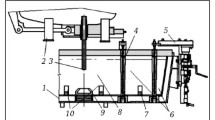

This article examines the configuration of elements of the chambers of a tundish on a four-strand continuous caster and aspects of organizing the movement of the flows of steel within the chambers. It is shown that new configurations and structural elements developed for the system that distributes the flows have a significant effect on their parameters and the removal of nonmetallic inclusions. The equipment upgrade ensures efficient formation of the flows and creates the conditions necessary to improve the quality of the cast steel.

Similar content being viewed by others

References

O. B. Isaev, E. E. Chichkarev, V. V. Kislitsa, et al., Modeling Modern Processes for the Secondary Treatment and Continuous Casting of Steel [in Russian] (Ed.: E. Kh. Shakhpazov), ZAO “Metallurgizdat,” Moscow (2008).

K. N. Vdovin, V. V. Tochilkin, and I. M. Yachikov, Continuous Casting of Steel. Fluid Dynamics of Continuous Casting Machines: Monograph [in Russian], MGTU im. G. I. Nosova, Magnitogorsk (2014).

V. V. Tochilkin, “Upgrade of a continuous-caster tundish to improve the quality of the cast steel,” Remont, Vosstaovlenie, Moderizatsiya, No. 2, 5 – 7 (2007).

S. N. Ushakov, A. A. Khomenko, K. N. Vdovin, et al., “Developing the equipment of a steel-flow distribution system for a tundish,” Stal’, No. 3, 13 – 17 (2009).

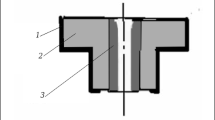

K. N. Vdovin, E. A. Melnichuk, A. V. Nefedov, et al., “Intake chamber of the tundish in a continuous slab-casting machine,” Steel in Translation, 44(3), 186 – 189 (2014).

J. Zekeli and N. El-Kadakh, “Computer-aided design (CAD–CAM-method) of a tundish,” [Russian translation] (Ed.: V. A. Kudrin). Proc. Conf. “Injection Metallurgy’86,” Metallurgiya, Moscow (1990), pp. 134 – 136.

K. Vdovin, O. A. Marochkin, and V. V. Tochilkin, “Creating a stream simulator to improve the wear resistance of refractories during the casting of steel on continuous section casters,” Refractories and Industrial Ceramics, 54(6), 435 – 437 (2014).

K. N. Vdovin, O. A. Marochkin, and V. V. Tochilkin, “Improvement of steel pouring in section CBCM, Metallurgist, 58(3/4), 306 – 309.

V. V. Tochilkin and A. M. Filatov, Pneumatic Drive for Metallurgical Manipulators: Monograph [in Russian], MGTU, Magnitogorsk (2005).

Russian Patent for Useful Model No. 38654. Tundish for the Continuous Casting of Metal, A. A. Morozov, V. F. D’yachenko, V. M. Korneev, K. N. Vdovin, V. V. Tochilkin, V. A. Osipov, V. N. Kungurtsev, and M. V. Semenov. No. 2094106951/20. Sub. 09.03.04, Publ. 10.07.04.

K. N. Vdovin, V. V. Tochilkin, and O. A. Filatova, “Improving the design of the refractories in the discharge chamber of a continuous-caster tundish,” Novye Ogneupory, No. 9, 3 – 7 (2015).

M. V. Semenov and V. V. Tochilkin, “Technique for calculating the effectiveness of the elements of the intermediate ladle of a CBCM,” Russian Engineering Research, 27(6), 347 – 349 (2007).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 2, pp. 3 – 5, February, 2016.

Rights and permissions

About this article

Cite this article

Vdovin, K.N., Tochilkin, V.V. & Tochilkin, V.V. Technologies for Controlling Flows of Steel and the Development of Refractory Structures for the Tundish of a Four-Strand Continuous Caster. Refract Ind Ceram 57, 6–8 (2016). https://doi.org/10.1007/s11148-016-9916-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-016-9916-7