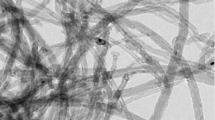

Creation of ceramics and refractories with improved physicomechanical properties is possible with use of nanomaterials in their technology. Introduction of SiC nanoparticles into a ceramic material charge by using modified filler powders is proposed. Fillers modified with tetraethoxysilane during grinding leads to powder crystal structure breakdown and SiC mechanochemical synthesis. The amount of β-SiC synthesized in this way depends on the amount of modifying additive. Results are provided for modified filler phase composition before and after heat treatment at 1000°C, and mechanochemically synthesized SiC thermal stability is established. It is shown that sintering of modified electro-corundum worsens with an increase in amount of synthesized silicon carbide nanoparticles. The difference is demonstrated in phase composition formation with heat treatment of a mixture of modified and normal finely ground electrocorundum with a sol-gel binder and firing up to 1600°C. Silicon carbide nanoparticle synthesis does not exceed 3 – 7 % in both cases. Recommendations are given for use of corundum filler with a different amount of modifying additive.

Similar content being viewed by others

References

G. D. Semchenko, Structural Ceramics and Refractories [in Russian], Shtrikh, Khar’kov (2000).

G. D. Semchenko, I. Yu. Shuteeva, A. N. Butenko, et al., Polyfunctional Purpose Sol-Gel Composition [in Russian], Raduga, Khar’kov (2011).

G. D. Semchenko, I. Yu. Shuteeva, and A. N. Borisenko, Corundum Coatings for High-Temperature Protection of Graphite from Oxidation [in Russian], Raduga, Khar’kov (2011).

G. D. Semchenko, I. N. Opryshko, and L. A. Angolenko, “Part II. Theoretical bases of low-temperature SiC synthesis from gel and practical implementation of this process in ceramic and refractory technology. 1. Phase formation during hot pressing of modified silicon carbide powder and mixtures with sintering additions, structure, and material properties,” Ogneupor. Tekhn. Keram., No. 1, 16 – 24 (2000).

G. D. Semchenko, E. E. Starolat, V. V. Kalin, and D. A. Kobyzeva, Materials of the CIS Country Scientific and Scientific-Technical Complex: Coll. Work [in Russian], NPO Botum, Odessa (1993).

G. D. Semchenko, I. N. Oryshko, L. A. Angolenko, et al., “Mechanochemical nucleus formation and new formation stability,” Novye Ogneupory, No. 2, 34 – 38 (2004).

G. D. Semchenko, Sol-Gel Process in Ceramic Technology [in Russian], AO Biznes Inform, Khar’kov (1997).

G. D. Semchenko, I. Yu. Shuteeva, and M. A. Kushchenko, “Creation of β-SiC in an intermediate layer of corundum coatings based on sol-gel binder for protecting graphite objects from oxidation,” in: Proven by Flame and Time [in Russian], Raduga, Khar’kov (2013).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 6, pp. 29 – 33, June, 2014.

Rights and permissions

About this article

Cite this article

Semchenko, G.D., Shuteeva, I.Y., Ryshchenko, M.I. et al. Formation of Material Prescribed Phase Composition from Refractory Filler Silica Powder Modified with Alkoxide and Sol-Gel Composite. Refract Ind Ceram 55, 240–243 (2014). https://doi.org/10.1007/s11148-014-9697-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-014-9697-9