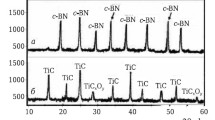

The phase composition of synthesized TiC and TiN, microstructure, relative density, open porosity, linear shrinkage, elasticity modulus, Vickers hardness, ultimate strength in compression, and linear dependence of elasticity modulus and ultimate strength in compression of mullite–TiC–TiN-specimens with a different ratio of TiC and TiN sintered by a plasma-arc method in the range 1200 – 1600°C with a compaction load of 30 MPa, are studied. Synthesized powders have intense crystallization of TiC and TiN. Sintered specimens with a different ratio of TiC and TiN demonstrate intense mullitization in the range 1200 – 1600°C. Specimens with a TiC/TiN ratio of 50/50, 70/30, and 90/10 mol.% demonstrate a gradual increase in TiC from 1200 – 1400°C compared with a more intense increase in TiC from 1400 to 1600°C. An increase in TiC concentration and a reduction in TiN content in powder mixtures sintered at 1500°C facilitates formation of a uniform density sintered microstructure with presence of small pores. Specimens in the ratios TiC/TiN of 50/50 and 70/30 mol.% point to a more intense increase in relative density and linear shrinkage; a reduction in open porosity and an increase in elasticity modulus, Vickers hardness, and ultimate strength in compression. This leads to an increase in specimen crack formation resistance in the presence of microcracks with a relatively rectilinear propagation trajectory (composition M50TiC50TiN), and absence of microcracks (composition M70TiC30TiN) around an indenter impression, with the greatest linear dependence of elasticity modulus and ultimate strength in compression in the range 1200 – 1600°C.

Similar content being viewed by others

Change history

06 March 2018

Figure 5 is incorrect on page 423. The correct Fig. 5 appears here:

References

H. J. Ryu, Y. W. Lee, and S. H. Hong, “Sintering behavior and microstructures of carbides and nitrides for the inert matrix fuel by spark plasma sintering,” J. Nucl. Mater., 352(1 – 3), 341 – 348 (2006).

D. Sciti and M. Nygren, “Spark plasma sintering of ultra refractory compounds,” J. Mater. Sci., 43(5), 6414 – 6421 (2008).

L. Cheng, Z. Xie, G. Liu, and W. Liu, “Densification and mechanical properties of TiC by SPS-effects of holding time, sintering temperature and pressure condition,” J. Europ. Ceram. Soc., 32(12), 3399 – 3406 (2012).

X. Wei, Ch. Back, O. Izhvanov, et al., “Zirconium carbide produced by spark plasma sintering and hot pressing: densification kinetics, grain growth, and thermal properties,” Mat., 577(9), 1 – 16 (2016).

M. Hotta and T. Goto, “Spark plasma sintering of TiN – cubic BN composites,” J. Ceram. Soc. Japan, 118(2), 137 – 140 (2010).

Y. Li, H. Katsui, and T. Goto, “Spark plasma sintering of TiC – ZrC composites,” Ceram. Internat., 41(5), 7103 – 7108 (2015).

B. Niu, F. Zhang, W. Ji, and J. Y. Zhang, “Effect of solid solution formation on densification of spark plasma sintered ZrC ceramics with TiC as sintering aid,” Adv. Apll. Ceram., 115(1), 55 – 59 (2016).

M. Hotta and T. Goto, “Densification and microstructure of Al2O3 – cubic BN composites prepared by spark plasma sintering,” J. Ceram. Soc. Japan, 116(6), 744 – 748 (2008).

M. Hotta and T. Goto, “Densification, phase transformation and hardness of mullite-cubic BN composites prepared by spark plasma sintering,” J. Ceram. Soc. Japan, 118(2), 157 – 160 (2010).

D. Ghahremani and T. E. Ebadzadeh, “Densification, microstructure and mechanical properties of mullite – TiC composites prepared by spark plasma sintering,” Ceram. Internat., 41(2), 1957 – 1962 (2015).

P. Klimczyk, M. E. Cura, and A. M. Vlaicu, “Al2O3 – cBN composites sintered by SPS and HPHT methods,” J. Europ. Ceram. Soc., 36(7), 1783 – 1789 (2016).

A. V. Hmelov, “Preparation of mullite–TiC–ZrC ceramic materials by a plasma – ARC method and their properties,” Refract. Indust. Ceram., 57(6), 645 – 650 (2017).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 8, pp. 22 – 30, August, 2017.

A correction to this article is available online at https://doi.org/10.1007/s11148-018-0152-1.

Rights and permissions

About this article

Cite this article

Hmelov, A.V. Preparation of Mullite–TiC–TiN Materials by a Plasma Spark Method and Their Properties. Refract Ind Ceram 58, 418–425 (2017). https://doi.org/10.1007/s11148-017-0122-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-017-0122-z