Abstract

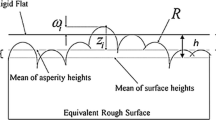

In this paper, we study the effects of plastic strain hardening and damage on the friction response of a surface at the microscopic and macroscopic scales. At the microscale, the role played by hardening and damage in the response of a single asperity is determined using three-dimensional finite element analysis. The sample materials for the asperity are Al 2024-T3 and Ti6Al4V, which are modeled as isotropic bilinear plastic and include Johnson–Cook damage. The friction responses for two different damage models (Johnson–Cook and Bao–Wierzbicki) are also compared for the perfectly plastic case. In the simulations the asperity is initially compressed in order to induce a normal preload and then sheared to study the friction response. Then a statistical homogenization approach is used to propagate these effects to the macroscale. Toward this end, the surface is modeled as an isotropic Gaussian random process. The computed microscale responses are parameterized, and the overall macroscopic response of the surface is determined. Results of this study show that, at the microscale, strain hardening increases the coefficient of friction, particularly at low interference values. Similarly, material response plays a significant role at the macroscale over a wide range of normal force values.

Similar content being viewed by others

References

Bogy, D.: An elastic-plastic model for the contact of rough surfaces. J. Tribol. 109, 257 (1987). doi:10.1115/1.3261348

Evseev, D., Medvedev, B., Grigoriyan, G.: Modification of the elastic-plastic model for the contact of rough surfaces. Wear 150(1), 79 (1991). doi:10.1016/0043-1648(91)90307-G, http://www.sciencedirect.com/science/article/pii/004316489190307G

Chang, W.: An elastic-plastic contact model for a rough surface with an ion-plated soft metallic coating. Wear 212(2), 229 (1997). doi:10.1016/S0043-1648(97)00148-8

Zhao, Y., Maietta, D., Chang, L.: An asperity microcontact model incorporating the transition from elastic deformation to fully plastic flow. J. Tribol. 122(1), 86 (2000). doi:10.1115/1.555332

Kucharski, S., Klimczak, T., Polijaniuk, A., Kaczmarek, J.: Finite-elements model for the contact of rough surfaces. Wear 177(1), 1 (1994). doi:10.1016/0043-1648(94)90112-0, http://www.sciencedirect.com/science/article/pii/0043164894901120

Vu-Quoc, L., Zhang, X., Lesburg, L.: A normal force-displacement model for contacting spheres accounting for plastic deformation: force-driven formulation. J. Appl. Mech. 67(2), 363 (2000). doi:10.1115/1.1305334

Kogut, L., Etsion, I.: Elastic-plastic contact analysis of a sphere and a rigid flat. J. Appl. Mech. 69(5), 657 (2002). doi:10.1115/1.1490373

Jackson, R., Green, I.: A finite element study of elasto-plastic hemispherical contact against a rigid flat. J. Tribol. 127(2), 343 (2005). doi:10.1115/1.1866166

Shankar, S., Mayuram, M.: A finite element based study on the elastic-plastic transition behavior in a hemisphere in contact with a rigid flat. J. Tribol. 130(4), 044502 (2008). doi:10.1115/1.2958081

Chatterjee, B., Sahoo, P.: Effect of strain hardening on elastic-plastic contact of a deformable sphere against a rigid flat under full stick contact condition. Adv. Tribol. 2012, 8 (2012). doi:10.1155/2012/472794

Mindlin, R.: Compliance of elastic bodies in contact. J. Appl. Mech. 16, 259–268 (1949)

Mindlin, R., Deresiewicz, H.: Elastic spheres in contact under varying oblique forces. J. Appl. Mech. 20, 327–344 (1953)

Tabor, D.: Junction growth in metallic friction: the role of combined stresses and surface contamination. Proc. R. Soc. Lond. A Math. Phys. Eng. Sci. 251(1266), 378 (1959). doi:10.1098/rspa.1959.0114

Hamilton, G.: Proceedings of the institution of mechanical engineers. Part C J. Mech. Eng. Sci. 197(1), 53 (1983)

Kogut, L., Etsion, I.: A semi-analytical solution for the sliding inception of a spherical contact. J. Tribol. Trans. ASME 125(3), 499 (2003). doi:10.1115/1.1538190

Brizmer, V., Kligerman, Y., Etsion, I.: Elastic-plastic spherical contact under combined normal and tangential loading in full stick. Tribol. Lett. 25(1), 61 (2007). doi:10.1007/s11249-006-9156-y

Wu, A., Shi, X., Polycarpou, A.: An elastic-plastic spherical contact model under combined normal and tangential loading. J. Appl. Mech. 79(5), 051001 (2012)

Wu, A., Shi, X.: Numerical investigation of adhesive wear and static friction based on the ductile fracture of junction. J. Appl. Mech. 80(4), 041032 (2013)

Bao, Y., Wierzbicki, T.: On fracture locus in the equivalent strain and stress triaxiality space. Int. J. Mech. Sci. 46(1), 81 (2004)

Johnson, G., Cook, W.: Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures. Eng. Fract. Mech. 21(1), 31 (1985). doi:10.1016/0013-7944(85)90052-9, http://www.sciencedirect.com/science/article/pii/0013794485900529

Hooputra, H., Gese, H., Dell, H., Werner, H.: A comprehensive failure model for crashworthiness simulation of aluminium extrusions. Int. J. Crashworth. 9(5), 449 (2004). doi:10.1533/ijcr.2004.0289

Sista, B., Vemaganti, K.: A computational study of dry static friction between elastoplastic surfaces using a statistically homogenized microasperity model. J. Tribol. 137(2), 021601 (2015)

Longuet-Higgins, M.: Statistical properties of an isotropic random surface. Philos. Trans. R. Soc. Lond. Ser. A Math. Phys. Sci. 250(975), 157 (1957)

Nayak, P.R.: Random process model of rough surfaces. J. Lubr. Technol. 93, 398 (1971)

Francis, H.: Application of spherical indentation mechanics to reversible and irreversible contact between rough surfaces. Wear 45(2), 221 (1977)

Sista, B., Vemaganti, K.: Estimation of statistical parameters of rough surfaces suitable for developing micro-asperity friction models. Wear 316, 6 (2014)

Eriten, M., Polycarpou, A., Bergman, L.: Physics-based modeling for partial slip behavior of spherical contacts. Int. J. Solids Struct. 47(18), 2554 (2010). doi:10.1016/j.ijsolstr.2010.05.017, http://www.sciencedirect.com/science/article/pii/S0020768310001952

Rabinowicz, E.: Friction and Wear of Materials. Wiley series on the science and technology of materials. Wiley, New York (1965). http://books.google.com/books?id=kuVSAAAAMAAJ

Moosbrugger, C.: ASM International, Ohio p. 299 (2002)

Bao, Y., Wierzbicki, T.: A comparative study on various ductile crack formation criteria. J. Eng. Mater. Technol. 126(3), 314 (2004)

Lesuer, D.: Experimental investigation of material models for ti-6al-4v and 2024-t3. Tech. Rep. FAA Report DOT/FAA/AR-00/25. US Department of Transportation, Federal Aviation Administration (2000)

Giglio, M., Manes, A., Viganò, F.: Numerical simulation of the slant fracture of a helicopter’s rotor hub with ductile damage failure criteria. Fatigue Fract. Eng. Mater. Struct. 35(4), 317 (2012)

Bhushan, B.: Contact mechanics of rough surfaces in tribology: single asperity contact. Appl. Mech. Rev. 49(5), 275 (1996). doi:10.1115/1.3101928

Timoshenko, S., Goodier, J.: Theory of Elasticity, 3rd edn. McGraw-Hill Kogakusha Ltd , Tokyo (1970). Previous ed. (B51-9908) 1951, classified at 539.3[1]

Chang, W., Etsion, I., Bogy, D.: Static friction coefficient model for metallic rough surfaces. J. Tribol. 110(1), 57 (1988). doi:10.1115/1.3261575

MathWorks, Inc. MATLAB: Version 7.9.0 Documentation (2010)

Acknowledgements

This work was partially supported by the University of Cincinnati Simulation Center. We gratefully acknowledge an allocation of computing time from the Ohio Supercomputer Center.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bhagwat, P., Sista, B. & Vemaganti, K. A Computational Study of the Effects of Strain Hardening in Micro-asperity Friction Models. Tribol Lett 65, 154 (2017). https://doi.org/10.1007/s11249-017-0939-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-017-0939-0