Abstract

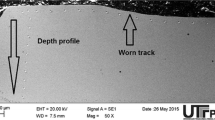

The progress of wear associated with the compound and diffusion layers of nitrided samples was studied by employing laboratory tests at low, medium and high contact pressures, simulating the conditions occurring during the hot extrusion of aluminium. It was found that with increasing of contact pressure also wear rates increase that indicates on predominately frictional removal of compound layer which was confirmed by scanning electron microscopy and back-scattered electron micrographs as well as energy-dispersive spectroscopy analysis of tested surfaces. Testing at medium contact pressures reveals some common features observed at testing at lower as well as at higher contact pressures. The essential difference between the testing at medium and low contact pressures is in the density of the obtained micro-craters and appearance of their extension in sliding direction at medium contact pressures. At higher contact pressure, removal of compound layer is already preferentially oriented in sliding direction in the first stage, while at medium contact pressure, this is observed only in later stages of degradation progress.

Similar content being viewed by others

References

Björk, T., Bergström, J., Hogmark, S.: Tribological simulation of aluminium hot extrusion. Wear 224, 216–225 (1999)

Arif, A.F.M.: Effect of extrusion die profile on the uniformity of nitrided layer. Mater. Manuf. Process. 24, 619–625 (2009)

Björk, T., Westegård, R., Hogmark, S.: Wear of surface treated dies for aluminium extrusion—a case study. Wear 249(2), 316–323 (2001)

Terčelj, M., Kugler, G., Turk, R., Cvahte, P., Fajfar, P.: Measurement of temperature on bearing surface of industrial die and assessment of heat transfer coefficient in aluminium hot extrusion—a case study. Int. J. Veh. Des. 39(1–2), 93–109 (2005)

Clode, I., Sheppard, T.: Formation of die lines during extrusion of AA 6063. Mater. Sci. Technol. 6, 755–763 (1990)

Akhtar, S.S., Arif, A.F.M., Yilbas, B.S.: Evaluation of gas nitriding process with in-process variation of nitriding potential for AISI H13 tool steel. Int. J. Adv. Manuf. Technol. 47, 687–698 (2010)

Castro, G., Fernández-Vicente, A., Cid, J.: Influence of the nitriding time in the wear behaviour of an AISI H13 steel during a crankshaft forging process. Wear 263, 1375–1385 (2007)

Hernandez, M., Staia, M.H., Puchi-Cabrera, E.S.: Evaluation of microstructure and mechanical properties of nitrided steels. Surf. Coat. Technol. 202, 1935–1943 (2008)

Björk, T., Bergström, J., Hogmark, S.: Optimization of nitriding parameters for extrusion dies, evaluated in an extrusion simulation. Seventh Int. Alum. Extrus. Technol. Semin. 2, 317–325 (2000)

Friehling, P.F., Poulsen, F.W., Somers, M.A.J.: Nucleation of iron nitrides during gaseous nitriding of iron; effect of a preoxidation treatment. Z. Metallkd. 92(6), 589–595 (2001)

Chang, S.-H., Tang, T.-P., Chen, Y.-C., Cchen, J.-K.: Enhancement of erosion resistance on AISI H13 tool steel by oxynitriding treatment. ISIJ Int. 49(3), 421–424 (2009)

Basso, R.L.O., Candal, R.J., Figueroa, C.A., Wisnivesky, D., Alvarez, F.: Influence of microstructure on the corrosion behavior of nitrocarburized AISI H13 tool steel obtained by pulsed DC plasma. Surf. Coat. Technol. 203, 1293–1297 (2009)

Matteis, P., Scavino, G., Quadrini, E., Perucci, P., Firrao, D.: Damage of repeatedly nitrocarburised steel dies for aluminium extrusion. Surf. Eng. 25(7), 507–516 (2009)

Wen, D.C.: Microstructure and corrosion resistance of the layers formed on the surface of precipitation hardenable plastic mold steel by plasma-nitriding. Appl. Surf. Sci. 256, 797–804 (2009)

Cai, W., Meng, F., Gao, X., Hu, J.: Effect of QPQ nitriding time on wear and corrosion behavior of 45 carbon steel. Appl. Surf. Sci. 261, 411–414 (2012)

Baranowska, J., Szczecinski, K., Wysiecki, M.: Increasing of gas nitriding kinetics via surface pre-treatment. Surf. Coat. Technol. 151–152, 534–539 (2002)

Keramis, M.B., Gercekcioglu, E.: Wear behaviour of plasma nitrided steels at ambient and at elevated temperature. Wear 243, 76–84 (2000)

Smolik, J., Gulde, M., Walkowicz, J., Suchanek, J.: Influence of the structure of the composite: ‘nitrided layer/PVD coating’on the durability of forging dies made of steel DIN-1.2367. Surf. Coat. Technol. 180–181, 506–511 (2004)

Arif, A.F.M., Sheikh, A.K., Qamar, S.Z.: A study of die failure mechanisms in aluminium extrusion. J. Mater. Process. Technol. 134, 318–328 (2003)

Lim, S.C., Ashby, M.F.: Wear-mechanisms maps. Acta Metall. Mater. 24(5), 805–810 (1990)

So, H., Chen, H.M., Chen, L.W.: Extrusion wear and transition of wear mechanisms of steel. Wear 265, 1142–1148 (2008)

Terčelj, M., Smolej, A., Fajfar, P., Turk, R.: Laboratory assessment of wear of nitrided surfaces of dies for hot extrusion of aluminium. Tribol. Int. 40, 374–384 (2007)

Pellizzari, M., Zadra, M., Molinari, A.: Tribological properties of surface engineered hot work tool steel for aluminium extrusion dies. Surf. Eng. 23(3), 165–168 (2007)

Pellizzari, M.: High temperature wear and friction behaviour of nitrided, PVD-duplex and CVD coated tool steel against 6082 Al alloy. Wear 271, 2089–2099 (2011)

Wang, L., Zhou, J., Duszczyk, J., Katgerman, L.: Identification of a friction model for the bearing channel of hot aluminium extrusion dies by using ball-on-disc tests. Tribol. Int. 50, 66–75 (2012)

Vilasecaa, M., Molasa, S., Casellasa, D.: High temperature tribological behaviour of tool steels during sliding against aluminium. Wear 272, 105–109 (2011)

Wen, D.C.: Effect of nitrocarburizing time on the microstructures and erosion behavior of cold-work tool steel. ISIJ Int. 49(11), 1762–1768 (2009)

Wen, D.C.: Erosion and wear behavior of nitrocarburized DC53 tool steel. Wear 268, 629–636 (2010)

Birol, Y.: Analysis of wear of a gas nitrided H13 tool steel die in aluminium extrusion. Eng. Fail. Anal. 26, 203–210 (2012)

Wang, L., He, Y., Zhou, J., Duszczyk, J.: Effect of temperature on the frictional behaviour of an aluminium alloy sliding against steel during ball-on-disc tests. Tribol. Int. 43, 299–306 (2010)

Wang, L., Hea, Y., Zhang, Y., Cai, J., Zhou, J., Duszczyk, J., Katgerman, L.: Modeling of double action extrusion—a novel extrusion process for friction characterization at the billet–die bearing interface. Tribol. Int. 43, 2084–2091 (2010)

Wang, L., He, Y., Zhou, J., Duszczyk, J.: Modelling of plowing and shear friction coefficients during high-temperature ball-on-disc tests. Tribol. Int. 42, 15–22 (2009)

Wang, L., Yang, H.: Friction in aluminium extrusion—part 2: a review of friction models for aluminium extrusion. Tribol. Int. 56, 99–106 (2012)

Wang, L., Zhou, J., Duszczyk, J., Katgerman, L.: Friction in aluminium extrusion—part 1: a review of friction testing techniques for aluminium extrusion. Tribol. Int. 56, 89–98 (2012)

Ma, X., de Rooij, M.B., Schipper, D.J.: Friction conditions in the bearing area of an aluminium extrusion process. Wear 278–279, 1–8 (2012)

Birol, Y., Yuksel, B.: Performance of gas nitrided and AlTiN coated AISI H13 hot work tool steel in aluminium extrusion. Surf. Coat. Technol. 207, 461–466 (2012)

Birol, Y.: Sliding wear of CrN, AlCrN and AlTiN coated AISI H13 hot work tool steels in aluminium extrusion. Tribol. Int. 57, 101–106 (2013)

Gharam, A.A., Lukitsch, M.J., Balogh, M.P., Irish, N., Alpas, A.T.: High temperature tribological behavior of W-DLC against aluminium. Surf. Coat. Technol. 206, 1905–1912 (2011)

Jakubéczyová, D., Hvizdoš, P., Selecká, M.: Investigation of thin layers deposited by two PVD techniques on high speed steel produced by powder metallurgy. Appl. Surf. Sci. 258(12), 5105–5110 (2012)

Kugler, G., Tercelj, M.: Laboratory simulation of wear during hot extrusion of aluminium. In: Sadler, B.A. (ed.) Light Metals 2013, pp. 515–520. Wiley, Hoboken, NJ, USA (2013)

Wei, Y., Gong, C.: Effects of pulsed bias duty ratio on microstructure and mechanical properties of TiN/TiAlN multilayer coatings. Appl. Surf. Sci. 257(17), 7881–7886 (2011)

Lidtke, D., Baudis, U., Bosslet, J., Huchel, U., Klümper-Westkamp, H., Leche, W., Spies, H.J.: Warmebehandlung von Werkstoffen, Nitrieren und nitrocarburieren. ISBN 3-8169-2416-6, Expert Verlag (2006)

Kendall, K.: Adhesion, molecules and mechanics. Science 263(5154), 1720–1725 (1994)

Newby, B.Z., Chaudhury, M.K., Brown, H.R.: Macroscopic evidence of the effect of interfacial slippage on adhesion. Science 269(5229), 1407–1409 (1995)

Maeda, N., Chen, N., Tirrell, M., Israelachvili, J.N.: Adhesion and friction mechanisms of polymer-on-polymer surfaces. Science 297(5580), 379–382 (2002)

Novák, P., Michalcová, A., Marek, I., Mudrová, M., Saksl, K., Bednarcík, J., Zikmund, P., Vojtech, D.: On the formation of intermetallics in FeAl system: an in situ XRD study. Intermetallics 32, 127–136 (2013)

Krishnaraj, N., Bala-Srinivasan, P., Iyer, L.J.L., Sundaresan, S.: Optimization of compound layer thickness for wear resistance of nitrocarburized H11 steel. Wear 215, 123–130 (1998)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Terčelj, M., Peruš, I. & Kugler, G. Wear Progress of Nitrided Layer at Low, Medium and High Contact Pressures During a Laboratory Simulation of Aluminium Hot Extrusion. Tribol Lett 55, 69–81 (2014). https://doi.org/10.1007/s11249-014-0333-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-014-0333-0