Abstract

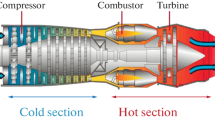

Oxidation and hot corrosion occur on metallic parts of gas turbines on account of exposure to high temperature. Thermal barrier coatings (TBCs) are used to protect gas turbine components made of Ni-based superalloys from high temperature oxidation as well as hot corrosion. The stability of coated metallic gas turbine components is higher than that of non-coated ones. Suitable coating is crucial for obtaining higher turbine inlet temperature. However, the problem of conventional TBC system is the failure of yittria-stabilized zirconia (YSZ) top coat due to formation of thermally grown oxide (TGO) layer between the bond coat and YSZ top coat. The TGO formation should be properly controlled in order to prevent the spallation of the top coat. In the current review paper, an attempt has been made to focus oxidation and hot corrosion behavior of conventional thermal barrier coatings applied on gas turbine components for increasing the efficiency of gas turbines.

Graphical Abstract

Similar content being viewed by others

References

V. Ebrahimzade, H. Uchtmann, L. Singheiser, M. Küger, and J. Malzbender, Microstructure and cyclic oxidation behavior of APS TBC systems drilled with various laser methods. Surface and Coatings Technology. 378, 2019 (1–11).

V. Sankar, Thermal barrier coatings material selection, method of preparation and applications-Review. International Journal of Mechanical Engineering and Robotics Research. 3, 2014 (510–517).

R. A. Miller, Oxidation-based model for thermal barrier coating life. Journal of the American Ceramic Society. 67, 1984 (517–521).

A. G. Evans, D. R. Mumm, J. W. Hutchinson, G. H. Meier, and F. S. Pettit, Mechanisms controlling the durability of thermal barrier coatings. Progress in Materials Science. 46, 2001 (505–553).

V. Tolpygo, D. R. Clarke, and K. S. Murphy, The effect of grit blasting on the oxidation behavior of a Platinum-modified Nickel-Aluminide coating. Metallurgical and Materials Transactions A. 32, 2001 (1467–1478).

V. K. Tolpygo and D. R. Clarke, Morphological evolution of thermal barrier coatings induced by cyclic oxidation. Surface and Coatings Technology. 163–164, 2003 (81–86).

N. M. Yanar, F. S. Pettit, and G. H. Meier, Failure characteristics during cyclic oxidation of yttria stabilized zirconia thermal barrier coatings deposited via electron beam physical vapor deposition on platinum aluminide and on NiCoCrAlY bond coats with processing modifications for improved performances. Metallurgical and Materials Transactions A. 37, 2006 (1563–1580).

M. J. Stiger, N. M. Yanar, R. W. Jackson, S. J. Laney, F. S. Pettit, G. H. Meier, A. S. Gandhi, and C. G. Levi, Development of intermixed zones of alumina/zirconia in thermal barrier coating systems. Metallurgical and Materials Transactions A. 38, 2007 (848–857).

N. M. Yanar, M. Helminiak, G. H. Meier, and F. S. Pettit, Comparison of the failures during cyclic oxidation of yttria-stabilized (7 to 8 weight percent) zirconia thermal barrier coatings fabricated via electron beam physical vapor deposition and air plasma spray. Metallurgical and Materials Transactions A. 42, 2011 (905–921).

D. Liu, P. E. J. Flewitt, and K. R. Hallam, Influence of oxidation temperature and time on stresses in thermal barrier coated aerofoil sections. Materials at High Temperatures. 29, 2012 (181–186).

M. J. Pomeroy, Coatings for gas turbine materials and long term stability issues. Materials & Design. 26, 2005 (223–231).

H. Rana, A review paper on thermal barrier coatings (TBC) to improve the efficiency of gas turbine. IJSRD-International Journal for Scientific Research & Development. 4, 2016 (1161–1165).

X. Q. Cao, R. Vassen, and D. Stoever, Ceramic materials for thermal barrier coatings. Journal of the European Ceramic Society. 24, 2004 (1–10).

J. D. Osorio, A. Toro, and J. P. Hernandez-Ortiz, Thermal barrier coatings for gas turbine applications: failure mechanisms and key microstructural features. Dyna. 79, 2012 (149–158).

T. M. Pollock and S. Tin, Nickel-based superalloys for advanced turbine engines: chemistry, microstructure and properties. Journal of Propulsion and Power. 22, 2006 (361–374).

C. Lin, Y. Chai, and Y. Li, Oxidation simulation of thermal barrier coatings with actual microstructures considering strength difference property and creep-plastic behavior. Coatings. 8, 2018 (338–356).

M. Góral, T. Kubaszek, and M. Pytel, Isothermal oxidation of thermal barrier coatings deposited using LPPS, CVD, and PS-PVD methods on MAR M247 nickel superalloy. Advances in Manufacturing Science and Technology. 44, 2020 (9–14).

F. I. S. Omoniyi, P. A. Olubambi, and E. R. Sadiku, High temperature oxidation resistance of Ni22Cr11Al bond coat produced by Spark Plasma Sintering as thermal barrier coatings. Journal of Material Science & Engineering. 5, 2016 (1–5).

F. H. Latief, l-Sayed E, Sherif M Kakehi K, Role of aluminide coating on oxidation resistance of Ni-based single crystal super alloy at 900℃. International Journal of Electrochemical Science. 10, 2015 (1873–1882).

X. Zhou, Graphene oxidation barrier coating. Undergraduate Honors Theses, University of Colorado, Boulder. 2011; p. 704.

S. Sreenivas, U. Chandrasekhar, K. H. Reddy, K. Elangaan, and B. R. Sridhar, Dilapidation of the TBC system during the burner rig test. International Journal of Engineering and Technology. 7, 2015 (868–875).

G. Sridhar, M. Divya, D. Mathew, and H. Gowrishree, CFD analysis of a thermal barrier coated blade. International Journal of Scientific and Research Publications. 9, 2019 (50–58).

S. Datta and S. Das, A new high temperature resistant glass-ceramic coating developed in CGCRI, Kolkata. Transactions of the Indian Ceramic Society 64, 2005 (25–32).

S. Datta and S. Das, A new high temperature resistant glass-ceramic coating for gas turbine engine components. Bulletin of Material Science. 28, 2005 (689–696).

S. Das, S. Datta, D. Basu, and G. C. Das, Glass-ceramics as oxidation resistant bond coat in thermal barrier coating system. Ceramics International. 35, 2009 (1403–1406).

S. Das, S. Datta, D. Basu, and G. C. Das, Thermal cyclic behavior of glass-ceramic bonded thermal barrier coating on nimonic alloy substrate. Ceramics International. 35, 2009 (2123–2129).

K. M. Doleker, Y. Ozgurluk, A. S. Parlakyigit, D. Ozkan, T. Gulmez, and A. C. Karaoglanli, Oxidation behavior of NiCr/YSZ thermal barrier coatings (TBCs). Open Chemistry. 16, 2018 (876–881).

J. J. Gu, S. S. Joshi, Y. S. Ho, B. W. Wei, T. Y. Huang, J. Lee, D. Berman, N. B. Dahotre, and S. M. Aouadi, Oxidation-induced healing in laser-processed thermal barrier coatings. Thin Solid Films. 688, 2019 137481.

K. M. Doleker and A. C. Karaoglanli, Comparison of oxidation behavior of YSZ and Gd2Zr2O7thermal barrier coatings (TBCs). Surface and Coatings Technology. 318, 2017 (198–207).

S. Mahade, R. Li, N. Curry, and S. Björklund, Markocsan N and Nylén P, Isothermal oxidation behavior of Gd2Zr2O7/YSZ multilayered thermal barrier coatings. International Journal of Applied Ceramic Technology. 13, 2016 (198–207).

X. Li, X. Y. Peng, H. Dong, et al., The evaluation of durability of plasma-sprayed thermal barrier coatings with double-layer bond coat. Coatings. 9, 2019 (241–252).

M. Saremi, A. Keyvani, and M. H. Sohi, Hot corrosion resistance and mechanical behaviour of atmospheric plasma sprayed conventional and nanostructured zirconia coatings. International Journal of Modern Physics: Conference Series. 5, 2012 (720–727).

Y. Wang and C. Zhou, Hot corrosion behavior of nanostructured Gd2O3 doped YSZ thermal barrier coating in presence of Na2SO4+V2O5 molten salts. Progress in Natural Science: Materials International. 27, 2017 (507–513).

T. E. Strangman, Thermal barrier coatings for turbine air foils. Thin Solid Films. 127, 1985 (93–106).

C. Leyers, I. G. Wright, and B. A. Pint, Hot corrosion of an EB-PVD thermal-barrier coating system at 950℃. Oxidation of Metals. 54, 2000 (401–424).

J. Wells, N. Chapman, J. Sumner, and P. Walker, The use of APS thermal barrier coatings in corrosive environments. Oxidation of Metals. 88, 2017 (97–108).

M. P. Borom, C. A. Johnson, and L. A. Peluso, Role of environment deposits and operating surface temperature in spallation of air plasma sprayed thermal barrier coatings. Surface and Coatings Technology. 86–87, 1996 (116–126).

C. G. Levi, J. W. Hutchinson, M.-H. Vidal-Setif, and C. A. Johnson, Environmental degradation of thermal barrier coatings by molten deposits. MRS Bulletin. 37, 2012 (932–941).

H. Zhao, C. G. Levi, and H. N. G. Wadley, Molten silicate interactions with thermal barrier coatings. Surface and Coatings Technology. 251, 2014 (74–86).

V. Tolpygo, Vapor-phase CMAS-induced degradation of adhesion of thermal barrier coatings. Oxidation of Metals 88, 2017 (87–96).

Z. Soleimnipour, S. Baghshahi, R. Sheja-razavi, and M. Salehi, Hot corrosion behavior of Al2O3 laser clad plasma sprayed YSZ thermal barrier coatings. Ceramics International. 42, 2016 (17698–17705).

V. Viswanathan, G. Dwivedi, and S. Sampath, Multilayer, multimaterial thermal barrier coating systems: design, synthesis, and performance assessment. Journal of the American Ceramic Society. 98, 2015 (1769–1777).

X. Xie, H. Guo, S. Gong, and H. Xu, Hot corrosion behavior of double ceramic layer LaTi2Al9O19 / YSZ thermal barrier coatings. Chinese Journal of Aeronautics. 25, 2012 (137–142).

M. K. Prasad, K. S. Rao, M. Reddy, and G. P. Sreedha, Hot corrosion of SrTiO3 perovskite in Na2SO4 + 50 wt.% V2O5 and Na2SO4 + 10 wt.% NaCl environments at 900℃. International Journal of Corrosion 2018, 2018 (1–7).

R. L. Jones, Some aspects of the hot corrosion of thermal barrier coatings. Journal of Thermal Spray Technology. 6, 1997 (77–84).

W. B. Gong, C. K. Sha, D. Q. Sun, and W. Q. Wang, Microstructures and thermal insulation capability of plasma sprayed nanostructured ceria stabilized zirconia coatings. Surface and Coating Technology. 201, 2006 (3109–3115).

S. Y. Park, J. H. Kim, M. C. Kim, H. S. Song, and C. G. Park, Microscopic observation of degradation behavior in yittria and ceria stabilized zirconia thermal barrier coatings under hot corrosion. Surface and Coating Technology. 190, 2005 (357–365).

M. R. Rahimipour and M. S. Mahdipoor, Comparative study of plasma sprayed yittria and ceria stabilized zirconia properties. International Journal of Engineering. 26, 2013 (13–18).

D. A. Shifler, Hot corrosion: a modification of reactants causing degradation. Materials at High Temperatures. 35, 2018 (225–235).

S. Das, S. Datta, D. Basu, and G. C. Das, Hot corrosion of glass coating on nickel base superalloy. Ceramics International. 34, 2008 (1215–1222).

N. Jegadeeswaran, M. R. Ramesh, and K. U. Bhat, Combating corrosion degradation of turbine materials using HVOF sprayed 25% (Cr3C2-25(Ni20Cr)) + NiCrAlY coating. International Journal of Corrosion. 2013, 2013 (1–11).

Acknowledgments

The authors acknowledge the financial support of Aeronautics Research and Development Board (AR&DB), India, through a sponsored project (GAP0263).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Roy, P., Ghosh, S. Oxidation and Hot Corrosion Behavior of Thermal Barrier Coatings-A Brief Review. High Temperature Corrosion of mater. 99, 331–343 (2023). https://doi.org/10.1007/s11085-023-10160-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-023-10160-8