Abstract

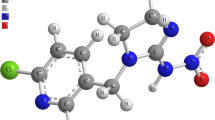

This study focuses on the utilization of mineral carbonation as a means to capture carbon dioxide (CO2) from the atmosphere. The approach involves using various composites consisting of an inert matrix with an active phase. To evaluate the efficiency of mineral carbonation for CO2 sequestration, three composites were synthesized based on calcium-rich and calcium/magnesium-rich minerals using sol–gel techniques. The results obtained from the characterization techniques used, namely X-ray diffraction, infrared spectroscopy and scanning electron microscopy, demonstrate the formation of composite materials such as calcium oxide and calcium/magnesium oxides. After the bubbling process, these techniques confirmed the formation of stable calcium and magnesium carbonates. In addition, to assess the efficiency of the synthesized composites in CO2 capture, a Bernard’s Calcimeter was used to determine the operating parameters favouring the mineral carbonation reaction. Analysing these operating parameters reveals that under atmospheric pressure and at room temperature, increasing the mass of the compound used leads to an increase in the percentage of captured CO2 up to 0.5 g, but this rate remains relatively constant when the mass is increased to 1 g. Additionally, increasing the particle size results in a higher CO2 capture rate. The initial pH of the solution plays a crucial role in promoting mineral carbonation, as an increase in the initial pH also leads to an increase in the CO2 fixation rate. It is essential for the medium to be basic, as this is one of the critical parameters contributing to the enhanced CO2 sequestration rate through the mineral carbonation method.

Similar content being viewed by others

References

Miller SA, Grubert E (2021) US industrial sector decoupling of energy use and greenhouse gas emissions under COVID: durability and decarbonization. Environ Res Commun 3:031003. https://doi.org/10.1088/2515-7620/abf0f2

Clabeaux R, Carbajales-Dale M, Ladner D, Walker T (2020) Assessing the carbon footprint of a university campus using a life cycle assessment approach. J Clean Prod 273:122600. https://doi.org/10.1016/j.jclepro.2020.122600

Dahmani J, Kharchafi A, El-Khalfaouy R et al (2022) Sequestration of carbon dioxide by a mineral residue: application on the ca-sepiolite material composite. Chem Africa 5:1703–1713. https://doi.org/10.1007/s42250-022-00444-y

Borzenkova II, Ershova AA, Zhiltsova EL, Shapovalova KO (2021) Arctic sea ice in the light of current and past climate changes. Ice Snow 61:533–546. https://doi.org/10.31857/S2076673421040106

Kuriyama A, Abe N (2018) Ex-post assessment of the Kyoto protocol quantification of CO2 mitigation impact in both annex B and non-annex B countries-. Appl Energy 220:286–295. https://doi.org/10.1016/j.apenergy.2018.03.025

Klimenko VV, Klimenko AV, Tereshin AG (2019) From Rio to Paris via Kyoto: how the efforts to protect the global climate affect the world energy development. Therm Eng 66:769–778. https://doi.org/10.1134/S0040601519110028

Yoro KO, Daramola MO (2020) Chapter 1 CO2 emission sources, greenhouse gases, and the global warming effect. In: Rahimpour MR, Farsi M, Makarem MA (eds) Advances in carbon capture. Woodhead Publishing, Sawston, pp 3–28

Rogelj J, den Elzen M, Höhne N et al (2016) Paris agreement climate proposals need a boost to keep warming well below 2 °C. Nature 534:631–639. https://doi.org/10.1038/nature18307

Seifritz W (1990) CO2 disposal by means of silicates. Nature 345:486. https://doi.org/10.1038/345486b0

Lee S, Kim JW, Chae S et al (2016) CO2 sequestration technology through mineral carbonation: an extraction and carbonation of blast slag. J CO2 Util 16:336–345. https://doi.org/10.1016/j.jcou.2016.09.003

Du Breuil C, Pasquier LC, Dipple G et al (2019) Impact of particle size in serpentine thermal treatment: implications for serpentine dissolution in aqueous-phase using CO2 in flue gas conditions. Appl Clay Sci 182:105286. https://doi.org/10.1016/J.CLAY.2019.105286

Ababou A, Kharchafi A, Taleb M, Kherbeche A (2020) CO2 carbonation on alkaline materials BT. In: Ezziyyani M (ed) Advanced intelligent systems for sustainable development (AI2SD’2019). Springer International Publishing, Cham, pp 131–143

Sanna A, Uibu M, Caramanna G et al (2014) A review of mineral carbonation technologies to sequester CO2. Chem Soc Rev 43:8049–8080. https://doi.org/10.1039/c4cs00035h

Huijgen WJJ, Witkamp GJ, Comans RNJ (2006) Mechanisms of aqueous wollastonite carbonation as a possible CO2 sequestration process. Chem Eng Sci 61:4242–4251. https://doi.org/10.1016/J.CES.2006.01.048

Béarat H, McKelvy MJ, Chizmeshya AVG et al (2006) Carbon sequestration via aqueous olivine mineral carbonation: role of passivating layer formation. Environ Sci Technol 40:4802–4808. https://doi.org/10.1021/es0523340

Wolff-Boenisch D, Galeczka IM (2018) Flow-through reactor experiments on basalt-(sea)water-CO2 reactions at 90 degrees C and neutral pH. What happens to the basalt pore space under post-injection conditions? Int J Greenh GAS Control 68:176–190. https://doi.org/10.1016/j.ijggc.2017.11.013

Pind Aradóttir ES, Hjálmarsson E (2018) CarbFix—public engagement and transparency. Energy Procedia 146:115–120. https://doi.org/10.1016/j.egypro.2018.07.015

Gíslason SR, Sigurdardóttir H, Aradóttir ES, Oelkers EH (2018) A brief history of CarbFix: challenges and victories of the project’s pilot phase. Energy Procedia 146:103–114. https://doi.org/10.1016/j.egypro.2018.07.014

Macario A, Katovic A, Giordano G et al (2005) Synthesis of mesoporous materials for carbon dioxide sequestration. Microporous Mesoporous Mater 81:139–147. https://doi.org/10.1016/j.micromeso.2005.02.002

Sánchez-Zambrano KS, Lima Duarte L, Soares Maia DA et al (2018) CO2 capture with mesoporous silicas modified with amines by double functionalization: assessment of adsorption/desorption cycles. Materials 11:887. https://doi.org/10.3390/ma11060887

Azmi AA, Aziz MAA (2019) Mesoporous adsorbent for CO2 capture application under mild condition: a review. J Environ Chem Eng 7:103022. https://doi.org/10.1016/j.jece.2019.103022

Xu Z, Jiang T, Zhang H et al (2021) Efficient MgO-doped CaO sorbent pellets for high temperature CO2 capture. Front Chem Sci Eng 15:698–708. https://doi.org/10.1007/s11705-020-1981-2

Wang K, Gu F, Clough PT et al (2020) Porous MgO-stabilized CaO-based powders/pellets via a citric acid-based carbon template for thermochemical energy storage in concentrated solar power plants. Chem Eng J 390:124163. https://doi.org/10.1016/j.cej.2020.124163

Ayub SA, Tsegab H, Rahmani O, Pour AB (2020) Potential for CO2 mineral carbonation in the paleogene segamat basalt of Malaysia. Minerals 10:1045. https://doi.org/10.3390/min10121045

Lacinska AM, Styles MT, Bateman K et al (2017) An experimental study of the carbonation of serpentinite and partially serpentinised peridotites. Front Earth Sci 5:1–20. https://doi.org/10.3389/feart.2017.00037

Matter JM, Kelemen PB (2009) Permanent storage of carbon dioxide in geological reservoirs by mineral carbonation. Nat Geosci 2:837–841. https://doi.org/10.1038/ngeo683

Stephen AL, Jenkin GRT, Styles MT et al (2013) Tracing carbon: natural mineral carbonation and the incorporation of atmospheric vs. recycled CO2. Energy Procedia 37:5897–5904. https://doi.org/10.1016/j.egypro.2013.06.515

Gadikota G, Park AA (2015) Chapter 8 accelerated carbonation of Ca- and Mg-bearing minerals and industrial wastes using CO2. In: Styring P, Quadrelli EA, Armstrong K (eds) Carbon dioxide utilisation closing the carbon cycle. Elsevier, Amsterdam, pp 115–137

Bokov D, Turki Jalil A, Chupradit S et al (2021) Nanomaterial by Sol-Gel method: synthesis and application. Adv Mater Sci Eng 2021:5102014. https://doi.org/10.1155/2021/5102014

Furlan PY, Furlan AY, Kisslinger K et al (2019) Water as the solvent in the stober process for forming ultrafine silica shells on magnetite nanoparticles. ACS Sustain Chem Eng 7:15578–15584. https://doi.org/10.1021/acssuschemeng.9b03554

Kumar S, Malik MM, Purohit R (2017) Synthesis methods of mesoporous silica materials. Mater Today Proc 4:350–357. https://doi.org/10.1016/j.matpr.2017.01.032

Shin YS, Jo MK, Cho YS, Yang SH (2022) Diffusion-controlled crystallization of calcium phosphate in a hydrogel toward a homogeneous octacalcium phosphate/agarose composite. ACS Omega 7:1173–1185. https://doi.org/10.1021/acsomega.1c05761

Kogaya Y, Furuhashi K (1988) Comparison of the calcium distribution pattern among several kinds of hard tissue forming cells of some living vertebrates. Scanning Microsc 2:2029–2043

Suresh Kumar S, Mohanavel V (2022) An overview assessment on magnesium metal matrix composites. Mater Today Proc 59:1357–1361. https://doi.org/10.1016/j.matpr.2021.12.015

Epp J (2016) 4 X-ray diffraction (XRD) techniques for materials characterization. In: Hübschen G, Altpeter I, Tschuncky R, Herrmann HG (eds) Materials characterization using nondestructive evaluation (NDE) methods. Elsevier, Amsterdam, pp 81–124

Chen Q, Hui T, Sun H et al (2020) Synthesis of magnesium carbonate hydrate from natural talc. Open Chem 18:951–961. https://doi.org/10.1515/chem-2020-0154

Chen H, Zhao C, Yang Y, Zhang P (2012) CO2 capture and attrition performance of CaO pellets with aluminate cement under pressurized carbonation. Appl Energy 91:334–340. https://doi.org/10.1016/j.apenergy.2011.09.032

Ţucureanu V, Matei A, Avram AM (2016) FTIR spectroscopy for carbon family study. Crit Rev Anal Chem 46:502–520. https://doi.org/10.1080/10408347.2016.1157013

Lamas F, Irigaray C, Oteo C, Chacón J (2005) Selection of the most appropriate method to determine the carbonate content for engineering purposes with particular regard to marls. Eng Geol 81:32–41. https://doi.org/10.1016/j.enggeo.2005.07.005

Zhang H, Shao Y, Zhang N et al (2022) Carbonation behavior of engineered cementitious composites under coupled sustained flexural load and accelerated carbonation. Mater (Basel, Switzerland) 15:6192. https://doi.org/10.3390/ma15186192

Hu L, Chen Z, Hu J (2022) Carbon sequestration, mechanical properties and carbonation kinetics of PP-fiber-reinforced cement-based composites with CO2-curing treatment. Coatings 12:1339. https://doi.org/10.3390/coatings12091339

Fagerlund J, Nduagu E, Zevenhoven R (2011) Recent developments in the carbonation of serpentinite derived Mg(OH) 2 using a pressurized fluidized bed. Energy Procedia 4:4993–5000. https://doi.org/10.1016/j.egypro.2011.02.470

Cui H, Zayat M, Levy D (2006) Effect of HCl on the PPO assisted sol-gel synthesis of olivine-type Co2SiO4 ultrafine particles. J Sol-Gel Sci Technol 40:83–87. https://doi.org/10.1007/s10971-006-8216-y

Boyadzhieva T, Koleva V, Kukeva R et al (2020) Storage performance of Mg(2+) substituted NaMnPO(4) with an olivine structure. RSC Adv 10:29051–29060. https://doi.org/10.1039/d0ra05698g

Jiang X, Tang X, Tang L et al (2019) Synthesis and formation mechanism of amorphous silica particles via sol–gel process with tetraethylorthosilicate. Ceram Int 45:7673–7680. https://doi.org/10.1016/j.ceramint.2019.01.067

Tran TN, Pham TVA, Le MLP et al (2013) Synthesis of amorphous silica and sulfonic acid functionalized silica used as reinforced phase for polymer electrolyte membrane. Adv Nat Sci Nanosci Nanotechnol 4:045007. https://doi.org/10.1088/2043-6262/4/4/045007

Imoisili PE, Ukoba KO, Jen TC (2020) Synthesis and characterization of amorphous mesoporous silica from palm kernel shell ash. Bol Soc Esp Ceram Vidr 59:159–164. https://doi.org/10.1016/j.bsecv.2019.09.006

Sanna A, Ramli I, Maroto-Valer MM (2014) Novel Na-silicates CO2 sorbents from fly ash. Energy Procedia 63:739–744. https://doi.org/10.1016/j.egypro.2014.11.081

Kamran U, Choi JR, Park S-J (2020) A role of activators for efficient CO(2) affinity on polyacrylonitrile-based porous carbon materials. Front Chem 8:1–18. https://doi.org/10.3389/fchem.2020.00710

Pardakhti M, Jafari T, Tobin Z et al (2019) Trends in solid adsorbent materials development for CO2 capture. ACS Appl Mater Interfaces 11:34533–34559. https://doi.org/10.1021/acsami.9b08487

Gao X, Yang S, Hu L et al (2022) Carbonaceous materials as adsorbents for CO2 capture: synthesis and modification. Carbon Capture Sci Technol 3:100039. https://doi.org/10.1016/j.ccst.2022.100039

Molahid VLM, Mohd Kusin F, Syed Hasan SN et al (2022) CO2 Sequestration through mineral carbonation: effect of different parameters on carbonation of Fe-rich mine waste materials. Processes 10:432

Wu L, Liu J, Shang H et al (2021) Capture CO2 from N2 and CH4 by zeolite L with different crystal morphology. Microporous Mesoporous Mater 316:110956. https://doi.org/10.1016/j.micromeso.2021.110956

Singh R, Ram Reddy MK, Wilson S et al (2009) High temperature materials for CO2 capture. Energy Procedia 1:623–630. https://doi.org/10.1016/j.egypro.2009.01.082

Farmer VC, Russell JD (1964) The infra-red spectra of layer silicates. Spectrochim Acta 20:1149–1173. https://doi.org/10.1016/0371-1951(64)80165-X

Mino L, Mandrile L, Iannarelli L et al (2020) Chapter 4.6 Vibrational spectroscopy. In: Hodoroaba VD, Unger WES, Shard AG (eds) Micro and nano technologies. Elsevier, Amsterdam, pp 457–480

Sai Bhargava Reddy M, Ponnamma D, Sadasivuni KK et al (2021) Carbon dioxide adsorption based on porous materials. RSC Adv 11:12658–12681. https://doi.org/10.1039/d0ra10902a

Ben Baaziz M, Ghibate R, Merzougui A et al (2023) Synthesis, structural characterizations and vibrational spectroscopy studies of Ba2 −xPbxSr(PO4)2; (0 ≤ x ≤ 2). Chem Pap 77:2905–2915. https://doi.org/10.1007/s11696-023-02674-x

Chen Y, Liu P, Yu Z (2018) Effects of environmental factors on concrete carbonation depth and compressive strength. Mater (Basel, Switzerland) 11:2167. https://doi.org/10.3390/ma11112167

Ho H-J, Iizuka A, Shibata E et al (2020) CO2 utilization via direct aqueous carbonation of synthesized concrete fines under atmospheric pressure. ACS Omega 5:15877–15890. https://doi.org/10.1021/acsomega.0c00985

Esquivias L, Morales-Flórez V, Santos A (2016) Xerogels, Aerogels, and Aerogel/mineral composites for CO2 sequestration. In: Klein L, Aparicio M, Jitianu A (eds) Handbook of sol-gel science and technology. Springer International Publishing, Cham, pp 1–20

Neeraj YS (2020) Carbon storage by mineral carbonation and industrial applications of CO2. Mater Sci Energy Technol 3:494–500. https://doi.org/10.1016/j.mset.2020.03.005

Kwon S, Fan M, DaCosta HFM et al (2011) Chapter 10 CO2 sorption. In: Bell DA, Towler BF, Fan MBT (eds) Coal gasification and its applications. William Andrew Publishing, Boston, pp 293–339

Estrada-Mendoza TA, Burgess TF, Edirisinghe DS et al (2022) Silicate as a versatile matrix for the aqueous synthesis of metal sulfide nanoparticles. Chem Methods. https://doi.org/10.1002/cmtd.202100077

Gadikota G (2021) Carbon mineralization pathways for carbon capture, storage and utilization. Commun Chem 4:1–5. https://doi.org/10.1038/s42004-021-00461-x

Penel G, Leroy G, Rey C, Bres E (1998) MicroRaman spectral study of the PO4 and CO3 vibrational modes in synthetic and biological apatites. Calcif Tissue Int 63:475–481. https://doi.org/10.1007/s002239900561

Ylmén R, Jäglid U (2013) Carbonation of portland cement studied by diffuse reflection fourier transform infrared spectroscopy. Int J Concr Struct Mater 7:119–125. https://doi.org/10.1007/s40069-013-0039-y

Daval D (2018) Carbon dioxide sequestration through silicate degradation and carbon mineralisation: promises and uncertainties. Npj Mater Degrad 2:1–4. https://doi.org/10.1038/s41529-018-0035-4

Klitou P, Rosbottom I, Karde V et al (2022) Relating crystal structure to surface properties: a study on quercetin solid forms. Cryst Growth Des 22:6103–6113. https://doi.org/10.1021/acs.cgd.2c00707

Huijgen WJJ, Witkamp GJ, Comans RNJ (2005) Mineral CO2 sequestration by steel slag carbonation. Environ Sci Technol 39:9676–9682. https://doi.org/10.1021/es050795f

Snæbjörnsdóttir SÓ, Sigfússon B, Marieni C et al (2020) Carbon dioxide storage through mineral carbonation. Nat Rev Earth Environ 1:90–102. https://doi.org/10.1038/s43017-019-0011-8

Blain S, Quéguiner B, Armand L et al (2007) Effect of natural iron fertilization on carbon sequestration in the Southern Ocean. Nature 446:1070–1074. https://doi.org/10.1038/nature05700

Hua K, Wang D, Guo X, Guo Z (2014) Carbon sequestration efficiency of organic amendments in a long-term experiment on a vertisol in Huang-Huai-Hai plain China. PLoS ONE 9:e108594. https://doi.org/10.1371/journal.pone.0108594

Meng D, Unluer C, Yang EH, Qian S (2022) Carbon sequestration and utilization in cement-based materials and potential impacts on durability of structural concrete. Constr Build Mater 361:129610. https://doi.org/10.1016/j.conbuildmat.2022.129610

Rathnaweera TD, Ranjith PG, Perera MSA (2016) Experimental investigation of geochemical and mineralogical effects of CO2 sequestration on flow characteristics of reservoir rock in deep saline aquifers. Sci Rep 6:19362. https://doi.org/10.1038/srep19362

Björklöf T, Zevenhoven R (2012) Energy efficiency analysis of CO2 mineral sequestration in magnesium silicate rock using electrochemical steps. Chem Eng Res Des 90:1467–1472. https://doi.org/10.1016/j.cherd.2012.02.001

Pugaev D, Nicol M, Senanayake G (2011) The mechanisms of the passivation of sulfide minerals in oxidative leaching processes. In: 6th Southern African base metals conference 2011, pp 39–48

Miao E, Du Y, Wang H et al (2021) Experimental study and kinetics on CO2 mineral sequestration by the direct aqueous carbonation of pepper stalk ash. Fuel 303:121230. https://doi.org/10.1016/j.fuel.2021.121230

Liu RS, Shi XD, Wang CT et al (2021) Advances in post-combustion CO2 capture by physical adsorption: from materials innovation to separation practice. Chemsuschem 14:1428–1471. https://doi.org/10.1002/cssc.202002677

Xie H, Wang J, Hou Z et al (2016) CO2 sequestration through mineral carbonation of waste phosphogypsum using the technique of membrane electrolysis. Environ Earth Sci 75:1216. https://doi.org/10.1007/s12665-016-6009-3

Ozdemir E (2016) Role of pH on CO2 sequestration in coal seams. Fuel 172:130–138. https://doi.org/10.1016/j.fuel.2016.01.021

Azdarpour A, Karaei MA, Hamidi H et al (2017) CO2 sequestration using red gypsum via pH-swing process: effect of carbonation temperature and NH4HCO3 on the process efficiency. Int J Miner Process 169:27–34. https://doi.org/10.1016/j.minpro.2017.09.014

Park AHA, Fan LS (2004) CO2 mineral sequestration: physically activated dissolution of serpentine and pH swing process. Chem Eng Sci 59:5241–5247. https://doi.org/10.1016/j.ces.2004.09.008

Bergaya F, Theng BKG, Lagaly G (2006) Chapter 1 general introduction: clays, clay minerals and clay science. In: Bergaya F, Lagaly G (eds) Handbook of clay science. Elsevier, Amsterdam

Li Q, Ma Y, Chen J et al (2023) The negative effect of the high pH of waste concrete in constructed wetlands on COD and N removal. J Water Process Eng 51:103356. https://doi.org/10.1016/j.jwpe.2022.103356

Acknowledgements

The authors thank the Ministry de University, Research and Innovation of the Junta de Andalucía (Spain), (Group FQM-393) for the financial support provided to carry out this research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kharchafi, A., Dahmani, J., Tanji, K. et al. The effect of different synthetic methods of silica-based matrices compounds on the CO2 sequestration. Reac Kinet Mech Cat 136, 1983–2002 (2023). https://doi.org/10.1007/s11144-023-02452-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-023-02452-6