Abstract

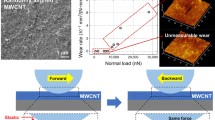

A modified carbon nanotube composite film was designed and prepared by self-assembled molecular film technology. The carbon nanotubes modified by 3-glycidoxypropyltrimethoxy-silane (KH560) were grafted onto a silicon substrate by using N-3-(trimethoxysilyl)propylethyl-enediamine (DA) molecules as an intermediate connecting layer. Compared with the silicon surface, the surface wettability of the modified carbon nanotube composite thin film changes from super-hydrophilic to hydrophobic. At the nanoscale, the surface adhesion and friction forces decreased by nearly 91% and 87%, respectively, and at the microscale, the friction coefficient was reduced by 84%. The anti-wear lifetime is prolonged to 72 min under an applied load of 1 N, which is over 35 times longer than that of silicon. Due to the great wear-resistant properties of modified carbon nanotubes, they are expected to be widely used in micro/nanoelectromechanical systems.

Similar content being viewed by others

References

Wear of silicon surfaces in MEMS: Wear of silicon surfaces in MEMS. Wear 271, 1050–1058 (2011)

Kim, S.H., Asay, D.B., Dugger, M.T.: Nanotribology and MEMS. Nano Today 2, 22–29 (2007)

Wang, X.D., Yu, J.X., Chen, L., Qian, L.M., Zhou, Z.R.: Effects of water and oxygen on the tribochemical wear of monocrystalline Si (1 0 0) against SiO2 sphere by simulating the contact conditions in MEMS. Wear 271, 1681–1688 (2011)

Huo, L.X., Du, P.C., Zhou, H., Zhang, K.F., Liu, P.: Fabrication and tribological properties of self-assembled monolayer of n-alkyltrimethoxysilane on silicon: effect of SAM alkyl chain length. Appl. Surf. Sci. 396, 865–869 (2017)

Pandey, A., Dutta, S., Kaushik, J., Gupta, N., Gupta, G., Raman, R., Kaur, D.: Growth, structural and electrical properties of Al N/Si (1 1 1) for futuristic MEMS applications. Mater. Sci. Semicond. Process. 123, 105567 (2021)

Chen, H., Filleter, T.: Effect of structure on the tribology of ultrathin graphene and graphene oxide films. Nanotechnology 26, 135702 (2015)

Panjwani, B., Sinha, S.K.: Tribology and hydrophobicity of a biocompatible GPTMS/PFPE coating on Ti6Al4V surfaces. J. Mech. Behav. Biomed. Mater. 15, 103–111 (2012)

Yang, Q.P., Nanney, W., Hu, X.L., Ye, T., Martini, A.: Nanoscale friction of hydrophilic and hydrophobic self-assembled monolayers in water. Tribol. Lett. 68, 63 (2020)

Yang, J., Zhou, M.Y., Liu, J.Z., Wang, H., Weng, C.: Fabrication and tribological properties of self-assembled monolayers of alkanethiols on nickel substrates. Appl. Surf. Sci. 559, 149967 (2021)

Turchanin, A., Gölzhäuser, A.: Carbon nanomembranes from self-assembled monolayers: functional surfaces without bulk. Prog. Surf. Sci. 87, 108–162 (2012)

Yong, W., Wang, Y.H., Zhang, Q., Wang, Z.Q., Xu, Z., Liu, C.S., Zhang, J.Y.: Enhanced tribology durability of a self-assembled monolayer of alkylphosphonic acid on a textured copper substrate. Appli. Surf. Sci. 259, 147–152 (2012)

Makowiec, M.E., Blanchet, T.A.: Improved wear resistance of nanotube- and other carbon-filled PTFE composites. Wear 375, 77–85 (2017)

Ujah, C.O., Popoola, P., Popoola, O., Aigbodion, V., oladijo, P.: Improving tribological and thermal properties of Al alloy using CNTs and Nb nanopowder via SPS for power transmission conductor. T. Nonferr. Metal. SOC 30, 333–343 (2020)

Yang, Z.X., Bhowmick, S., Banerji, A., Alpas, A.T.: Role of carbon nanotube tribolayer formation on low friction and adhesion of aluminum alloys sliding against CrN. Tribol. Lett. (2018). https://doi.org/10.1007/s11249-018-1090-2

Radhamani, A.V., Lau, H.C., Kamaraj, M., Ramakrishna, S.: Structural, mechanical and tribological investigations of CNT-316 stainless steel nanocomposites processed via spark plasma sintering. Tribol. Int. 152, 106524 (2020)

Zhai, W.Z., Srikanth, N., Kong, L.B., Zhou, K.: Carbon nanomaterials in tribology. Carbon 119, 150–171 (2017)

Wang, L., Pan, Y.T.: Abstracts of New Carbon Materi als 2010(6). Carbon 49, 1806–1809 (2011)

Ding, Y.X., Cao, X.J., Weng, G.S., Yin, Q.Y., Wang, L.T., Chen, Z.R.: Crack growth behavior of natural rubber influenced by functionalized carbon nanotubes. J. Appli. Polym. Sci. 134, 44527–44535 (2017)

Yuan, Y.B., Chen, H.L.: Controlling and tuning the dispersion properties of calcined kaolinite particles in various organic solvents via stepwise modification method using 3-glycidoxypropyltrimethoxysilane and dodecylamine. Appli. Surf. Sci. 277, 281–287 (2013)

Wang, Z.Q., Rui, R.R., Song, H.J., Jia, X.H.: Improved tribological properties of the synthesized copper/carbon nanotube nanocomposites for rapeseed oil-based additives. Appli. Surf. Sci. 428, 630–639 (2018)

Liu, S.S., Yuan, S.S., Huang, X.N., Ortiz, A., Jiang, S.Q., Liu, G.: Micro/nano-tribological properties of binary-doped ionic liquid lubricating films on alkyi silane-modified silicon surfaces. Tribol. lett. 68, 12 (2020)

Xiong, D.S., Deng, Y.L., Wang, N., Yang, Y.Y.: Influence of surface PMPC brushes on tribological and biocompatibility properties of UHMWPE. Appl. Surf. Sci. 298, 56–61 (2014)

Pu, J.B., Huang, D.M., Wang, L.P., Xue, Q.J.: Tribology study of dual-layer ultrathin ionic liquid films with bonded phase: influences of the self-assembled underlayer. Colloid Surf. A 372, 155–164 (2010)

Acknowledgments

The authors are grateful for the support of the National Natural Science Foundation of China (52175191) and the Nature Science Foundation of Hunan Province (21B0118).

Funding

This work was funded by the National Natural Science Foundation of China (Grant No. 52175191) and the Nature Science Foundation of Hunan Province (Grant No. 21B0118).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could influence the work reported in the paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, S., Deng, Y., Sun, H. et al. Composite Lubricating Films with Silane Coupling Agent-Modified Carbon Nanotubes on a Silicon Substrate with Enhanced Wear-Resistant Properties. Tribol Lett 70, 111 (2022). https://doi.org/10.1007/s11249-022-01650-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-022-01650-y