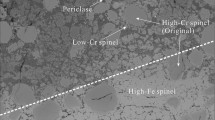

The chemical and mineral compositions of periclase-chromite refractories used in the lining of the furnace for the processing of sulfide raw materials were investigated before and after the overhaul period. It was shown that dusty gas has an effect on the refractories composition and structure, causing saturation of the surface layer with both dust and gas components. Copper, zinc and lead penetrate the materials at a depth of up to 5 mm, whereas traces of elevated levels of sulfur associated with the formation of sulfates Fe12S11O51, MgSO4 and PbSO4 were detected at 20 mm deep. Waste refractories can be used as lining at the non-critical components of thermal units and kilns, and as refractory powder to prepare gun mixtures.

Similar content being viewed by others

References

A. V. Vanyukov and N. I. Utkin, Complex Processing of Copper and Nickel Raw Materials: A Textbook for Universities [in Russian], Metallurgiya, Chelyabinsk (1988) 432 p.

Refractory Manufacture: Handbook in 2 vol. [in Russian], Vol. 2; Ed. D. I. Gavrisha, Metallurgiya, Moscow (1965) 584 p.

T. I. Shchekina, A. M. Batanova, T. N. Kurbyko, et al., “Comparative study of chromitepericlase and periclase-carbon refractory stability during reaction with nickel production melts (experimental data). 1. Behavior of chromite-periclase refractories in the presence of metal-slag and slag melts,” Refract. Ind. Ceram., 55(6), 526 – 528 (2015).

V. G. Kozhin, V. V. Belyaev, E. N. Selivanov, “Improving the refractory lining durability of pyrometallurgical plants in service at the Svyatogor Joint-Stock Co.,” Refract. Ind. Ceram., 45(4), 228 – 231 (2004).

A. Kil’skii, L. Obshinska, J. Mondkevich, “A study of the corrosion of periclase chrome refractories for the lining of copper-smelting converters” [in Russian], Ongneupory i Tekhnicheskaya Keramika, No. 11/12, 73 – 76 (2012).

E. N. Selivanov, “Impregnation of a periclasechromite lining with nickel matte,” Refractories, 36(6), 191 – 193 (1995).

I. D. Kashcheev, Properties and Application of Refractories: Reference Edition [in Russian], Teplotekhnik, Moscow (2004) 352 p.

N. Z. Fotoyi and R. H. Eric, “Interaction of MgO–MgR2O4 (R: Al, Cr, Fe) with SO2-containing gasses” [in Russian], Southern African Institute of Mining and Metallurgy, Johannesburg, 6 – 9 March 2011, p. 373 – 388.

L. M. Aksel’rod, T. V. Yarushina, I. G. Maryasev, and V. L. Nechunayev, “Investigation of the wear of chromite-periclase refractories in the waelz kiln reaction zone in zinc production” [in Russian], Tsvetnye Metally, No. 12, 14 – 19 (2016).

L. M. Aksel’rod, T. V. Yarushina, I. G. Maryasev, et al., “Chromite-periclase refractory wear in zinc production waelz kiln reaction zone,” Refract. Ind. Ceram., 57(6), 563 – 568 (2016).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 10, pp. 3 – 7, October 2017.

Rights and permissions

About this article

Cite this article

Klyushnikov, A.M., Pikulin, K.V., Belyaev, V.V. et al. Structure of Periclase-Chromite Refractories After the Service Life in Furnaces for the Processing of Sulfide Raw Material. Refract Ind Ceram 58, 481–486 (2018). https://doi.org/10.1007/s11148-018-0131-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-018-0131-6