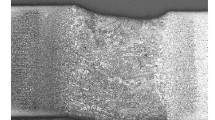

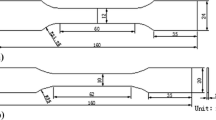

Microstructural changes and microhardness profiles of laser-welded dual-phase DP600 and bake-hardened 220BH steels were evaluated. The joints of these steels were butted with different welding parameters. They exhibited the microstructural changes, from ferrite and martensite in dual-phase steels or ferrite in bake-hardened steels to acicular ferrite, bainite and martensite in the fusion and heat-affected zones of the weld joints. As a result of welding, microhardness increases significantly in the fusion zones and even more in the heat-affected zones near DP600 steel.

Similar content being viewed by others

References

H. Gong, S. Wang, P. Knysh, and Y. P. Korkolis, “Experimental investigation of the mechanical response of laser welded dissimilar blanks from advanced- and ultra-high-strength steels,” Mater. Des., 90, 1115–1123 (2016).

D. C. Saha, D. Westerbaan, S. S. Nayak, et al., “Microstructure-properties correlation in fiber laser welding of dual-phase and HSLA steels,” Mater. Sci. Eng. A, 607, 445–453 (2014).

N. Farabi, D. L. Chen, and Y. Zhou, “Microstructure and mechanical properties of laser welded dissimilar DP600/DP980 dual-phase steel joints,” J. Alloys Compd., 509, 982–989 (2011).

Y. X. Chen, C. D. Yang, X. J. Wang, and H. B. Chen, “Evaluation of metal-active gas double-sided double-power arc welded joints of high-strength low-alloy steel,” Strength Mater., 47, No. 1, 164–169 (2015).

J. Meško, A. Zrak, K. Mulczyk, and S. Tofil, “Microstructure analysis of welded joints after laser welding,” Manuf. Technol., 14, No. 3, 355–359 (2014).

S. Krajewski and J. Nowacki, “Dual-phase steels microstructure and properties consideration based on artificial intelligence techniques,” Arch. Civil Mech. Eng., 14, No. 2, 278–286 (2014).

M. S. Weglowski, K. Kwiecinski, K. Krasnowski, and R. Jachym, “Characteristics of Nd:YAG laser welded joints of dual phase steels,” Arch. Civil Mech. Eng., 9, No. 4, 85–97 (2009).

N. Farabi, D. L. Chen, J. Li, et al., “Microstructure and mechanical properties of laser welded DP600 steel joints,” Mater. Sci. Eng. A, 527, 1215–1222 (2010).

J. Vinas and M. Abel, “Analysis of laser welds on automotive steel sheets,” Mater. Sci. Forum, 818, 239–242 (2015).

M. Merklein, M. Johannes, M. Lechner, and A. Kuppert, “A review on tailored blanks – Production, applications and evaluation,” J. Mater. Process. Technol., 214, No. 2, 151–164 (2014).

HanSur Bang, HeeSeon Bang, M. J. Na, et al., “Application of Taguchi approach to optimize laser-arc hybrid welding parameters of galvanized steel,” Strength Mater., 48, No. 1, 146–151 (2016).

Acknowledgments

This study was supported by the Slovak Research and Development Agency under contract No. APVV-0281-12.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Problemy Prochnosti, No. 4, pp. 14 – 20, July – August, 2016.

Rights and permissions

About this article

Cite this article

Švec, P., Schrek, A. & Csicsó, T. Fiber Laser Welding of Dual-Phase and Bake-Hardened Steels. Strength Mater 48, 481–486 (2016). https://doi.org/10.1007/s11223-016-9789-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11223-016-9789-5