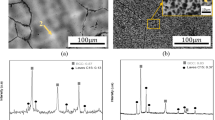

In this study, Ta–W–Ti–Al multialloys were prepared by spark plasma sintering (SPS) as a new powder metallurgy technology based on discharge activation and thermoplastic deformation process. The oxidation behavior of the as-obtained sintered alloys were investigated under 1000 and 1200°C in air atmosphere. Microstructures and phase compositions of alloys and oxides were analyzed using various analytical methods, such as X-ray diffraction (XRD), scanning electron microscopy (SEM) equipped with energy dispersive spectroscopy (EDS), and backscatter electron microscopy (BSE). The sintered samples possessed relative densities reaching up to 98% with achievable densification. The densities of all specimens with high Ti contents exceeded 100%, suggesting the great impact of Ti addition on liquid-phase precipitation. Intermetallic compounds were formed in Ta–W–Al alloys, and samples with high Ti contents displayed grain boundary phases rich in titanium and oxygen. The addition of Ti and Al effectively improved the oxidation resistance of the resulting alloys. A protective alumina layer was formed after oxidation at 1000°C that made oxidation kinetics of the alloys obeying pseudo-parabolic laws. At the oxidation temperature of 1200°C, Al2O3 reacted with Ta2O5 to form the AlTaO4 alloy with reduced protective effect. The mass gain in the alloys after oxidation at 1200°C for 4 h was about 7 times higher compared to processing at 1000°C.

Similar content being viewed by others

References

T. Laurila, K. Zeng, J.K. Kivilahti, J. Molarius, T. Riekkinen, and I. Suni, “Tantalum carbide and nitride diffusion barriers for Cu metallization,” Microelect. Eng., 60, No. 1–2, 71–80 (2001).

S. Li, H.S. Park, M.H. Liang, T.H. Yip, and O. Prabhakar, “Effects of Cu diffusion behaviors on electronic property of Cu/Ta/SiO2/Si structure,” Thin Sol. Films., 462, No. 3, 192–196 (2004).

T. Balaji, R. Govindaiah, M.K. Sharma, Y. Purushotham, A. Kumar, and T.L. Prakash, “Sintering and electrical properties of tantalum anodes for capacitor applications,” Mater. Let., 56, No. 4, 560–563 (2002).

K. Shimizu, K. Kobayashi, G.E. Thompson, and G.C. Wood, “The apparent induction period for γ-Al2O3 development in thermal oxide films on aluminium,” Oxid. Metals, 36, No. 1–2, 1–13 (1991).

F.J. Harvey, “High temperature oxidation of tungsten wires in O2–Ar mixtures,” Metal. Transac., 4, No. 6, 1513–1517 (1973).

A. Dollár and S. Dymek, “Microstructure and high temperature mechanical properties of mechanically alloyed Nb3Al-based materials,” Intermetallics, 11, No. 4, 341–349 (2003).

Y. Murayama and S. Hanada, “High temperature strength, fracture toughness and oxidation resistance of Nb–Si–Al–Ti multiphase alloys,” Sci. Technol. Adv. Mater., 3, No. 2, 145–156 (2002).

V.K. Sikka and E.A. Loria, “Characteristics of a multicomponent Nb–Ti–Al alloy via industrial-scale practice,” Mater. Sci. Eng.: A, 239–240, No. 97, 745–751 (1997).

Franz Müller, Bronislava Gorr, Hans-Jürgen Christ, Hans Chen, Alexander Kauffmann, and Martin Heilmaier, “Effect of microalloying with silicon on high temperature oxidation resistance of novel refractory high-entropy alloy Ta–Mo–Cr–Ti–Al,” Mater. High Temp., 1–9 (2017).

Jiaxin Li, Yuhong Chen, Yongquan Li, Zhangjun Bai, and Kang Wang, “Influence of aluminum addition on oxidation resistance of Ta–W alloy,” Powder Metal., 62, No. 5, 322–330 (2019).

Li Dan, Yi Dan-qing, Zhang Xia, and Yang Jie, “Oxidation behavior of Nb–38Ti–11Si–3Al novel high temperature alloy,” Mater. Sci. Eng. Powder Metal. [in Chinese], 11, No. 3, 149–154 (2006).

V.T. Witusiewicz, A.A. Bondar, U. Hecht, J. Zollinger, V. Petyukh, O. Fomichov, V.M. Voblikov, S. Rex, “Experimental study and thermodynamic re-assessment of the binary Al–Ta system,” Intermetallics, 18, No. 1, 92–106 (2010).

Z. Lin, E.J. Lavernia, and F.A. Mohamed, “High-temperature deformation in a Ta–W alloy,” Acta Mater. 47, No. 4, 1181–1194 (1999).

Vojtech Dalibor and Popela Tomá, “Structure and high-temperature oxidation of Ti–Al–Nb and Ti–Al–Ta intermetallics,” Key Eng. Mater., 465, 227–230 (2011).

D.T. Murphy, V. Fung, and S. Schmid, “Structural Investigation of the Incommensurate Modulated Ta2O5 · Al2O3 System,” Aperiodic Crystals, Springer, Netherlands (2013).

H. Mitsui, H. Habazaki, K. Hashimoto, and S. Mrowec, “The sulfidation and oxidation behavior of sputterdeposited Al–Ta alloys at high temperatures,” Corros. Sci., 39, No. 1, 59–76 (1997).

Xu Liang-liang, Zhang Xia, Xiao Lai-rong, and Yi Dan-qing, “Oxidation behavior of Nb–Ti–Al alloys at high temperature,” Rare Metals Cemented Carbides [in Chinese], 34, No. 4, 6–10 (2006).

Zhao Yongqing, Qu Henglei, Zhu Kangying, Wu Huan, and Zhou Lian, “Oxidation and peel-off mechanisms of oxide layer of the highly stabilized β type burn resistant alloy Ti40” [in Chinese], Rare Metal Mater. Eng., 30, No. 1, 35–39 (2001).

Li Meiquan, High Temperature Corrosion of Metals [in Chinese], Metallurgical Industry Press, Beijing (2001).

Acknowledgments

This work was supported financially by National Natural Science Foundation of China (No. 51464001).

Author information

Authors and Affiliations

Corresponding author

Additional information

Published in Poroshkova Metallurgiya, Vol. 59, Nos. 11–12 (536), pp. 50–60, 2020.

Rights and permissions

About this article

Cite this article

Zhangjun, B., Yuhong, C., Lu, L. et al. Oxidation Behavior of Ta–W–Ti–Al Multialloys Prepared by Spark Plasma Sintering. Powder Metall Met Ceram 59, 651–660 (2021). https://doi.org/10.1007/s11106-021-00200-w

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-021-00200-w