) hydrogels: beyond the fishing net. Soft Matter 16, 9789–9798 (2020). https://doi.org/10.1039/d0sm01536a

Baselga, J., Llorente, M.A., Hernández-Fuentes, I., Piérola, I.F.: Polyacrylamide gels. Process of network formation. Eur. Polym. J. 25, 477–480 (1989). https://doi.org/10.1016/0014-3057(89)90189-4

Meier, Y.A., Zhang, K., Spencer, N.D., Simič, R.: Linking friction and surface properties of hydrogels molded against materials of different surface energies. Langmuir 35, 15805–15812 (2019). https://doi.org/10.1021/acs.langmuir.9b01636

Simič, R., Spencer, N.D.: Controlling the friction of gels by regulating interfacial oxygen during polymerization. Tribol. Lett. 69, 86 (2021). https://doi.org/10.1007/s11249-021-01459-1

Martínez-Ruvalcaba, A., Becerra-Bracamontes, F., Sánchez-Díaz, J.C., González-Álvarez, A.: Polyacrylamide-gelatin polymeric networks: effect of pH and gelatin concentration on the swelling kinetics and mechanical properties. Polym. Bull. 62, 539–548 (2009). https://doi.org/10.1007/s00289-008-0037-4

Xiong, B., Loss, R.D., Shields, D., Pawlik, T., Hochreiter, R., Zydney, A.L., Kumar, M.: Polyacrylamide degradation and its implications in environmental systems. NPJ Clean Water 1, 17 (2018). https://doi.org/10.1038/s41545-018-0016-8

Zhao, Q., Sun, J., Lin, Y., Zhou, Q.: Study of the properties of hydrolyzed polyacrylamide hydrogels with various pore structures and rapid pH-sensitivities. React. Funct. Polym. 70, 602–609 (2010). https://doi.org/10.1016/j.reactfunctpolym.2010.04.010

Turan, E., Çaykara, T.: Swelling and network parameters of pH-sensitive poly(acrylamide-co-acrylic acid) hydrogels. J. Appl. Polym. Sci. 106, 2000–2007 (2007). https://doi.org/10.1002/app.26848

Thakur, A., Wanchoo, R.K., Singh, P.: Structural parameters and swelling behavior of pH sensitive poly(acrylamide-co-acrylic acid) hydrogels. Chem. Biochem. Eng. Q. 25, 181–194 (2011)

Nesrinne, S., Djamel, A.: Synthesis, characterization and rheological behavior of pH sensitive poly(acrylamide-co-acrylic acid) hydrogels. Arab. J. Chem. 10, 539–547 (2017). https://doi.org/10.1016/j.arabjc.2013.11.027

Prouvé, E., Drouin, B., Chevallier, P., Rémy, M., Durrieu, M.C., Laroche, G.: Evaluating poly(acrylamide-co-acrylic acid) hydrogels stress relaxation to direct the osteogenic differentiation of mesenchymal stem cells. Macromol. Biosci. 21, 1–12 (2021). https://doi.org/10.1002/mabi.202100069

Deptula, A., Wade, M., Rogers, S.A., Espinosa-Marzal, R.M.: Charge-induced structural changes of confined copolymer hydrogels for controlled surface morphology, rheological response, adhesion, and friction. Adv. Funct. Mater. 32, 2111414 (2022). https://doi.org/10.1002/adfm.202111414

Sheikh, N., Jalili, L., Anvari, F.: A study on the swelling behavior of poly(acrylic acid) hydrogels obtained by electron beam crosslinking. Radiat. Phys. Chem. 79, 735–739 (2010). https://doi.org/10.1016/j.radphyschem.2009.12.013

Chau, A.L., Getty, P.T., Rhode, A.R., Bates, C.M., Hawker, C.J., Pitenis, A.A.: Superlubricity of pH-responsive hydrogels in extreme environments. Front. Chem. (2022). https://doi.org/10.3389/fchem.2022.891519

Nalam, P.C., Gosvami, N.N., Caporizzo, M.A., Composto, R.J., Carpick, R.W.: Nano-rheology of hydrogels using direct drive force modulation atomic force microscopy. Soft Matter 11, 8165–8178 (2015). https://doi.org/10.1039/C5SM01143D

Wilems, T.S., Lu, X., Kurosu, Y.E., Khan, Z., Lim, H.J., Smith Callahan, L.A.: Effects of free radical initiators on polyethylene glycol dimethacrylate hydrogel properties and biocompatibility. J. Biomed. Mater. Res. A 105, 3059–3068 (2017). https://doi.org/10.1002/jbm.a.36160

McGhee, E.O., Chau, A.L., Cavanaugh, M.C., Rosa, J.G., Davidson, C.L.G., Kim, J., Urueña, J.M., Sumerlin, B.S., Pitenis, A.A., Sawyer, W.G.: Amphiphilic gel lubrication and the solvophilic transition. Biotribology (2021). https://doi.org/10.1016/j.biotri.2021.100170

de Gennes, P.G.: Scaling concepts in polymer physics. Cornell University Press, Ithaca (1979)

Hoshino, K.I., Nakajima, T., Matsuda, T., Sakai, T., Gong, J.P.: Network elasticity of a model hydrogel as a function of swelling ratio: from shrinking to extreme swelling states. Soft Matter 14, 9693–9701 (2018). https://doi.org/10.1039/c8sm01854e

Flory, P.J.: Principles of polymer chemistry. Cornell University Press, Ithaca (1953)

Ahmed, M.A., Erdőssy, J., Horváth, V.: The role of the initiator system in the synthesis of acidic multifunctional nanoparticles designed for molecular imprinting of proteins. Period. Polytech. Chem. Eng. 65, 28–41 (2020). https://doi.org/10.3311/PPch.15414

Awasthi, S., Singhal, R.: Mathematical modeling for the prediction of the overall swelling profile from poly (AM-co-AA-co-HEA) hydrogels: effect of glycidyl methacrylate and ammonium per sulphate. Int. J. Plast. Technol. 19, 241–262 (2015). https://doi.org/10.1007/s12588-015-9124-1

Tomal, W., Ortyl, J.: Water-soluble photoinitiators in biomedical applications. Polymers 12, 1073 (2020). https://doi.org/10.3390/polym12051073

Simič, R., Mandal, J., Zhang, K., Spencer, N.D.: Oxygen inhibition of free-radical polymerization is the dominant mechanism behind the “mold effect” on hydrogels. Soft Matter (2021). https://doi.org/10.1039/d1sm00395j

Kiyama, R., Yoshida, M., Nonoyama, T., Sedlačík, T., Jinnai, H., Kurokawa, T., Nakajima, T., Gong, J.P.: Nanoscale TEM imaging of hydrogel network architecture. Adv. Mater. 35, 1–11 (2023). https://doi.org/10.1002/adma.202208902

Wang, Z., Li, J., Liu, Y., Luo, J.: Macroscale superlubricity achieved between zwitterionic copolymer hydrogel and sapphire in water. Mater. Des. 188, 108441 (2020). https://doi.org/10.1016/j.matdes.2019.108441

Raviv, U., Giasson, S., Kampf, N., Gohy, J.F., Jéröme, R., Klein, J.: Lubrication by charged polymers. Nature 425, 163–165 (2003). https://doi.org/10.1038/nature01970

Gaisinskaya, A., Ma, L., Silbert, G., Sorkin, R., Tairy, O., Goldberg, R., Kampf, N., Klein, J.: Hydration lubrication: exploring a new paradigm. Faraday Discuss. 156, 217–233 (2012). https://doi.org/10.1039/c2fd00127f

Klein, J.: Hydration lubrication. Friction 1, 1–23 (2013). https://doi.org/10.1007/s40544-013-0001-7

Lin, W., Klein, J.: Hydration lubrication in biomedical applications: from cartilage to hydrogels. Acc. Mater. Res. 3, 213–223 (2022). https://doi.org/10.1021/accountsmr.1c00219

Gong, J.P., Kagata, G., Osada, Y.: Friction of gels. 4. Friction on charged gels. J. Phys. Chem. B 103, 6007–6014 (1999). https://doi.org/10.1021/jp9902553

Oogaki, S., Kagata, G., Kurokawa, T., Kuroda, S., Osada, Y., Gong, J.P.: Friction between like-charged hydrogels—combined mechanisms of boundary, hydrated and elastohydrodynamic lubrication. Soft Matter 5, 1879–1887 (2009). https://doi.org/10.1039/b815102d

Ahmed, J., Guo, H., Yamamoto, T., Kurokawa, T., Takahata, M., Nakajima, T., Gong, J.P.: Sliding friction of zwitterionic hydrogel and its electrostatic origin. Macromolecules 47, 3101–3107 (2014). https://doi.org/10.1021/ma500382y

Preočanin, T., Selmani, A., Lindqvist-Reis, P., Heberling, F., Kallay, N., Lützenkirchen, J.: Surface charge at Teflon/aqueous solution of potassium chloride interfaces. Colloids Surf. A 412, 120–128 (2012). https://doi.org/10.1016/j.colsurfa.2012.07.025

Behrens, S.H., Grier, D.G.: The charge of glass and silica surfaces. J. Chem. Phys. 115, 6716–6721 (2001). https://doi.org/10.1063/1.1404988

Bruice, P.Y.: Organic chemistry. Pearson, Upper Saddle River (2017)

Muller, G., Fenyo, J.C., Selegny, E.: High molecular weight hydrolyzed polyacrylamides. III. Effect of temperature on chemical stability. J. Appl. Polym. Sci. 25, 627–633 (1980). https://doi.org/10.1002/app.1980.070250409

Ma, Q., Shuler, P.J., Aften, C.W., Tang, Y.: Theoretical studies of hydrolysis and stability of polyacrylamide polymers. Polym. Degrad. Stab. 121, 69–77 (2015). https://doi.org/10.1016/j.polymdegradstab.2015.08.012

Zeynali, M.E., Rabbii, A.: Alkaline hydrolysis of polyacrylamide and study on poly(acrylamide-co-sodium acrylate) properties. Iran. Polym. J. 11, 269–275 (2002)

Tanaka, T., Sun, S.T., Nishio, I., Swislow, G., Shah, A.: Phase transitions in ionic gels. Phys. Rev. Lett. 30, 97 (1980). https://doi.org/10.1080/00150198008209494

Xiong, C., Wei, F., Li, W., Liu, P., Wu, Y., Dai, M., Chen, J.: Mechanism of polyacrylamide hydrogel instability on high-temperature conditions. ACS Omega 3, 10716–10724 (2018). https://doi.org/10.1021/acsomega.8b01205

Kheradmand, H., François, J., Plazanet, V.: Hydrolysis of polyacrylamide and acrylic acid-acrylamide copolymers at neutral pH and high temperature. Polymer 29, 860–870 (1988). https://doi.org/10.1016/0032-3861(88)90145-0

Tanaka, T.: Collapse of gels and the critical endpoint. Phys. Rev. Lett. 40, 820–823 (1978). https://doi.org/10.1103/PhysRevLett.40.820

Kizilay, M.Y., Okay, O.: Effect of hydrolysis on spatial inhomogeneity in poly(acrylamide) gels of various crosslink densities. Polymer 44, 5239–5250 (2003). https://doi.org/10.1016/S0032-3861(03)00494-4

Takata, S.I., Norisuye, T., Shibayama, M.: Preparation temperature dependence and effects of hydrolysis on static inhomogeneities of poly(acrylamide) gels. Macromolecules 32, 3989–3993 (1999). https://doi.org/10.1021/ma990188a

Ilavský, M., Hrouz, J., Stejskal, J., Bouchal, K.: Phase transition in swollen gels. 6. Effect of aging on the extent of hydrolysis of aqueous polyacrylamide solutions and on the collapse of gels. Macromolecules 17, 2868–2874 (1984). https://doi.org/10.1021/ma00142a072

Zhou, Y., Jin, L.: Hydrolysis-induced large swelling of polyacrylamide hydrogels. Soft Matter 16, 5740–5749 (2020). https://doi.org/10.1039/d0sm00663g

Garces, F.O., Sivadasan, K., Somasundaran, P., Turro, N.J.: Interpolymer complexation of poly(acrylic acid) and polyacrylamide: structural and dynamic studies by solution- and solid-state NMR. Macromolecules 27, 272–278 (1994). https://doi.org/10.1021/ma00079a040

Li, W., Zhao, H., Teasdale, P.R., John, R., Zhang, S.: Synthesis and characterisation of a polyacrylamide-polyacrylic acid copolymer hydrogel for environmental analysis of Cu and Cd. React. Funct. Polym. 52, 31–41 (2002). https://doi.org/10.1016/S1381-5148(02)00055-X

Zhou, X., Weng, L., Chen, Q., Zhang, J., Shen, D., Li, Z., Shao, M., Xu, J.: Investigation of pH sensitivity of poly(acrylic acid-co-acrylamide) hydrogel. Polym. Int. 52, 1153–1157 (2003). https://doi.org/10.1002/pi.1207

Çaykara, T., Akçakaya, I.: Synthesis and network structure of ionic poly(N, N-dimethylacrylamide-co-acrylamide) hydrogels: comparison of swelling degree with theory. Eur. Polym. J. 42, 1437–1445 (2006). https://doi.org/10.1016/j.eurpolymj.2006.01.001

Gupta, M.K., Bansil, R.: Laser Raman spectroscopy of polyacrylamide. J. Polym. Sci. Polym. Phys. Ed. 19, 353–360 (1981). https://doi.org/10.1002/pol.1981.180190214

Dai, H., Chen, Q., Qin, H., Guan, Y., Shen, D., Hua, Y., Tang, Y., Xu, J.: A temperature-responsive copolymer hydrogel in controlled drug delivery. Macromolecules 39, 6584–6589 (2006). https://doi.org/10.1021/ma060486p

Koda, S., Nomura, H., Nagasawa, M.: Raman spectroscopic studies on the interaction between counterion and polyion. Biophys. Chem. 15, 65–72 (1982). https://doi.org/10.1016/0301-4622(82)87017-8

Acknowledgements

This work was inspired by Prof. Anne Neville’s significant contributions to the tribology community. Special thanks to Prof. Fyl Pincus, Prof. Javier Read de Alaniz, Dr. Sophia Bailey, Dr. Juan Manuel Urueña, Andrew Rhode, Rachel Lee, and Ruby Cossio-Hernandez for valuable discussions and support, and Katie Shaffer for assistance with surface roughness measurements. We gratefully acknowledge the Center for Science and Engineering Partnerships (CSEP) Summer Institute in Mathematics and Science (SIMS) program.

Funding

This work was supported by the National Science Foundation (NSF) Materials Research Science and Engineering Center (MRSEC) at UC Santa Barbara through DMR-2308708 (IRG-2). Use of the shared facilities of the MRSEC is gratefully acknowledged. The UC Santa Barbara MRSEC is a member of the Materials Research Facilities Network (https://www.mrfn.org/). The confocal Raman microscope was provided by the Quantum Structures Facility within the California NanoSystems Institute, supported by the University of California, Santa Barbara and the University of California, Office of the President. ALC acknowledges support from the NSF Graduate Research Fellowship Program under Grant No. 1650114. AAP acknowledges funding support from the NSF CAREER award (CMMI-CAREER-2048043). MTV acknowledges funding support from the NSF (DMR-2004937). This work was partially supported by the BioPACIFIC Materials Innovation Platform of the National Science Foundation under Award No. DMR-1933487.

Author information

Authors and Affiliations

Contributions

ALC, CDP, and AAP conceived the idea and scope of research. Material preparation, data collection, and analysis were performed by ALC, CDP, and MEM. TEM assisted with XPS measurements and data analysis. YT and CDE assisted with Raman spectroscopy measurements and data analysis. ALC and AAP wrote the manuscript, and all authors discussed the results and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Chau, A.L., Pugsley, C.D., Miyamoto, M.E. et al. pH-Dependent Friction of Polyacrylamide Hydrogels. Tribol Lett 71, 108 (2023). https://doi.org/10.1007/s11249-023-01779-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-023-01779-4