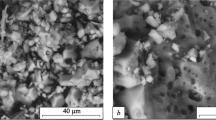

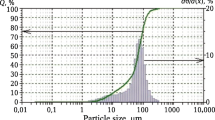

Results of studying the influence of Russian commercial milling additives of various chemical nature on the process of dry milling calcined alumina are presented. It is shown that use of the additives studied makes it possible not only to reduce the time of alumina raw material fine milling of by a factor of 1.5 – 2, but also to increase the submicron particle fraction (<1 μm) yield within finished activated product.

Similar content being viewed by others

References

S. E. Andreev, Crushing, Refinement, and Screening of Useful Raw Materials [in Russian], Nedra. Moscow (1980).

P. M. Sidenko, Refinement in the Chemical Industry [in Russian], Khimiya, Moscow (1977).

Yu. Guangbin, M. M. Kuznetsova, M. B. Marakhovskii, and A. A. Aleksina, “Determination of solid material refinement process energy expenditure,” Zh. Tekhn. Fiz, 85(5), 145 – 147 (2015).

Yu. G. Nosov and D. I. Derkachenko, “Sequence during testing corundum for microhardness,” Zh. Tekhn. Fiz., 73(10), 139 – 142 (2003).

P. Prziwara and A. Kwade, “Grinding aids for dry fine grinding processes — Part I: Mechanism of action and lab-scale grinding,” Powder Technology, No. 375, 146 – 160 (2020).

Yu. E. Pvinskii, Rheology of Dispersed Systems and Ceramic Concretes. Elements of Nanotechnology in Silicate Material science [in Russian]. Politekhnika, St. Petersburg (2012).

V. N. Glukharev, Dry Milling Under Electro-Neutralization Conditions [in Russian], Izd. Politekhn. Univ., St Petersburg (2014).

J. Tomas and S. Kleinschmidt, “ Improvement of flowability of fine cohesive powders by flow additives,” Chem. Eng. Technol., 32(10), 1470 – 1483 (2009).

B. V. Deryagin, N. V. Curaev, and V. M. Muller, Surface Forces [in Russian], Nauka, Moscow (1985).

P. Prziwara, S. Breitung-Faes, and A. Kwade, “Comparative study of the grinding aid effects for dry fine grinding of different materials,” Miner. Eng., 144, 106030 (2019).

H. Hasegawa, M. Kimata, and T. Shoji, “Effect of liquid additives and behavior of alumina powder in ultrafine grinding of alumina,” Journal of the Society of Powder, 39(10), 736 – 742 (2002).

P. A. Rebinder and E. D. Shchukin, “Surface phenomena in solids during deformation and failure,” Uspekhi Fiz. Nauk, 108(9), 3 – 42 (1972).

V. Chipakwe, P. Semsari, T. Karlkvist, et al., “A critical review on the mechanisms of chemical additives used in grinding and their effects on the downstream processes,” Journal of Materials, Research and Technology, 9(4), 8148 – 8162 (2020).

K. Schönert, “Role of fracture physics in understanding comminution phenomena,” Trans. Soc. Min. Eng. AIME, No. 252, 21 – 26 (1972).

F. W. Locher and H. M. Seebach, “Influence of adsorption on industrial grinding,” Ind. Eng. Chem. Proc., No. 11, 190 – 197 (1972).

H. Dombrowe, B. Hoffmann, andW. Scheibe, “ÜberWirkungsweise und Einsatzmöglichkeiten von Mahlhilfsmitteln,” Zement – Kalk – Gips., No. 11, 571 – 580 (1982).

H. Schubert, “Effects of fluids and additives on grinding processes,” Aufbereitungstechnik, No. 8, 115 – 120 (1988).

P. Prziwara and A. Kwade, “Grinding aids for dry fine grinding processes—Part II: Continuous and industrial grinding,” Powder Technology, 394, 207 – 213 (2021).

M. Madzhistri, D. Padovani, and P. Forni, “Optimization of cement properties with additions using milling intensifiers,” Tsement evo Primenenie, No. 5, 115 – 116 (2013).

S. P. Sivkov, “Ammonia emission from cement concretes,” Tekhnol. Betona, No. 5/6, 15 – 17 (2012).

P. A. Demidov and R. M. Gainutdinov, “Effective chemical additives for cement production,” Tsement evo Primenen., No. 1, 2 (2019)

M. A. Trubitsyn, N. A. Volvicheva,, L. V. Furda, and N. S. Skrynikov, “Study of the effect Vestn. V. G. Shukova BGTU, No. 12, 84 – 97 (2021).

M. A. Trubutsyn, N. A. Volovicheva, L. V. Furda, et al., “Research in the field of preparing activated aluminum oxide. Part 1. Method for preparing activated alumina,” Novye Ogneupory, No. 3, 16 – 22 (2022).

M.Weibel and R. K. Mishra, “Comprehensive understanding of grinding aids,” Zement – Kalk – Gips., No. 6, 28 – 39 (2014).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated from Novye Ogneupory, No. 7, pp. 33 – 41, July, 2022.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Trubitsyn, M.A., Volovicheva, N.A., Furda, L.V. et al. Research in the Area of Preparing Activated Alumina. Part 3. Efficiency of Using Russian Additive-Intensifiers during Milling High-Alumina Raw Materials. Refract Ind Ceram 63, 370–377 (2022). https://doi.org/10.1007/s11148-023-00738-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-023-00738-9