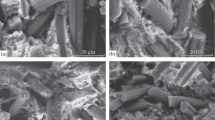

The effect of carbon fiber dimensions on mechanical and tribological properties of the composites based on two thermoplastic matrices of different physical-chemical nature (polyphenylene sulfide, PPS, and ultrahigh molecular weight polyethylene, UHMWPE) is compared. It is shown that the supermolecular structure formed by compression sintering of PPS and UHMWPE controls the distribution pattern of carbon fibers in the matrix, which affects the level of tribological properties. The composites on a high-strength PPS-matrix, designed for structural/tribotechnical applications and loaded with short carbon fibers (70 μm), can be fabricated at a high loading degree (40 wt.%), which provides a five-fold increase in wear resistance and a 1.7-fold decrease in friction coefficient. The wear resistance increases due to the formation of a third body consisting of wear debris, which essentially reduces the friction coefficient. Loading the PPS with carbon nanofibers modifies the polymer matrix structure through the dispersion hardening mechanism but does not improve its tribological properties. Adding chopped carbon fibers (with a length of a few millimeters) into the PPS matrix gives rise to substantial hardening but significantly degrades the tribological properties. The UHMWPE composites can be manufactured via filling the matrix with 10 wt.% chopped carbon fibers evenly distributed in it. Carbon nanofibers are thought to be the most efficient fillers for the UHMWPE matrix of a spherulitic supermolecular structure in terms of increasing its wear resistance. They play the role of a solid lubricant medium (wear resistance increases 2.7 times, the friction coefficient is decreased twice). Comparatively long chopped carbon fibers of the millimeter range (2–3 mm) play a reinforcing role in contrast to the short carbon fibers measuring tens and hundreds of micrometers (70, 200 μm). They neither increase the friction coefficient nor result in the abrasive wear of the steel counterpart. The role of interphase adhesion, polymer matrix hardness, its chemical reactivity and supermolecular structure in forming the tribomechanical properties of carbon composites based on thermoplastic matrices of different physical-chemical nature is discussed.

Similar content being viewed by others

References

B. J. Briscoe and S. K. Sinha, Tribological Applications of Polymers and Composites: Past, Present and Future Prospects, Elsevier, Amsterdam (2008).

S. Kurtz, UHMWPE Biomaterials Handbook, 3-rd Edition (Ed. Steven M. Kurtz), William Andrew Publishing, N.Y. (2016).

M. C. Galetz, T. Blar, H. Ruckdaschel, et al., J. Appl. Polym. Sci., 104, 4173– 4181 (2007).

E. M. Lee, Y. S. Oh, H. S. Ha, and B. K. Kim, Polym. Adv. Technol., 20, 1121– 1126 (2009).

W. Zhai, R. Sun, and H. Sun, Mater. Lett., 229, 13–16 (2018).

M. S. Ramli, M. S. Wahab, M. Ahmad, and A. S. Bala, ARPN J. Eng. Appl. Sci., 11, No. 8, 5473–5480 (2016).

K. Stoeffler, S. Andjelic, N. Legros, et al., Compos. Sci. Technol., 84, 65–71 (2013).

R. Sebastian, A. Noll, G. Zhang, et al., Tribol Int., 64, 187–195 (2013).

L. Yu, S. Bahadur, and Q. Xue, Wear, 214, 54–63 (1998).

M. H Cho and S. Bahadur, Wear, 258, 835–845 (2005).

A. Noll and T. Burkhart, Compos. Sci. Technol., 71, 499–505 (2011).

S. V. Panin, V. O. Alexenko, D. G. Buslovich, et al., IOP Conf. Ser.: Earth Environ. Sci., 115, 012010, 1–7 (2018).

S. V. Panin, L. A. Kornienko, V. O. Alexenko, et al., Izv. Vyssh. Uchebn. Zaved. Khim. Khim. Tekhnol., 59, No. 9, 99–105 (2016).

S. V. Panin, S. V. Shilko, L. A. Kornienko, et al., MOJ Appl. Bio Biomech., 1(5), 00030 (2017).

G. V. Kozlov, P. G. Rizvanova, I. V. Dolbin, and G. M. Magomedov, Russ. Phys. J., 62, No. 1, 127–131 (2019).

A. I. Dmitriev and B. C. Jim, Russ. Phys. J., 62, No. 8, 1409–1416 (2019).

S. V. Panin, V. O. Alexenko, L. A. Kornienko, et al., AIP Conf. Proc., 2051, 020227 (2018).

S. V. Panin, V. O. Alexenko, L. A. Kornienko, et al., Izv. Vyssh. Uchebn. Zaved. Khim. Khim. Tekhnol., 61, No. 11, 88–95 (2018).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Izvestiya Vysshikh Uchebnykh Zavedenii, Fizika, No. 4, pp. 22–29, April, 2020.

Rights and permissions

About this article

Cite this article

Panin, S.V., Kornienko, L.A., Hiep, L.T.M. et al. The Effect of Physical-Chemical Nature of UHMWPE and PPS Thermoplastic Matrices on the Formation of Mechanical and Tribological Properties of their Carbon Fiber Filled Composites. Russ Phys J 63, 554–562 (2020). https://doi.org/10.1007/s11182-020-02069-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11182-020-02069-5