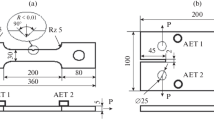

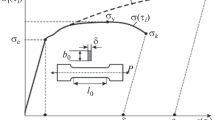

The system for monitoring acoustic emission (AE) parameters in mechanical testing of materials built up from electronic equipment and corresponding software is described. The electronic equipment based on a high-speed data storage module with a USB interface provides conversion of AE signals, their amplification, filtering, and digital input to a personal computer. The AEMonitor software performs continuous analog-digital conversion of AE signals, evaluation of their spectral distribution (fast Fourier transform), online display, accumulation, and storage of experimental data with load parameters for their further analysis. The software features an online automatic display of the spectral distribution of signals and corresponding stresses against the number of AE pulses from tested materials. The functional potentials of the system were verified in bending tests of corundum refractory and glass fiber plastic specimens with recording AE parameters. The relations between major AE parameters, form, and spectral distribution of pulses under loading of those materials were greatly different due to varied fracture mechanisms.

Similar content being viewed by others

References

C. Grosse and M. Ohtsu, Acoustic Emission Testing, Springer-Verlag, Berlin–Heidelberg (2008). https://doi.org/https://doi.org/10.1007/978-3-540-69972-9

W. Li, Y. Liu, J. Peng, et al., “Study on delamination damage of CFRP laminates based on acoustic emission and micro visualization,” Materials, 15, 1483 (2022). https://doi.org/https://doi.org/10.3390/ma15041483

S. Gholizadeh, Z. Lemana, and B. T. H. T. Baharudin, “A review of the application of acoustic emission technique in engineering,” Struct Eng Mech, 54, No. 6, 1075–1095 (2015). http://dx.doi.org/https://doi.org/10.12989/sem.2015.54.6.1075

M. Lebyodkin, K. Amouzou, T. Lebedkina, et al., “Complexity and anisotropy of plastic flow of α-Ti probed by acoustic emission and local extensometry,” Materials, 11, 1061 (2018). http://dx.doi.org/https://doi.org/10.3390/ma11071061

Z. Han, H. Luo, Y. Zhang, and J. Cao, “Effects of micro-structure on fatigue crack propagation and acoustic emission behaviors in a micro-alloyed steel,” Mater Sci Eng A, 559, 534–542 (2013). http://dx.doi.org/https://doi.org/10.1016/j.msea.2012.08.138

S. Esola, B. J. Wisner, P. A. Vanniamparambil, et al., “Part qualification methodology for composite aircraft components using acoustic emission monitoring,” Appl Sci, 8, 1490 (2018). http://dx.doi.org/https://doi.org/10.3390/app8091490

J. M. Waller, C. T. Nichols, D. J. Wentzel, and R. L. Saulsberry, “Use of modal acoustic emission to monitor damage progression in carbon fiber/epoxy and implications for composite structures,” AIP Conf Proc, 1335, 919 (2011). https://doi.org/https://doi.org/10.1063/1.3592036

M. G. R. Sause and E. Jasiūnienė, Structural Health Monitoring Damage Detection Systems for Aerospace, Springer Cham (2021).

DSTU 2374-94. Strength Calculations and Testing of Technical Products. Acoustic Emission. Terms and Definitions [in Ukrainian], Valid since January 1, 1995.

R. Khamedi, S. Abdi, A. Ghorbani, et al., “Damage characterization of carbon/epoxy composites using acoustic emission signals wavelet analysis,” Compos Interface, 27, No. 1, 111–124 (2019), https://doi.org/https://doi.org/10.1080/09276440.2019.1601939

V. Arumugam, C. Suresh Kumar, C. Santulli, et al., “A global method for the identification of failure modes in fiberglass using acoustic emission,” J Test Eval, 39, No. 5 (2011). https://doi.org/10.1520/JTE103730

VALLEN AE SUITE SOFTWARE: https://www.vallen.de/products/software/

AEWIN™ – REAL-TIME DATA ACQUISITION AND REPLAY SOFTWARE: https://www.physicalacoustics.com/ content/literature/software/AEwin_Software_Bulletin.pdf

NOESIS – What’s New (for versions 4.1–14.0): https://www.physicalacoustics.com/content/literature/multichannel_systems/Noesis_Whats_New_4.1-14.0.pdf

USB DAQ USB-1210: https://www.adlinktech.com/Products/Data_Acquisition/USBDAQ/USB-1210?lang=en

G. A. Gogotsi and A. V. Drozdov, “Acoustic emission in the deformation and failure of corundum refractories,” Ogneupory, No. 4, 15–19 (1986).

A. V. Drozdov, “Investigation on the microcracking of ceramic materials using the acoustic emission method,” Strength Mater, 46, No. 1, 71–79 (2014), https://doi.org/https://doi.org/10.1007/s11223-014-9517-y

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Problemy Mitsnosti, No. 3, pp. 76 – 86, May – June, 2023

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Drozdov, O.V., Volkov, Y.M. Compact System for Monitoring Acoustic Emission Parameters in Mechanical Testing of Materials. Strength Mater 55, 516–524 (2023). https://doi.org/10.1007/s11223-023-00544-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11223-023-00544-1