Abstract

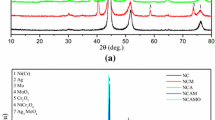

Ni-based composite that contains TiO2 and Al2O3 was prepared by powder metallurgical hot pressing method. TiO2 and Al2O3 being added to Ni-based composite at the same mass fraction and the effects on some mechanical and tribological properties of the composites when rubbing against alumina ball were investigated from room temperature to 700 °C. The results show that the tribological properties of the composites were improved by adding TiO2 and Al2O3 simultaneously. The best comprehensive properties of mechanics and tribology were obtained when TiO2 and Al2O3 in the alloy have the same content of 10 wt%. The friction coefficient and wear rate of the composites decrease with the increasing of temperature and TiO2 and Al2O3 contents, and the composites with addition of 10 wt% TiO2 and 10 wt% Al2O3 exhibit the lowest friction coefficient (0.32) and wear rate (1.71 × 10−5 mm3/N m) at 700 °C. XRD and SEM equipped with EDS analysis shows that the lubrication films consist of aluminum titanate and several kinds of titanium oxide formed on rubbing surface with the temperatures elevated. The synergistic action of titanium oxide and aluminum titanate and NiTiO3 in the wear surface at high temperature is responsible for the improving of tribological properties of the composites.

Similar content being viewed by others

References

Spikes, H.: Tribology research in the twenty-first century. Tribol. Int. 34, 789–799 (2001)

Lu, J.J., Xue, Q.J., Wang, J.B., Ouyang, J.L.: The effect of CeF3 on the mechanical and tribological properties of Ni-based alloy. Tribol. Int. 9, 659–662 (1997)

Sliney, H.E.: Solid lubricant materials for high temperatures—a review. Tribol. Int. 15, 303–315 (1982)

DellaCorte, C., Sliney, H.E.: Tribological properties of PM212-a high-temperature, self-lubricating, powder-metallurgy composite. Lubr. Eng. 47, 298–303 (1991)

DellaCorte, C., Sliney, H.E.: Tribological and mechanical comparison of sintered and HIPped PM212: high temperature self-lubricating composites. Lubric. Eng. 48, 877–885 (1992)

DellaCorte, C., Fellenstein, J.A.: The effect of compositional tailoring on the thermal expansion and tribological properties of PS300: a solid lubricant composite coating. Tribol. Trans. 40, 639–642 (1997)

Liu, F., Jia, J.: Tribological properties and wear mechanisms of NiCr–Al2O3–SrSO4–Ag self-lubricating composites at elevated temperatures. Tribol. Iett. 49, 281–290 (2013)

Dong, X., Jahanmir, S., Hsu, S.M.: Tribological characteristics of α-alumina at elevated temperatures. J. Am. Ceram. Soc. 74, 1036–1044 (1991)

Cho, S.J., Moon, H., Hockey, B., Hsu, S.: The transition from mild to severe wear in alumina during sliding. Acta Metall. Mater. 40, 85–192 (1992)

Senda, T., Yasuda, E., Kaji, M., Bradt, R.C.: Effect of grain size on the sliding wear and friction of alumina at elevated temperatures. J. Am. Ceram. Soc. 82, 1505–1511 (1999)

Park, N.R., Ko, I.Y., Doh, J.M., Kong, W.Y., Yoon, J.K., Shon, I.J.: Rapid consolidation of nanocrystalline 3Ni–Al2O3 composite from mechanically synthesized powders by high frequency induction heated sintering. Mater. Charact. 61, 277–282 (2010)

Martin, C., Katarzyna, P.: Processing, microstructure and mechanical properties of Al2O3–Cr nanocomposites. J. Eur. Ceram. Soc. 27, 1273–1279 (2007)

Edemir, A.: A crystal-chemical approach to lubrication by solid oxides. Tribol. Lett. 8, 97–102 (2000)

Padhy, N., Kamal, S., Chandra, R., Mudali, U.K., Raj, B.: Electrophoretic deposition of TiO2 and TiO2+CeO2 coatings on type 304L stainless steel. Surf. Eng. 23(4), 267–272 (2007)

Xiao, H., Senda, T., Yasuda, E.: Dynamic recrystallization during the sliding wear of alumina at elevated temperatures. J. Am. Ceram. Soc. 79, 3243–3249 (1996)

Jahanmir, S., Dong, X.: Mechanism of mild to severe wear transition in alpha-alumina. ASME Trans. J. Tribol. 114, 403–411 (1992)

Cho, S.J., Moon, H., Hockey, B., Hsu, S.: The transition from mild to severe wear in alumina during sliding. Acta Metall. Mater. 40, 185–192 (1992)

Hu, Z.S., Dong, J.X.: Study on antiwear and reducing friction additive of nanometer titanium oxide. Wear 216, 92–96 (1998)

Gardos, M.N.: The effect of anion vacancies on the tribological properties of rutile (Ti02-x). Tribol. Trans. 31, 427–436 (1988)

Gardos, M.N., Hong, H.-S., Winer, W.O.: Effect of anion vacancies on the tribological properties of rutile (TiO2-x) part II. Experimental evidence. Tribol. Trans. 32, 209–212 (1990)

Gardos, M.N.: New materials approaches to tribology: theory and applications. In: Pope L.E., Fehrenbacher L.L., Winer W.O. (eds.) Materials Research Society Symposium Proceedings, Vol. 140, pp. 325–338 (1989)

Skopp, A., Woydt, M.: Ceramic and ceramic composite materials with improved friction and wear properties. Tribol. Trans. 38(2), 233–242 (1995)

Wang, Y., Jiang, S., Wang, M., Wang, S., Xiao, T.D., Strutt, P.: Abrasive wear characteristics of plasma sprayed nanostructured alumina/titania coatings. Wear 237, 176–185 (2000)

Lin, X., Zeng, Y., Ding, C., Zhang, P.: Effects of temperature on tribological properties of nanostructured and conventional Al2O3-3 wt% TiO2 coatings. Wear 256, 1018–1025 (2004)

Habib, K.A., Saura, J.J., Ferrer, C., Damra, M.S., Giménez, E., Cabedo, L.: Comparison of flame sprayed Al2O3/TiO2 coatings: their microstructure, mechanical properties and tribology behavior. Surf. Coat. Technol. 201, 1436–1443 (2006)

Freudenberg, B., Mocellin, A.: Aluminum titanate formation by solid-state reaction of coarse Al2O3 and TiO2 powders. J. Am. Ceram. Soc. 71(1), 22–28 (1988)

Wohlfortnm, H., Pena, P., Moya, J.S.: Al2TiO5 formation in alumina/titania multilayer composites. J. Am. Ceram. Soc. 75(12), 3473–3476 (1992)

Chen, C., Awaji, H.: Temperature dependence of mechanical properties of aluminum titanium ceramics. J. Am. Ceram. Soc. 27, 13–18 (2007)

Acknowledgments

The authors acknowledge the financial supports by the National Natural Science Foundation of China (Grant Nos. 50972148, 51175490).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, JY., Shan, Y., Guo, H. et al. The Tribological Properties of NiCr–Al2O3–TiO2 Composites at Elevated Temperatures. Tribol Lett 58, 1 (2015). https://doi.org/10.1007/s11249-015-0491-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-015-0491-8