Abstract

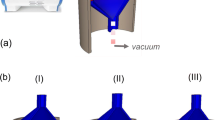

An alternative method to integrate the SCR functionality in diesel particulate filters has been investigated. In contrast to coated filters, SCR active materials like Cu exchanged silico-alumino-phosphates (Cu-SAPO) and acidic CeO2/ZrO2 were added directly to the slip and were coextruded with silicon carbide matrix and silicon dioxide glass; the latter serving to bond the SCR active material with the matrix. Due to silicon dioxide glass addition, the extruded honeycomb samples can be hardened at 900 °C. Preliminary investigations proved the stability of the SCR active material at this temperature range. In this work, parameters like slip composition, grain size of the powders and hardening conditions were varied. Measured differential pressures indicated that the manufactured samples have open pores with porosities between 41 and 54 %, making them suitable for particulate filter application. The porosity was controlled by varying the grain sizes of the powder materials as well by the hardening conditions like temperature and time. Initially, the silicon dioxide glass enclosed the SCR active materials and reduced BET surface area, yielding in poor NOx-conversion. By an improved two-step slip preparation method, the BET surface area and the NOx-conversion was increased. A NOx-conversion of about 70 % at a feed ratio of 1.5 was achieved at 300 °C in simulated exhaust. We consider this approach worth for being further investigated and improved.

Similar content being viewed by others

References

Mollenhauer K, Tschöke H (2010) Handbook of diesel engines. Springer Science & Business Media, New York, pp 427–428

Liebeck M, Schuler A, Votsmeier M, Drochner A, Vogel H (2013) Top Catal 56:210–214

Grossale A, Nova I, Tronconi E, Chatterjee D, Weibel M (2009) Top Catal 52:1837–1841

Deutschmann O, Grunwaldt J-D (2013) Chemie Ingenieur Technik 85:1–24

Schuler A, Votsmeier M, Kiwic P, Gieshoff J, Hauptmann W, Drochner A, Vogel H (2009) Chem Eng J 154:333–340

Johnson T (2014) SAE Technical paper, 2014-01-1491

Benjamin SF, Roberts CA (2014) SAE Technical paper, 2014-01-2819

Ballinger T, Cox J, Konduru M, De D, Manning W, Andersen P (2009) SAE Technical paper, 2009-01-0910

Harth K (2012) MTZ 73(9):650–654

Verdier S, Crinière G, Larcher O, Rohart E, Feeley M, Bradshaw H, Harris D, Butler C (2007) SAE Technical paper, 2007-01-0238

Verdier S, Rohart E, Bradshaw H, Harris D (2008) SAE Technical paper, 2008-01-1022

Rohart E, Kröcher O, Casapu M, Marques R, Harris D, Jones C (2011) SAE Technical paper, 2011-01-1327

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Schütt, M., Gallinger, M. & Moos, R. Particulate Filter Substrates with SCR-Functionality Manufactured by Co-extrusion of Ceramic Substrate and SCR Active Material. Top Catal 60, 204–208 (2017). https://doi.org/10.1007/s11244-016-0598-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11244-016-0598-7