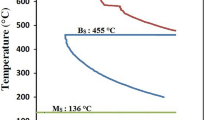

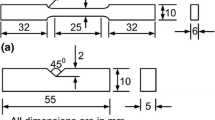

In the present study, the fracture toughness of hardened and tempered powder metallurgical (PM) high-speed steel ASP 2030 was investigated using notched and unnotched bending specimens and the finite element method. The normal flexural strength of notched and unnotched specimens marquenched by austenitizing at 1150, 1170, and 1185°C, followed by quenching to room temperature is measured after triple tempering at 560°C for 2 h. The finite element method (FEM) analysis is performed to observe the true stress distribution and calculate the critical fracture stress in the specimens under the experimental conditions of the bending test. The microstructural features of the specimens were investigated by X-ray diffraction (XRD) and a field emission scanning electron microscope (FESEM) with an electron backscatter detector (EBSD). No retained austenite was detected in the tempered specimens, and according to the results of the EBSD analysis and XRD tests, the microstructure of the matrix consists of martensitic ferrite laths. It can be observed that with the increase of austenitizing temperature from 1150 to 11850C, the normal flexural strength of the specimens decreases. The decrease in flexural strength of the specimens is due to the increase in the prior austenite grain size and consequently the martensitic ferrite laths after tempering. In addition, as the austenitizing temperature increases, the volume fraction of the undissolved carbides decreases, which causes the size of the undissolved carbides to increase and the flexural strength to decrease. According to FEM, the critical crack length calculated from the critical fracture stress is approximately equal to the average diameter of undissolved carbides.

Similar content being viewed by others

References

A. M. Bayer, B. A. Becherer, and T. Vasco, High-Speed Tool Steels, ASM Handbook, Vol. 16, ASM International (1989), pp. 51–59.

F. Velasco, R. Isabel, N. Antón, et al., “TiCN – high speed steel composites: sinterability and properties,” Compos. Part A-Appl. S., 33, No. 6, 819–827 (2002).

L. R. Cornwell, Mechanical Properties of Brittle Materials, Department of Mechanical Engineering, Texas A&M University (1992), pp. 367–373.

G. Quinn, B. Sparenberg, P. Koshy, et al., “Flexural strength of ceramic and glass rods,” J. Test. Eval., 37, 222–244 (2009).

R. Morrell, Flexural Strength Testing of Ceramics and Hardmetals, Ser.: A National Measurement Good Practice Guide, No. 7, National Physical Laboratory (2007).

Y. Torres, S. Rodrı́guez, A. Mateo, et al., “Fatigue behavior of powder metallurgy high-speed steels: fatigue limit prediction using a crack growth threshold-based approach,” Mater. Sci. Eng. A, 387–389, 501–504 (2004).

S. Wu, H. Jin, Y. Sun, and L. Cao, “Critical cleavage fracture stress characterization of A508 nuclear pressure vessel steels,” Int. J. Pres. Ves. Pip., 123–124, 92–98 (2014).

H. Peng, L. Hu, X. Zhang, et al., “Microstructural evolution, behavior of precipitates, and mechanical properties of powder metallurgical high-speed steel S390 during tempering,” Metall. Trans., 50, 51–59 (2018).

H. Wang, D. Hong, L. Hou, et al.,, “Influence of tempering temperatures on the microstructure, secondary carbides and mechanical properties of spray-deposited AISI M3:2 high-speed steel,” Chem. Phys., 255, 123554 (2020).

O. Filho, J. Liberati, W. Monteiro, et al., “Transverse rupture strength of M3:2 high speed steel produced through conventional casting and powder metallurgy techniques,” Mater. Sci. Forum, 514–516, 584–588 (2006).

D. J. Alexander, J. J. Lewandowski, W. J. Sisak, and A. W. Thompson, “Yielding and work hardening effects in notched bend bars,” J. Mech. Phys. Solids, 34, 433–454 (1986).

L.W. Crane and A. P. Bigg, “Fracture toughness of high speed steels,” Mater. Sci. Tech., 6, No. 10, 993–998 (1990).

B. Liu, T. Qin, W. Xu, et al., “Effect of tempering conditions on secondary hardening of carbides and retained austenite in spray-formed M42 high-speed steel”, Materials (Basel), 12, 3714 (2019).

B. Shakerifard, J. Galan Lopez, and L. A. I. Kestens, “A new electron backscatter diffraction-based method to study the role of crystallographic orientation in ductile damage initiation,” Metals, 10, No. 1, 113 (2020).

A. Iqbal and J. E. King, “The role of primary carbides in fatigue crack propagation in aeroengine bearing steels,” Int. J. Fatigue, 12, No. 4, 234–244 (1990).

P. W. Shelton and A. S. Wronski, “Cracking in M2 high speed steel,” Met. Sci., 17, No. 11, 533–540 (1983).

Y. Luo, H. Guo, X. Sun, et al., “Effects of austenitizing conditions on the microstructure of AISI M42 high-speed steel,” Metals, 7, No. 1, 27 (2017).

D. Shi, J. H. Liu, and Y. Q. Cheng, “Cleavage fracture in high carbon bainite,” Mater. Sci. Eng. A, 158, 11– 19 (1992).

T.Simm, L. Sun, S. McAdam, et al., “The influence of lath, block and prior austenite grain (PAG) size on the tensile, creep and fatigue properties of novel maraging steel,” Materials (Basel), 10, No. 7, 730 (2017).

G. Will,Powder Diffraction: The Rietveld Method and the Two Stage Method to Determine and Refine Crystal Structures from Powder Diffraction Data, Springer, Berlin–Heidelberg (2006).

W. Bochnowski, H. Leitner, L. Major, et al., “Primary and secondary carbides in high-speed steels after conventional heat treatment and laser modification,” Mater. Chem. Phys., 81, Nos. 2–3, 503–506 (2003).

P. I. Patil and R. Tated, “Comparison of effects of cryogenic treatment on different types of steels. A review,” in: IJCA Proceedings on International Conference in Computational Intelligence (2012), pp. 10–29.

D. A. Curry, “Cleavage micromechanisms of crack extension in steels,” Met. Sci., 14, Nos. 8–9, 319–326 (1980).

K.-H. Lee, S.-G. Park, M.-C. Kim, and B.-S. Lee, “Cleavage fracture toughness of tempered martensitic Ni–Cr–Mo low alloy steel with different martensite fraction,” Mater. Sci. Eng. A, 534, 75–82 (2012).

T. Gladman, “Precipitation hardening in metals,” Mater. Sci. Tech., 15, No. 1, 30–36 (1999).

Q. Wang, Z. Li, S. Pang, et al., “Coherent precipitation and strengthening in compositionally complex alloys: a review,” Entropy, 20, No. 11, 878 (2018).

Z. Li, F. Chai, L. Yang, et al., “Mechanical properties and nanoparticles precipitation behavior of multi-component ultra high strength steel,” Mater. Design, 191, 108637 (2020).

A. Pastor, P. Valles, P. Pérez, and S. F. Medina, “Measurement of martensitic packet size by EBSD in the high strength steel X38CrMoV5-1 and estimation of its influence on cleavage fracture,” Kovove Mater., 58, 267–274 (2020).

A. Carpinteri, C. Scavia, and G. P. Yang, “Microcrack propagation, coalescence and size effects in compression,” Eng. Fract. Mech., 54, No. 3, 335–347 (1996).

Acknowledgments

The authors are grateful to the Sahand University of Technology for providing the research facilities. Special thanks to Dr. Hossein Salimi for his help with the simulation, which was essential to the research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Problemy Mitsnosti, No. 6, p. 109, November – December, 2022.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Firouzi, A., Yazdani, S., Tavangar, R. et al. Fracture Toughness Evaluation of Powder Metallurgical ASP2030 High-Speed Steels Using Flexural Specimens and Finite Element Method. Strength Mater 54, 1064–1081 (2022). https://doi.org/10.1007/s11223-023-00482-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11223-023-00482-y