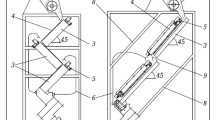

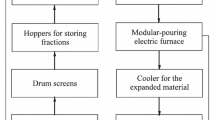

The paper presents the results of analytical and experimental studies of the thermal zones in the working space of the modules of an electric pouring furnace. To increase the production rate and reduce the energy content of the work process, the local granular media flows were distributed between such zones depending on their heating. The modular-pouring furnace, equipped with plate accelerators located inside the modules to accelerate the local granular media flows, has been upgraded by adapting a drum dispenser provided with the longitudinal stepped slots having variable depth. Based on the analysis of the incident, effective, and resulting flows in the working spaces of the modules, performed by the methods of algebra of radiant fluxes, the causes of the formation of a non-uniform thermal field on the refractory surfaces of the firing modules were established. The analysis of experimental data, confirming the conclusions of the analytical study, was carried out, and the width of each thermal zone was determined. By comparing the heat quantities absorbed by vermiculite, used as an example, the minimum amount of time required for its particles to travel through each thermal zone and the average local velocities of the particles within such zones were determined. It was shown that the nature of the distribution of the average local velocities of vermiculite flows between the thermal zones is nonlinear. The local and overall production rates of the furnace were determined with the latter (equal to 0.95 m3/sec) being 27% higher compared to a prototype pilot furnace under equal power consumption.

Similar content being viewed by others

References

A. I. Nizhegorodov, “Theory and practical use of modular-pouring electric furnaces for firing vermiculite,” Refract. Ind. Ceram., 56(4), 361 – 365 (2015).

A. I. Nizhegorodov, A. N. Gavrilin, and B. B. Moyzes, “Application and production technology of thermal activation products of serpentine minerals from industrial waste,” Bulletin of the Tomsk Polytechnic University, Geo Assets Engineering, 329(5), 67 – 75 (2018).

A. I. Nizhegorodov and A. V. Zvezdin, Power-engineering Systems for Processing Vermiculite Concentrates [in Russian], Izd. IRNITU, Irkutsk (2015).

A. S. Telegin, V. S. Shvydkii, and Yu. G. Yaroshenko, Heat and Mass Transfer [in Russian], ITsK Akademkniga, Moscow (2002).

S. S. Kutateladze, Heat Transfer and Hydrodynamic Resistance: Reference Book [in Russian], Energoatomizdat, Moscow (1990).

F. Kreith and W. Black, Basic Heat Transfer [in Russian], Transl. from English, Mir, Moscow (1983).

A. I. Nizhegorodov, “Modeling of radiant energy transfer to granular media in electric furnaces with top-mounted radiating elements,” Novye Ogneupory, No. 2, 10 – 14 (2020).

A. V. Zvezdin, T. B. Bryanskikh, and A. I. Nizhegorodov, “Analytical model of absorption-reflection properties of vermiculite under thermal radiation conditions,” Refract. Ind. Ceram., 58(1), 19 – 24 (2017).

L. G. Loitsyanskii and A. I. Lurye, Course in Theoretical Mechanics, Vol. 2: Dynamics [in Russian], Nauka, Moscow (1983).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 12, pp. 16 – 23, December, 2020.

Rights and permissions

About this article

Cite this article

Nizhegorodov, A.I., Gavrilin, A.N., Moyses, B.B. et al. Modular-Pouring Furnace with the Local Granular Media Flow Rates Distributed Between Thermal Zones. Refract Ind Ceram 61, 631–638 (2021). https://doi.org/10.1007/s11148-021-00533-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-021-00533-4