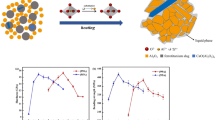

Slag-resistant highly refractory alumina-periclase-carbon ceramic materials are synthesized on the basis of electrocorundum (Kazogneupor), Zinel’bulaksk (Uzbekistan) talc, and enriched graphite concentrate (Uzbekistan). The crystal structure of the material is represented by corundum and spinel. Ceramic specimen refractoriness is above 1800°C, density if 2520 – 2880 kg/m3, water absorption is 6.75 – 11.71%, open porosity is 16 – 29%, and the ultimate strength in compression is 100 – 120 MPa.

Similar content being viewed by others

References

W. E. Lee, S. Zhang, and M. Karakus, “Refractories: controlled microstructure composites for extreme environments,” J. Mater. Sci., 39, 6675 – 6685 (2004).

A. M. Chuklai, N. G. Goreev, O. F. Shatilov, V. Ya. Gushchin, V. N. Koptelov, O. I. Frolov, S. V. Spesivtsev, and T. B. Elkina, RF Patent 2167123, Spinel-periclase-carbon refractory, No. 97118322/03, Claim 10.30.97, Publ. 05.20.01, Bull. No. 14.

I. D. Kashcheev and K. G. Zemlyanoi, “Features of the structure and properties of fine spinel and periclase powders after different forms of grinding,” Proc. All-Russia Conf. “Ceramics and composite materials,” 2027 June (2004). Syktyvkar.

GOST 5341–2016. Refractory objects for lining steel-pouring ladles. Interstate standard. Intro. 01.01.2017. Standartinform (2016).

Z. Babakhanova, M. Aripova, N. Khodjaev, and R. Khamidov,” The study of the mineralogical composition and flotation parameters of quartz graphitized schist,” Chemistry & Chemical Technology, 10, No. 3, 343 – 348 (2016).

V. V. Kartashov, A. V. Vlasov, É. I. Denisova, and D. K. Aleshin, “Nanomodified ceramic materials,” VI Sci.-Tech. Conf. OAO OKB Novator, 24 – 26 Mar. (2008), Ekaterinburg.

W. S. Resende, R. M. Stoll, S. M. Justus, et al., “ Key features of alumina/magnesia/graphite refractories for steel ladle lining,” J. Eur. Ceram. Soc., 20, 1419 – 1427 (2000).

V. P. Semyannikov, V. E. Gel’fenbein, Yu. L. Zhuravlev, and V. Ya. Gushchin, RF Patent 20768849, Carbon-containing refractory, No. 96 96113624, Claim 07.22.96, Publ. 04.10.97.

K. S. Sanakulov, “Composition and development trends for comprehensive use of AGMK zinc and copper-molybdenum production waste,” Gorn. Vestn. Uzbekistana, No. 2 (69), 139 – 144 (2017).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 9, pp. 23 – 27, September, 2018.

Rights and permissions

About this article

Cite this article

Babakhanova, Z.A., Aripova, M.K. Highly Refractory Alumina-Periclase-Carbon Ceramic Materials Based on a Spinel Binder. Refract Ind Ceram 59, 454–458 (2019). https://doi.org/10.1007/s11148-019-00253-w

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-019-00253-w