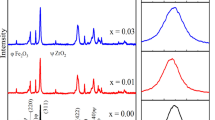

The paper examines the impact of heating temperature and isothermal holding time during sintering in a vacuum on the phase composition, structure, and mechanical properties of Fe3Al iron aluminide synthesized from a mixture of iron and aluminum powders. Dilatometric studies have shown the complexity of occurring changes in the density of the billets during sintering. First, the porosity increases from 15% in the initial billet to 45% during sintering at 950°C, and after decreases to 5% at a sintering temperature of 1450°C. The synthesis of intermetallic compounds at powder mixture heating was examined by the X-ray diffraction method. It was shown that up to 30% of intermetallic compound Fe2Al5 is formed during an hour-long isothermal holding at 600°C. Increasing the holding time to 3 hours or temperature to 950°C results in the formation and gradual growth of FeAl (B2) aluminide content. With a further increase of sintering temperature up to 1450°C, the amount of A2 phase becomes bigger, and concentration of iron and aluminum in it approaches to stoichiometric ratio Fe3Al. The mechanical properties of iron aluminide intensify with increasing sintering temperature, especially rapidly after sintering at 1450°C, when planar pores close and perfect interparticle contacts form.

Similar content being viewed by others

References

S.C. Deevi and V.K. Sikka, “Nickel and iron aluminides: an overview on properties, processing, and applications,” Intermetallics, 4, No. 5, 357−375 (1996).

J. Wang, J. Xing, Z. Qiu, X. Zhi, and L. Cao, “Effect of fabrication methods on microstructure and mechanical properties of Fe3Al-based alloys,” J. Alloys Compds., 488, 117–122 (2009).

L.M. Peng, H. Li, J.H. Wang, and M. Gong, “High strength and high fracture toughness ceramic−iron aluminide (Fe3Al) composites,” Mater. Letters, 60, 883–887 (2006).

M. Zamanzade, A. Barnoush, and C. Motz, “A review on the properties of iron aluminide intermetallics,” Crystals., 6, No. 10, 1–29 (2016).

N. S. Stoloff, “Iron aluminides: present status and future prospects,” Mater. Sci. Eng. A., 258, 1–14 (1998).

C.T. Liu, E.P. George, P.J. Maziasz, and J.H. Schneibel, “Recent advances in B2 iron aluminide alloys: deformation, fracture and alloy design,” Mater. Sci. Eng., A258, 84−98 (1998).

X.Q. Yu and Y.S. Sun, “Hot working of Fe3Al based alloy,” Mater. Sci. Technol., 20, 339−342 (2004).

B. Voyzelle and J. D. Boyd, “High-temperature deformation behaviour of Fe3Al,” Materials Science and Engineering A., 258, 243−248 (1998).

E. Godlewska, S. Szczepanik, R. Mania, J. Krawiarz, and S. Kozinski, “FeAl materials from intermetallic powders,” Intermetallics, 11, No. 4, 307−312 (2003).

Q. He, C. Jia, and J. Meng, “Influence of iron powder particle size on the microstructure and properties of Fe3Al intermetallics prepared by mechanical alloying and spark plasma sintering,” Mater. Sci. Eng. A, 428, 314–318 (2006).

X. Q. Yu and Y.S. Sun, “Hot working of Fe3Al based alloy,” Mater. Sci. Technol., 20, 339–342 (2004).

H. Song, Y. Wu, C. Tang, S. Yuan, Q. Gong, and J. Liang, “Microstructure and mechanical properties of feal intermetallics prepared by mechanical alloying and hot-pressing,” Tsinghua Sci. Technol., 14, No. 3, 300–306 (2009).

G.A. Bagliuk, A.I. Tolochin, A.V. Tolochina, R.V. Iakovenko, and V.S. Kurikhin, “Hot forging of powdered Fe3Al intermetallic alloys,” Mater. Sci. Non-Equilibrium Phase Transform., 1, Issue 2, 53–57 (2015).

S. Gedevanishvili and S.C. Deevi, “Processing of iron aluminides by pressureless sintering through Fe + Al elemental route,” Mater. Sci. Eng. A, 325, 163–176 (2002).

H. Gao, Y. He, P. Shen, J. Zou, N. Xu, Y. Jiang, B. Huang, and C.T. Liu, “Porous FeAl intermetallics fabricated by elemental powder reactive synthesis,” Intermetallics, 17, 1041–1046 (2009).

P. Novak, A. Michalcova, I. Marek, M. Mudrova, K. Saksl, J. Bednarcik, P. Zikmund, and D. Vojtech, “On the formation of intermetallics in Fe–Al system—an in-situ XDR study,” Intermetallics, 32, 127–136 (2013).

H.Z. Kang and C.T. Hu, “Swelling behavior in reactive sintering of Fe–Al mixtures,” Mater. Chem. Physics., 88, 264–272 (2004).

B. Sundman, I. Ohnuma, N. Dupin, U.R. Kattner, and S.G. Fries, “An assessment of the entire Al–Fe system including D03 ordering,” Acta Mater., 57, Issue 10, 2896–2908 (2009).

G.V. Kirik, O.P. Gaponova, V.B. Tarelnyk, O.M. Myslyvchenko, and B. Antoszewski, “Quality analysis of aluminized surface layers produced by electrospark deposition,” Powder Metall. Met. Ceram., 56, No. 11– 12, 688–696 (2018).

D.E. Alman, J.A. Hawk, J.H. Tylczak, C.P. Dogan, and R.D. Wilson, “Wear of iron–aluminide intermetallic-based alloys and composites by hard particles,” Wear, 251, 875–884 (2001).

H.E. Maupin, R.D. Wilson, and J.A. Hawk, “An abrasive wear study of ordered Fe3Al,” Wear, 159, 241–247 (1992).

V.V. Skorokhod and S.M. Solonin, Physical Metallurgy Properties of Sintering, Moscow (1984), pp. 158.

G.A. Baglyuk, A.I. Tolochin, A.V. Tolochina, R.V. Iakovenko, A.N. Gripachevckii, and M.E. Golovkova, “Effect of process conditions on the structure and properties of the hot-forged Fe3Al intermetallic alloy,” Powder Metall. Met. Ceram., 55, No. 5–6, 297–305 (2016).

G.A. Baglyuk, A.I. Tolochin, A.V. Tolochina, R.V. Iakovenko, V.K. Kud, Ya.I. Evich, and A.N. Gripachevckii, Influence of titanium diboride on structure and properties of hot-forged Fe3Al intermetallic alloy,” Naukovi Notatky, 50, 8–17 (2015).

Yu.N. Podrezov, V.A. Nazarenko, A.V. Vdovichenko, V.I. Danilenko, O.S. Koryak, and Ya.I. Evich, “Mechanical properties of powder titanium at different production stages. III. Contact formation in powder titanium based on examination of mechanical properties in sintering,” Powder Metall. Met. Ceram., 48, No. 3–4, 201–210 (2009).

Yu.N. Podrezov, V.A. Nazarenko, A.V. Laptev, A.I. Tolochin, V.I. Danilenko, Ya.I. Evich, and O.S. Koryak, “Mechanical properties of powder titanium at different production stages. IV. Mechanical properties and contact formation in powder titanium produced by dynamic hot pressing,” Powder Metall. Met. Ceram., 48, No. 5–6, 295–301 (2009).

O.V. Mikhailov and M.B. Shtern, “Considering stress and compaction multimodulus behavior in the theory of plasticity of porous bodies,” Powder Metall. Met. Ceram., No. 5, 17–23 (1984).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkova Metallurgiya, Vol. 59, Nos. 3–4 (532), pp. 42–54, 2020.

Rights and permissions

About this article

Cite this article

Tolochyn, O., Tolochyna, O., Bagliuk, H. et al. Influence of Sintering Temperature on the Structure and Properties of Powder Iron Aluminide Fe3Al. Powder Metall Met Ceram 59, 150–159 (2020). https://doi.org/10.1007/s11106-020-00150-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-020-00150-9