A mixture of boric acid, silicon dioxide, and titanium dioxide powders in the eutectic ratio was reduced by carbon (as soot) at 1600°C in vacuo in order to produce phases in the B4C–SiC–TiB2 system. Only the expected phases were identified in the synthesis products. The synthesized powders were boron carbide crystals ìm in size and nanoparticles.

Similar content being viewed by others

References

S. S. Ordan’yan, V. I. Rumyantsev, D. D. Nesmelov, and D. V. Korablev, “Physicochemical basis of creating new ceramics with participation of boron-containing refractory compounds and its practical implementation,” Nov. Ogneupory, No. 3, 153 – 156 (2012); Refract. Ind. Ceram., 53(2), 108 – 111 (2012).

C.-H. Jung, M.-J. Lee, and C.-J. Kim, “Preparation of carbon-free B4C powder from B2O3 oxide by carbothermal reduction process,” Mater. Lett., 58, 609 – 614 (2004).

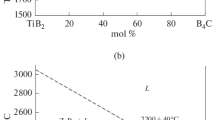

W.-J. Li, R. Tu, and T. Goto, “Preparation of directionally solidified B4C–TiB2–SiC ternary eutectic composites by a floating zone method and their properties,” Mater. Trans., JIM, 46(9), 2067 – 2072 (2005).

A. K. Suri, J. Subrahmanyan, J. K. Sonber, and T. S. R. C. Murthy, “Synthesis and consolidation of boron carbide: A review,” Int. Mater. Rev., 55(1), 4 – 40 (2010).

M. Patel, J. Subrahmanyam, V. V. B. Prasad, and R. Goyal, “Processing and characterization of B4C–SiC–Si—TiB2 composites,” Mater. Sci. Eng., A, No. 527, 4109 – 4112 (2010).

E. M. Heian, S. K. Khalsa, J.W. Lee, et al., “Synthesis of dense, high-defect-concentration B4C through mechanical activation and field-assisted combustion,” J. Am. Ceram. Soc., 87(5), 779 – 783 (2004).

S. S. Ordanyan, S. V. Vikhman, D. D. Nesmelov, et al., “Nonoxide high-melting point compounds as materials for extreme conditions,” Adv. Sci. Technol., 89, 47 – 56 (2014).

Yu. P. Udalov, E. E. Valova, and S. S. Ordan’yan, “Preparation and abrasive properties of eutectic compositions in the B4C–SiC–TiB2 system,” Refractories, 36(7/8), 233, 234 (1995).

J. E. Zorzi, C. A. Perottonic, and J. A. H. da Jornada, “Hardness and wear resistance of B4C ceramics prepared with several additives,” Mater. Lett., 59, 2932 – 2935 (2005).

A. N. Sokolov, “Sintering of high-boron compounds at high pressure and temperature,” in: Rock-destroying and Metalworking Tool – Technique and Technology for Fabrication and Use, Collection of Scientific Works [in Russian], ISM im. V. N. Bakulya, NAN Ukrainy, Kiev, 2009, No. 12, pp. 259 – 265.

V. V. Ivzhenko, et al., “Preparation of B4C—TiB2 composites with increased destruction viscosity,” in: Rock-destroying and Metal-working Tool – Technique and Technology for Fabrication and Use, Collection of Scientific Works [in Russian], ISM im. V. N. Bakulya, NAN Ukrainy, Kiev, 2010, No. 13, pp. 235 – 239.

I. Gunjishima, T. Akashi, and T. Goto, “Characterization of directionally solidified B4C—TiB2 composites prepared by a floating zone method,” Mater. Trans., JIM, 43(4), 712 – 720 (2002).

K. Kobayashi, K. Maeda, and Y. Uchiyama, “Formation and oxidation resistance of the coating formed on carbon material composed of B4C–SiC powders,” Carbon, 33(4), 397 – 403 (1995).

Y. Wang, H. Peng, F. Ye, and Y. Zhou, “Effect of TiB2 content on microstructure and mechanical properties of in-situ fabricated TiB2/B4C composites,” Trans. Nonferrous Met. Soc. China, 21, 369 – 373 (2011).

F. Thevenot, “Sintering of boron carbide and boron carbide-silicon carbide two-phase materials and their properties,” J. Nucl. Mater., 152, 154 – 162 (1988).

O. N. Grigor’ev, G. A. Gogotsi, Yu. G. Gogotsi, et al., “Synthesis and properties of ceramics in the SiC–B4C–MeB2 system,” Powder Metall. Metal Ceram., 39(5/6), 239 – 250 (2000).

V. I. Rumyantsev, D. V. Korablev, V. N. Fishchev, and S. S. Ordan’yan, RU Pat. No. 2,396,232, IPC C04B35/56, C04B35/573, F41H5/00, Appl. Apr. 10, 2009; Publ. Aug. 10, 2010, “Ceramic material based on boron carbide and method of obtaining it”.

B. Buyuk and A. B. Tugrul, “An investigation on gamma attenuation behavior of titanium diboride reinforced boron carbide-silicon carbide composites,” Radiat. Phys. Chem., 97, 354 – 359 (2014).

D. To, R. Dave, X. Yin, and S. Sundarsan, “Deagglomeration of nanoparticle aggregates via rapid expansion of supercritical or high-pressure suspensions,” AICHE J., 5(11), 2807 – 2826 (2009).

A. Li, Y. Zhen, Q. Yin, et al., “Microstructure and properties of (SiC, TiB2)/B4C composites by reaction hot pressing,” Ceram. Int., 32, 849 – 856 (2006).

J.-H. Han, S.-W. Park, and Y.-D. Kim, “Reaction synthesis and mechanical properties of B4C-based ceramic composites,” Mater. Sci. Forum, 534 – 536, 917 – 920 (2007).

B. X. Zhu, Y. J. Zhen, Q. Yin, et al., “Hot-press sintering densification, microstructure and properties of SiC–TiB2/B4C composites,” Key Eng. Mater., 602/603, 488 – 493 (2014).

D. D. Nesmelov, E. A. Vlasova, and S. S. Ordan’yan, “Combined elemental synthesis of boron and silicon carbides,” Nov. Ogneupory, No. 10, 37 – 41 (2016).

A. G. Alekseev, G. A. Bovkun, A. S. Bolgar, and A. L. Borisova, in: Properties, Preparation and Use of Refractory Compounds: Handbook [in Russian], T. Ya. Kosolapova (ed.), Metallurgiya, Moscow, 1986, 928 pp.

S. Hayun, N. Frage, H. Dilman, et al., “Synthesis of dense B4C–SiC–TiB2 composites,” Ceram. Trans., 178, 37 – 44 (2006).

Acknowledgments

The work was sponsored by the Ministry of Education and Science of Russia (Project No. 10.2525.2014/K).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 3, March, pp. 139 – 143, 2017.

Rights and permissions

About this article

Cite this article

Kotsar’, T.V., Danilovich, D.P., Ordan’yan, S.S. et al. Combined Carbothermal Synthesis of Powders in the B4C–SiC–TiB2 System. Refract Ind Ceram 58, 174–178 (2017). https://doi.org/10.1007/s11148-017-0076-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-017-0076-1