Abstract

Among oxide scales, α-alumina (α-Al2O3) is the most stable and protective oxide against high-temperature oxidation and corrosion. α-Al2O3 forms on heat-resistant alloys by replacing a metastable θ-Al2O3, which provides poor oxidation resistance. Thus, determining the concentration of θ-Al2O3 is critical for evaluating the performance of heat-resistant alloys. Herein, the author developed a method to determine the concentrations of θ-Al2O3 and α-Al2O3 in oxide scales on the surface of heat-resistant alloys from the emission intensities of the peaks of α-Al2O3 (694.2 nm) and θ-Al2O3 (683.4 nm) observed in cathodoluminescence (CL) spectra. The concentrations of θ-Al2O3 and α-Al2O3 on β-NiAl heated at 1000 °C agreed with those estimated from the peak intensities of α-Al2O3 and θ-Al2O3 in the XRD patterns. This method can also be applied to areas ranging from the millimeter to micrometer scale and provide a short acquisition time (< 10 s), enabling the rapid determination of the durability and performance of heat-resistant alloys.

Similar content being viewed by others

References

H. Hindam and D. P. Whittle, Microstructure, adhesion and growth kinetics of protective scales on metals and alloys. Oxidation of Metals 18, 1982 (245–284).

F. H. Stott, G. C. Wood, and J. Stringer, The influence of alloying elements on the development and maintenance of protective scales. Oxidation of Metals 44, 1995 (113–145).

D. J. Young, High Temperature Oxidation and Corrosion of Metals, vol. 1. (Elsevier, Amsterdam, 2016),.

A. S. Khanna, Introduction to High Temperature Oxidation and Corrosion, (ASM International, Materials Park, 2002).

C. Houngniou, S. Chevalier, and J. P. Larpin, High-temperature-oxidation behavior of iron–aluminide diffusion coatings. Oxidation of Metals 65, 2006 (409–439).

G. Y. Lai, High-Temperature Corrosion and Materials Applications, (ASM International, Ohio, 2007).

C. A. C. Sequeira, High Temperature Corrosion: Fundamentals and Engineering, (John Wiley and Sons, Inc, Hoboken, 2019).

Z. G. Zhang, F. Gesmundo, P. Y. Hou, et al., Criteria for the formation of protective Al2O3 scales on Fe–Al and Fe–Cr–Al alloys. Corrosion Science 48, 2006 (741–765).

B. A. Pint, High Temperature Corrosion of Alumina-forming Iron, Nickel and Cobalt-base Alloys. in Shreir’s Corrosion, eds. R. A. Cottis, et al. (Elsevier, Amsterdam, 2010), pp. 606–645.

G. C. Rybicki and J. L. Smialek, Effect of the θ-Al2O3 transformation on the oxidation behavior of β-NiAl + Zr. Oxidation of Metals 31, 1989 (275–304).

M. W. Brumm and H. J. Grabke, The oxidation behaviour of NiAl–I. Phase transformations in the alumina scale during oxidation of NiAl and NiAl–Cr alloys. Corrosion Science 33, 1992 (1677–1690).

A. Andoh, S. Taniguchi, and T. Shibata, Phase transformation of Al2O3 scales formed on Al-deposited Fe–Cr–Al alloy foil. Tetsu To Hagane Journal of the Iron and Steel Institute of Japan 83, 1997 (205–210).

J. Doychak, J. L. Smialek, and T. E. Mitchell, Transient oxidation of single-crystal β-NiAl. Metallurgical Transactions A 20, 1989 (499–518).

A. Andoh, S. Taniguchi, and T. Shibata, TEM observation of phase transformations of alumina scales formed on Al-deposited Fe–Cr–Al foils. Materials Science Forum 369–372, 2001 (303–310).

G. Pauletto, A. Vaccari, G. Groppi, et al., FeCrAl as a catalyst support. Oxidation of Metals 120, 2020 (7516–7550).

C. A. Stewart, A. Suzuki, T. M. Pollock, et al., Rapid assessment of oxidation behavior in Co-based γ/γ′ alloys. Oxidation of Metals 90, 2018 (485–498).

A. S. Marfunin, Spectroscopy, Luminescence and Radiation Centers in Minerals, (Springer-Verlag, Berlin, 1979).

B. G. Yacobi and D. B. Holt, Cathodoluminescence scanning electron microscopy of semiconductors. Journal of Applied Physics 59, 1986 (R1–R24).

V. I. Petrov, Cathodoluminescence scanning microscopy. Physica Status Solidi (a) 133, 1992 (189–230).

C. M. Parish and P. E. Russell, Scanning Cathodoluminescence Microscopy. in Advances in Imaging and Electron Physics, vol. 147, ed. P. Hawkes (Elsevier, Amsterdam, 2007), pp. 1–135.

S. Imashuku and K. Wagatsuma, Non-destructive evaluation of alumina scale on heat-resistant steels using cathodoluminescence and X-ray-excited optical luminescence. Corrosion Science 154, 2019 (226–230).

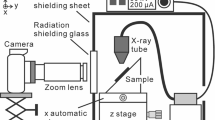

S. Imashuku and K. Wagatsuma, X-ray-excited optical luminescence imaging for on-site analysis of alumina scale. Oxidation of Metals 94, 2020 (27–36).

S. Imashuku and K. Wagatsuma, Cathodoluminescence analysis for the nondestructive evaluation of silica scale on an iron-based alloy. Oxidation of Metals 93, 2020 (175–182).

S. Imashuku, W. Hashimoto, and K. Wagatsuma, Nondestructive thickness measurement of silica scale using cathodoluminescence. Spectrochimica Acta Part A: Molecular and Biomolecular Spectroscopy 246, 2021 119022.

S. Imashuku, M. Fukumoto, K. Nakajima, et al., Characterization of α-Al2O3 in structural isomers of alumina formed by oxidation of Fe–Cr–Al alloys. ISIJ International 62, 2022 (1880–1885).

S. Imashuku, W. Hashimoto, and K. Wagatsuma, Nondestructive, rapid identification of aluminum nitride and internal alumina scales on a heat-resistant alloy using cathodoluminescence. Oxidation of Metals 96, 2021 (519–529).

S. Imashuku, Determination of the maximum surface chromia thickness for the nondestructive identification of internal alumina scales on a heat-resistant alloy using cathodoluminescence. High Temperature Corrosion of Materials (2023):Submitted.

S. Imashuku, Nondestructive identification of internal α-alumina scales on heat-resistant Ni–Al alloys based on cathodoluminescence spectra. ISIJ International (2023):in press.

R. Prescott, D. F. Mitchell, M. J. Graham, et al., Oxidation mechanisms of β-NiAl + Zr determined by SIMS. Corrosion Science 37, 1995 (1341–1364).

S. Imashuku, H. Tsuneda, and K. Wagatsuma, Rapid and simple identification of free magnesia in steelmaking slag used for road construction using cathodoluminescence. Metallurgical and Materials Transactions B 51, 2020 (27–34).

S. Imashuku and K. Wagatsuma, Identification of monazite and estimation of its content in ores by cathodoluminescence imaging. Minerals Engineering 173, 2021 107228.

S. Imashuku and K. Wagatsuma, Scanning electron microscopy-cathodoluminescence imaging of industrial steelmaking slag for identifying and determining the free magnesia content. Metallurgical and Materials Transactions B 53, 2022 (3459–3468).

S. Imashuku, Cathodoluminescence imaging for rapid identification of low-melting CaO–MgO–SiO2 phases in MgO-based refractories involving the steelmaking process. Journal of the European Ceramic Society 42, 2022 (7328–7334).

D. Wolff, Visser: Absolute intensities-Outline of Recommended Practice. Technique for obtaining absolute intensities with internal standard, in TNO ENT. H, (1964), pp. 202–204.

P. M. de Woolf and J. W. Visser, Absolute intensities—outline of a recommended practice. Powder Diffr 3, 2013 (202–204).

J. Ponahlo, Cathodoluminescence as a Tool in Gemstone Identification. in Cathodoluminscence in Geosciences, eds. M. Pagel, V. Barbin, P. Blanc and D. Ohnenstetter (Springer, Berlin, 2000), pp. 479–500.

M. Gaft, R. Reisfeld, and G. Panczer, Luminescence Spectroscopy of Minerals and Materials, (Springer, Berlin, 2005).

C. M. MacRae and N. C. Wilson, Luminescence database I—minerals and materials. Microscopy and Microanalysis 14, 2008 (184–204).

C. Guguschev, J. Gotze, and M. Gobbels, Cathodoluminescence microscopy and spectroscopy of synthetic ruby crystals grown by the optical floating zone technique. American Mineralogist 95, 2010 (449–455).

H. H. Kusuma, B. Astuti, and Z. Ibrahim, Absorption and emission properties of ruby (Cr:Al2O3) single crystal. Journal of Physics: Conference Series 1170, 2019 012054.

Q. Wen, D. M. Lipkin, and D. R. Clarke, Luminescence characterization of chromium-containing θ-alumina. Journal of the American Ceramic Society 81, 1998 (3345–3348).

L. Shen, C. Hu, S. Zhou, et al., Phase-dependent photoluminescence behavior of Cr-doped alumina phosphors. Optical Materials 35, 2013 (1268–1272).

A. Rastorguev, M. Baronskiy, A. Zhuzhgov, et al., Local structure of low-temperature γ-Al2O3 phases as determined by the luminescence of Cr3+ and Fe3+. RSC Advances 5, 2015 (5686–5694).

D. M. Lipkin and D. R. Clarke, Measurement of the stress in oxide scales formed by oxidation of alumina-forming alloys. Oxidation of Metals 45, 1996 (267–280).

R. J. Christensen, D. M. Lipkin, D. R. Clarke, et al., Nondestructive evaluation of the oxidation stresses through thermal barrier coatings using Cr3+ piezospectroscopy. Appl Phys Lett. 69, 1996 (3754–3756).

Y. H. Sohn, K. Vaidyanathan, M. Ronski, et al., Thermal cycling of EB-PVD/MCrAlY thermal barrier coatings: II. Evolution of photo-stimulated luminescence. Surface and Coatings Technology 146–147, 2001 (102–109).

D. B. Hovis and A. H. Heuer, Confocal photo-stimulated microspectroscopy (CPSM)—residual stress measurements in Al2O3 using confocal microscopy. Scripta Materialia 53, 2005 (347–349).

L. Qiu, F. Yang, W. Zhang, et al., Effect of Al content on the lifetime of thermally grown oxide formed on Ni–Al alloys after isothermal oxidation. Corrosion Science 89, 2014 (13–20).

C. Nordhorn, R. Mücke, K. A. Unocic, et al., Effects of thermal cycling parameters on residual stresses in alumina scales of CoNiCrAlY and NiCoCrAlY bond coats. Surface and Coatings Technology 258, 2014 (608–614).

Q. Ma and D. R. Clarke, Stress measurement in single-crystal and polycrystalline ceramics using their optical fluorescence. Journal of the American Ceramic Society 76, 1993 (1433–1440).

Acknowledgements

Financial support for the present study was provided by JSPS KAKENHI Grant Number 22H01837. The author thanks to Prof. Xiao Xu (Tohoku University) for the preparation of β-NiAl rod.

Author information

Authors and Affiliations

Contributions

SI wrote the main manuscript text, prepared all figures, and reviewed the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Imashuku, S. Rapid Determination of α- and θ-Alumina Concentrations in Heat-Resistant Alloys Using Cathodoluminescence Analysis. High Temperature Corrosion of mater. 100, 145–156 (2023). https://doi.org/10.1007/s11085-023-10178-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-023-10178-y