Abstract

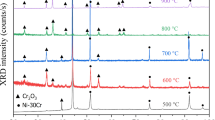

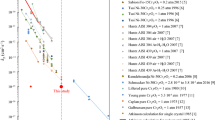

Ni-30Cr alloy samples were oxidized at temperatures between 500 and 900 °C to investigate the link between the evolution of the microstructure and the chemical composition in the alloy substrate beneath a growing chromia layer. Before oxidation, a layer of ultrafine grains was observed between the surface and a thick lamellar layer. This structure was replaced by some larger recrystallized grains after oxidation. The growth kinetics of the recrystallized grains was described by a parabolic law with a kinetic constant following an Arrhenius law from 500 to 700 °C. For samples oxidized at 800 and 900 °C, all Cr profiles showed a gradient close to the shape predicted by Wagner models. In the samples oxidized between 500 and 700 °C, many Cr profiles showed a two-step shape, with the smaller Cr fraction in the step closer to the alloy/oxide interface. By considering a fast diffusion accelerated by grain boundaries in the zone of recrystallized grains, the two-step shape can be simulated by numerical resolution of diffusion problem.

Similar content being viewed by others

References

F. Cattant, D. Crusset, and D. Féron, Materials Today 11, 2008 (32).

M. Perrut, P. Caron, M. Thomas, and A. Couret, Comptes Rendus Physique 19, 2018 (657).

S. J. Zinkle and G. S. Was, Acta Materialia 61, 2013 (735).

K. L. Murty and I. Charit, Journal of Nuclear Materials 383, 2008 (189).

D. J. Young, High Temperature Oxidation and Corrosion of Metals, (Elsevier, Oxford, UK, 2008).

T. Hodgkiess, G. C. Wood, D. P. Whittle, and B. D. Bastow, Oxidation of Metals 12, 1978 (439).

C. Wagner, Journal of the Electrochemical Society 99, 1952 (369).

A. Nicolas, V. Barnier, E. Aublant, and K. Wolski, Scripta Materialia 65, 2011 (803).

E. Schmucker, C. Petitjean, L. Martinelli, P.-J. Panteix, B. Lagha, and M. Vilasi, Corrosion Science 111, 2016 (467).

D. P. Whittle, Corrosion Science 12, 1972 (869).

B. D. Bastow, D. P. Whittle, and G. C. Wood, Oxidation of Metals 12, 1978 (413).

R. Pillai, H. Ackermann, and K. Lucka, Corrosion Science 69, 2013 (181).

D. P. Whittle, D. J. Evans, D. B. Scully, and G. C. Wood, Acta Metallurgica 15, 1967 (1421).

Huang X. Défauts ponctuels dans Cr2O3 et oxydation d’un alliage Ni-30Cr à haute température : approches expérimentale et numérique. Université Grenoble Alpes [2020-....]; 2022.

R. Pillai, A. Chyrkin, and W. J. Quadakkers, Oxidation of Metals 96, 2021 (385).

D. P. Whittle, Oxidation of Metals 4, 1972 (171).

G. L. Wulf, M. B. McGirr, and G. R. Wallwork, Corrosion Science 9, 1969 (739).

F. Gesmundo and P. Y. Hou, Oxidation of Metals 59, 2003 (63).

C. Desgranges, N. Bertrand, K. Abbas, D. Monceau, and D. Poquillon, Materials Science Forum 461–464, 2004 (481).

N. Bertrand, C. Desgranges, M. Nastar, G. Girardin, D. Poquillon, and D. Monceau, Materials Science Forum 595–598, 2008 (463).

C. Desgranges, F. Lequien, E. Aublant, M. Nastar, and D. Monceau, Oxidation of Metals 79, 2013 (93).

Y. Ustinovshikov, B. Pushkarev, and I. Igumnov, Journal of Materials Science 37, 2002 (2031).

D. P. Whittle, G. C. Wood, D. J. Evans, and D. B. Scully, Acta Metallurgica 15, 1967 (1747).

T. Gheno, C. Desgranges, and L. Martinelli, Corrosion Science 173, 2020 108805.

P. Nash, Bulletin of Alloy Phase Diagrams 7, 1986 (466).

F. Xue and E. A. Marquis, Acta Material 240, 2022 118343.

L. Bataillou, L. Martinelli, C. Desgranges, et al., Oxidation of Metals 93, 2020 (329).

X. Huang, L. Martinelli, S. Bosonnet, P. C. M. Fossati, L. Latu-Romain, and Y. Wouters, Oxidation of Metals 96, 2021 (69).

L. Karmazin, Materials Science and Engineering 54, 1982 (247).

K. Monma, H. Suto, and H. Oikawa, Journal of Japanese Install Metal 28, 1964 (188).

P. Moulin, A. M. Huntz, and P. Lacombe, Acta Metallurgica 27, 1979 (1431).

K. S. Rajeshwari, S. Sankaran, K. C. Hari Kumar, et al., Acta Material 195, 2020 (501).

J. Růžičková and B. Million, Material Science Engineering 50, 1981 (59).

T.-F. Chen, Y. Iijima, K. Hirano, and K. Yamauchi, Journal of Nuclear Materials 169, 1989 (285).

T.-F. Chen, G. P. Tiwari, Y. Iijima, and K. Yamauchi, Materials Transactions 44, 2003 (40).

D. D. Pruthi, M. S. Anand, and R. P. Agarwala, Journal of Nuclear Material 64, 1977 (206).

T. Gheno, F. Jomard, C. Desgranges, and L. Martinelli, Materialia 3, 2018 (145).

T. Gheno, F. Jomard, C. Desgranges, and L. Martinelli, Materialia 6, 2019 100283.

B. Million, J. Růžičková, and J. Vřešťál, Journal of Material Science Engineering 72, 1985 (85).

J. Čermák, Materials Science and Engineering: A, 148, 1991 (279).

D. Prokoshkina, V. A. Esin, G. Wilde, and S. V. Divinski, Acta Mater. 61, 2013 (5188).

G. Stechauner and E. Kozeschnik, Fe and Ni. Calphad. 47, 2014 (92).

F. J. Humphreys and M. Hatherly, Recrystallization and related annealing phenomena, (Elsevier, Oxford, UK, 2004).

V. Randle and D. Horton, Scripta Metallurgica et Materialia 31, 1994 (891).

M. C. Iordache, S. H. Whang, Z. Jiao, and Z. M. Wang, Nanostructured Mater. 11, 1999 (1343).

L. Z. Zhou and J. T. Guo, Scripta Material 40, 1998 (139).

L. G. Harrison, Trans Faraday Social 57, 1961 (1191).

P. Heitjans and J. Kärger, Diffusion in Condensed Matter, (Springer, Berlin, Heidelberg, 2005).

A. M. Glaeser and J. W. Evans, Acta Metallurgica 34, 1986 (1545–1552).

Mathews JH, Fink KD. Numeric Method Using Matlab. Upper Saddle River, NJ: Pearson prentice hall; 2004.

L. Latu-Romain, S. Mathieu, M. Vilasi, et al., Oxidation of Metals 88, 2016 (481).

L. Latu-Romain, Y. Parsa, S. Mathieu, et al., Oxidation of Metals 86, 2016 (497).

L. Latu-Romain, Y. Parsa, S. Mathieu, M. Vilasi, A. Galerie, and Y. Wouters, Corrosion Science 126, 2017 (238).

L. Latu-Romain, Y. Parsa, M. Ollivier, et al., Materials at High Temperatures 35, 2018 (159–167).

Acknowledgements

The authors would like to thank the advice of Kévin Ginestar for oxidation tests and SEM observation, Florence Robaut for SEM-FIB preparation and Thomas Demonchaux for TEM-EDX analysis.

Author information

Authors and Affiliations

Contributions

X.H. wrote the main manuscript text and all authors reviewed the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Appendix: Table of variables

Appendix: Table of variables

Variable | Unit | Description |

|---|---|---|

\({d}_{\mathrm{g}}\) and \({d}_{\mathrm{g},0}\) | cm | Grain diameters at time \(t\) and at the initial time |

\(D\) and \({D}_{0}\) | cm−2.s−1 | Diffusion coefficient of Ni or Cr in volume, in dislocations or in grain boundaries and its pre-exponential factor |

\(\widetilde{D}\) | cm−2.s−1 | Interdiffusion coefficient in volume or in grain boundaries or apparent interdiffusion coefficient |

\(e\) | cm | Thickness of the oxide layer |

\({E}_{\mathrm{a}}\) | J.mol−1 | Activation energy |

\(f\) | dimensionless | Volume fraction of dislocations or grain boundaries |

\({J}_{\mathrm{Cr},\mathrm{i}}\) | mol.cm−2.s−1 | Flux of Cr at the alloy/oxide interface |

\({k}_{\mathrm{d}}\) | cm3.s−1 | Kinetic constant for recovery |

\(k\), \({k}_{\mathrm{p}}\) and \({k}_{\mathrm{c}}\) | cm−2.s−1 | Parabolic kinetic constants for grain growth, oxidation and recession processes, respectively |

\(n\) | dimensionless | Exponent of the kinetic law |

\({N}_{\mathrm{Cr}}\) | at% | Molar fraction of Cr at the depth \(x\), at the interface or in the bulk |

\(s\) | dimensionless | Segregation factor |

\(t\) | s | Time |

\(T\) | K | Temperature |

\({V}_{\mathrm{m}}\) | cm3.mol−1 | Molar volumes of the Ni-30Cr alloy or the Cr2O3 oxide |

\(x\) and \({\Delta x}_{\mathrm{m}}\) | cm | Depth in the alloy from the alloy/oxide interface and recession depth, respectively |

\(\delta\) | cm | Grain boundary width |

\({\lambda }_{\mathrm{vol}}\) | cm | Characteristic length of volume diffusion |

\({\rho }_{\mathrm{d}}\) and \({\rho }_{\mathrm{d},0}\) | cm−2 | Density of dislocations at time \(t\) and at the initial time |

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Huang, X., Martinelli, L., Bosonnet, S. et al. Chromium Depletion in a Ni-30Cr Alloy During High-Temperature Oxidation. High Temperature Corrosion of mater. 100, 745–773 (2023). https://doi.org/10.1007/s11085-023-10198-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-023-10198-8