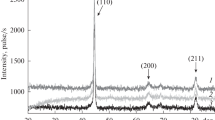

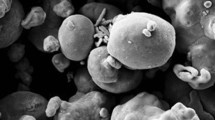

The mechanical (hardness and elastic modulus) and tribological (friction force and wear rate) properties of the Fe–Cu–Ni–Sn–VN composites produced by cold pressing and subsequent vacuum hot pressing at different temperatures are studied. The starting iron, copper, nickel, and tin powders have 5–50 μm particles and the vanadium nitride powder has 0.1–0.7 μm particles. When vacuum hot pressing temperature rises from 800 to 1000°C, the hardness increases from 3.75 to 5.37 GPa and the elastic modulus decreases from 176 to 125 GPa. As a result, the friction force reduces from 115 to 80 mN and the wear rate from 1.93 ∙ 10–5 to 0.45 ∙ 10–5 mm3 ∙ N–1 ∙ m–1. The factors promoting improvement of the mechanical and tribological properties of the sintered composites are discussed. In particular, the main factor improving the mechanical properties is that the grains are refined from 5–50 μm to 20–400 nm through the α → γ → α transformation when VN dissolves in α-Fe. In this case, the composite consists of a supersaturated solid solution of nitrogen and vanadium in α-iron, intermetallic Cu9NiSn3, and primary and secondary particulate vanadium nitride phases. A relationship between the structure and mechanical and tribological properties is established. The H/E and H3/E2 parameters that describe the elastic strain resistance and plastic strain resistance correlate with the wear resistance. The sintered composites are regarded as promising materials for developing a new generation of diamond-containing composites for stone processing industry.

Similar content being viewed by others

References

V.A. Mechnik, “Diamond–Fe–Cu–Ni–Sn composites with predictably stable characteristics,” Fiz. Khim. Mekh. Mater., No. 5, 34–42 (2012).

A.A. Zaitsev, D.A. Sidorenko, E.A. Levashov, V.V. Kurbatkina, S.I. Rupasov, and P.V. Sevastianov, “Development and use of a precipitation-strengthened Cu–Ni–Fe–Sn alloy matrix for hardmetal cutting tools,” Sverkhtverd. Mater., No. 4, 75–88 (2012).

D.A. Sidorenko, A.A. Zaitsev, A.N. Kirichenko, E.A. Levashov, V.V. Kurbatkina, P.A. Loginov, S.I. Rupasov, and V.A. Andreev, “Interaction of diamond grains with nanosized alloying agents in metal–matrix composites as studied by Raman spectroscopy,” Diamond Relat. Mater., No. 38, 59–62 (2013).

V.A. Mechnik, “Production of diamond–(Fe–Cu–Ni–Sn) composites with high wear resistance,” Powder Metall. Met. Ceram., 52, No. 9–10, 577–587 (2014).

V.A. Mechnik, N.A. Bondarenko, N.O. Kuzin, and B.A. Lyashenko, “Role of structurization in the mechanical properties of diamond–(Fe–Cu–Ni–Sn) composites,” Trenie Iznos, 37, No. 4, 482–490 (2016).

Z. Nitkiewicz and M. Swierzy, “Tin influence on diamond-metal matrix hot pressed tools for stone cutting,” J. Mater. Proc. Tech., 175, No. 1–3, 306–315 (2006).

E. Gevorkyan, V. Mechnik, N. Bondarenko, R. Vovk, S. Lytovchenko, V. Chishkala, and O. Melnik, “Peculiarities of obtaining diamond–(Fe–Cu–Ni–Sn) composite materials by hot pressing,” Funct. Mater., No. 24, 31–45 (2017).

Janusz Konstanty, Powder Metallurgy Diamond Tools, Oxford, UK (2005).

V.A. Aleksandrov, N.A. Alekseenko, and V.A. Mechnik, “Study of force and energy parameters in the cutting of granite with rotary diamond saws,” Sverkhtverd. Mater., No. 6, 35–39 (1984).

A.N. Zhukovskii, A.L. Maistrenko, V.A. Mechnik, and N.A. Bondarenko, “Stress–strain state of the matrix near the diamond grains subjected to normal and tangential loads. Part 1. Model,” Trenie Iznos, 23, No. 3, 146–153 (2002).

A.N. Zhukovskii, A.L. Maistrenko, V.A. Mechnik, and N.A. Bondarenko, “Stress–strain state of the matrix near the diamond grains subjected to normal and tangential loads. Part 2. Analysis,” Trenie Iznos, 23, No. 4, 393–396 (2002).

V.A. Aleksandrov, A.N. Zhukovskii, and V.A. Mechnik, “Temperature field and wear of inhomogeneous diamond disk in convective heat transfer. Part 1,” Trenie Iznos, 15, No. 1, 27–35 (1994).

V.A. Aleksandrov, A.N. Zhukovskii, and V.A. Mechnik, “Temperature field and wear of inhomogeneous diamond disk in convective heat transfer. Part 2,” Trenie Iznos, 15, No. 2, 196–201 (1994).

V.A. Dutka, V.M. Kolodnitskyi, S.D. Zabolotny, I.A. Sveshnikov, and V.A. Lukash, “Modeling the temperature level in rock cutting components of drilling bits,” Sverkhtverd. Mater., No. 2, 66–73 (2004).

V.A. Dutka, V.M. Kolodnitskyi, O.V. Melnichuk, and S.D. Zabolotny, “Mathematical model of thermal processes in interaction of rock cutting components of drilling bits with rock masses,” Sverkhtverd. Mater., No. 1, 67–77 (2005).

V.A. Aleksandrov and V.A. Mechnik, “Effect of the thermal conductivity of diamonds and heat exchange coefficient on the contact temperature and wear of cutting wheels,” Trenie Iznos, 14, No. 6, 1115–1117 (1993).

V.A. Aleksandrov, A.N. Zhukovskii, and V.A. Mechnik, “Temperature field, thermoelastic state, and wear of diamond wheel in cutting with cooling. Part 1,” Trenie Iznos, 12, No. 2, 210–218 (1991).

V.A. Aleksandrov, A.N. Zhukovskii, and V.A. Mechnik, “Temperature field, thermoelastic state, and wear of diamond wheel in cutting with cooling. Part 2,” Trenie Iznos, 12, No. 3, 417–427 (1991).

A.A. Zaitsev, D.A. Sidorenko, E.A. Levashov, V.V. Kurbatkina, V.A. Andreev, and S.I. Rupasov, “Diamond tools for cutting highly reinforced concrete with a nanoparticle-strengthened metallic matrix,” Sverkhtverd. Mater., No. 6, 78–89 (2010).

V.A. Mechnik, “Structurization in the diamond–Fe–Cu–Ni–Sn–CrB2 system,” Fiz. Khim. Mekh. Mater., No. 1, 85–92 (2013).

V.A. Mechnik, “Effect of hot recompaction parameters on the structure and properties of diamond–(Fe–Cu–Ni–Sn–CrB2) composites,” Powder Metall. Met. Ceram., 52, No. 11–12, 709–721 (2014).

V.N. Kolodnitskyi and O.V. Bagirov, “On structurization of diamond-containing composites used in drilling and stone-processing tools (Overview),” Sverkhtverd. Mater., No. 1, 3–26 (2017).

V.A. Mechnik, N.A. Bondarenko, N.O. Kuzin, and E.S. Gevorkian, “Effect of VN additions on the structure and service properties of diamond–(Fe–Cu–Ni–Sn) composites,” Trenie Iznos, 39, No. 2, 101–107 (2018).

S. Zhang, X. L. Bui, J. Jiang, and X. Li, “Microstructure and tribological properties of magnetron sputtered nc-TiC/a-C nanocomposites,” Surf. Coat. Technol., 198, 206–211 (2005).

B.K. Tay, Y.H. Cheng, X.Z. Ding, S.P. Lau, X. Shi, G.F. You, and D. Sheeja, “Hard carbon nanocomposite films with low stress,” Diamond Relat. Mater., 10, 1082–1087 (2001).

D.G. Teer, “New solid lubricant coatings,” Wear, 251, 1068–1074 (2001).

Z.Z. Valiev and I.V. Aleksandrov, Bulk Nanostructured Materials [in Russian], IKTs Akademkniga, Moscow (2007).

Yu.I. Golovin, Introduction to Nanoengineering [in Russian], Mashinostroenie, Moscow (2007).

J. Musil, “Tribological and mechanical properties of nanocrystalline n-TiC/a-C nanocomposite thin films,” J. Vac. Sci. Technol. A, 28, No. 2, 244–249 (2010).

H. Gleiter, “Nanostructured materials: basic concepts and microstructure,” Acta Mater., 48, 1–29 (2000).

H. Gleiter, “Materials with ultrafine microstructures: Retrospectives and perspectives,” Nanostruct. Mater., No. 1, 1–19 (1992).

A.I. Gusev, Nanomaterials, Nanostructures, and Nanotechnologies [in Russian], Fizmatlit, Moscow (2009), p. 416.

W.U. Zhiwei, J. Zhang, Yi Chen, and M. Liang, “Effect of rare earth addition on microstructural, mechanical and electrical characteristics of Cu–6% Fe microcomposites,” J. Rare Earths, 27, No. 1, 87–91 (2009).

L. He and E. Ma, “Processing and microhardness of bulk Cu–Fe,” Nanostruct. Mater., 7, No. 3, 327–339 (1996).

N.A. Akhmadeev, N.P. Kobelev, R.R. Mulyukov, Ya.M. Soifer, and R.Z. Valiev, “The effect of heat treatment on the elastic and dissipative properties of copper with the submicrocrystalline structure,” Acta Metall. Mater., 41, No. 4, 1041–1046 (1993).

A.I. Gusev, “Effects of the nanocrystalline state in solids,” Fiz. Usp., 41, 49–76 (1998).

A. Robertson, U. Erb, and G. Palumbo, “Practical applications for electrodeposited nanocrystalline materials,” Nanostruct. Mater., 12, No. 5–8, 1035–1040 (1999).

V.A. Mechnik, N.A. Bondarenko, S.N. Dub, V.M. Kolodnitskyi, Yu.V. Nesterenko, N.O. Kuzin, I.M. Zakiev, and E.S. Gevorkyan, “A study of microstructure of Fe–Cu–Ni–Sn and Fe–Cu–Ni–Sn–VN metal matrix for diamond containing composites,” Mater. Charact., 146, 209–216 (2018).

V.A. Mechnik, N.A. Bondarenko, V.M. Kolodnitskyi, V.I. Zakiev, I.M. Zakiev, M. Storchak, S.N. Dub, and N.O. Kuzin, “Physico-mechanical and tribological properties of Fe–Cu–Ni–Sn and Fe–Cu–Ni–Sn–VN nanocomposites obtained by powder metallurgy methods,” Tribol. Ind., 41, No. 2, 188–198 (2019).

E. Rabinowicz, Friction and Wear of Materials, Wiley, New York (1995).

A. Leyland and A. Matthews, “On the significance of the H/E ratio in wear control: a nanocomposite coating approach to optimized tribological behavior,” Wear, No. 246, 1–11 (2000).

N.V. Novikov, M.A. Voronkin, S.N. Dub, I.N. Lupich, V.G. Malogolovets, B.A. Maslyuk, and G.A. Podzyarey, “Transition from polymer-like to diamond-like a-C:H films: Structure and mechanical properties,” Diamond Related. Mater., No. 6, 574–578 (1997).

J. Soldan and J. Musil, “Structure and mechanical properties of DC magnetron sputtered TiC/Cu films,” Vacuum, No. 81, 531–538 (2006).

J. Musil, “Tribological and mechanical properties of nanocrystalline n-TiC/a-C nanocomposites thin films,” J. Vac. Sci. Technol. A, 28, No. 2, 244–249 (2010).

I.A. Sveshnikov and V.N. Kolodnitskyi, “Optimization of placing hardmetal cutters in drill bits,” Sverkhtverd. Mater., No. 4, 70–75 (2006).

V.Y. Kodash and E.S. Gevorkian, “Tungsten carbide cutting tool materials,” US Patent 6617271 B1, IC C04B 35/56, publ. September 9 (2003).

W. Kraus and G. Nolze, “Powder Cell–A program for the representation and manipulation of crystal structures and calculation of the resulting X-ray powder patterns,” J. Appl. Crystallogr., No. 29, 301–303 (1996).

Selected Powder Diffraction Data for Education Straining (Search Manual and Data Cards), International Centre for Diffraction Data, USA (1988), p. 432.

W. C. Oliver and G. M. Pharr, “An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments,” J. Mater. Res., 7, 1564–1583 (1992).

V. Zakiev, A. Markovsky, E. Aznakayev, I. Zakiev, and E. Gursky, “Micro-mechanical properties of biomaterials,” in: Proc. SPIE 5959, Medical Imaging, 595916 (September 23, 2005), Event: Congress on Optics and Optoelectronics, Warsaw, Poland (2005), https://doi.org/10.1117/12.628396

S.A. Firstov, V.F. Gorban, N.A. Krapivka, E.P. Pechkovskii, N.I. Danilenko, and M.V. Karpets, “Mechanical properties of multicomponent titanium alloy,” Strength Mater., No. 42, 622–630 (2010).

Y.L. Hao, S.J. Li, S.Y. Sun, C.Y. Zheng, and R. Vang, “Elastic deformation behavior of Ti–24Nb–4Zn–7.9Sn for biomedical application,” Acta Biomater., 3, No. 2, 277–286 (2007).

S. Hassani, M. Bielawski, W. Beres, L. Martinu, M. Balazinski, and J.E. Klemberg-Sapieha, “Predictive tools for the design of erosion resistant coatings,” Surf. Coat. Technol., 203, 204–210 (2008).

E. Bousser, M. Benkahoul, L. Martinu, and J.E. Klemberg-Sapieha, “Effect of microstructure on the erosion resistance of Cr–Si–N coatings,” Surf. Coat. Technol., 203, 776–778 (2008).

Acknowledgements

The research has been conducted within a state-budget research program in compliance with coordination plans of the Ministry for Education and Science of Ukraine (State Registration No. 0117U000391).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mechnik, V.A., Bondarenko, N.A., Kolodnitskyi, V.M. et al. Effect of Vacuum Hot Pressing Temperature on the Mechanical and Tribological Properties of the Fe–Cu–Ni–Sn–VN Composites. Powder Metall Met Ceram 58, 679–691 (2020). https://doi.org/10.1007/s11106-020-00125-w

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-020-00125-w