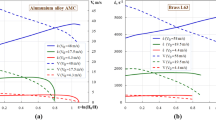

Tensile tests of titanium alloy and austenitic steel specimens have been conducted in the range of temperatures 300–4 K. Under deep-freezing conditions, there occurs a new type of scale effect – variation of low-temperature jumplike deformation, which causes a sharp variation of the plasticity characteristic (the relative elongation). The difference between jumplike deformation values in the maximum and minimum cross-sectional areas of standard cylindrical specimens is introduced as the scale effect measure. Via mathematical modeling performed for 03Kh20N16AG6 steel, we have obtained dependencies of the scale effect on the most critical factors – the trigger stress of deformation jump and specimen–test machine system stiffness. The scale effect nature is studied, and options of its minimization, in reference to the standardization of mechanical tests, are discussed.

Similar content being viewed by others

References

V. A. Strizhalo, V. Yu. Bugaev, and I. I. Medved’, “Effect of the scale factor on special features of deformation of structural alloys in static loading at low temperatures (4.2 K),” Strength Mater., 22, No. 5, 698–704 (1990).

E. V. Vorob’ev, “Peculiarities of neck formation under low-temperature discontinuous yield of metals. Part 2. Plane strain,” Strength Mater., 40, No. 4, 439–444 (2008).

P. Hähner and E. Rizzi, “On the kinematics of Portevin–Le Chatelier bands: theoretical and numerical modelling,” Acta Mater., 51, No. 12, 3385–3397 (2003).

B. Skoczeń, J. Bielski, S. Sgobba, and D. Marcinek, “Constitutive model of discontinuous plastic flow at cryogenic temperatures,” Int. J. Plasticity, 26, No. 12, 1659–1679 (2010).

B. Skoczeń, J. Bielski, and J. Tabin, “Multiaxial constitutive model of discontinuous plastic flow at cryogenic temperatures,” Int. J. Plasticity, 55, 198–218 (2014).

A. K. Emaletdinov, “Self-oscillating modes of plastic deformation of metals at helium temperatures,” Fiz. Metal. Metalloved., 91, No. 4, 3–9 (2001).

V. V. Pustovalov, “Jumplike deformation of metals and alloys at low temperatures (review),” Fiz. Nizk. Temper., 34, No. 9, 871–913 (2008).

A. Seeger, Dislocation and Mechanical Properties of Crystals, Wiley, New York (1957).

E. T. Wessel, “Some exploratory observation of the tensile properties of metals at very low temperatures,” Trans. ASME, 49, No. 1, 149–172 (1957).

Z. S. Basinski, “The instability of plastic flow of metalls at very low temperatures,” Proc. Royal Soc., A240, 229–242 (1957).

R. P. Walsh, “Tension–compression testing at low temperatures,” in: ASM Handbook. Vol. 8: H. Kuhn and D. Medlin (Eds.), Mechanical Testing and Evaluation (2000), pp. 164–171.

E. V. Vorob’ev and T. V. Anpilogova, “Modeling of the process of low-temperature jumplike deformation of metals,” Strength Mater., 43, No.1, 77–86 (2011).

E. V. Vorob’ev and T. V. Anpilogova, “Numerical analysis of the deformation instability of metals in liquid helium,” Comp. Mat. Sci., 68, 66–72 (2013).

GOST 22706-77. Metals. Tensile Test Method at Temperatures from −100 to −269°C [in Russian], Izd. Standartov, Moscow, Valid since January 1, 1979.

ISO 19819:2004 (E). Metallic Materials – Tensile Testing in Liquid Helium (2004).

V. A. Strizhalo and E. V. Vorob’ev, “Simulation of low-temperature discontinuous yield by the method of additional pulse loading,” Strength Mater., 29, No. 3, 269–274 (1997).

DSTU 7305:2013. Metals. Tensile Test Method at Low and Criogenic Temperatures [in Ukrainian], Valid since January 1, 2014.

Author information

Authors and Affiliations

Additional information

Translated from Problemy Prochnosti, No. 6, pp. 56 – 65, November – December, 2014.

Rights and permissions

About this article

Cite this article

Vorob’ev, E.V., Anpilogova, T.V. Jumplike Deformation as the Scale Effect Measure for the Metal Deformed Volume Under Deep-Freezing Conditions: Experiment and Modeling. Strength Mater 46, 765–772 (2014). https://doi.org/10.1007/s11223-014-9609-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11223-014-9609-8