The mechanisms of phase interactions in granular media were studied to elaborate the results obtained previously at the Nekrasov Iron and Steel Institute of the National Academy of Sciences of Ukraine to establish analytical methods for predicting the strength acquired by compacts produced from fine-grained materials. This allowed the development of theoretical ideas on the adhesive bonds formed in pellets to propose local models of adhesive processes for two basic particle interaction schemes: ‘particle + particle’ and ‘particle + liquid phase + particle’. Types of adhesion processes occurring simultaneously, as well as their nature and combinations, were established for each local model. This provided grounds for selecting factors that governed the formation of adhesive bonds and indicators that determined the rate of their development. Experimental studies were conducted in laboratory facilities of the Nekrasov Iron and Steel Institute for assessing the nature and extent of influence exerted by the selected factors on the strength of compacts. The experimental results were used to establish analytical dependences to describe the strength as a function of integral indicators of adhesive bond formation, taking into account the pelletizing pressure. These dependencies underlay the proposed method for predicting the strength of pellets produced from fine-grained materials with zero moisture in the range of pelletizing pressures from 50 to 220 MPa. The proposed computational and analytical method allowed determining the strength of pellets with high accuracy. Thus, it can be successfully used to develop processes for the production of pellets and the development of compaction equipment. The proposed method may be developed further through the expansion of its capabilities by predicting the strength of compacts considering liquid bonding agents introduced into the starting charge.

Similar content being viewed by others

References

B.N. Maymur, A.Yu. Khudyakov, V.I. Petrenko, S.V. Vashchenko, and K.V. Baiul, “Pelletizing of metallurgical feedstock. Relevance and ways for developing the method,” in: Bulletin of Scientific and Technical and Economic Information. Ferrous Metallurgy, Issue 1, 74–81 (2016).

S.V. Vashchenko, A.Yu. Khudyakov, K.V. Baiul, and Yu.S. Semenov, “Selecting the batch composition in briquetting. Steel in translation,” Allerton Press. Inc., 48, No. 8, 509–512 (2018).

K.V. Baiul, “Synthesis of roller press rational design for composite solid fuel production,” Probl. Reg. Energ., 43, No. 2, 103–116 (2019).

V.A. Noskov and S.V. Vashchenko, “Analysis of methods and devices for compacting fine-grained feedstock,” in: Fundamental and Applied Issues of Ferrous Metallurgy (Collected Scientific Papers) [in Russian], Inst. Chern. Metall. NAN Ukrainy, Dnepropetrovsk (2005), Issue 10, pp. 313–320.

A.Yu. Khudyakov and S.V. Vashchenko, “Analysis of known dependencies and construction of new compaction equations for fine materials of the mining and metallurgical complex,” Refract. Indu. Ceram., 60, No. 6, 618–626 (2020).

Yu.S. Semenov, V.V. Gorupakha, A.M. Kuznetsov, I.Yu. Semion, E.I. Schumel’chik, S.V. Vashchenko, and A. Yu. Khudyakov, “Experience of using manganese-containing materials in blast-furnace charge,” Metallurgist, 63, No. 9–10, 1013–1023 (2020).

S.V. Vashchenko, B.N. Maimur, V.I. Petrenko, K.V. Baiul, A.Yu. Khudyakov, N.A. Solodkaya, and E.B. Prokudina, “Examining the conditions and mechanisms of imparting strong bonds in compacts in pelletizing of fine-grained feedstock,” in: Fundamental and Applied Issues of Ferrous Metallurgy (Collected Scientific Papers) [in Russian], Inst. Chern. Metall. NAN Ukrainy, Naukova Dumka, Kyiv (2015), Issue 30, pp. 347–362.

N.A. de Bruyne and R. Houwink (eds.), Adhesion and Adhesives, Elsevier, Houston–Amsterdam (1951).

B.V. Deryagin, N. A. Krotova, and V. P. Smilga, Adhesion of Solids [in Russian], Nauka, Moscow (1973), p. 280.

I.G. Kaplan, Introduction to the Theory of Molecular Interactions [in Russian], Nauka, Moscow (1982), p. 312.

A.D. Zimon, Adhesion of Dust and Powders [in Russian], 2nd ed., Khimiya, Moscow (1976), p. 432.

A.D. Zimon, Adhesion of Liquid and Wetting [in Russian], Khimiya, Moscow (1974), p. 416.

Cohesion. Physical Encyclopedia [in Russian], Bolshaya Rosiyskaya Entsyklopedia, Moscow (1992), p. 39.

J.N. Israelachvili, Intermolecular and Surface Forces, Academic Press (2011).

O.V. Almyasheva, V.V. Gusarov, and O.A. Lebedev, Surface Phenomena: Textbook [in Russian], Izd. SPbGETU LETI, Saint-Petersburg (2004), p. 28.

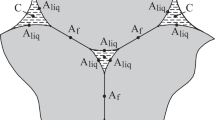

S.V. Vashchenko, A.Yu. Khudyakov, K.V. Baiul, and Yu.S. Semenov, “Development of local models for adhesive bonding of particles in pelletizing,” Stal, No. 5, 4–8 (2019).

B.N. Maymur, I.G. Muravieva, V.I. Petrenko, and S.V. Vashchenko, “Effect of the properties of fine-grained feedstock materials on their compaction in roller pellet presses,” Fundamental and Applied Issues of Ferrous Metallurgy (Collected Scientific Papers) [in Russian], Inst. Chern. Metall. NAN Ukrainy, Naukova Dumka, Kyiv (2014), Issue 28, pp. 310–325.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkova Metallurgiya, Vol. 60, Nos. 3–4 (538), pp. 148–159, 2021.

Rights and permissions

About this article

Cite this article

Vashchenko, S., Khudyakov, A., Baiul, K. et al. Method for Predicting the Strength of Pellets Produced from Dry Fine-Grained Materials. Powder Metall Met Ceram 60, 247–256 (2021). https://doi.org/10.1007/s11106-021-00233-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-021-00233-1