Abstract

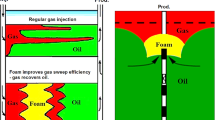

Foam application in subsurface processes including environmental remediation, geological carbon-sequestration, and gas-injection enhanced oil recovery (EOR) has the potential to enhance contamination remediation, secure \(\hbox {CO}_{2}\) storage, and improve oil recovery, respectively. Nanoparticles are a promising alternative to surfactants in creating foam in harsh environments. We conducted \(\hbox {CO}_{2}\)-in-brine foam generation experiments in Boise sandstones with surface-treated silica nanoparticle in high-salinity conditions. All the experiments were conducted at the fixed \(\hbox {CO}_{2}\) volume fraction and fixed flow rate which changed in steps. The steady-state foam apparent viscosity was measured as a function of injection velocity. The foam flowing through the cores showed higher apparent viscosity as the flow rate increased from low to medium and high velocities. At very high velocities, once foam bubbles were finely textured, the foam apparent viscosity was governed by foam rheology rather than foam creation. A noticeable hysteresis occurred when the flow velocity was initially increased and then decreased, implying multiple (coarse and strong) foam states at the same superficial velocity. A normalized generation function was combined with CMG-STARS foam model to cover full spectrum of foam behavior in the experiments. The new model successfully captures foam generation and hysteresis trends in presented experiments in this study and data from the literature. The results indicate once foam is generated in porous media, it is possible to maintain strong foam at low injection rates. This makes foam more feasible in field applications where foam generation is limited by high injection rates that may only exist near the injection well.

Similar content being viewed by others

Abbreviations

- epcap :

-

Shear-thinning exponent in STARS foam model

- epdry :

-

Factor governing abruptness of dry-out calculation \((F _{\mathrm{dry-out}})\) in STARS foam model

- epgcp :

-

Foam generation exponent in STARS foam model

- \(F_{\mathrm{dry-out}}\) :

-

Foam dry-out (coalescence) function in STARS foam model

- \(f_{\mathrm{g}}\) :

-

Gas fractional flow (foam quality)

- \(f_{\mathrm{w}}\) :

-

Water fractional flow

- \(F_{\mathrm{gen}}\) :

-

Foam generation function in STARS foam model

- \(\bar{F}_{\mathrm{gen}}\) :

-

Normalized foam generation function introduced in improved STARS foam model

- fgenc :

-

Normalized foam generation value for coarse foam in improved STARS foam model

- \(\hbox {FM}\) :

-

Foam resistance factor in STARS foam model

- fmcap :

-

Reference rheology capillary number in STARS foam model

- fmdry :

-

Reference water saturation in dry-out calculation \((F_{\mathrm{dry-out}})\) in STARS foam model

- fmgcp :

-

Critical foam generation capillary number in STARS foam model

- fmmob :

-

Maximum resistance factor in STARS foam model

- \(F_{\mathrm{shear}}\) :

-

Foam shear-thinning function in STARS foam model

- \(f_{\mathrm{w}}\) :

-

Water fractional flow

- k :

-

Permeability \([\hbox {L}^{2}]\)

- \(k_{\mathrm{rw}}\) :

-

Water relative permeability

- \(k_{\mathrm{rw}}^\mathrm{{o}}\) :

-

Water endpoint relative permeability

- \(k_{\mathrm{rg}}\) :

-

Gas relative permeability

- \(k_{\mathrm{rg}}^\mathrm{{o}}\) :

-

Gas endpoint relative permeability

- \(k_{\mathrm{rg}}^\mathrm{{f}}\) :

-

Gas relative permeability in the presence of foam

- \(N_{\mathrm{ca}}\) :

-

Capillary number

- \(N_{\mathrm{ca}}^\mathrm{{max}}\) :

-

Capillary number at which foam generation reaches its maximum limit

- \(n_{\mathrm{g}}\) :

-

Gas relative permeability exponent

- \(n_{\mathrm{w}}\) :

-

Water relative permeability exponent

- Q :

-

Flow rate \([\hbox {L}^{3}\hbox {t}^{-1}]\)

- \(S_{\mathrm{gr}}\) :

-

Residual gas saturation

- \(S_{\mathrm{n}}\) :

-

Normalized water saturation

- \(S_{\mathrm{w}}\) :

-

Water saturation

- \(S_{\mathrm{w}}^*\) :

-

Limiting water saturation

- \(S_{\mathrm{wr}}\) :

-

Residual water saturation

- \({u}_\mathrm{t}\) :

-

Total Darcy velocity \([\hbox {Lt}^{-1}]\)

- \(u_{\mathrm{w}}\) :

-

Water Darcy velocity \([\hbox {Lt}^{-1}]\)

- \(v_{\mathrm{t}}\) :

-

Total interstitial velocity \([\hbox {Lt}^{-1}]\)

- \(v_{\mathrm{w}}\) :

-

Water interstitial velocity \([\hbox {Lt}^{-1}]\)

- \(\Delta P\) :

-

Pressure drop \([\hbox {ML}^{-1}\hbox {t}^{-2}]\)

- \(\nabla P\) :

-

Pressure gradient \([\hbox {ML}^{-2}\hbox {t}^{-2}]\)

- \(\nabla \varPhi \) :

-

Phase potential gradient \([\hbox {ML}^{-2}\hbox {t}^{-2}]\)

- \(\mu _{\mathrm{g}}\) :

-

Gas viscosity \([\hbox {ML}^{-1}\hbox {t}^{-1}]\)

- \(\mu _{\mathrm{w}}\) :

-

Water viscosity \([\hbox {ML}^{-1}t^{-1}]\)

- \(\mu _{\mathrm{app}}^\mathrm{{f}}\) :

-

Foam apparent viscosity \([\hbox {ML}^{-1}\hbox {t}^{-1}]\)

- \(\sigma _{\mathrm{wg}}\) :

-

Water–gas interfacial tension \([\hbox {Mt}^{-2}]\)

- \(\phi \) :

-

Porosity

References

Almajid, M.M., Kovscek, A.R.: Pore-level mechanics of foam generation and coalescence in the presence of oil. Adv. Colloid Interface Sci. (2015, in press)

Andrianov, A., Farajzadeh, R., Mahamoodi Nick, M., Talanana, M., Zitha, P.L.J.: Immiscible foam for enhancing oil recovery: bulk and porous media experiments. Ind. Eng. Chem. Res. 51(5), 2214–2226 (2012)

Baghdikian, S.Y., Handy, L.L.: Transient behavior of simultaneous flow of gas and surfactant solution in consolidated porous media. Topical report performed under U.S. DOE contract FG22-90BC14600(1991)

Beygi, M.R., Delshad, M., Pudugramam, V.S., Pope, G.A., Wheeler, M.F.: Novel three-phase compositional relative permeability and three-phase hysteresis models. SPEJ 20(01), 21–34 (2015)

Beygi, M.R., Varavei, A., Lotfollahi, M., Delshad, M.: Low-tension gas modeling in surfactant alternating gas and surfactant/gas coinjection processes. Paper SPE 174678 presented at SPE Asia Pacific enhance oil recovery conference, Kuala Lumpur, 11–13 Aug 2015

Boeije, C.S., Rossen, W.R.: Fitting foam simulation model parameters to data. Presented at the 17th European symposium on improved oil recovery, Petersburg, 16–18 April 2013

Cheng, L., Reme, A.B., Shan, D., Coombe, D.A., Rossen W.R.: Simulating foam processes at high and low foam qualities. Paper SPE 59278 presented at the SPE, DOE improved oil recovery symposium, Tulsa, 3–5 April 2000

Chou, S.I.: Conditions for generating foam in porous media. Paper SPE 22628 presented at SPE annual technical conference and exhibition, Dallas, 6–9 Oct 1991

Cohen, D., Patzek, T.W., Radke, C.J.: Onset of mobilization and the fraction of trapped foam in porous media. Transp. Porous Media 28(3), 253–284 (1997)

Computer Modeling Group Ltd. STARS User Guide. Advanced processes & thermal reservoir simulator. Calgary, Alberta Canada (2012)

Egermann, P., Vizika, O., Dallet, L., Requin, C., Sonier, F.: Hysteresis in three-phase flow: experiments, modeling and reservoir simulations. Paper SPE 65127 presented at SPE European petroleum conference, Paris, 24–25 Oct 2000

Falls, A.H., Hirasaki, G.J., Patzek, T.W., Gauglitz, D.A., Mille, D.D., Ratulowski, J.: Development of a mechanistic foam simulator: the population balance and generation by snap-off. SPE Res. Eng. 3(03), 884–892 (1988)

Farajzadeh, R., Lotfollahi, M., Eftekhari, A.A., Rossen, W.R., Hirasaki, G.J.: Effect of permeability on implicit-texture foam model parameters and the limiting capillary pressure. Energy Fuels 29(5), 3011–3018 (2015)

Friedmann, F., Jensen, J.A.: Some parameters influencing the formation and propagation of foams in porous media. Paper SPE 15087 presented at SPE California regional meeting, Okland, 2–4 April 1986

Gauglitz, P.A., Friedmann, F., Kam, S., Rossen, W.R.: Foam generation in homogeneous porous media. Chem. Eng. Sci. 57(19), 4037–4052 (2002)

Kam, S.I., Rossen, W.R.: A model for foam generation in homogeneous porous media. SPEJ 8(4), 417–425 (2003)

Kam, S.I.: Improved mechanistic foam simulation with foam catastrophe theory. Colloids Surf. A Physicochem. Eng. Asp. 318(1–3), 62–77 (2008)

Kibodeaux, K.R.: Experimental and Theoretical Studies of Foam Mechanisms in Enhanced Oil Recovery and Matrix Acidization Applications. Ph.D. Dissertation, The University of Texas at Austin (1997)

Kim, I., Worthen, A.J., Johnston, K.P., DiCarlo, D.A., Huh, C.: Size-Dependent Properties of Silica Nanoparticles for Picking Stabilization of Emulsions and Foams. J. Nanopart. Res. 18, 82 (2016)

Kovscek, A.R., Radke, C.J.: Fundamentals of foam transport in porous media. In: Schramm, L. (ed.) Foams: Fundamentals and Applications in the Petroleum Industry, ACS Symposium Series, vol. 242, pp. 115–163. American Chemical Society, Washington (1994)

Lake, L.W., Johns, R.T., Pope, G.A., Rossen, W.R.: Fundamentals of Enhanced Oil Recovery. Society of Petroleum Engineers, Richardson (2014)

Larsen, J.A., Skauge, A.: Methodology for Numerical simulation with cycle-dependent relative permeabilities. SPEJ 3(02), 163–173 (1998)

Lotfollahi, M., Farajzadeh, R., Delshad, M., Varavei, A., Rossen, W.R.: Comparison of implicit-texture and population-balance foam models. Paper SPE 179808 presented at the SPE EOR conference at oil and gas West Asia, Muscat, 21–23 March 2016

Lotfollahi, M.: Development of a Four-Phase Flow Simulator to Model Hybrid Gas/Chemical EOR Processes. Ph.D. Dissertation, The University of Texas at Austin (2015)

Ma, K., Lopez-Salinas, J.L., Puerto, M.C., Miller, C.A., Biswal, S.L., Hirasaki, G.J.: Estimation of parameters for the simulation of foam flow through porous media. Part 1: the dry-out effect. Energy Fuels 27(5), 2363–2375 (2013)

Ma, K., Ren, G., Mateen, K., Morel, D., Cordelier, P.: Modeling techniques for foam flow in porous media. SPEJ 20(03), 453–470 (2015)

Radke, C.J., Gillis, J.V.: A dual gas tracer technique for determining trapped gas saturation during steady foam flow in porous media. Paper SPE 20519 presented at SPE annual technical conference and exhibition, New Orleans, 23–26 Sep 1990

Ransohoff, T.C., Radke, C.J.: Mechanisms of foam generation in glassbead packs. SPE Res. Eng. 3(2), 573–585 (1988)

Rossen, W.R., Gauglitz, P.A.: Percolation theory of creation and mobilization of foam in porous media. A.I.Ch.E. J. 36(8), 1176–1188 (1990)

Rossen, W.R.: Foams in enhanced oil recovery. In: Prud’homme, R.K., Khan, S. (eds.) Foams: Theory, Measurements and Applications. Marcel Dekker, New York (1996)

Schramm, L.L.: Foams: Fundamentals and Applications in the Petroleum Industry, vol. 242. American Chemical Society, Washington (1994)

Shi, X.: Simulation and Experimental Studies of Foam for Enhanced Oil Recovery. Ph.D. Dissertation, The University of Texas at Austin(1996)

Tang, G.Q., Kovscek, A.R.: Trapped gas fraction during steady-state foam flow. Transp. Porous Media 65(2), 287–307 (2006)

Tanzil, D., Hirasaki, G.J., Miller, C.A.: Conditions for foam generation in homogeneous porous media. Paper SPE 75176 presented at SPE/DOE improved oil recovery symposium, Tulsa, 13–17 April 2002

Worthen, A.J., Bagaria, H.G., Chen, Y.S., Bryant, S.L., Huh, C., Johnston, K.P.: Nanoparticle-stabilized carbon dioxide-in-water foams with fine texture. J. Colloid Interface Sci. 391, 142–151 (2013)

Acknowledgements

This work was supported by the Nanoparticles for Subsurface Engineering Industrial Affiliates Program at The University of Texas at Austin. We acknowledge the financial support from Denbury Resources Inc., and the donation of silica nanoparticles from Nissan Chemical America Corp. We would like to thank Dr. William R. Rossen and Dr. Rouhi Farajzadeh for helpful discussions.

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix 1: STARS Foam-Model Summary

In the STARS foam model, when foam is present, the gas relative permeability \(\left( {k_\mathrm{{rg}} } \right) \) is reduced by a resistance factor of FM,

where fmmob is maximum mobility reduction factor when all conditions are favorable. The \(F_i\) functions reflect the effect of different physical parameters on foam behavior in porous media. We only use dry-out, shear-thinning, and generation functions in this paper.

The dry-out function represents foam coalescence and is defined as,

where fmdry is the water saturation at which foam experiences significant coalescence. epdry controls the sharpness of foam transition from high-quality to low-quality regime. For the large values of epdry, foam collapses at a very narrow range of water saturation and fmdry approaches to the limiting water saturation \(\left( {S_\mathrm{{w}}^*}\right) \) (Farajzadeh et al. 2015). In the recent version of STARS (2015), fmdry and epdry were substituted with sfdry and sfbet, respectively. Then, sfdry can be represented as a function of surfactant concentration, oil saturation, salt concentration, and capillary number. Disabling the other functionalities, keeps sfdry constant playing the same role as fmdry does.

The shear-thinning function is defined as,

fmcap is the reference rheology capillary number and typically set to the smallest value that foam may encounter in the simulations (Cheng et al. 2000; Boeije and Rossen 2013; Farajzadeh et al. 2015). epcap represents the shear-thinning exponent. For the Newtonian behavior, \(epcap=0\). A positive epcap corresponds to the shear-thinning behavior. \(N_\mathrm{{ca}}\) is capillary number and is defined as

where \(\nabla \varPhi \) is the gradient of phase potential, k is absolute permeability, and \(\sigma _\mathrm{{wg}}\) is interfacial tension between water and gas.

The foam generation is modeled as a power-law function of capillary number as below,

where fmgcp is critical foam generation capillary number and epgcp is generation exponent. For \(epgcp=0\), foam generation is independent of capillary number. Lotfollahi et al. (2016) assumed a constant bubble generation rate to compute dimensionless foam texture implicit in STARS model.

Appendix 2: Water and Gas Relative Permeability Functions

Two-phase foam-free water-gas relative permeabilities are calculated from the following expressions

where \(k_\mathrm{{rw}}\) and \(k_\mathrm{{rg}}\) are water and gas relative permeabilities, \(k_\mathrm{{rw}}^\mathrm{o}\) and \(k_\mathrm{{rg}}^{\ rm o}\) are water and gas endpoint relative permeabilities, and \(n_\mathrm{{w}}\) and \(n_\mathrm{{g}}\) are water and gas Corey’s exponents. \(S_\mathrm{{n}}\) is normalized water saturation and is defined as,

where \(S_\mathrm{{wr}}\) and \(S_\mathrm{{gr}}\) are residual water and residual gas saturations, respectively.

Rights and permissions

About this article

Cite this article

Lotfollahi, M., Kim, I., Beygi, M.R. et al. Foam Generation Hysteresis in Porous Media: Experiments and New Insights. Transp Porous Med 116, 687–703 (2017). https://doi.org/10.1007/s11242-016-0796-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11242-016-0796-6