Abstract

Just as geological samples from Earth record the natural history of our planet, astromaterials hold the natural history of our solar system and beyond. Astromaterials acquisition and curation practices have direct consequences on the contamination levels of astromaterials and hence the types of questions that can be answered about our solar system and the degree of precision that can be expected of those answers. Advanced curation was developed as a cross-disciplinary field to improve curation and acquisition practices in existing astromaterials collections and for future sample return activities, including meteorite and cosmic dust samples that are collected on Earth. These goals are accomplished through research and development of new innovative technologies and techniques for sample collection, handling, characterization, analysis, and curation of astromaterials. In this contribution, we discuss five broad topics in advanced curation that are critical to improving sample acquisition and curation practices, including (1) best practices for monitoring and testing of curation infrastructure for inorganic, organic, and biological contamination; (2) requirements for storage, processing, and sample handling capabilities for future sample return missions, along with recent progress in these areas; (3) advancements and improvements in astromaterials acquisition capabilities on Earth (i.e., the collection of meteorites and cosmic dust); (4) the importance of contamination knowledge strategies for maximizing the science returns of sample-return missions; and (5) best practices and emerging capabilities for the basic characterization and preliminary examination of astromaterials. The primary result of advanced curation research is to both reduce and quantify contamination of astromaterials and preserve the scientific integrity of all samples from mission inception to secure delivery of samples to Earth-based laboratories for in-depth scientific analysis. Advanced curation serves as an important science-enabling activity, and the collective lessons learned from previous spacecraft missions and the results of advanced curation research will work in tandem to feed forward into better spacecraft designs and enable more stringent requirements for future sample return missions and Earth-based sample acquisition.

Similar content being viewed by others

1 Introduction

Human fascination with the night sky and with celestial objects that fall to the Earth from the sky is as old as our species, and use of these astromaterials as a natural resource occurred at least as early as the Bronze Age (Jambon 2017; McCoy 2018; McCoy et al. 2017). However, the initial curation of astromaterials as objects of scientific interest to understand our universe began more recently (Marvin 2006) and in earnest with the curation of meteorite samples in museums starting in the year 1748 at the Natural History Museum Vienna (Brandstätter 2006). Meteorites have remained objects of fascination by scientists and the public alike with the establishment of many meteorite collections across the world. Meteorite recovery and curation practices vary widely and are highly dependent on many factors, including the knowledge and resources of the finder and the financial and technical support available for the collection in which the sample is curated. The scientific importance of the sample can also be a determining factor, but this is predicated on the aforementioned factors. All meteorites, regardless of how they were handled from recovery to curation, have experienced uncontrolled entry and exposure to the terrestrial environment, including, at minimum, the terrestrial atmosphere and the ground. This exposure results in terrestrial contamination, the amount of which is typically dependent on the physicochemical properties of the meteorite, the conditions at the fall site, and the amount of exposure time to the terrestrial environment. Consideration of these factors can also be determining factors in how a meteorite sample is curated. An overview of meteorite collections, their contents, and curation practices is available in McCall et al. (2006).

Until the 1960’s, delivery of all astromaterials to Earth were unplanned events that required reactionary responses for recovery and curation. However, with the initiation of the Apollo program, direct return of pristine astromaterials from another body became possible, and with it, established the need to design a facility to keep those samples in a pristine state for an indefinite period of time. Planning for the Lunar Receiving Laboratory (LRL) began in 1964, and the facility was completed in 1967 (Calaway et al. 2017; McLane et al. 1967). As part of this planning, stringent protocols in the handling, storage, and processing of samples were developed. These protocols ensured that portions of the samples remained pristine or as close to an “as returned” state as possible in perpetuity to enable future scientific discoveries from the returned samples. The delivery of Apollo 11 samples to Earth occurred on July 24, 1969 at 12:50 EDT, four days after the first successful human landing on the Moon. This round-trip journey marked a transformative milestone in human history and as the first sample return mission, provided the initial fuel to drive the burgeoning field of planetary sample science.

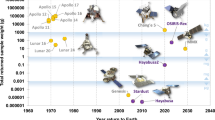

The planning process for curation prior to the return of the Apollo 11 samples set the precedent that curation involvement and planning begins at the inception of a sample return mission, and this founding principle has guided sample return missions subsequent to Apollo (e.g., Allen et al. 2011; Yada et al. 2014). There have been a total of 13 successful sample return missions, including six manned Apollo missions from NASA, three unmanned lunar sample return missions from the Union of Soviet Socialist Republics (USSR), the NASA Long Duration Exposure Facility that exposed various materials to the low-Earth orbit environment for approximately 6 years, the NASA Genesis mission that returned solar wind from the Earth-Sun Lagrange point 1 (L1), the NASA Stardust mission that returned particles embedded in aerogel from the coma of Comet Wild 2 and from interstellar space, and JAXA’s Hayabusa mission that returned material from the surface of asteroid Itokawa (Table 1). In addition, there are two sample return missions in flight, including JAXA’s Hayabusa2 mission that will return samples from the asteroid Ryugu and NASA’s OSIRIS-REx mission that will return material from the asteroid Bennu (Table 1). Further details about each of these missions are provided in Table 1. With each successive sample return mission comes with it an important set of lessons learned that are used to inform subsequent sample return missions, and these lessons learned extend to curation standards and practices.

The Apollo program offered the first set of lessons learned and set forth the modern era of curation practices for astromaterials from the solar system. With the exception of USSR Luna missions, all sample return missions in the last two decades have built upon the legacy of Apollo. While recent missions have contributed to lessons learned, the majority of lessons learned and established practices can be linked to Apollo. The Apollo program actively sought out a wide range of scientists and eventually levied the scientific community at large to influence mission conception and design. Mission decisions and laboratory research on returned samples, at least peripherally, were focused substantially in maximizing science obtained from samples in laboratory research. The majority of these sample scientists were found in the field of geological sciences. The management environment was an integration of human spaceflight mission objectives, engineering constraints, sample scientists, and those responsible to prevent back contamination of the Earth. In this management structure, conflicts routinely arose and were not only turf battles, but were rooted in basic technical conflicts to balance crew safety, lunar sample preservation, and potential hazard containment for unknown biological pathogens. Since Apollo was a series of missions, it was possible to improve sampling hardware and laboratory handling devices using experience and samples from the lunar surface. For example, regolith drive tube function was greatly improved through redesign for Apollo missions 15–17 to allow deep penetration with minimal distortion of stratigraphy. Knowledge gained from examination of the first samples (Apollo missions 11–14) allowed the switch from a high-vacuum gloved handling environment to pure gaseous nitrogen positive pressure gloveboxes, which better preserved sample cleanliness and ease of use. A mission series like Apollo allows fine tuning of sample collection and returned sample handling as knowledge is acquired. Building upon Apollo and later sample return missions, a series of lessons learned and best practices for future sample return missions were developed and listed as follows:

World-class scientific expertise: Integration of planetary sample scientists as advisors on science issues through formal organizations such as the historical Lunar Sample Analysis Planning Team (LSAPT) and Lunar and Planetary Science Team (LAPST) and as well as today’s Curation and Analysis Planning Team for Extraterrestrial Materials (CAPTEM). CAPTEM currently presents findings to NASA on sample allocations ensuring best science and fair access to samples, current curation facilities, and inspection of laboratory operations, capabilities, capacity needs, and staffing. CAPTEM also provides findings for publicizing sample characterization information and service to the community. In addition, CAPTEM provides NASA with findings on design review of sample receiving and curation facilities as well as material restrictions/suggestions to preserve science value of samples.

The integration of planetary science and geology training for astronauts, mission managers, and engineers involved in sample return missions.

The integration of sample scientists into landing site selection, traverse planning, and sample acquisition.

The integration of sample scientists into mission control operations and advisors during missions.

The integration of Earth receiving and curation operations personnel into mission conception and engineering spacecraft design is critical for any sample return mission.

Selection of materials that have low to zero particulate shedding mechanical properties for spacecraft, primary sample containment, handling, and storage equipment to preserve sample integrity.

Selection of materials that have low to zero outgassing mechanical properties for spacecraft, primary sample containment, handling, and storage equipment to preserve sample integrity.

Selection of a diversity of materials for primary sample containment, handling, and storage equipment to enable scientific investigations of the entire periodic table, organic compounds, and biological matter.

Sample return missions should establish a concept of sample segregation for primary mission goals (e.g., segregation of samples in different containment/isolation used for inorganic, organic, and biological investigations as well as focused goals of the mission). Sample acquisition and containment must always focus on prohibiting cross-contamination and preservation of the scientific integrity of each sample.

The integration of curation, proper material selection, and cleaning into mission contamination control requirements and implementation during Assembly, Test, and Launch Operations (ATLO) is critical for sample return.

Use of inert and/or vacuum environments or environments close to native collection environments for processing and storage of astromaterials. Develop standard practices to mitigate contamination from terrestrial atmosphere, pressures, and temperatures.

Use of environmental monitoring methods, cleanroom technology, and biological safety isolation to maintain desired processing and storage environments.

Lessons learned not only inform our best practices, but they also help to identify strategic knowledge gaps that require new research to fill. Furthermore, if we look only at improving upon our current curation capabilities, we will not be prepared when returned samples require care that is very different from those within our current collections. At present, most returned samples are geological in nature, with the exception of the Genesis solar wind atoms that are implanted within a number of high purity material substrates. Most of the samples are kept close to room temperature and, when kept in the pristine environments of a clean laboratory, will maintain their fidelity indefinitely. However, future sample return missions could bring back samples that require storage and handling conditions outside of current capabilities, including gases, liquids, ices, or biological materials. To successfully curate these sensitive materials also requires new research, and we describe here a field of research that we refer to as advanced curation.

Advanced Curation is a cross-disciplinary field that seeks to improve curation practices in existing astromaterials collections, including meteorite and cosmic dust samples that are collected on Earth. Specifically, advanced curation has two primary goals that include (1) expansion of the sample processing and storage capabilities of astromaterials facilities to prepare for future sample return missions and Earth-based collection of astromaterials and (2) to maximize the science returns of existing astromaterials sample collections. These goals are accomplished through research and development of new innovative technologies and techniques for sample collection, handling, characterization, analysis, and curation of astromaterials. In addition, advanced curation includes testing and evaluation of new technologies and operational procedures for future sample return missions through human and robotic analog studies. Here we outline best practices and procedures and highlight new results, capabilities, and ongoing activities in the field of advanced curation of astromaterials. In particular, we outline (1) the best practices for monitoring and testing of curation infrastructure for contamination, (2) the development of new storage, processing, and sample handling capabilities, (3) the development and improvement of new astromaterials acquisition capabilities on Earth (i.e., the collection of meteorites and cosmic dust), (4) the importance of contamination knowledge strategies for maximizing the science returns of sample-return missions, (5) best practices and emerging capabilities for the preliminary examination and initial characterization of astromaterials, and finally (6) a summary of the biggest challenges that lie ahead as we look toward future sample-return initiatives.

2 Monitoring and Testing of Curation Infrastructure

All sample return curation facilities are designed and built to meet specific controlled environment and cleanliness standards for the curated samples. Curation infrastructure is defined as all engineering systems that control the sample’s storage and processing environment. This definition incorporates brick and mortar, temporary, modular, and mobile facilities. In addition, specialized equipment is included such as isolation chambers, gloveboxes, and desiccators that have the ability to alter the atmospheric chemistry, temperature, and pressure of the environment. During the Apollo program, curation infrastructure borrowed many innovative technologies from handling radioactive materials and biological quarantine practices. Today, curation infrastructure is derived from many industries including the nuclear, biotechnology, pharmaceutical, and semiconductor industries (USP 2013; Whyte 2001; Ramstorp 2000). Methods and techniques are either borrowed, augmented, or invented to maintain the controlled environment to mitigate terrestrial cross-contamination. Contamination covers any element that could compromise sample integrity. To quote the definition of pristine from Dworkin et al. (2018), it means that “no foreign material is introduced to the sample in an amount that hampers the ability to analyze the chemistry and mineralogy of the sample”. While sample return missions designate contamination limits on specific elements and compounds at time of launch with focused science goals, samples are effectively allocated over time to study everything on the periodic table. Therefore, the implementation of curation infrastructure should be mindful that everything could be a contaminant to some research group. Modern cleanroom facilities have substantial infrastructure footprints that require continual monitoring to ensure they operate within the defined strict contamination control guidelines. This requires continuous monitoring and testing of the labs to verify that the sample processing environments remain clean from the standpoint of inorganic, organic, and biological contamination. As it is unrealistic to eliminate all contamination, careful monitoring and contamination knowledge must be conducted. To this end, curation laboratories that house astromaterials have developed numerous protocols and methods to monitor curation facilities and we outline those practices below.

2.1 Real-Time Continuous Monitoring and Testing of Curation Cleanroom Laboratories

Cleanrooms are a specialized controlled environment that must be continually monitored to verify whether they are working to defined parameters and specifications. The international standards organization (ISO) have developed fundamental standards for cleanrooms, namely ISO 14644. Curation cleanroom laboratories follow this standard as well as many adopted recommend practices from several industries (e.g., IEST, SEMI, GSA, etc.). For curation facilities, cleanroom measurements are regularly made to ensure that the heating ventilation, and air conditioning (HVAC) system is creating the appropriate cascade of positive or negative pressure and that Fan Filter Units (FFU), in conjunction with the HVAC system, are delivering the proper level of airborne particles to accepted limits for the planned ISO class. Temperature and humidity are also kept within pre-specified limits within the intended operational parameters of the HVAC system.

Ideally, real-time remote monitoring can track airborne particulates, room-to-room differential pressures, temperature, humidity, and HVAC operations. Remote airborne particle counters have either internal or external pumps with a flow rate of 0.1 CFM (2.83 LPM) or 1.0 CFM (28.3 LPM) dependent on ISO Class and desired statistics. Many of them can output up to 6 channels of simultaneous data within the range of 0.3–25.0 μm. For ISO Class 4 and below, a dedicated 0.1 μm particle counter is desired to improve particle count statistics. While real-time remote monitoring is ideal, hand-held manual particle counters are sometimes used for spot checking spaces and annual ISO Class audits. For ISO Class 5 and above, these handheld particle counting instruments are typically set-up for a 2 minute measurement with a total sampling volume of 5.68 L and particle channels set at 0.3, 0.5, 0.7, 1.0, 5.0, and 10.0 μm. In lieu of real-time continuous remote monitoring, weekly particle counts of all curation labs are desirable of key areas with a full ISO audits conducted annually or bi-annually.

Curation cleanroom laboratories primarily use a positive pressure differential barrier to reduce contamination. A pressure differential barrier is based on the concept of using positive pressure air flow cascade to create a cleaner zone towards a less clean zone as a first line of defense to prevent cross-contamination between two adjacent spaces. The pressure differential should be of significant magnitude and stability to prevent any reversal of air flow between barriers including when barrier thresholds are crossed and/or doors are opened. However, the pressure differential should not be too high as to create turbulent air flow that could compromise the clean zone. In addition, too high of pressure between zones can also prevent doors from opening. For example, at 0.10 inH2O (inches of water), a \(3 \times 7\) ft. door requires 11 lbs. of force to open and close. Furthermore, this pressure results in unwanted turbulent air flow. ISO 14644-4, the design, construction, and start-up of cleanrooms and associated controlled environment, contains the international standard for cleanroom air-flow monitoring. ISO 14644-4 Section A.5.3 states that the pressure between clean zones should be set at: \(\Delta P = 0.02\) to 0.08 inH2O (5 to 20 Pa).

The cleanroom technology literature generally recommends a pressure differential of 0.04 inH2O (10 Pa) between two cleanrooms and a pressure differential of 0.06 inH2O (15 Pa) between the cleanroom and an unclassified room (Sakraida 2008; Whyte 2001). Whyte (2010) discusses the reason for ISO 14644-4 acceptable minimum of 0.02 inH2O (5 Pa) pressure between adjacent rooms. This acceptable minimum was established for processing facilities that handle products that can be adversely affected from greater pressures. These low pressure differentials can sometimes be found in long tunnels between processing cleanrooms that contain air flow sensitive products. Whyte (2010) further discusses if 0.02 inH2O (5 Pa) must be used; confirmation of the air flow direction must be verifiable with routine observable smoke flow tests (assuming such tests would not be a source of contamination). Sakraida (2008) discusses recent experimental studies that have tested the optimal pressure differential between clean zones. Pressure differentials between 0.03 to 0.05 inH2O were determined to be optimal for mitigating cross-contamination. The study further suggested that clean zones with pressures above 0.05 inH2O showed little increased benefit to mitigate contamination compared to increased energy costs of operating the air handling unit.

Based on ISO 14644-4 standards and available cleanroom technology literature, astromaterials curation laboratories should ideally maintain ≥ 0.05 inH2O between interior “dirty” hallways to laboratory anterooms and a minimum of 0.03 to 0.05 inH2O in most adjacent rooms between anteroom and main laboratory. For primary astromaterials storage areas and processing laboratories, ideally 0.05 to 0.08 inH2O should be maintained to mitigate the long-term infiltration of contaminates. However, it is important to note that higher pressures may be desired to create a buffer to mitigate the risk of dropping below 0.05 inH2O based on air flow stability from the HVAC and laboratory layout.

Real-time continuous remote monitoring is common for modern cleanrooms with a desired differential pressure accuracy of about \(\pm 0.001\) inH2O or better. For older cleanroom laboratories, manual magnehelic differential pressure gauges are sometimes still used for monitoring differential pressures. In addition, annual or biannual differential pressure audits are conducted between each room doorway threshold with a handheld manometer and data placed on a building map to verify proper cascade of pressures.

HVAC ON/OFF and velocity (\(\mbox{m}/\mbox{s}\)) are continually monitored in real-time. The data displayed are also used to check air changes per hour towards the as-built of the cleanroom and ISO standards. The FFUs are biannually or annually checked to be running at \(90 \pm 10\) fpm. While FFUs are typically not monitored in real-time, this is an important routine check to assess failing blower motors and the efficiency of the ULPA or HEPA filters to determine when they need to be replaced.

Electrostatic charging and discharging in curation laboratories has the potential to cause damage to samples and equipment. In addition, electrostatic discharges are a serious safety hazard to laboratory personnel. Most curation cleanrooms maintain a temperature between 24 to \(15\ ^{\circ}\mbox{C} \pm 1.0\ ^{\circ}\mbox{C}\) and relative humidity (RH%) of <65% to \({>}35\% \pm 1.0\%\) RH. These ranges are based on ISO 14644-4 and ISO 14644-5 standards and are only for laboratory environments and do not reflect the environment of containment, such as in gloveboxes where moisture (H2O) is commonly measured below 1 ppm.

A deviation in any of these parameters or over a certain threshold (per curation protocol specific to the collection) triggers an investigation to understand the source of the problem and mitigate any faults. In case the issue cannot be resolved in a timely manner, samples are securely placed into storage and work stops in the lab, especially for samples processed outside of gloveboxes.

2.2 Real-Time Continuous Monitoring of Curation Infrastructure Systems

2.2.1 Inert Environments

Most pristine astromaterials benefit from not being stored and processed in terrestrial atmosphere. Since Earth’s atmosphere is an oxidizing environment, preservation of astromaterials are preferred to be placed in an indigenous, vacuum, or inert environment. Most astromaterials on Earth are stored and processed in an inert gas such as nitrogen, argon, or helium, with the exception of JAXA’s vacuum receiving glovebox used for the Hayabusa mission. Of these three inert gases, nitrogen is the most cost effective and is often chosen over argon and helium for routine storage. However, nitrogen analysis of astromaterials samples are compromised by processing in nitrogen, so nitrogen is not used exclusively.

At NASA Johnson Space Center (JSC), building 31 and 31N has a dedicated 15000 gallon liquid nitrogen (LN2) tank and tank farm that converts high purity LN2 to gaseous nitrogen (GN2) for the entire building infrastructure. This nitrogen gas system provides an inert environment for processing and storing all NASA extraterrestrial sample collections where gloveboxes and desiccators consume ∼3500 scfh of GN2. After gas production, the GN2 is filtered for particulates by the use of sintered 316 stainless steel filters (1 micron filtration at the tank farm and 3 nm point-of-use filters connected to all devices). In addition to 3 nm particulate filtration, the Genesis lab uses point of use Pall gas purifiers that reduces any H2O, CO2, O2, and CO in the GN2 to \(< 1\) ppb. The LN2 is a modified Grade C per MIL-PRF-27401G [LN2 purity 99.995%; H2O <10 ppm; Total Hydrocarbons as CH4 <1.0 ppm; \(\mbox{O}_{2} <10\) ppm; \(\mbox{H}_{2} <10\) ppm; Ar <20 ppm; CO2 <10 ppm; CO <10 ppm; and particulates \({<}1.0~\mbox{mg}/\mbox{L}\)]. LN2 is delivered to JSC weekly and the Curation Office periodically tests the purity of the liquid nitrogen beyond the NASA contract audits. For periodic sampling of the LN2, a cryogenic liquid sampler is connected directly to the LN2 tanker truck with the sampler hose. The LN2 sample is taken to an outside laboratory for analysis. The boil-off of this LN2 at the tank farm produces high purity gaseous nitrogen (GN2). JSC currently tests the purity of the delivered GN2 by conducting airborne molecular organic sampling and SEM triage of inorganic particulates captured in 3 nm sintered stainless steel filters. Adsorbent sample tubes are used for sample collection and sent outside to Balazs Nanoanalysis for TD-GC-MS analysis. GN2 results routinely show no infiltration particulates past the filters and organic compounds and all hydrocarbon loads are below the reporting limit of \(< 0.1~\mbox{ng}/\mbox{L}\) for >C7. The GN2 is also tested monthly for the nitrogen isotopic ratio in a Finnigan MAT 253 IR-MS to ensure that no fractionation occurs over time or within the line. K-bottles of GN2, Ar, and He are also supplied at high purity research grade when required for certain processing activities or experiments. For example, the Subzero Facility for Curation of Astromaterials at the University of Alberta (see Cold Curation section) uses high-purity (99.998%) Ar as a source, which is then further refined using a purification system to bring oxygen (O2) and moisture (H2O) levels to <0.1 ppmv (Herd et al. 2016).

2.2.2 High Purity Cleaning Agents

Cleaning curation sample handling tools, containers, and other equipment (such as gloveboxes, isolation chambers, and desiccators) is required for the curation of astromaterials. Precision cleaning is typically required where equipment is cleaned to a specified cleanliness and the cleanliness is measured and verified to a standard. These precision cleaning facilities are not a small foot-print and use substantial consumables and equipment for operations. During final precision cleaning, specialized equipment is needed to purify the aqueous cleaning solutions. Historically, Apollo used Freon 113 as the final cleaning agent. The Freon 113 recycled in-house by distillation to achieve the required high purity. Today, NASA JSC uses ultrapure water (UPW) as the final cleaning agent and requires substantial initial investment (>$3M USD) and monthly maintenance cost. For JSC, UPW is not only used for precision cleaning, but is also used to decontaminate Genesis solar wind materials contaminated by macro particles during the hard landing (see Genesis section).

The UPW purity is maintained and monitored in continuously flowing production lines. The JSC UPW plant produces 10 gallons/minute of UPW serving 5 laboratories throughout the building within a continuous flowing final loop connected to a 1000 gallon supply tank. Future upgrades to the system will increase the capacity to a 5000 gallon tank producing 15 gallons/minute serving 7 laboratories. Once UPW leaves the final flowing loop, within <5 seconds, CO2 and other compounds in the air quickly dissolve into the highly deionized water and resistivity is immediately lowered from ∼18.18 M\(\Omega \)-cm to <1.0 M\(\Omega \)-cm. Therefore, UPW cannot be stored or transported in containers for use and UPW must be used directly from the flowing final loop for the maximum cleaning effectiveness. The UPW system is outfitted with a continuous real-time monitoring of critical components of the system as well as final water quality. The system monitors flow rate, pressure, resistivity, conductivity, temperature, particulates, total organic carbon, and tank levels. The UPW system conforms to ASTM D 5127-13, Standard Guide for Ultra-Pure Water Used in the Electronics and Semiconductor Industries and produces E-1.1 or better quality of water with a resistivity of 18.18 M\(\Omega \)-cm and total organic carbon (TOC) between 1 to 3 ppb. The quality of the water is routinely tested at least once a year or more for the following: (1) Anions by IC ranging from \(> 0.05\) to 0.02 ppb (\(\upmu \mbox{g}/\mbox{L}\)) of Fluoride (F−), Chloride (Cl−), Nitrite (NO2−), Bromide (Br−), Nitrate (NO3−), Phosphate (\(\mbox{HPO}_{4} ^{2-}\)), and Sulfate (\(\mbox{SO}_{4} ^{2-}\)); (2) Monovalent & Divalent Cations by IC ranging from \(> 0.02\) to 0.01 ppb (\(\upmu \mbox{g}/\mbox{L}\)) of Lithium (Li+), Sodium (Na+), Ammonium (NH\(_{4} ^{+}\)), Potassium (K+), Magnesium (Mg2+), and Calcium (Ca2+); (3) 30 elements Ultra Low Level in UPW by ICP-MS ranging from \(> 10\) to 0.02 ppt (\(\mbox{ng}/\mbox{L}\)) of Aluminum (Al), Antimony (Sb), Arsenic (As), Barium (Ba), Bismuth (Bi), Boron (B), Cadmium (Cd), Calcium (Ca), Chromium (Cr), Cobalt (Co), Copper (Cu), Gallium (Ga), Germanium (Ge), Iron (Fe), Lead (Pb), Lithium (Li), Magnesium (Mg), Manganese (Mn), Mercury (Hg), Molybdenum (Mo), Nickel (Ni), Potassium (K), Silver (Ag), Sodium (Na), Strontium (Sr), Tin (Sn), Titanium (Ti), Tungsten (W), Vanadium (V), and Zinc (Zn); (4) Low-level Dissolved Silica at \(> 0.1\) ppb (\(\upmu \mbox{g}/\mbox{L}\)); (5) Bacteria-ASTM Method-F1094—87 48 Hr Incubation reported in \(>1\) Bacteria per 100 mL cfu.

2.2.3 Gloveboxes and Desiccators

The inert environments of gloveboxes and desiccators that house astromaterials in storage or during processing should also be monitored. These environments are typically monitored continuously in real-time for their pressure, temperature, and known contaminates. For Apollo lunar material stored and processed in inert GN2, as well as the Subzero Facility used for processing Tagish Lake and other pristine astromaterials (Herd et al. 2016), gloveboxes are continuously monitored for O2 and H2O at a resolution of ±1 ppm. For the lunar sample collection at JSC, these environments are required to be at 1 inH2O positive pressure, room temperature, <25 ppm of O2, and <50 ppm of H2O; but actual achievable can be <1.0 ppmv for H2O and <15 ppmv for O2 with the current system. It should be noted that the vast majority of H2O and O2 levels in gloveboxes do not originate from the GN2 supply lines, but from the isolator gaskets and gloves through molecular infiltration of terrestrial atmosphere even under 1.0 inH2O positive pressure.

2.3 Inorganic and Organic Testing of Curation Clean Labs

Since 1998, the NASA JSC Curation Office has contracted Air Liquide Balazs Nanoanalysis to analyze airborne molecular inorganic and organic contaminates in cleanrooms and laboratory suites (Calaway et al. 2014). Following sampling protocols developed for the semiconductor industry, vertical exposure of \(8''\) and \(6''\) diameter high purity silicon semiconductor wafers are exposed for 24-hours on a work surface or inside gloveboxes to better understand the airborne molecular contamination (AMC). The AMC data is also used to calculate the rate of deposition of surface molecular contamination (SMC). The inorganic and organic AMC for cleanroom monitoring is reported using ISO 14644-8 Classification of Air Cleanliness by Chemical Contamination (ACC) and the SMC for ISO 14644-10 Classification of Surface Cleanliness by Chemical Concentration.

For routine inorganic lab and glovebox monitoring, pre-cleaned \(8''\) silicon wafers are packaged in two separate polypropylene wafer carriers; one for sample exposure and one for control, which is not opened. After a 24 or 48 hour of vertical exposure, Vapor Phase Decomposition Inductively Coupled Plasma Mass Spectrometry (VPD ICP-MS) is conducted at Balazs laboratories in Freemont, CA. The VDP-ICP-MS analyses report 35 elements (Al, As, B, Ba, Be, Ca, Cd, Ce, Co, Cr, Cu, Fe, Ga, Ge, Hf, In, K, La, Li, Mg, Mn, Mo, Na, Ni, Pb, Sb, Sn, Sr, Ta, Ti, W, V, Y, Zn, and Zr) with reporting limits ranging from \(10^{8}\) to \(10^{10}~\mbox{atoms}/\mbox{cm}^{2}\).

For routine organic lab and glovebox monitoring, two sets of prebaked \(8''\) silicon wafers are sandwiched together and triple-wrapped in baked-out aluminum foil; two for sample exposure and two for control, which are not opened. After a 24 or 48 hour vertical exposure on an aluminum stand, Thermal Desorption Gas Chromatography Mass Spectroscopy (TD-GC-MS) is conducted at Balazs laboratories. The TD-GC-MS measures organic compounds from C6 to C28 with a reporting limit of \(0.1~\mbox{ng}/\mbox{cm} ^{2}\).

In addition to organic wafer exposure, which collect airborne molecular and particulate contaminants well, proprietary air absorbent tests are routinely conducted to better understand hydrocarbon and volatile organic compound (VOC) load in cleanroom air or glovebox gaseous nitrogen environments. This test is implemented with an adsorbent tube with a pump running at \(100~\mbox{mL}/\mbox{min}\), for 6 hours that is exposed to the cleanroom or glovebox. The adsorbent tube is analyzed using the same TD-GC-MS method as the organic wafer, but with a reporting limit of \(0.1~\mbox{ng}/\mbox{L}\).

Besides these traditional methods of monitoring, the JSC Curation Office also employs the use of optical microscopy and Scanning Electron Microscopy (SEM) as a basic method of direct analysis for inorganic and organic contaminates for the cleanroom laboratory and infrastructure. Cleanroom construction materials, surfaces, sample handling tools, containers, and unknown visible material are analyzed directly or with tape-pulls or polyester wipes. Optical microcopy and SEM typically are used as an initial screening before using other methods of analysis. The following methods have been used in the past at the NASA JSC Curation office, on an as-needed basis, on witness plates, test coupons, millipore filters, and other material samples: (1) Optical Stereomicroscopy/Microscopy for macro particulate/other contamination, (2) FEG-SEM/EDX for micro particulate identification, (3) FT-IR and Raman Spectroscopy for surface contamination, (4) XPS for complete surface/thin-films/oxidation, (5) LA-HR-ICP-MS for gross surface inorganics, (6) VPD-HR-ICP-MS for molecular airborne inorganics, (7) TD-GC-MS with GL Sciences SWA-256 wafer analyzer for molecular airborne organics/outgassing, (8) DART-qTOF-MS for gross surface organics, (9) LC-MS for amino acids, and (10) AFM (Atomic Force Microcopy) for surface roughness/thin-films/cleaning changes. Although not continuously monitored, the Subzero Facility for the Curation of Astromaterials used solid phase microextraction (SPME) fiber GC-MS methods to characterize the glovebox atmosphere during commissioning (Herd et al. 2016); this method shows potential for use in continuous monitoring, although its use requires the assessment and selection of appropriate SPME fibers for the airborne organic compounds of interest.

2.4 Biological Testing of Curation Cleanlabs

Biological testing of clean labs is important in many commercial and academic settings, and biological testing in aerospace and medical settings, like spacecraft assembly facilities, hospital cleanrooms, and pharmaceutical production labs are discussed here in the context of the best practices for monitoring astromaterials curation facilities. The monitoring methods differ among these labs, but the overall goal, to reduce or eliminate contamination, is always the same. A key difference for curation facilities is the need to identify contaminants. Identification is not always a monitoring plan requirement in other industries. Microorganisms like bacteria and fungi are capable of physically and chemically altering astromaterials (Toporski and Steele 2007). Since the nutrient levels in cleanrooms are purposely kept at very low levels, it is likely that microorganisms will seek out nutrient bearing phases in the astromaterials themselves (e.g. phosphorous rich minerals, organic carbon). Therefore, it is important to identify organisms in cleanrooms and understand how they might affect samples stored within the cleanrooms. The most common monitoring method for any cleanroom is cultivation of viable microorganisms like bacteria and fungi. The implementation of a variety of culture-independent analysis techniques that are employed more sporadically are also discussed.

In the aerospace industry, biological testing is most commonly performed to meet planetary protection requirements for individual pieces of hardware and entire missions. The goals are defined by Article IX of the 1967 United Nations Treaty on, “Principles Governing the Activities of States in the Exploration and Use of Outer Space, Including the Moon and Other Bodies”. More detailed policies are outlined by COSPAR (Committee on Space Research) (COSPAR 2011). The sampling and testing methods are implemented by NASA (NASA 2010, 2017) and/or ESA (ECSS 2008).

NASA requirements for sampling an aerospace cleanroom to meet planetary protection requirements are described in the “Handbook for the Microbial Examination of Space Hardware” (NASA 2010). Briefly, samples are collected with sterile swabs or wipes made of cotton or preferably a synthetic material like polyester. The samples are exposed to \(80\ ^{\circ}\mbox{C}\) for 15 minutes and any surviving microorganisms are transferred to Petri dishes filled with Tryptic Soy Agar (TSA) and incubated at \(32\ ^{\circ}\mbox{C}\) for 72 hours. Cultured organisms are counted but not necessarily identified. ESA requirements are similar, but require cultivation on Reasoners 2 Agar (R2A) for oligotrophic bacteria, Thioglycolate Agar (TGA) for anaerobic bacteria, and Potato Dextrose Agar (PDA) for fungi in addition to TSA (ECSS 2008). Only one set of R2A plates are heat shocked, while the remaining samples are incubated without being exposed to heat. The ESA standards also include provisions for collecting air samples with an impactor style sampling device. Sampling to meet planetary protection requirements is conducted with the assumption that all of the hardware will be exposed to DHMR (dry heat microbial reduction) or an equivalent process to sterilize the spacecraft. Organisms that survive the heat-shock treatment are counted as a proxy for what might be capable of surviving DHMR. These are fit for purpose assays that are not designed or intended to capture the total diversity of the cleanroom environment. While some facilities and/or missions do identify and archive isolates, this is not required or routine in every instance. Similar culture-based assays have been used to monitor Chinese and Russian space craft assembly facilities as well (Novikova 2004; Zhang et al. 2018).

Cleanrooms used to manufacture pharmaceuticals and package food are also monitored for biological contamination. There are no detailed methods for how to monitor these types of cleanrooms, but cultivation-based techniques are generally the norm. ISO 14698-1 sets out very general principles and methods for biocontamination control in cleanrooms. The document states, “The appropriate sampling method and related procedures shall be selected and performed to reflect the complexity and variety of situations. Sampling shall be carried out using a device and method selected in accordance with the written procedure and in accordance with the instructions provided by the device manufacturer,” (ISO14698 2003). The United States Pharmacopeial Convention also relies on cultivation based methods without specifying a particular set of sampling tools, growth conditions, or nutrients (USP 2013). For example, air samples can be collected with a variety of tools, including: slit to agar samplers, centrifugal samplers, gelatin filter samplers, sieve impactors, impingers, and settle plates (USP 2013). However, the USP document does make several important points regarding sampling methods and data analysis: (1) Total particulate counts from air sampling do not correlate to microbial abundance, although this is an area of open research (Raval et al. 2012). (2) Microbial monitoring is semi-quantitative at best. (3) Colony counts (i.e. the number of culturable organisms) are highly variable from sample to sample and from day to day. Recovery rate is a more reliable statistic for defining a microbial baseline. Recovery rate is defined as: \(\frac{\#\ \mathit{of}\ \mathit{samples} \ \mathit{with}>0\ \mathit{CFU}}{\#\ \mathit{total}\ \mathit{number}\ \mathit{of}\ \mathit{samples}\ \mathit{collected}\ \mathit{during}\ \mathit{a}\ \mathit{sampling} \ \mathit{event}}\) where CFU is a colony forming unit. For example, an aseptic ISO 7 cleanroom should have a baseline recovery rate <10% (USP 2013). The USP document also emphasizes the importance of identifying cleanroom isolates and taking action when new isolates appear and or when an individual sample contains \(> 15\) CFU. In general, sampling of pharmaceutical cleanrooms is focused on cultivating mesophilic organisms from surface swabs, air samples, and cleanroom personnel (Sandle 2012; Whyte 2010). A variety of media types and growth conditions are acceptable as long as they are suitable for enumerating the organisms of concern.

Standard efforts to monitor microbial contamination in cleanrooms rely on cultivation based techniques across all industries. Cultivation based techniques are relatively cheap and easy to perform on a regular basis. However, they can be highly variable and even the most comprehensive culture-based sampling campaign is guaranteed to under-sample the environment (e.g., Hug et al. 2016; Lynch and Neufeld 2015; Rappe and Giovannoni 2003). The community recognizes the need to assess these, “unculturable,” organisms and has employed a variety of techniques to do so.

Next generation DNA sequencing is the most common culture-independent method. Amplification and sequencing of marker genes (tag or amplicon sequencing) like the ribosomal 16S gene for bacteria and archaea and the ITS region for fungi is one promising method for monitoring unculturable organisms in the cleanroom environment. This measurement has changed as the sequencing platforms have improved. Initial tag sequencing was performed using clone libraries and Sanger type sequencing, which only generates about 1000 base pairs of data for a single organism at a time (Shokralla et al. 2012). The 454 platform generates \(10^{2}\)–\(10 ^{4}\) sequences per sample and has allowed researchers to identify hundreds of OTU’s (operational taxonomic unit) or organisms per sample (La Duc et al. 2014; Moissl-Eichinger et al. 2015; Vaishampayan et al. 2013). Using this technology, archaea were found to be persistent, viable (Moissl-Eichinger 2011) members of some cleanroom communities (Moissl-Eichinger 2011; Moissl-Eichinger et al. 2015; Moissl et al. 2008). The Illumina sequencing platforms are the current standard for tag sequencing (Mahnert et al. 2015; Minich et al. 2018; Mora et al. 2016). These sequencers can generate \(10^{5}\)–\(10^{6}\) sequences per sample, allowing researchers to identify even more organisms. A recent tag sequencing survey of the SAF (spacecraft assembly facility) at JPL identified \(>16000\) OTU’s. Tag sequencing is a powerful monitoring tool, but it does have several important biases. PCR (polymerase chain reaction) based amplification of DNA is required for most low biomass samples. This amplification step does not amplify DNA from every organism equally. For example Moissl-Eichinger et al. (2015) were able to cultivate organisms that they did not detect using, “universal” PCR primers for amplification and subsequent tag sequencing. Secondly, sequencing of any type cannot distinguish DNA from viable organisms from relict environmental DNA inside dead organisms. Several researchers have started treating their samples with compounds like PMA (propidium monoazide) to destroy DNA from non-viable organisms prior to sequencing (e.g., Mahnert et al. 2015; Moissl-Eichinger et al. 2015; Mora et al. 2016; Weinmaier et al. 2015; Zhang et al. 2018). Due to variations in primer choice, sequence length, error rate, and total number of sequences produced, it is very difficult to quantitatively compare data generated by different sequencing platforms (Tremblay et al. 2015). Care should be taken to keep these variables as consistent as possible during monitoring. When changes are made, they should be directly compared to previous methods.

Rather than amplifying and sequencing specific marker genes, it is also possible to sequence all of the DNA in a sample (with or without amplification) using the same types of DNA sequencers discussed above. This sequencing technique is commonly referred to as shotgun metagenomics (e.g., Bashir et al. 2016; Minich et al. 2018; Moissl-Eichinger et al. 2015; Weinmaier et al. 2015). Shotgun metagenomics provides more information about the function of abundant organisms in the environment but often fails to detect rare members of the community (Tessler et al. 2017). Additionally, this technique generates large amounts of data that can be very challenging and time-consuming to interpret. At present, metagenomics is a powerful research tool, but it is probably not yet suitable for routine monitoring. New DNA sequencers, like the MinIon platform (Reuter et al. 2015), that generate longer reads may eventually be able to generate metagenomic data that are easier to assemble and interpret, but they are still being developed and improved.

DNA sequencing can be used to inform the design of more rapid assays for biological monitoring. qPCR (quantitative polymerase chain reaction) can be used to assess the number of copies of genes in a sample that directly correlates to microbial abundance (Cooper et al. 2011; Hubad and Lapanje 2013; Kwan et al. 2011; Mahnert et al. 2015; Moissl-Eichinger 2011; Moissl-Eichinger et al. 2015; Schwendner et al. 2013; Vaishampayan et al. 2013; Zhang et al. 2018). When interpreting qPCR data, care must be taken to account for organisms that have multiple copies of the 16S or other marker gene (Větrovský and Baldrian 2013). DNA microarrays like the Phylochip have also been investigated as potential monitoring tools (Cooper et al. 2011; Jimenez 2011; La Duc et al. 2009, 2014; Probst et al. 2010; Vaishampayan et al. 2013). Both of these techniques show promise as monitoring solutions, but they probably require initial investigation with culturing and DNA sequencing in order to ensure that probes and primers are designed to capture the communities present inside the cleanroom in question.

Techniques that do not involve sequencing DNA are also being tested in cleanroom settings. All living organisms on Earth produce a compound called ATP (adenosine triphosphate) for energy storage. Measuring the concentration of ATP in a cleanroom sample provides information about the total number of viable cells (Benardini and Venkateswaran 2016; La Duc et al. 2007; Mahnert et al. 2015; Venkateswaran et al. 2003), but it is not useful for identifying what organisms are present. MALDI-TOF (Matrix assisted laser desorption time of flight) mass spectrometry is now commonly used in the medical field to identify organisms, and it is being applied in aerospace cleanrooms as well (Andrade et al. 2018; Moissl-Eichinger et al. 2015). However, this technique is still dependent on culturing organisms. Fluorescence based monitoring systems can detect airborne cells but cannot identify them (Hallworth 2012).

Biological testing of clean labs suffers from a lack of repetition. Outside the NASA standard assay, very few measurements are routinely replicated between labs. In some respects, this is good and appropriate. Monitoring methods should be modified to suit the environment and the questions being asked. The microbial profile of cleanrooms will be different in different environments (e.g., La Duc et al. 2009). For example, cold curation facilities should explicitly test for the presence of psychrophilic organisms (Sandle and Skinner 2013). It would be a waste of resources to look for psychrophiles in labs maintained at room temperature. However, variations in sample collection, DNA extraction, DNA sequencing, and data processing methods make inter-lab comparisons very difficult. Testing new methods and techniques is an important area of research, but more effort should be made to relate these new measurements to previously generated data.

Curation labs should design a monitoring plan that is capable of quantifying and identifying the microbes present therein. Unfortunately, there is no single measurement or technique capable of thoroughly describing a microbial community. Each method discussed above has its strengths and weaknesses. Therefore, a selection of culture-based and culture-independent techniques should be used to monitor cleanroom ecology. Samples should be collected from the air and from surfaces regularly and as frequently as daily when critical operations are being conducted. Special care should be taken to avoid organic or inorganic contamination during sampling. For example, agar filled contact plates used in the pharmaceutical industry are inappropriate for curation labs since they would introduce bioavailable organic compounds and trace metals into the lab. Most importantly, sample collection and analysis methods should be as consistent as possible in order to generate a baseline dataset that can be used as a basis of comparison for new techniques. Regular and consistent sampling is the most important feature of any environmental monitoring program.

3 Development of New Storage, Processing, and Sample Handling Capabilities

As technological advancements and new ideas expand the variety and scope of scientific questions that can be asked with astromaterials samples, so expands the need for better storage, processing and sample handling capabilities of curation laboratories that house and process astromaterials samples. Here we summarize a number of important advancements and areas of growth in sample storage, processing, and handling techniques that will be important in the coming decades for maximizing science returns on astromaterials samples.

3.1 Cold Curation of Astromaterials and Associated Gases, Biological Samples, and Hardware

The ever-expanding plans for the return of samples from volatile-rich solar system targets and/or targets of astrobiological significance necessitates the development of curation at temperatures below that of typical curation facilities (\(20\ ^{\circ}\mbox{C}\)). Temperature requirements depend primarily on which volatiles are expected within the returned sample, which in turn relate to the conditions under which the material formed and has since been preserved. The term “cryogenic” is defined as relating to temperatures below \(-183\ ^{\circ}\mbox{C}\); the normal boiling points of the noble gases, oxygen, nitrogen, and air lie below this temperature. More generally, “cryogenic” refers to temperatures below approximately \(-150\ ^{\circ}\mbox{C}\) (https://www.nist.gov/mml/acmd/cryogenics/aboutcryogenics). The term “high temperature cryogenic” is used to refer to temperatures from the boiling point of liquid nitrogen, \(-196\ ^{\circ}\mbox{C}\), up to \(-50\ ^{\circ}\mbox{C}\), the generally defined limit of cryogenics (e.g., Zohuri 2017). The curatorial temperatures for terrestrial materials, including tissue samples and ice cores, include: \({\leq} {-}20\ ^{\circ}\mbox{C}\) (the temperature of typical walk-in freezers in which physical processing and documentation takes place); \({\leq} {-}40\ ^{\circ}\mbox{C}\) for archival storage (e.g., of ice cores); and −80 to \(-196\ ^{\circ}\mbox{C}\) (liquid nitrogen) for biological samples (e.g., Anchordoquy and Molina 2007; Rissanen et al. 2010). Thus, with the exception of biological tissue storage, the field of Earth materials curation has not yet entered the realm of cryogenics.

3.1.1 Past and Present Practices in Cold Curation of Astromaterials

The expected range of temperatures required to preserve solar system materials spans from those needed for (water) ice cores to cryogenic. Cold curation and sample handling of astromaterials has been done to a limited extent at NASA-JSC over several decades. Several Apollo 17 samples were initially processed under GN2 in a processing cabinet at room temperature for about a month before being transported to cold storage (\(-20\ ^{\circ}\mbox{C}\)) where they have remained. Furthermore, the US Antarctic meteorite collection utilizes cold storage of new Antarctic meteorites, and initially used cold stages in a nitrogen glovebox for cold sample handling. According to Annexstad and Cassidy (1980) “The specimens are transferred from a small staging freezer to the processing cabinet. A specially constructed stage, cooled by liquid nitrogen, is used to keep the sample frozen while an initial cold chip is removed from the meteorite. This chip is immediately returned to freezer storage for future experiments when a frozen piece may be required. The parent meteorite is then allowed to warm to ambient temperature naturally in the cabinet’s dry GN2 environment.” In the first few years of Antarctic meteorite handling at JSC, the staff gained experience with storing and handling samples frozen, using a cold processing plate in a cabinet and using a cold storage room. Although some hardware was assembled to do this, it became clear after detailed tests that this was not an effective way to handle samples due to the difficulty of keeping samples cold while still allowing dexterity of the sample processor, length of time required to process individual samples, and overall expense. The cold processing approach was abandoned at JSC in 1979, after review and discussion by the Meteorite working Group (MWG) (Righter et al. 2014).

More recently, insights into the benefits of curation and processing under cold conditions have been gained from the collection, curation, and study of the Tagish Lake meteorite (Herd et al. 2016 and references therein). Tagish Lake is a unique carbonaceous chondrite that fell January 18, 2000 onto the frozen surface of the eponymous lake in northern British Columbia, Canada. The meteorite was collected about a week after the fall, and collection was done without direct hand contact; more significantly, the meteorite specimens were kept below \(0\ ^{\circ}\mbox{C}\) after collection and during subsequent transport to curation facilities (Herd et al. 2016). The cold ambient temperatures at the location of the fall, coupled with the care with which the collection and subsequent curation were carried out places Tagish Lake among the most pristine meteorites ever collected (Herd et al. 2016). The meteorite is a type 2 carbonaceous chondrite with affinities to CM and CI meteorites (Blinova et al. 2014; Zolensky et al. 2002), and contains among the highest concentrations of organic matter measured in meteorites (Alexander et al. 2014; Grady et al. 2002; Herd et al. 2011). The pristine nature of the meteorite, coupled with the curation methods used to preserve it, have yielded new insights into the formation of nanoscale organic globules in the coldest regions of the protoplanetary disk (e.g., Nakamura-Messenger et al. 2006) as well as the role of asteroid parent-body aqueous alteration in the modification and synthesis of organic molecules (Herd et al. 2011; Hilts et al. 2014).

The majority of the Tagish Lake meteorite specimens are stored at \(-30\ ^{\circ}\mbox{C}\) and processed within the Subzero Curation Facility for Astromaterials at the University of Alberta; this facility houses an Ar glovebox within a walk-in freezer maintained at temperatures of −10 to \(-15\ ^{\circ}\mbox{C}\) (Herd et al. 2016). While there are no indications that the Tagish Lake meteorite contains water ice or other such volatiles, these conditions of storage and handling are justified by the discovery of especially volatile and/or reactive organic species (e.g., formic acid, naphthalene, and styrene; Hilts et al. 2014). Challenges and limitations of the Subzero Curation Facility include: mitigation of glovebox leaks, user comfort, and the extreme dryness of the Ar atmosphere, which would result in the sublimation of water or other ices from the samples (Herd et al. 2016). However, the facility achieves the goal of enabling documentation and processing of pristine astromaterials under low temperature in an inert atmosphere. The low-temperature curation of the Tagish Lake specimens reduces reaction rates, preserves intrinsic (volatile) organic compounds, and discourages microbial activity (Herd et al. 2016)—requirements that are desirable for returned samples from organic-rich asteroids, cometary nuclei, Mars, or other volatile-rich returned sample targets (lunar poles, icy moons, etc.) as discussed below.

3.1.2 Volatile-Rich Samples from the Lunar Poles

The lunar poles are high-priority targets for sample return due to the possibility of significant quantities of water-ice and other volatiles in permanently shadowed regions (PSRs). Remote sensing data indicates that volatiles comprise up to several weight percent of materials in PSRs; the composition of the volatiles in the crater Cabeus’ PSR included H2O, CO2, CO, H2S, CH4, OH, SO2, NH3, C2H4, and CH3OH (Colaprete et al. 2010; Gladstone et al. 2010). This mix of compounds present a complex curatorial challenge, and even more so in the presence of local regolith/silicates (largely anorthosite or basalt). The volatiles detected by LCROSS have a range of condensation temperatures, and a subset are highly reactive in the presence of silicate minerals. If the solid and volatile components of a lunar PSR sample are stored together, therefore, a mixed-phase, highly reactive sample will likely result. The preservation of a lunar polar sample would therefore be maximized by separating the solid and volatile components and storing them in that configuration for the long-term.

The presence of numerous reactive species presents several additional challenges. First, the corrosive nature of H2S limits the materials to which the sample can be exposed without alteration. Materials will therefore need to be selected that accommodate the curatorial requirements for isolation (materials should not significantly contract under cold temperatures), durability during sample processing/preliminary examination, and particulate contamination. Second, volatile-rich samples often contain gases that are hazardous to humans, even at low concentrations (e.g., CO, H2S, SO2, NH3). This additional risk—on top of the existing particulate exposure risk from solid samples—may require the use of respirators or special masks during preliminary examination and curatorial operations. The need to minimize leakage from curatorial hardware (gas containers, analytical equipment, gloveboxes, etc.) will be significantly higher for volatile-rich samples; because they will operate at cold temperatures, proper materials selection from the component to the system level will be a top priority.

3.1.3 Cometary Nucleus Samples

The preservation of a cometary nucleus sample lies at the extreme end of cold-curation storage requirements because the sample would contain hypervolatiles including noble gases, nitrogen, and oxygen (Bieler et al. 2015; Le Roy et al. 2015), although the retention of these gases would only likely be achieved if they are trapped within solid ices of primarily H2O, CO, and CO2. Insights from the ROsetta Spectrometer for Ion and Neutral Analysis (ROSINA) instrument, which measured volatiles in the coma of comet 67P/Churyumov-Gerasimenko demonstrate that, while dominated by water, the nucleus of 67P includes a wide range of volatile compounds, including molecular oxygen, CO, CO2, HCN, H2S, CH4, and many others (Bieler et al. 2015; Le Roy et al. 2015). Curation of these ices, which would almost certainly be intimately mixed with non-volatile, fine-grained silicate, oxide, sulfide and more refractory organic materials, would require significant technological development for cryogenic curation—assuming that the sample could be collected and returned to Earth under cryogenic conditions in the first place. Various options for the return of cometary nucleus volatiles have been studied, including cryogenic sample return, for which significant technical challenges exist (Veverka 2010b). Allowing volatile components to be released by warming a comet nucleus sample and capturing them in a separate container removes the need for cryogenic handling (Veverka 2010a), which was the approach proposed for the CAESAR mission concept to comet 67P. No truly cryogenic sample return missions are planned at the time of this writing.

3.1.4 Biological Samples

Curation facilities may be required to curate biological samples as part of a contamination knowledge collection from the spacecraft build and sampling of flight hardware. This requirement is currently in place for the Mars2020 mission, which may be the first leg in a Mars Sample Return Campaign. Although there are no requirements that the martian samples be kept cold, biological sampling during the spacecraft build and of the flight hardware includes microbiological samples, including swab samples, liquids, isolated pure cultures of bacteria and fungi, and DNA samples. The requirements for long term preservation of these biological samples varies with sample type and intended use. We will discuss two broad sample types: (1) Samples preserved for later growth and (2) samples intended for molecular analysis like DNA sequencing.

The guidelines for preserving bacteria and fungi for later cultivation are well established (CABRI 1998). Bacteria should be placed in a protective solution of 15–50% glycerol by volume and frozen at \(-80\ ^{\circ}\mbox{C}\). Commercially available products like cryobeads should be used to improve long-term viability. If viability needs to be maintained for \(> 5\) years, samples should be frozen at \(-130\ ^{\circ}\mbox{C}\). Some species of bacteria and fungi can be freeze dried with liquid nitrogen and stored at \(4\mbox{--}8\ ^{\circ}\mbox{C}\). It is important to test the survivability of each strain prior to committing to a preservation method.

Preservation of swabs, liquids, witness plates, or extracted DNA for later analysis is less straightforward. As a general rule, colder is better, but there is little consensus on what temperature is best. There is some evidence that storing samples at too low a temperature can cause more damage than it prevents (Anchordoquy and Molina 2007; Vaught and Henderson 2011). Rapid changes in DNA sequencing technology make it very difficult to predict how samples will be handled in the future (Reuter et al. 2015). DNA extraction techniques are also evolving and can have significant effects on sample quality (Dauphin et al. 2009; Mitchell and Takacs-Vesbach 2008; Rose et al. 2011; Zielińska et al. 2017). Barring additional research, the best strategy is to store unprocessed samples alongside extracted DNA so that future researchers have options for what to analyze.

Future sample return missions from icy moons will incorporate both the biological sensitivity of a Mars Sample Return (MSR) campaign and the temperature sensitivity of lunar or cometary samples (Fig. 1). Therefore, even if MSR does not have a low-temperature storage requirement, it is inevitable that biological containment and cold curation will eventually be needed concurrently. The challenges of operating a bio-safety level 4 (BSL-4) facility at cold temperatures are unique to astromaterials curation, and will need to be addressed in the coming years. Many materials suitable for biological containment (e.g., many plastics) become brittle at temperatures at or below the freezing point of water. The additional presence of salts (chlorides, sulfates, etc.) may pose challenges to the selection/durability of metal components. The overlapping requirements for sterility, particulate cleanliness, temperature control, leak prevention/sample isolation, gas safety, and curator comfort will need to be met in the coming years as exploration efforts at Europa, Enceladus, and other icy moons intensify.

3.2 Curation of Organics and Organic-Rich Materials at Room Temperature

Experience with the curation of the organic-rich Tagish Lake meteorite (Sect. 3.1), has provided ample evidence for the value of cold curation in the preservation of organics and organic-rich materials; namely, the retention of volatile organics, the mitigation of volatile organic contaminants, and the suppression of metabolism by any microorganisms in the curation facility (Herd et al. 2016). However, cold curation is not a requirement for the storage of organic-rich materials. For example, curation planning for OSIRIS-REx turned instead towards hermetically sealed storage of samples to preserve organics (Dworkin et al. 2018). This approach had some precedent with the Apollo missions samples (Fig. 2), avoids the potential contamination and time and dexterity intense processing issues associated with cold curation, and is cost effective utilizing known commercially available and tested hardware and approaches.

When handling organic-rich or organic sensitive materials the use of plastics should be extremely limited. PTFE or Teflon is acceptable in some situations, but glass or metal is preferable. Prior to use, tools and sample containers should be combusted at \(500\ ^{\circ}\mbox{C}\) to remove organic contaminants. Long-term storage of organically sensitive samples should use well-characterized glass baked at \(\geq 500\ ^{\circ}\mbox{C}\) wherever possible (e.g., Grosjean and Logan 2007; Peters et al. 2005; Sherman et al. 2007). Furthermore, frequent microbial monitoring of labs where organic-rich samples are stored and processed is critically important. Moreover, metagenomics studies of any microbes recovered from curation labs that house and process organic-rich samples will be important, particularly for microbes that can metabolize under anaerobic conditions. The primary goal of these metagenomic studies would be to characterize the metabolic function of these anaerobic microbes to understand how they might alter the samples if they are inadvertently introduced to the samples. This is particularly important for organic-rich sample collections stored at room temperature.

3.3 Future Restricted Earth Return Missions

In the 50 years since the Apollo 11 launch, advancements in knowledge and technology allow for not only unprecedented scientific investigations of extraterrestrial samples but also a greater understanding of the potential hazards of sample exposure or release into the environment (e.g. extraterrestrial life). However, in the case of a biological health hazard, more precautions are required, not only to protect the samples from Earth, but also to protect Earth from the samples. Under the UN Space Treaty of 1967, the Committee on Space Research (COSPAR) maintains a planetary protection policy at the international level for all space faring nations. The policy provides “international standard on procedures to avoid organic-constituent and biological contamination in space exploration” (COSPAR Planetary Protection Policy March 2017). The policy also promotes the prevention of “adverse changes in the environment of the Earth resulting from the introduction of extraterrestrial matter” as stated in the UN Space Treaty.

For the United States, the NASA Planetary Protection Office in the Office of Safety and Mission Assurance provides the policies and requirements for all NASA exploration missions regarding forward and backward control of biological contamination. NASA Policy Directive (NPD) 8020.7G, Biological Contamination Control for Outbound and Inbound Planetary Spacecraft, complies with the UN Space Treaty and COSPAR planetary protection policy stating “the Earth must be protected from the potential hazard posed by extraterrestrial matter carried by a spacecraft returning from another planet or other extraterrestrial sources”. NASA Procedural Requirements (NPR) 8020.12D, Planetary Protection Provisions for Robotic Extraterrestrial Missions, outlines requirements for meeting the NPD 8020.7G as well as specifies planning documents and reviews for Category V Restricted Earth Returns. The Planetary Protection Office classifies any “samples from solar system bodies that may harbor indigenous life” as Category V: Restricted Earth Return. Although there are currently three bodies with this designation (Mars, Europa, and Enceladus), this number can change in either direction as more information about any particular planetary body is gained. For example, during the first three Apollo sample return missions (Apollo 11, 12, 13, and 14), the Moon was considered Restricted. Consequently, the Apollo 11, 12, and 14 samples and astronauts were quarantined upon arrival while health assessments and biohazard tests were performed. However by Apollo 15, which launched just over two year after Apollo 11, the Moon was reclassified as Unrestricted and the final three Apollo missions (Apollo 15, 16, and 17) proceeded without the same level of biohazard Planetary Protection precautions.

The scientific community has identified Mars Sample Return (MSR) as a high priority sample return activity for many years, and support for such an endeavor has waxed and waned over the last few decades. Current efforts relating to MSR are focused on a multi-mission campaign, the first of which is the Mars 2020 rover mission to Jezero Crater. At the time of writing, no space agency has fully committed to returning the samples that will be collected by Mars 2020, but NASA and ESA are discussing the possibility of forming a partnership to complete the campaign and decisions are anticipated to be made in the year 2020. Due to both Planetary Protection and Science requirements, the Mars 2020 rover mission has the most stringent inorganic, organic, and biological contamination control requirements of any sample return mission in history. Strategies for satisfying these and other requirements related to MSR and Restricted Earth Return in general are described below.

3.3.1 Facility Preparation

Infrastructure

Samples returned from any planetary body designated as Restricted must be contained within a Biosafety Level 4 (BSL-4) facility until it can be demonstrated that either (1) the samples do not pose a threat to life on Earth or (2) the samples have been adequately sterilized for release (Rummel et al. 2002, NASA technical publication 211842). The requirements and processes associated with biohazard testing and/or sterilization are developed specifically for each mission and each set of samples. International space treaties with the United States, COSPAR planetary protection policies, and NASA planetary protection policy directives and requirements do not impose any specific design requirements on a biocontainment architecture or BSL-4 facility. The policies simply state that the Earth must be protected from the potential hazard posed by extraterrestrial matter and microbial containment is required on Category V (sample return) Restricted Earth Returns. The U.S. Dept. of Health and Human Services traditionally has jurisdiction of design and operating requirements for a BSL-4 facility in the United States. The “Biosafety in Microbiological and Biomedical Laboratories”, 5th Edition (Dec. 2009) authored by the U.S. Department of Health and Human Services: Public Health Service, Centers for Disease Control and Prevention, and the National Institutes of Health; HHS Publication No. (CDC) 21-1112 (hereafter BMBL, 2009), houses the primary recommendations, standards, and design requirements for all BSL labs. Under this regulation, any related agents with unknown risk of transmission are classified to be under BSL-4 containment. Presumably, an extraterrestrial or unknown pathogen would require, at minimum, a BSL-4 containment. At this time, we cannot predict what other federal or international agencies may wish to impose additional guidelines and requirements and/or request jurisdiction of a NASA BSL-4 sample return lab. For example, the National Institute of Health (NIH) imposed additional design requirements at the Galveston National Lab beyond the BMBL requirements. The World Health Organization also has guidelines and requirements for BSL-4 laboratories and the Dept. of Agriculture has claimed some jurisdiction of extraterrestrial soils. For the Apollo Program in January 1966, the Interagency Committee on Back Contamination (ICBC) was established to include the CDC with Dr. David Sencer of the CDC as chairman, Department of Agriculture, Department of the Interior, Department of Health, Education, and Welfare, National Academy of Sciences, and NASA, which imposed strict requirements on the construction of the Lunar Receiving Laboratory (LRL), JSC Bldg. 37. Therefore, historically, other agencies have been involved in the construction and operations of such a BSL-4 type lab.

One of the major challenges in designing a facility for Restricted Earth Return Missions is the integration of the Contamination Control (CC) requirements necessary to protect the samples from terrestrial contamination and Planetary Protection (PP) requirements necessary to protect the Earth and its inhabitants (all life: from humans to animals to plants, etc.) from a possible extraterrestrial pathogen (e.g., microbes, viruses, or prions). While walls can act as physical barriers for protections, developing the proper pressure differentials inside and outside the laboratory is vital (Fig. 3). Unlike the curation of traditional unrestricted samples, which utilizes positive pressure gradients to protect the samples from contamination, BSL-4 facilities rely on negative pressure gradients to protect the scientists and general public from the samples. Although there have been a number of possible iterations demonstrated in the Draft Test Protocol (Rummel et al. 2002; Fig. 3), the presumed baseline requirement is that the samples must be contained within a BSL-4 Facility (BMBL 2009). In order to best protect the samples and Earth, redundancies are built into the design schematic (Fig. 3). Specifically, not only will the entire cleanroom laboratory be constructed within a BSL-4 facility, but the use of a Biosafety Cabinet (BSC) III double walled isolator for sample processing within the cleanroom will add an additional level of protection with the corresponding differential pressure scheme. For current BSL facilities in the U.S., a Class III BSC glovebox gastight (leak rate) criterion is \(< 1\times 10\mbox{--}5~\mbox{cc}/\mbox{s}\) with 100% He tracer gas under 3 inH2O pressure in the cabinet (Stuart et al. 2012). Dependent on mission science requirements, specialized double walled glovebox or containment seals could be required for maintaining nitrogen or other inert gas environment purity under negative pressure. Non-glove storage isolators can achieve a He leak rate of \(< 1\times 10\mbox{--}7~\mbox{cc}/\mbox{s}\). However, achieving a better leak rate on double-walled isolated containment may require additional engineering development and challenges. While there have been some studies exploring how these requirements could be implemented (Beaty et al. 2009), these studies need to be updated to reflect some significant shifts in possible facility usage (e.g. no animal studies, long-term use, multi-mission use).